Contents

1 Printer usage and Care..................................................................................................................... 1

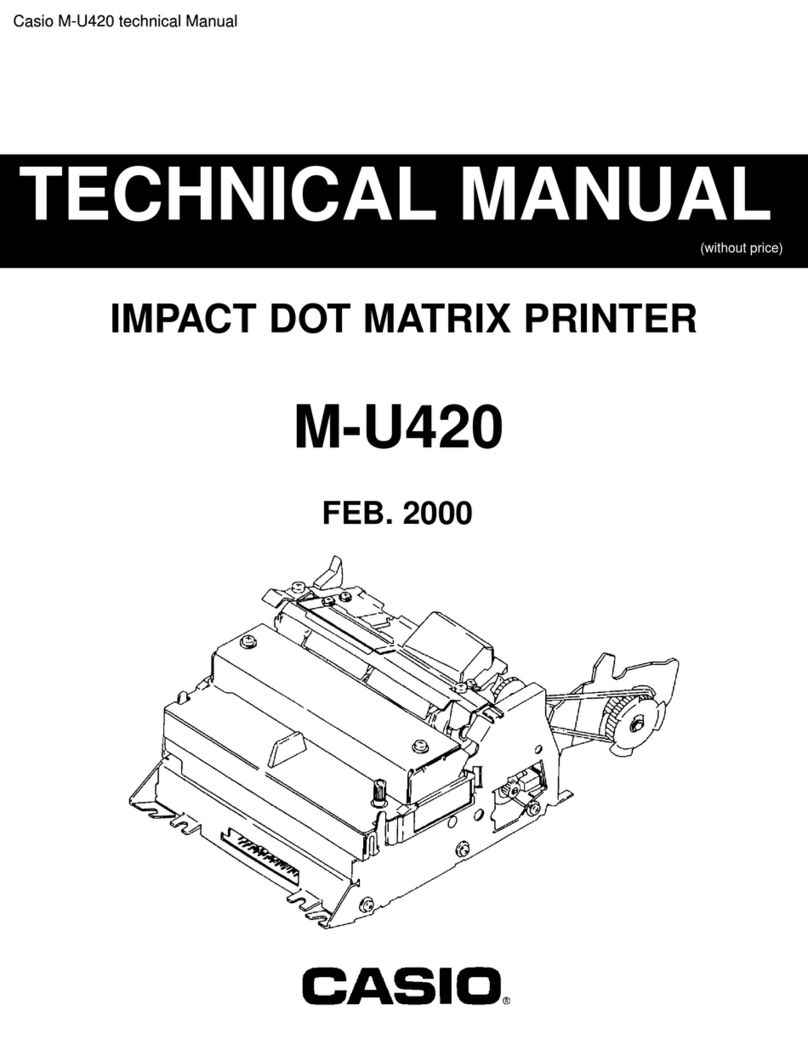

2 Specifications/Operating principles ................................................................................................... 2

2-1 Specifications............................................................................................................................ 2

2-2 Outline of mechanism ............................................................................................................... 3

2-3 Mechanism and operation principles ........................................................................................ 3

2-3-1 Power transmission mechanism ................................................................................... 3

2-3-2 Sensor mechanisms ..................................................................................................... 4

2-3-3 Print head mechanism.................................................................................................. 5

2-3-4 Paper feed mechanism................................................................................................. 8

2-3-5 Ribbon cartridge drive mechanism ............................................................................. 11

2-4 External connection terminals................................................................................................. 11

2-4-1 Terminal arrangement ................................................................................................ 11

2-4-2 Terminal mechanism .................................................................................................. 12

2-4-3 Terminal circuit diagram ............................................................................................. 12

3 Disassembly/Reassembly............................................................................................................... 13

3-1 Tools .................................................................................................................................... 13

3-2 Disassembly procedure .......................................................................................................... 13

3-3 Assembly procedure ............................................................................................................... 14

3-3-1 Setting paper feed solenoid assembly........................................................................ 14

3-3-2 Setting the head assembly ......................................................................................... 15

3-3-3 Setting the paper feed assembly ................................................................................ 16

3-3-4 Setting the main body assembly................................................................................. 18

4 Parts list .................................................................................................................................... 26

5 Exploded view................................................................................................................................. 28