CassidaPRO Zeus: Service Manual

2018 Cassida Corporation. All rights reserved.

Rev: 09/05/2018

cassidapro.com/partner/

1. OVERVIEW

1.1. Introduction from Cassida USA

1.2. Cross Section Side View Diagram

1.3. Specifications

1.4. Communication Ports / Pin-Outs

1.4.1. Serial/RS232

1.4.2. RJ11

1.4.3. RJ45

1.4.4. USB-A

1.4.5. USB-C

1.5. Accessories

1.6. Required Tools for Disassembly

1. 7. Definitions and Terms

1.8. Main PBA Connector Detail

1.9. Mecha PBA Connector Detail

1.10. Circuit Block Diagram

2. QUALITY CONTROL TESTING

2.1. Software Version Check and Update

2.2. Sensor and Mechanical Check

2.3. Currency and Function Check

3. PROCEDURES

3.1. Battery Replacement

3.2. Dust Cover Tension Adjustment

3.3. Re-aligning ADF Rollers

3.4. Dust Cover Hook Replacement

3.5. Connecting Remote Display

3.6. CIS Calibration

3 . 7. Hopper Sensor Calibration

3.8. Double Sensor Calibration

3.9. Adjustments after PBA Replacement

4. DISASSEMBLY

4.1. Side Covers (Left / Right)

4.2. Assembly Bank Note Guide

4.3. Assembly Hopper and Top Panel

4.4. Upper Door

4.5. Fly Wheel

4.6. Encoder Disk

4 . 7. Assembly Lower Guide

4.8. Assembly Power Supply

4.9. Main Motor

4.10. Assembly Reject Pocket

4 .11. Dust Cover

4.12. Assembly Guide CIS Upper

4.13. Assembly Guide CIS Lower

4.14. Assembly Stacker

4.15. PBA Replacement

4.16. Roller Replacement

4.17. Guide Reject Pocket Replacement

5. TROUBLESHOOTING GUIDE

5.1. PS Sensor Errors

5.2. Read/ID Errors

5.3. ID Errors

5.4. “ReStartRecognitionAPP” Error

5.5. Upgrading (When EMERGENCY

Screen is displayed)

5.6. Settings (Reset after Power Down/

Start-up Issues)

6. SERVICE MENU GUIDE

6.1. Starting Test Menu

6.2. Diagnosis

6.3. Program Update

6.4. Adjustments

6.5. Backup and Restore

6.6. Reports Clear

6 . 7. Statistics Report

6.8. Log Data

6.9. Data Download

6.10. Software Version

APPENDIX I: Spare Parts List

APPENDIX II: Error Codes/Messages

APPENDIX III: Contact Information

APPENDIX IV: Return Merchandise Authorization

APPENDIX V: Notices

This service manual is confidential and

exclusively for the use of current Cassida

PRO Series partners and their technicians.

This manual shall not be shared with outside

sources including but not limited to end users,

competitors, social media, or marketing

channels. No part of this document shall

be reproduced in whole or in part without

written permission from Cassida Corporation.

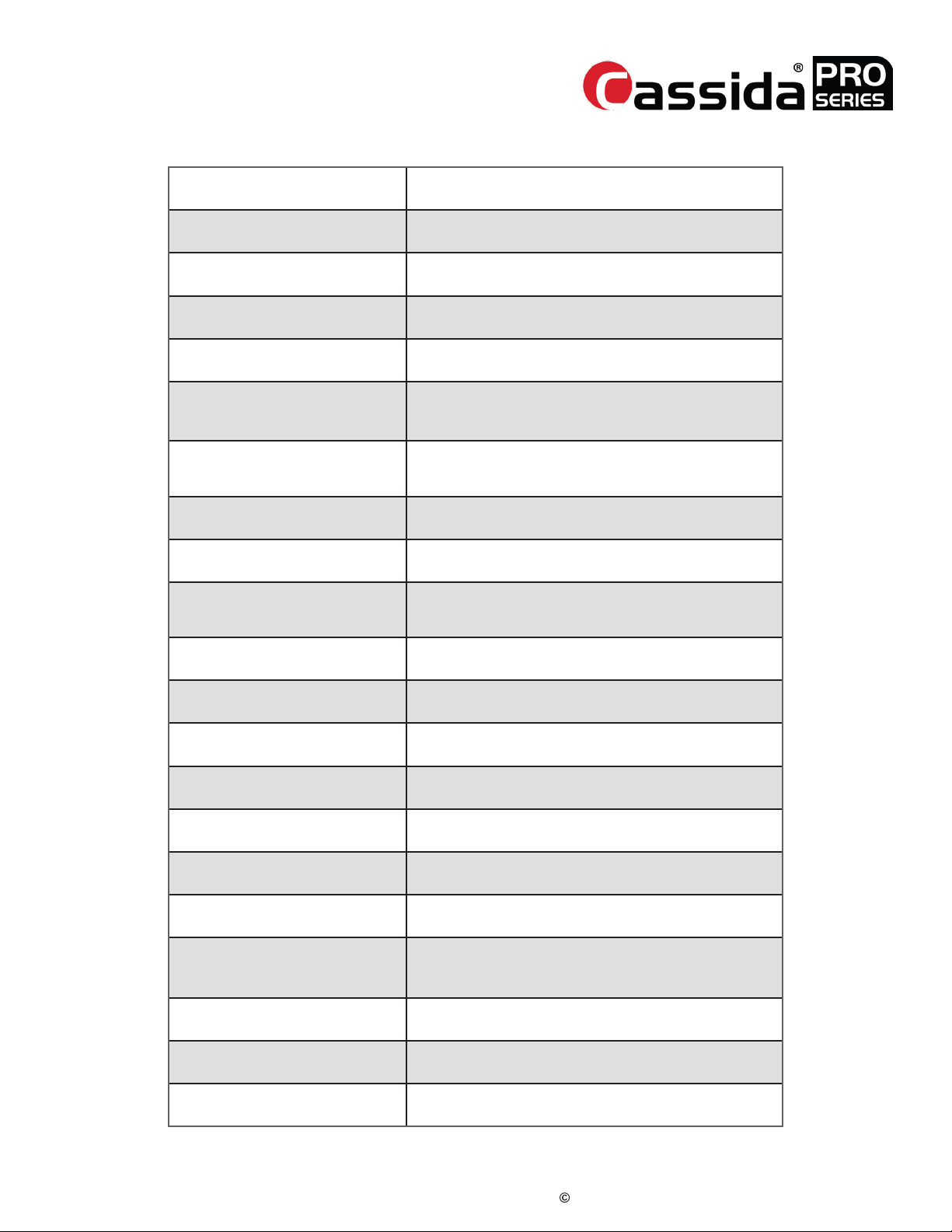

TABLE OF CONTENTS