1. DESCRIPTION OF THE GENERAL CHARACTERISTICS OF SCISSORS...............................3

1.1. Purpose of the manual ................................................................................................................. 3

1.2. Machine identification.................................................................................................................. 3

1.3. Machine description and technical data....................................................................................... 3

1.4. Subject to which the manual is addressed ................................................................................... 4

1.5. Protection and safety devices....................................................................................................... 5

1.6. Risks arising from the use of machinery ....................................................................................... 5

1.6.1.Noise risk 5

1.6.2.Vibration risk ................................................................................................................................ 5

1.6.3.Cut risk 5

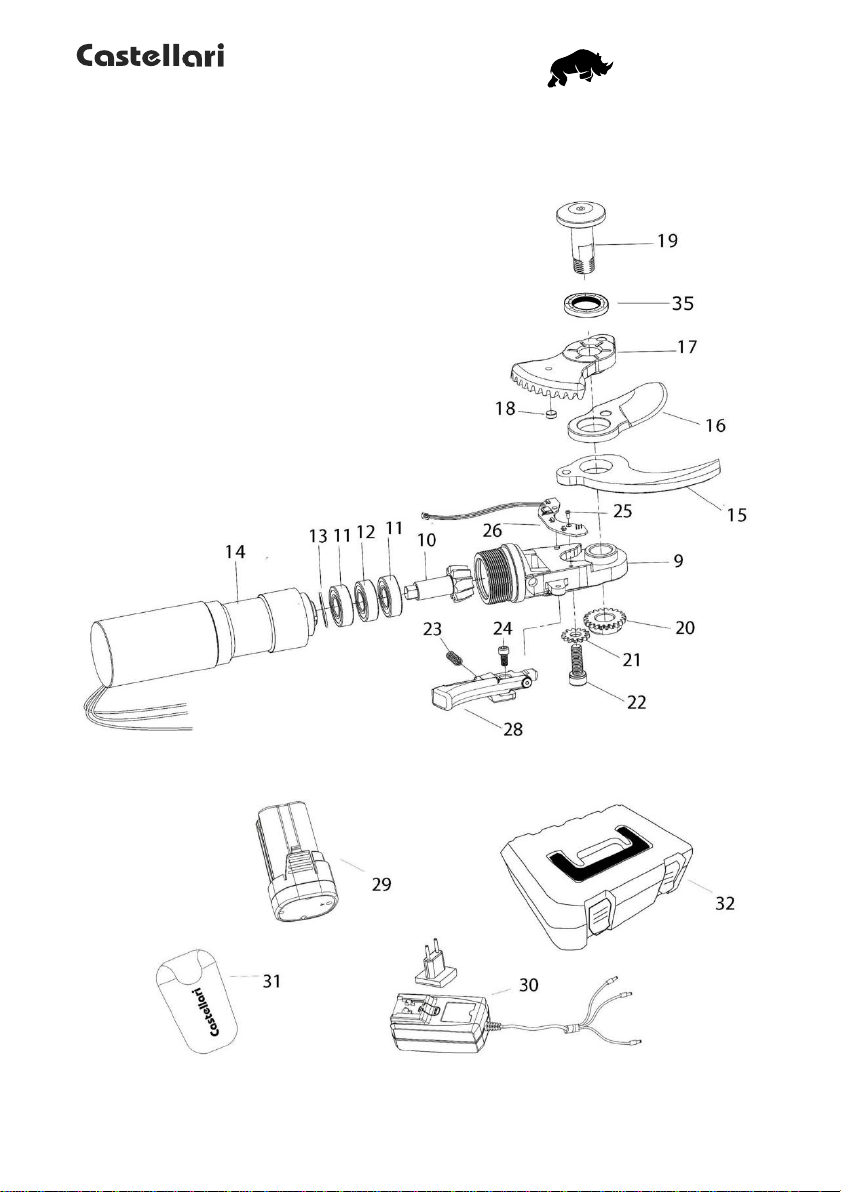

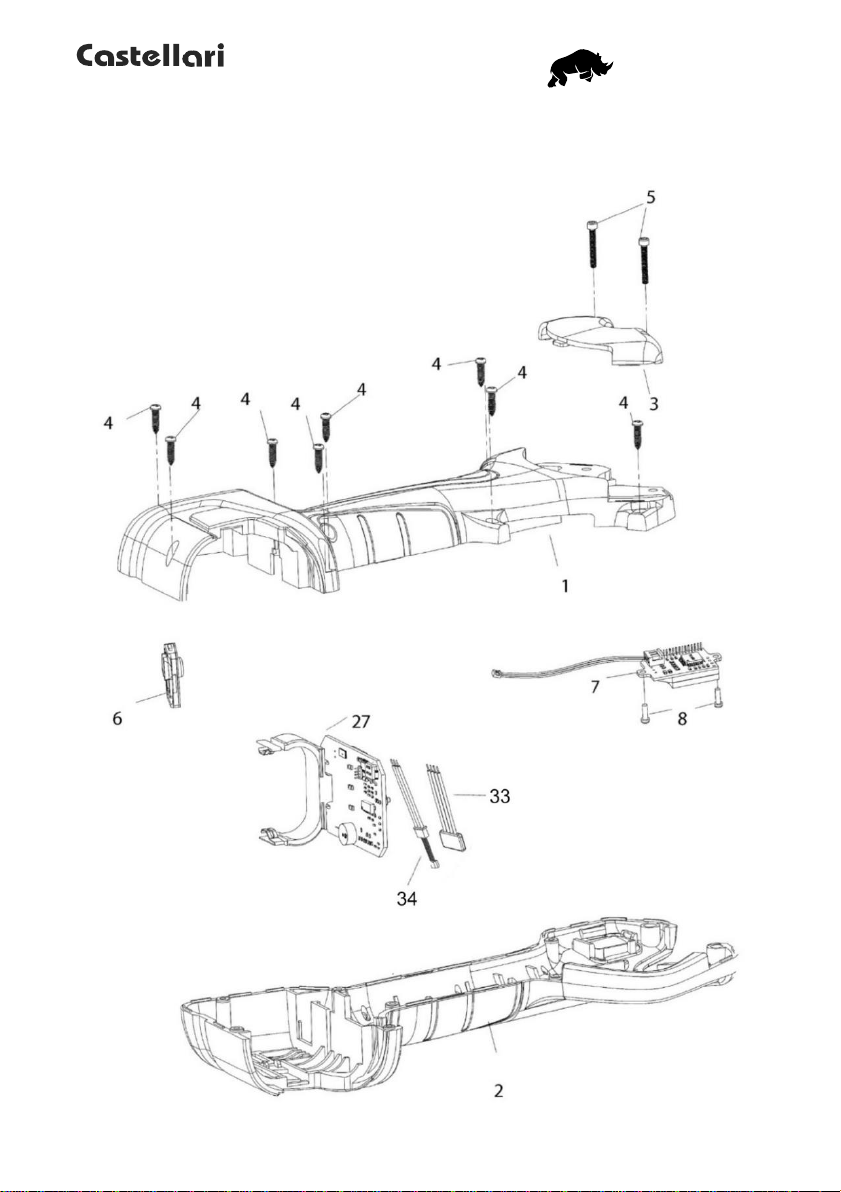

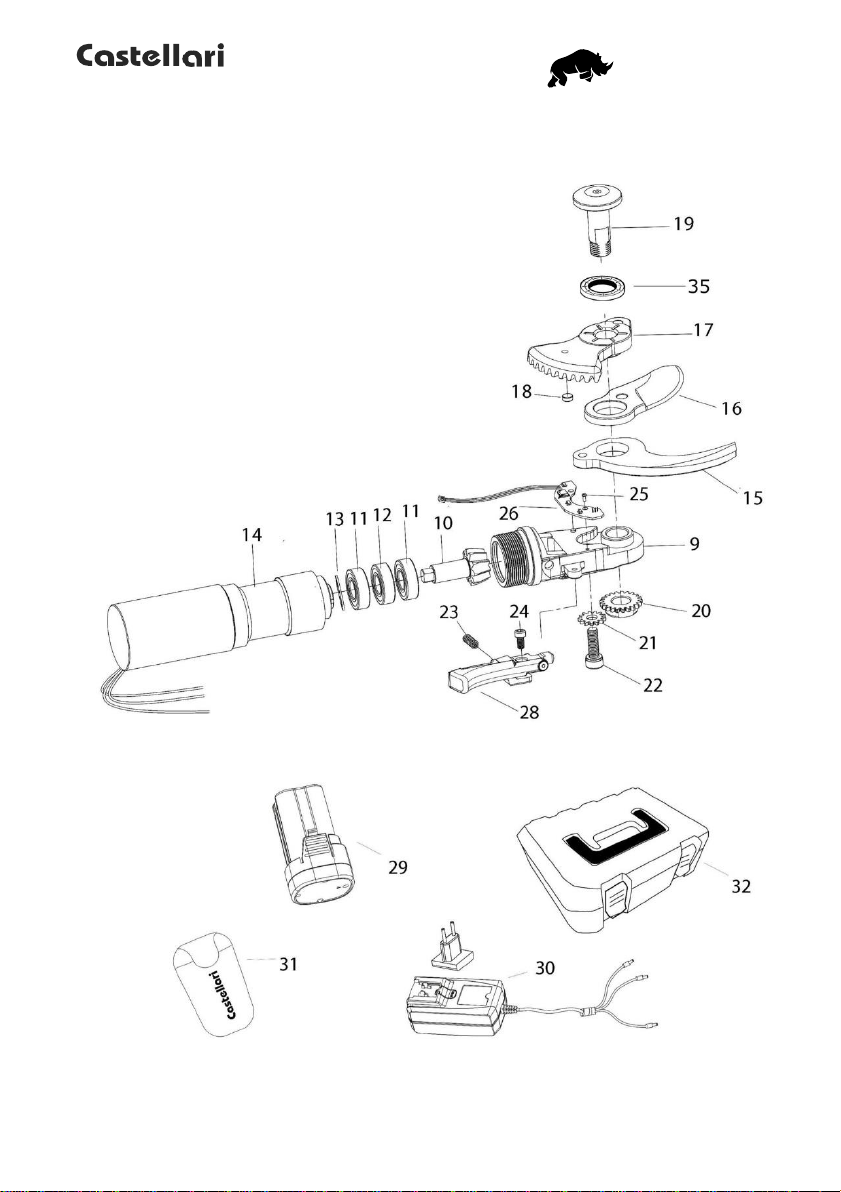

1.7. RYNO 40 Components .................................................................................................................. 6

1.8. RYNO 50 Components ........................................................... Errore. Il segnalibro non è definito.

1.9. RYNO 63 Components ................................................................................................................ 12

1.10. Specifica componenti RYNO 40 –RYNO 50 –RYNO 63............................................................... 15

2. SAFETY AND PREVENTION.......................................................................................15

2.1. Safety signs (pictograms)............................................................................................................ 15

2.2. General safety rules.................................................................................................................... 15

2.3. Safety in use and maintenance................................................................................................... 15

2.3.1.Safety in use and in the working environment............................................................................ 15

2.3.2.Safety in maintenance ................................................................................................................ 16

2.3.3 Electrical safety ........................................................................................................................... 16

2.4. Ecology and pollution ................................................................................................................. 16

2.4.1.Waste management ................................................................................................................... 16

2.4.2.Information to users ................................................................................................................... 16

3. USE..........................................................................................................................17

3.1. Handling and transport............................................................................................................... 17

3.2. Preparation for use..................................................................................................................... 17

3.3. Using the battery charger and charging the battery: ................................................................. 17

3.4. Use of machines ......................................................................................................................... 17

4. MAINTENANCE AND CLEANING ...................................................................................18

4.1. Routine maintenance ................................................................................................................. 18

4.2. Set-aside ..................................................................................................................................... 18

4.3. Dismantling of machines ............................................................................................................ 18

4.4. Spare parts.................................................................................................................................. 19

5. WARRANTY CONDITIONS .................................................................................................19

5.1. Disclaimer of Warranty............................................................................................................... 19

6. Declaration of conformity ...........................................................................................19