"Puma Eli"

UNIT; INSTRUCTIONS USE AND MAINTENANCE HANDBOOK

Page 2

Summary

Part I - Instructions use and maintenance handbook...............................................................................3

Important notice............................................................................................................................................... 4

Setting-up procedures ....................................................................................................................................... 5

Maintenance and revisions................................................................................................................................. 7

Informations about conformity by “Puma Eli” dental equipment at CEI EN 60601-1-2 Norms - 2001 Edition ........... 8

Technical data equipment.................................................................................................................................10

Unit identification label.....................................................................................................................................11

Medical devices applies to the unit - Unit operation ............................................................................................13

Pictures and descriptions ..................................................................................................................................14

Foot control functions.......................................................................................................................................20

Chair movements.............................................................................................................................................21

Autosteril/Time Flushing System .......................................................................................................................23

Separate supply system....................................................................................................................................25

Suction systems

(optional)

................................................................................................................................26

Conversion of the “Puma Eli" unit from right-handed to left-handed configuration

(only for ambidextrous dental units)

..................................................................................................................27

Disinfection and sterilization .............................................................................................................................28

Equipment sanitization schedule .......................................................................................................................30

Routine maintenance .......................................................................................................................................31

Routine maintenance program ..........................................................................................................................34

Products to be used with the Castellini dental unit .............................................................................................35

Part II – Operating lamp “Luna”..............................................................................................................36

Technical data .................................................................................................................................................37

Pictures and descriptions - Replacement of the bulb...........................................................................................38

Focusing of the “Luna” operating light - Pantograph arm regulation ....................................................................39

Overall dimensions...........................................................................................................................................40

Part IV – Operating instruments .............................................................................................................41

“Threesteril” Syringe ........................................................................................................................................42

“Cleanair 2000” - “Cleanlight 2000” Turbine.......................................................................................................44

"Hi–Power 2 Ceramic" – "Titanium Gold 2" - "Titanium Gold 2 Miniature" Turbine................................................48

“Implantor 2” Micromotor .................................................................................................................................52

"Air Power 2" Air micromotor ............................................................................................................................55

"Piezosteril 5" Scaler handpiece ........................................................................................................................57

"Leda" Polymerizing lamp .................................................................................................................................59

Part V – Instructions for the installation................................................................................................. 61

Essential requirements .....................................................................................................................................62

Permitted environmental conditions for transport and storage ............................................................................63

Installing the chair and the unit ........................................................................................................................64

Installing the right-hand unit ............................................................................................................................67

Installing the dental unit

(only ambidextrous units)

............................................................................................68

Safety covers...................................................................................................................................................78

Replacing the lamp of the negatoscope for intraoral X-rays ................................................................................81

Adjusting the tension of the levers on the instrument tray model S.P.R.I............................................................82

Adjusting the working pressures .......................................................................................................................83

Overall dimensions...........................................................................................................................................84

Unit hydraulic systems .....................................................................................................................................87

Unit electricic systems ......................................................................................................................................90

Part VI – Scheduled maintenance program – Servicing - Warranty conditions ......................................92

Scheduled maintenance and servicing ...............................................................................................................93

Servicing .........................................................................................................................................................94

Warranty conditions .........................................................................................................................................95

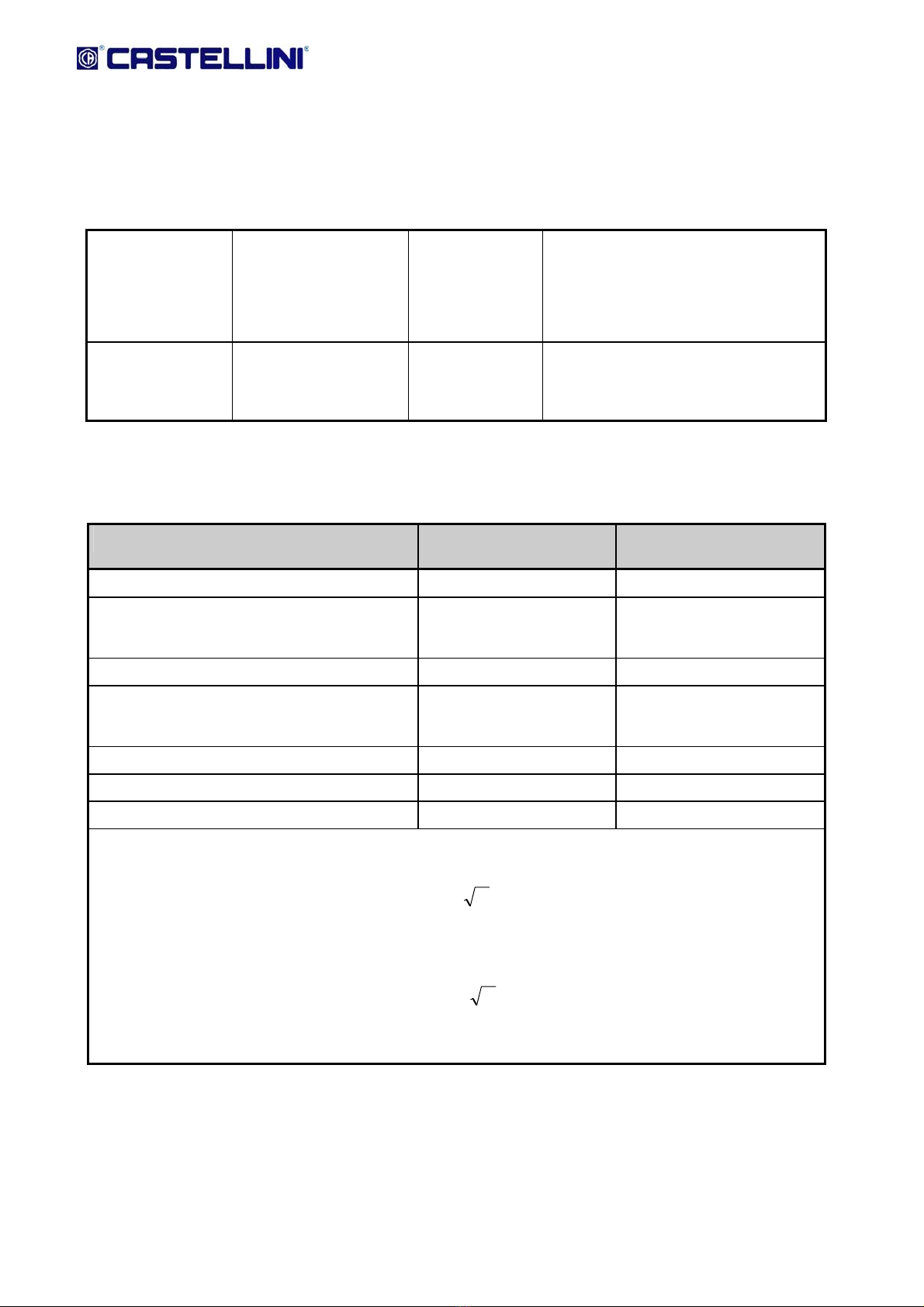

Forms for periodic checks (1 ÷ 10 Years) ..........................................................................................................96

Appendix I – Certifications