PARTS LIST

9

PB-1600 (07–99)

REF PART # DESCRIPTION QTY

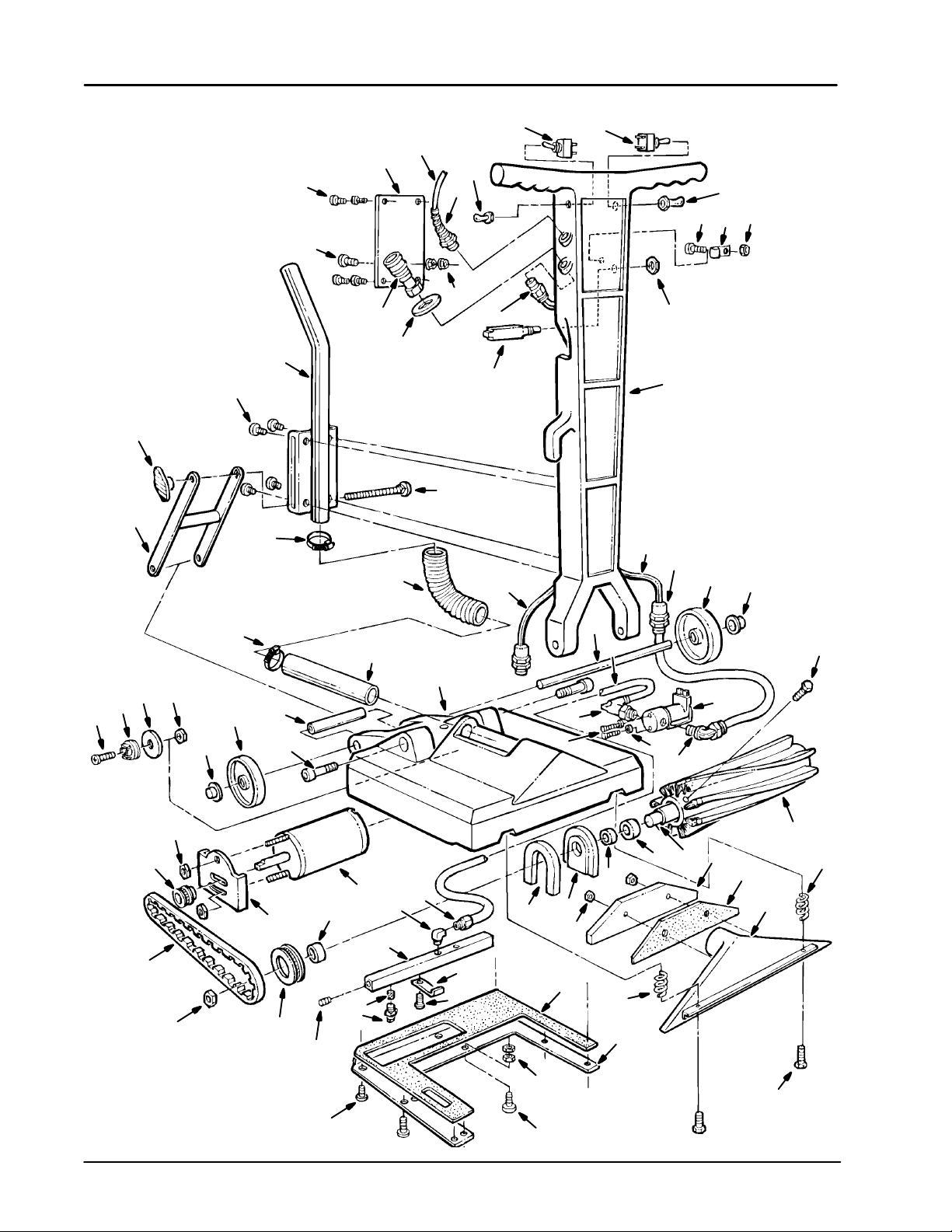

1. 140890 SCREW, 10–24x1/2” 3

2. 140887 SCREW, 10–24 x 3/8 14

3. 230304.BK PLATE, COVER 1

4. 130212 CORD, 18/3 x 25 FT. 120V 1

130271 CORD, 25 FT. 220V 1

130504 PLUG, TWIST LOCK(NOT SHOWN) 1

5. 130137 GRIP, CORD 1

6. 140519 NUT, 10–24 5

7. 140034 WASHER, FLAT 1/2” 1

8. 150913 COUPLER, QUICK 1

9. 608037 HANDLE, BLUE 1

10. 578337000 BREAKER, CIRCUIT 1.5A 1

11. 150024 CONNECTOR, 1/4”X3/8” 1

12. 130990 BOOT, RUBBER 1

13. 130728 SWITCH, SPRAY 1

14. 130751 SWITCH, ON/OFF 1

15. 130753 BOOT, SWITCH 1

16. 140848 SCREW, 10–24x1/2” 1

17. 140324 CLAMP, 5/16” 1

18. 160473 TUBING, 3/8” X55” 4.5FT.

19. 130181 GRIP, CORD 2

20. 230609 AXLE, WHEEL 1

21. 103007 WHEEL 2

22. 103029 CAP, HUB 2

23. 150421 ELBOW, 90°1/4”X3/8” 1

24. 210033 VALVE, SOLENOID 120V 60 HZ 1

25. 140023 WASHER, INT. LOCK #8 2

26. 140801 SCREW, 8–32x3/8 2

27. 150414 ELBOW, ST. 90°1/4 1

28. 160468 TUBING, 1/4”x.916 1

29. 140554 SCREW, 1/4–20x3/4 4

30. 240004 BRUSH, CYLINDER 16” 1

31. 230257 SHAFT, BRUSH 16” 1

32. 100049 SEAL, BRUSH BEARING 2

33. 140125 BEARING, BRUSH 2

34. 230261 BLOCK, BEARING 2

35. 100005 GASKET, BEARING BLOCK 1

36. 140546 NUT, LOCK 5/16–18 2

37. 230610.BK WEIGHT, VACUUM HEAD 1

38. 100144 GASKET, WEIGHT 1

39. 140419 SPRING 2

40. 230608 TOOL, PICKUP HEAD 1

41. 140221 SCREW, 5/16–18x1–1/4” 2

42. 100734.BK PLATE, BRUSH 1

REF PART # DESCRIPTION QTY

43. 100006 GASKET, BASE PLATE 1

44. 230605 BRACKET, MANIFOLD 1

45. 201004 NOZZLE, #8003 4

46. 150208 PLUG, 1/8 3

47. 230267 MANIFOLD, 16” SPRAYBAR 1

48. 150407 ELBOW, ST. 90°1/8 1

49. 150022 ADAPTER, 1/4” 1

50. 230363 SPACER, BRUSH PULLY 1

51. 230505 PULLEY, BRUSH 1

52. 140548 NUT, JAM 5/16 1

53. 230507 BELT, BRUSH DRIVE 1

54. 230506 PULLEY, MOTOR 1

55. 140518 NUT, KEP 10–32–S/S 2

56. 230366 PLATE, MOTOR MOUNT 1

57. 130471 MOTOR, BRUSH 120 VOLT 1

190150 BRUSH CARD REPLMT 1

130472 MOTOR, BRUSH 220 VOLT 1

190154 BRUSH CARD REPLMT 1

58. 140564 BOLT, SHOULDER 3/8 x 3/4 2

59. 140539 NUT, KEPS 6/32 1

60. 140041 WASHER, FENDER 1

61. 130304 RECTIFIER 1

62. 140831 SCREW, 6–32X5/8 1

63. 140601 SPACER, AXLE 1

64. 240179 TUBE, CLEAR VACUUM 1

65. 101348 BASE, BLUE 1

66. 130668 ASM., CORD16/4X55” 1

67. 160615 HOSE, VACUUM 1–1/2X.5ft. 1

68. 240194 KNOB, PLASTIC T–BAR 1

69. 230607 LINK , ARM 1

70. 140209 BOLT, CARRIAGE 5/16–18X4–1/2 1

71. 230606.BK TUBE, VACUUM HOSE ATTCHMNT 1

72. 140885 SCREW, 1/4–20X1/2 4

73. 140307 CLAMP, HOSE 2

DECALS (NOT SHOWN)

120513 DECAL, OPERATING INST. 1

120619 DECAL, “WARNING..” 1

120846 DECAL, “LOW PRESURE..” 1

608055 DECAL, “PB-1600” 1