Content

1Safety.................................................................................................................................2

1.1 Introduction..............................................................................................................2

1.2 Intended Use...........................................................................................................2

1.3 Safety Instructions for Commissioning.....................................................................2

1.4 Safety Instructions for Operation.............................................................................2

1.5 Safety Instructions for Servicing ..............................................................................3

1.6 Safety featuresl....................................................................................................................................3

1.7 Disposal of used oil .................................................................................................3

1.8 Machine demolition..................................................................................................3

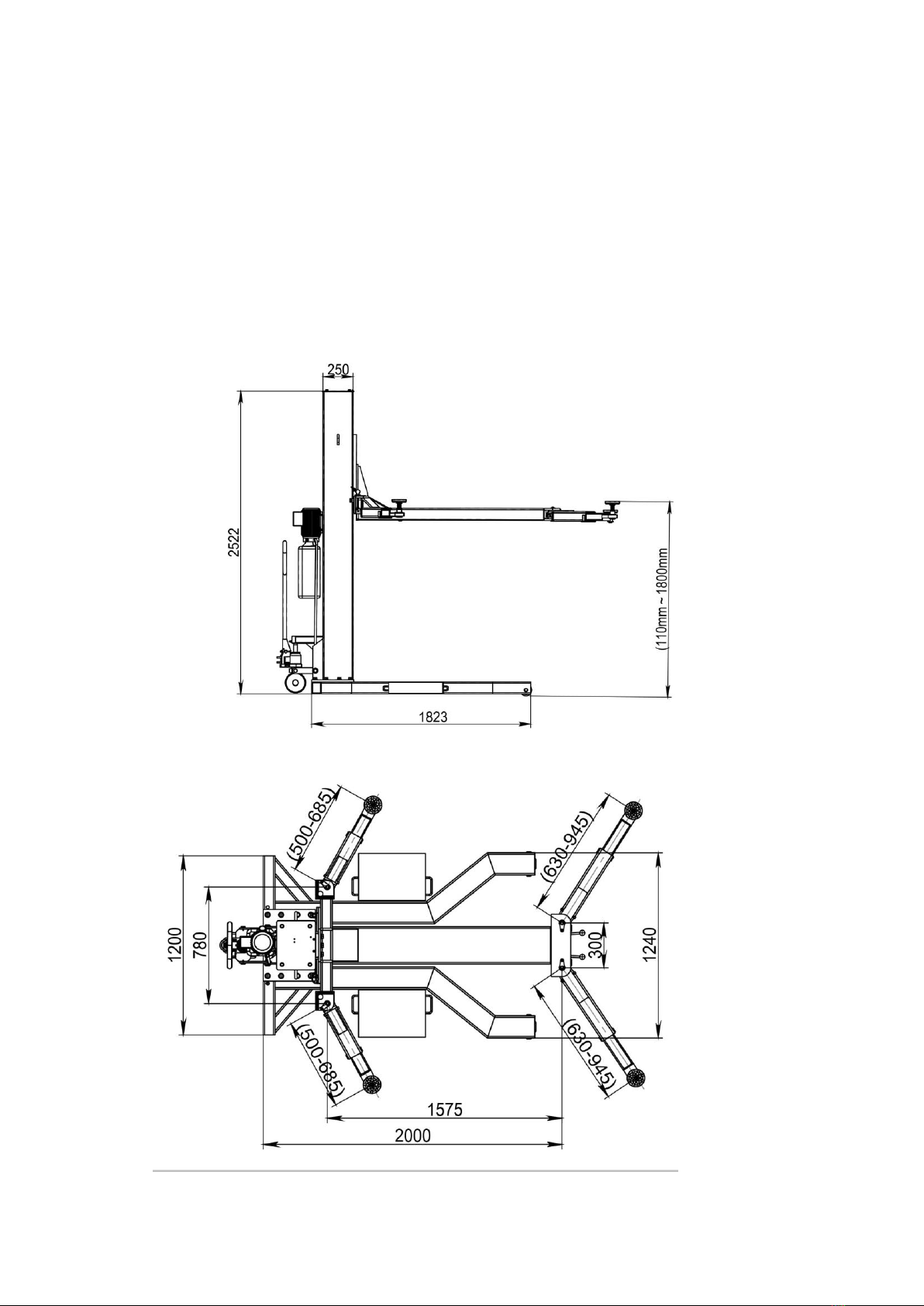

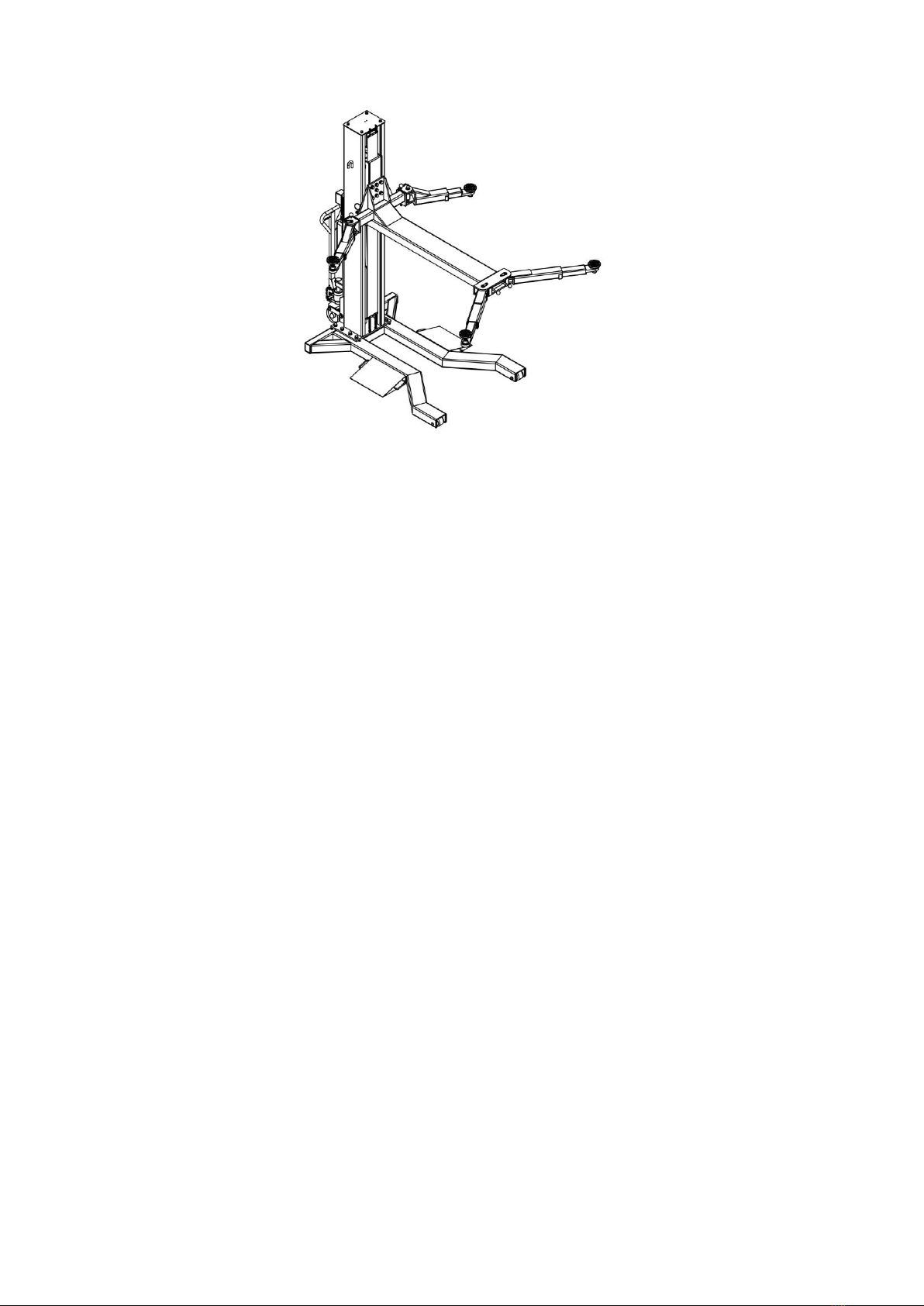

2. Structure Drawing: ...........................................................................................................4

3. Main Technical Mechanism Parameters Table.................................................................5

4. Packing, transport and storage....................................................................................5

4.1 Packing....................................................................................................................5

4.2 Lifting and handling .................................................................................................5

4.3 Storage and stacking of packages...........................................................................6

4.4 Delivery and check of packages..............................................................................6

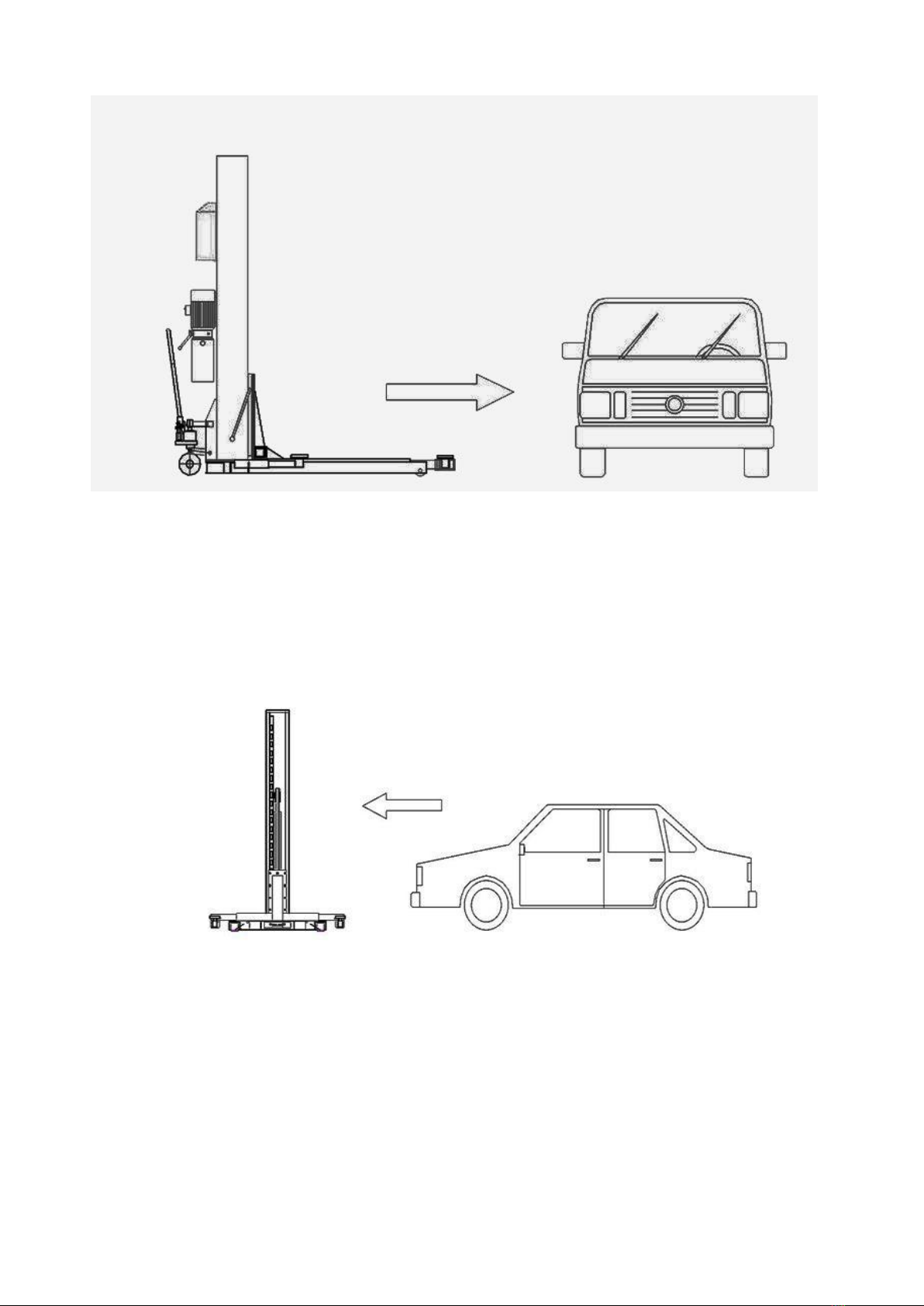

5 Installation.........................................................................................................................6

5.1Working Site.............................................................................................................6

5.2 Installation ...............................................................................................................6

6. Operation instruction........................................................................................................7

6.1 Operation Rules for mechanism System .................................................................7

6.2 Operating Steps for Electrical Control System.........................................................7

6.3 Operation Flow:.......................................................................................................7

6.4 Use lifting arm..........................................................................................................9

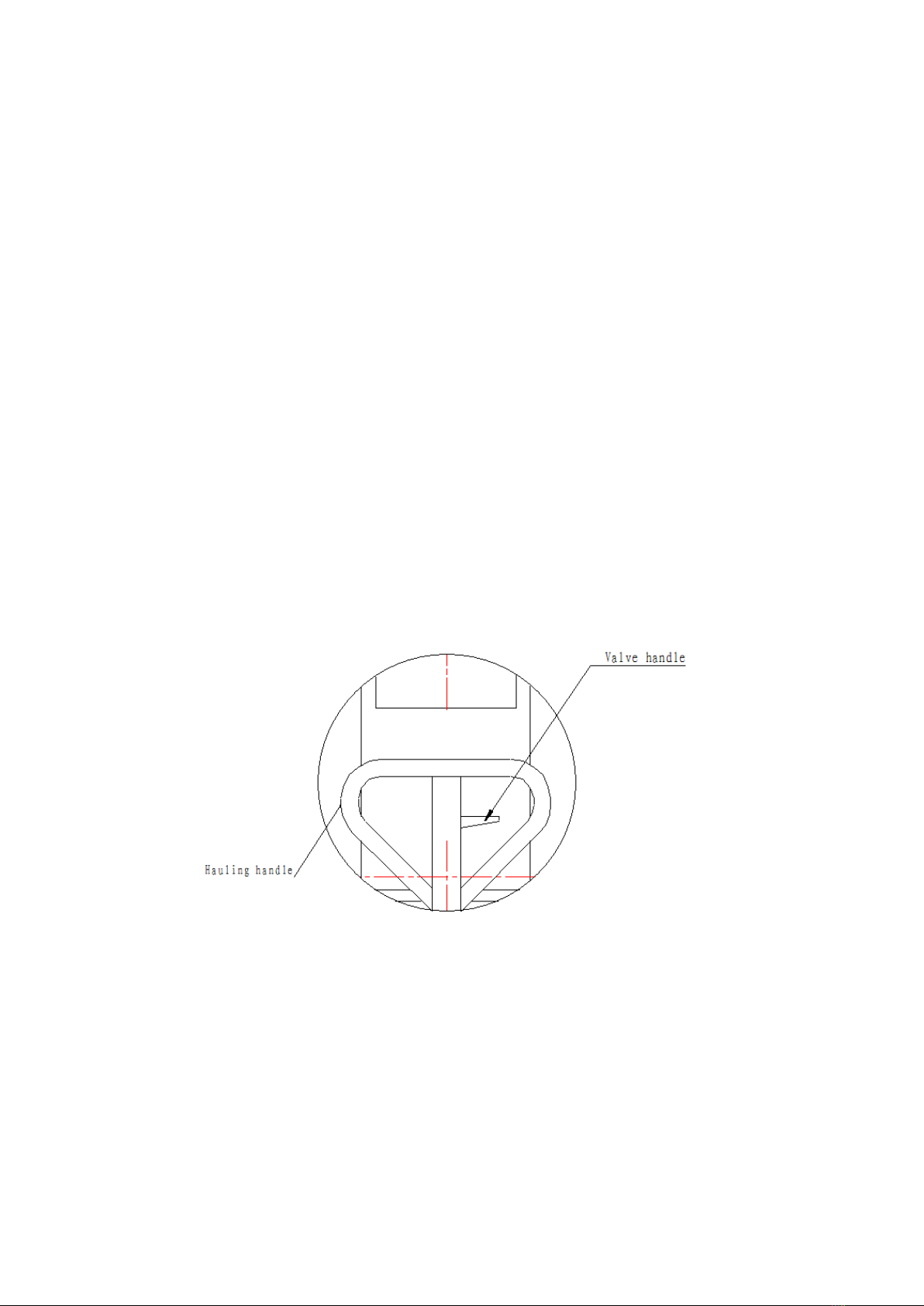

6.5 Control Unit............................................................................................................10

7. Maintenance and Troubleshooting.................................................................................10

7.1 Maintenance..........................................................................................................10

8. Troubleshooting.............................................................................................................11

Appendix............................................................................................................................13

1 Exploded drawing.....................................................................................................13

2 Circuit diagram .........................................................................................................14

3 Hydraulic diagram.....................................................................................................15