28

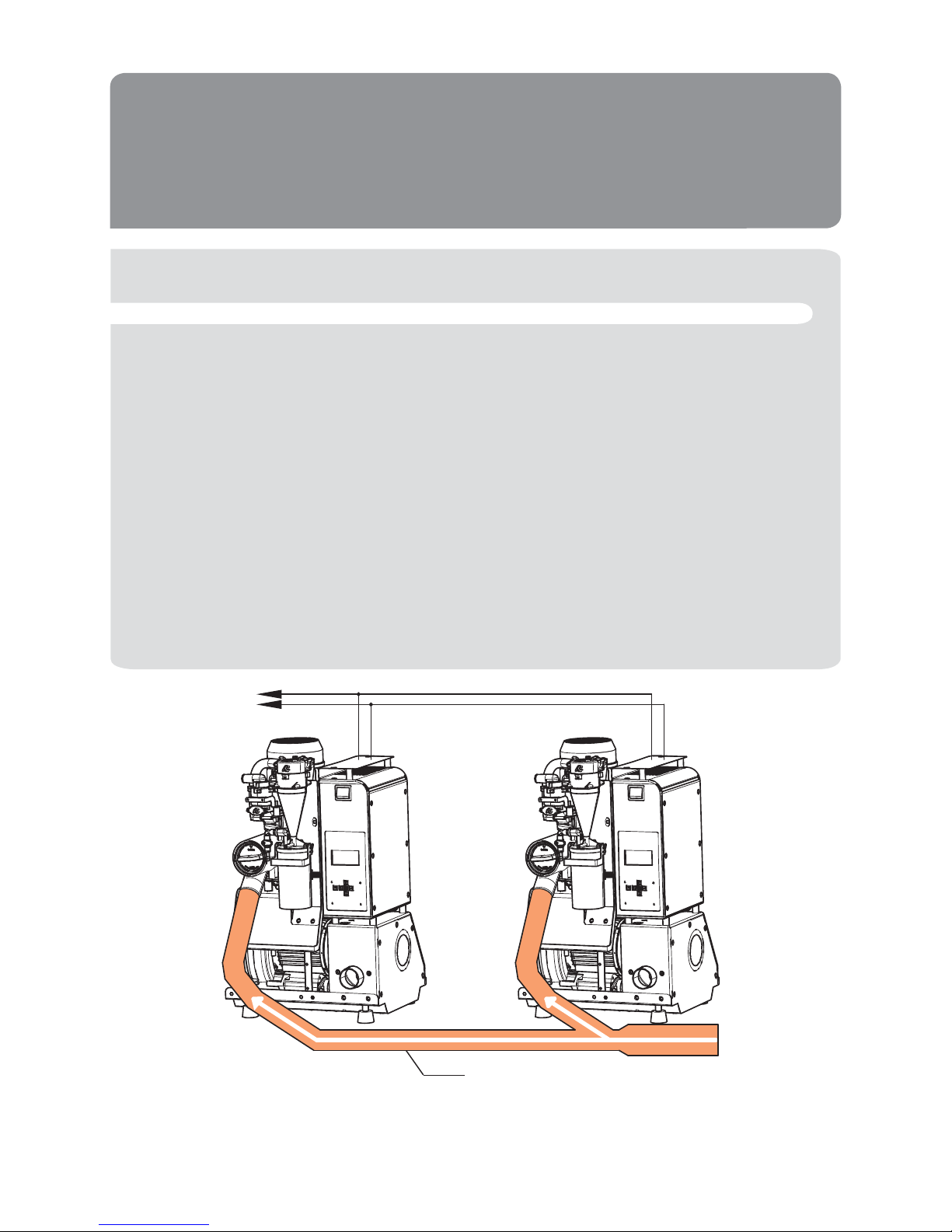

• Installation and starting

• Recommended precautions

Before unpacking the appliance, check the warning shock-

watch on the carton. In case of it being red or the carton

being damaged, accept the material reserving the right to

examine the machine.

Unpack the appliance following the instructions shown on

the package. The carton is recyclable. Dispose of it in com-

pliance with regulations in force.

The machine installation must be carried out by a specialist

equipped with the necessary tools. Install the appliance in

a clean location, far from heat sources, humidity and dust.

Turbo-Smart can be installed outdoors (on a balcony, in ve-

randa or gardens), provided that it is sheltered from rain,

splashing, humidity, frost and direct sunshine.

For outdoor installation we recommend the use of our

special designed box tted with double isolating roof, anti-

freeze and ventilation systems (both tted with xed ther-

mostat for automatic temperature control).

In the plant room temperature can range from a minimum of

+ 5 °C to +35 °C max.

Turbo-Smart tted with box, for indoors our outdoors in-

stallation, can be supplied with antifreeze device. In case

the plant room must be ventilated or air-conditioned, we

suggest to contact a thermo-technician for a personalized

project. The plant room must be closed to patients and ex-

traneous people. If such a room is not available, machines

must be protected by a suitable cover, which must not be

easy to remove. Use protections and danger warning bo-

ards to prevent accidental risk from electrical shocks or the

possibility (unlikely but not excludible) of re, explosion and

contaminating air or liquid leakage. Use indoors and outdo-

ors boxes designed and produced by the manufacturer of

the machines only.

Keep the plant room free from ammable material. Make

sure that there is no possibility for gas leakages. Do not

connect damaged appliances to the mains. Do not use ex-

tension leads, multiple plugs or sockets. Before connec-

ting the machine to the mains, ascertain that the feeding

line is complying with the regulations C.E.I. 64-8 and that

a thermal switch and a residual current operated circuit-

breaker (class A or B) (16A) according to the regulations

EN 61008-1 are present. Light coloured, wooden, linoleum,

rubber or marble oors can change colour or get marked if

they are kept in contact with rubber vibration-proof devices

(1). Therefore, it is necessary to use a rubber sheet or some

other suitable material to isolate vibration-proof devices

from the oor.

HANDLE

WITH CARE

WARNING

WARNING

SHOCKWATCH

R

RED INDICATES ROUGH HANDLING

IF RED, NOTE ON BILL OF LADING

INSPECTION MAY BE WARRANTED

MODEL L-55 (37g)

TOLL FREE 1-800-527-9497

www.shockwatch.com

Minima

Maxima

30

20

10

0

10

20

30

40

50

50

40

30

20

10

0

10

20

30

1