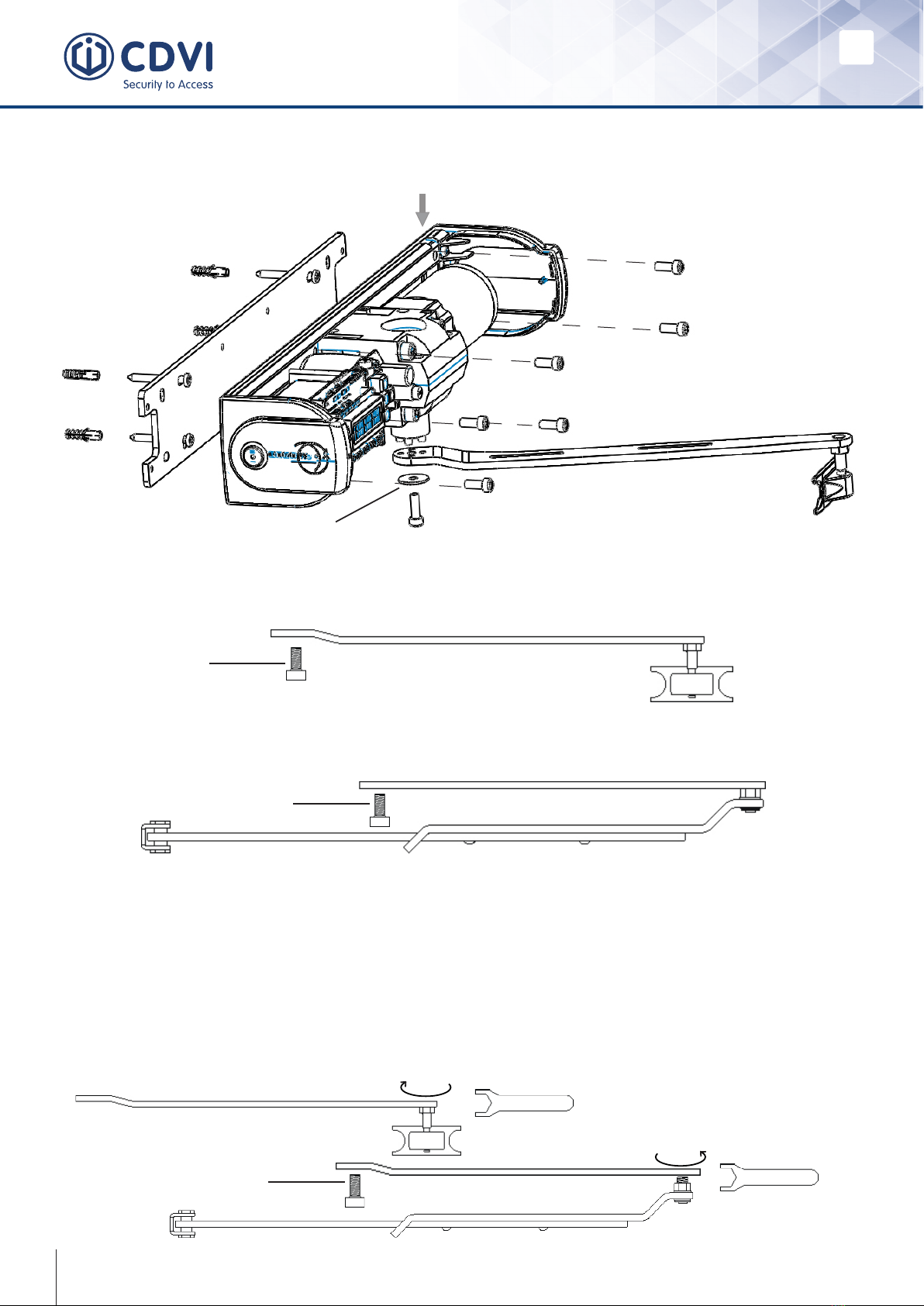

EN EN DIGIWAY Plus

Inward or Outward Door Operator

3

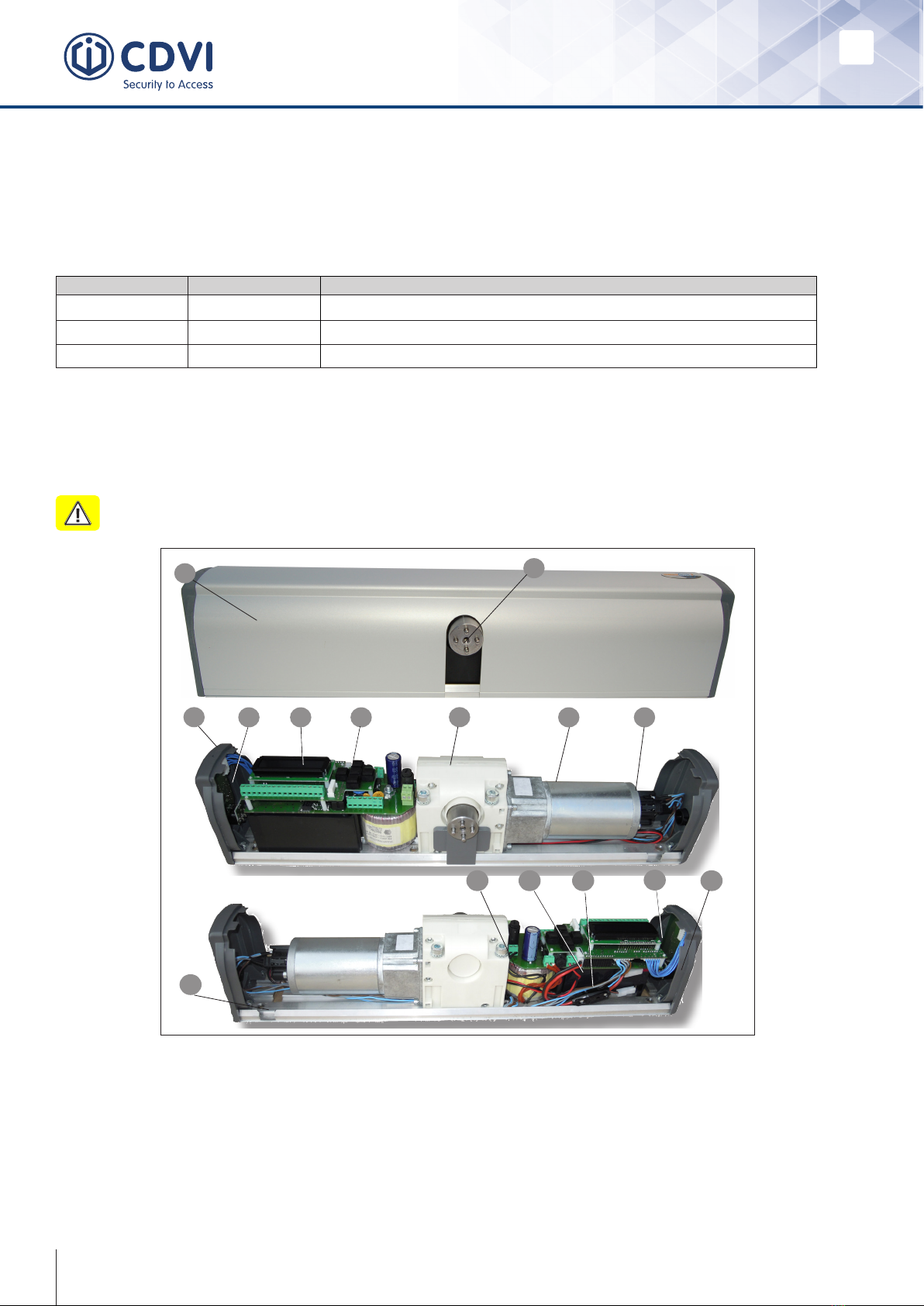

This manual is intended for professional installers, adequately trained.This manual is intended for professional installers, adequately trained.

Installation and connections must be carried out in accordance with Good WorkingInstallation and connections must be carried out in accordance with Good Working

Practice and in compliance with the current Regulations. Poor installation could bePractice and in compliance with the current Regulations. Poor installation could be

source of a health & safety hazard.source of a health & safety hazard.

First check all of the existing door and frame structure - verify its integrity, stability andFirst check all of the existing door and frame structure - verify its integrity, stability and

strength.strength.

If necessary modify the structure in order to make it standard, being aware of all theIf necessary modify the structure in order to make it standard, being aware of all the

possible problems that could occur during normal use.possible problems that could occur during normal use.

Verify that all the zones where there is a risk of crushing, dragging, shearing and otherVerify that all the zones where there is a risk of crushing, dragging, shearing and other

dangers, are protected by electronic safety, safety boards or barriers.dangers, are protected by electronic safety, safety boards or barriers.

This can be achieved if the distance does not exceed 8 mm. However, to avoid entrapmentThis can be achieved if the distance does not exceed 8 mm. However, to avoid entrapment

for the various parts of the body, the following distances are considered sufcient:for the various parts of the body, the following distances are considered sufcient:

Hand ngers > 25 mmHand ngers > 25 mm

Foot > 50 mmFoot > 50 mm

Head > 300 mmHead > 300 mm

Body > 500 mmBody > 500 mm

The forces developed by the complete system must comply with the current standardsThe forces developed by the complete system must comply with the current standards

and, where this is not possible, protect the zones with electronic safety devices.and, where this is not possible, protect the zones with electronic safety devices.

Apply hazardous area notices required by the applicable regulations. Before the actuatorApply hazardous area notices required by the applicable regulations. Before the actuator

is connected, make sure that the plate details correspond to those of the mains poweris connected, make sure that the plate details correspond to those of the mains power

and that there is a differential circuit-breaker and an adequate protection againstand that there is a differential circuit-breaker and an adequate protection against

overcurrents on the supply side of the system.overcurrents on the supply side of the system.

Fit a Dual Pole disconnection switch with contact opening gap of at least of 3 mm.Fit a Dual Pole disconnection switch with contact opening gap of at least of 3 mm.

Interrupt the power supply before opening the cover of the actuator for any maintenanceInterrupt the power supply before opening the cover of the actuator for any maintenance

or repairing intervention.or repairing intervention.

Handling of electronic parts must be carried out wearing grounded antistatic braceletsHandling of electronic parts must be carried out wearing grounded antistatic bracelets

to avoid any static damage.to avoid any static damage.

Servicing the actuator is of fundamental importance if the system is to operate correctlyServicing the actuator is of fundamental importance if the system is to operate correctly

and safely.and safely.

Comply with the manufacturer’s instructions described in this manual.Comply with the manufacturer’s instructions described in this manual.

Only use genuine spare parts if replacements or repairs are required. The motorOnly use genuine spare parts if replacements or repairs are required. The motor

manufacturer declines any responsibility if component parts tted are not compatible manufacturer declines any responsibility if component parts tted are not compatible

with safe and correct operation. The actuator must be installed inside only.with safe and correct operation. The actuator must be installed inside only.

IMPORTANT SAFETYIMPORTANT SAFETY

PRECAUTIONSPRECAUTIONS

The present document contains important precautions for safe use and operation.The present document contains important precautions for safe use and operation.

Read the instructionsRead the instructions carefullycarefully before commencing the installation. Keep thisbefore commencing the installation. Keep this

document even after installation.document even after installation.

!