1

Thank you very much for purchasing a TORQUE TESTER CD-100M / 10M

For safe and efficient operation, read this Operation Manual through before use, get a good understanding of the

operating precautions, capabilities of this product, how to use it, and other details, and use it correctly.

Contents

1 Safety Precautions.................................................................................................................................... 2

2Specification .............................................................................................................................................. 3

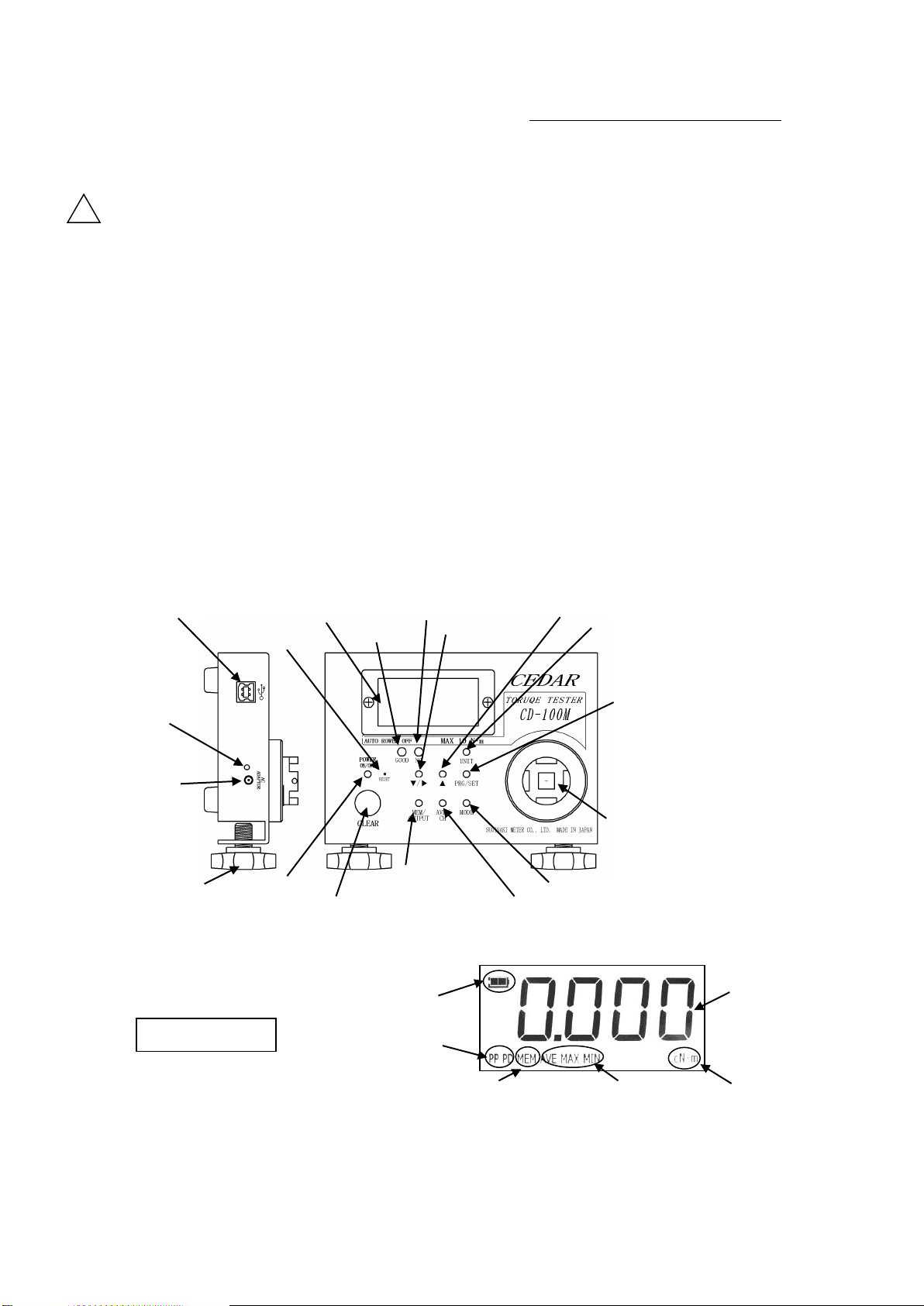

2.1 The name of each part, and the main uses .............................................................................................. 3

2.2 Specification........................................................................................................................................ 5

2.3 Outside dimension ............................................................................................................................... 5

3Preparation of Measurement...................................................................................................................... 6

3.1 Measurement Mode............................................................................................................................... 6

3.1.1 Kind in Measurement Mode............................................................................................................. 6

3.1.2 A setup and change in measurement mode ........................................................................................ 6

3.1.3 Setup and Change of Measurement Unit ......................................................................................... 6

3.2 Selection of Joint for Measurement ........................................................................................................ 7

3.2.1 SJ Joint .......................................................................................................................................... 7

3.3 Cautions at Time of Installation.............................................................................................................. 8

3.4 Power Source...................................................................................................................................... 8

3.5 About zero adjustment........................................................................................................................... 8

4Measuring Method..................................................................................................................................... 9

4.1 Measurement of Electric Driver ............................................................................................................. 9

4.1.1 Check of Torque, and Selection of Measurement Joint ....................................................................... 9

4.1.2 The method of measurement .......................................................................................................... 9

4.2 Measurement of Torque Driver Torque Wrench ..................................................................................... 10

4.2.1 Measurement of a torque driver...................................................................................................... 10

4.2.2 Measurement of Torque Wrench................................................................................................... 10

5About a convenient function .................................................................................................................... 11

5.1 Kind of Convenient Function............................................................................................................... 11

5.2 The setting method of a convenient functional numerical value .............................................................. 11

5.3 How to Use Convenient Function......................................................................................................... 13

5.3.1 Yes-no Decision............................................................................................................................ 13

5.3.2 Maximum, Minimum, and Average ................................................................................................ 14

5.3.3 It is Automatic in Display and Clear............................................................................................... 14

5.4 Real-time data output........................................................................................................................... 14

6Preservation, Display, and Output of Data............................................................................................... 14

6.1 Measurement Data .............................................................................................................................. 15

6.1.1 Preservation of Measurement Data................................................................................................. 15

6.1.2 Display and Elimination of Saved Measurement Data...................................................................... 15

6.1.3 Output of Saved Measurement Data ............................................................................................... 16

6.2 Output data......................................................................................................................................... 16

6.3 All Elimination of Saved Data.............................................................................................................. 17

6.4 Change of Output Speed of Data.......................................................................................................... 17

7System Reset............................................................................................................................................ 18

8Calibration Trust Service......................................................................................................................... 18

8.1 Periodical calibration ........................................................................................................................ 18

8.2 Guarantee.......................................................................................................................................... 18

8.3 When Troubled.................................................................................................................................. 19