3

1. GENERAL CHARACTERISTICS

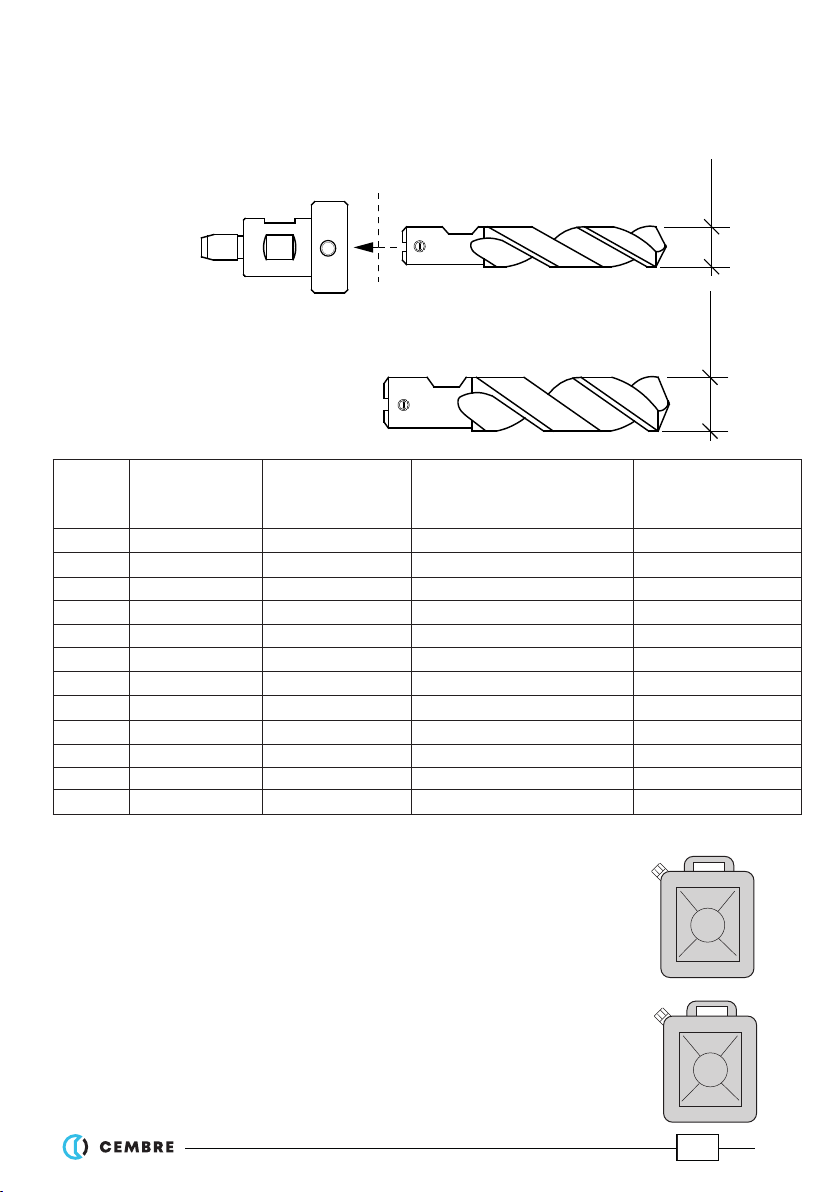

– Drilling capacity:................................................................................................................ 9/32" to 1 9/16"

(with special twist drill bits: hole diameters of 9/32" to 1-1/8" on rails up to 3 1/2" thick)

(with broach cutters: hole diameters of 3/4" to 1-9/16" on rails up to 2 3/4" thick)

– Speed without load:...................................................................................................................... n° 270 rpm

– Combustion engine:

Type:..............................................................Forced air cooled, 2 cycle, horizontal shaft, single cylinder

Model:............................................................................................................................................KAWASAKI TJ45E

Displacement:............................................................................................................................................. 45.4 cm3

Power (SAE J1349):.................................................................................................1.4 kW (1.9 hp) / 7500 rpm

Fuel tank capacity: ...........................................................................................................0.24 US gal (0.9 litres)

Clutch:.............................................................................................. centrifugal with automatic intervention

Starter:..........................................................................................................recoil sarter (with spring damper)

Ignition:..............................................................................................................solid state ignition (C.D.I. type)

Spark plug:............................................................................................................NGK BPMR7A or equivalents

Fuel:................................................................................................. 2% (1:50) oil/gasoline mixture (see § 12)

Fuel consumption: .................................................................................................. 470 g/kW.hr / 350 g/hp.hr

Emissions:................................................... according to "Phase 2" EPA regulation engines class V and

European Directives 97/68/EC, 2001/63/EC and 2002/88/EC

– Weight:.......................................................................................................................................................34.5 lbs

– Weight: with “DBG-Y” clamping device ........................................................................................41.5 lbs

– Gear sump:

Recommended oil:........................... MOBIL SUPER MULTIGRADE 10-30-SAE or

ESSO UNIFARM 10 W 30 or equivalent

–Acoustic noise (Directive 2006/42/EC, annexe 1, point 1.7.4.2 letter u)

– The weighted continuous acoustic pressure level equivalent

A at the work place LpA is equal to............................................................................................. 99.5 dB (A)

– The maximum value of the weighted acoustic displacement

pressure C at the work place LpCPeak is equal to....................................................................116.3 dB (C)

– The acoustic power level emitted by the machine

LWA is equal to..................................................................................................................................107.6 dB (A)

–Risks due to vibration (Directive 2006/42/EC, annexe 1, point 2.2.1.1)

Tests carried out in compliance with the indications contained in EN ISO 5349-1/2 Standard

and under operating conditions much more severe than those normally found, certify that the

weighted root mean square in frequency of the acceleration the upper limbs are exposed is

4.36 m/sec2 max.