2

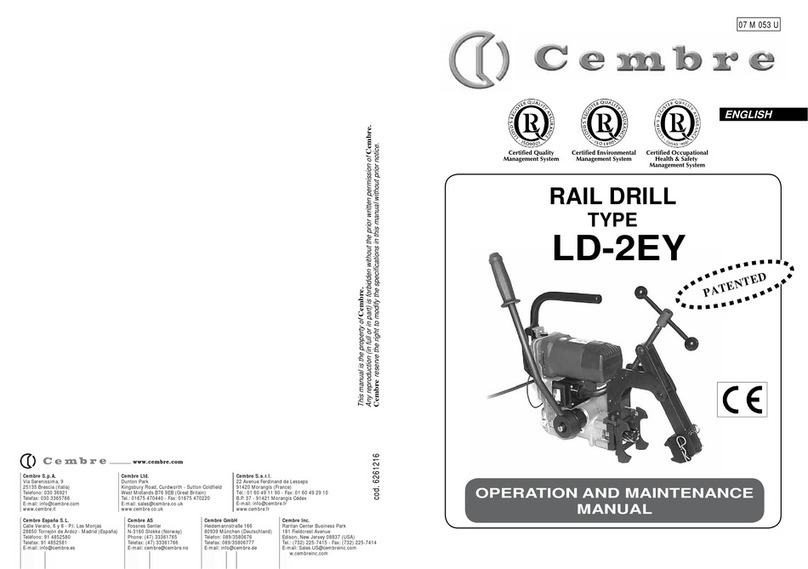

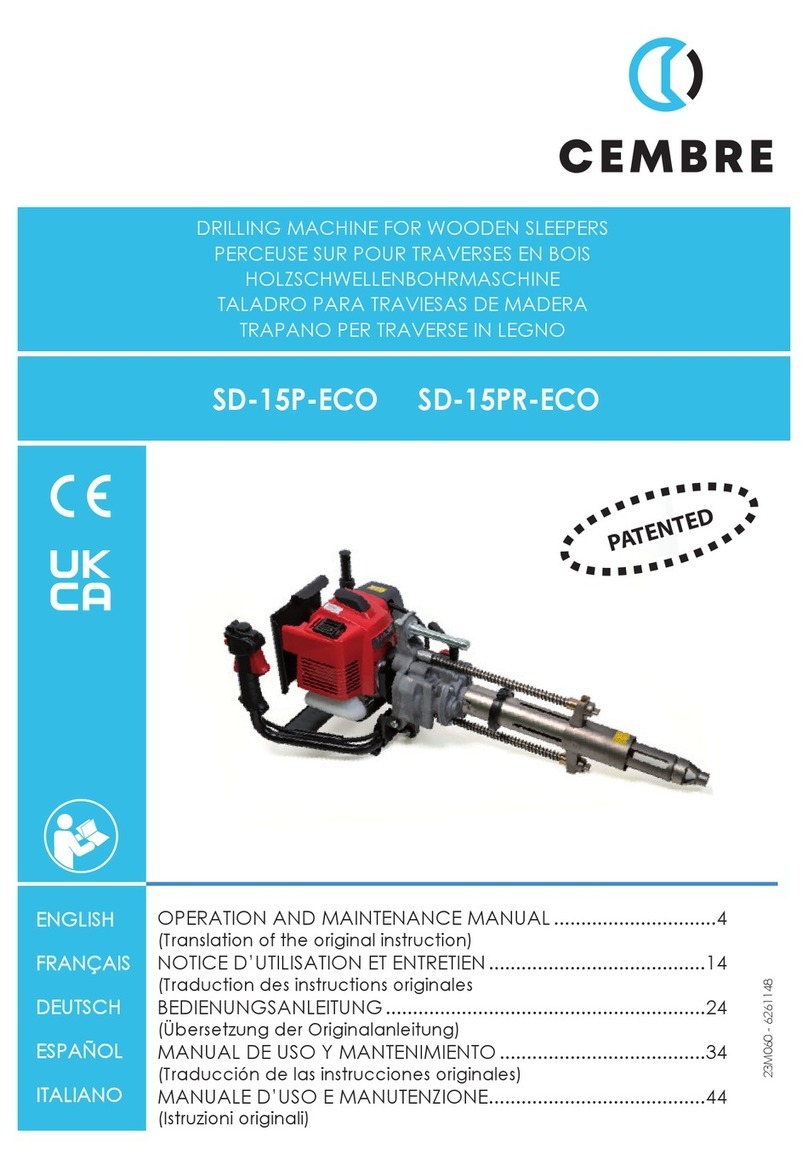

INDEX page

1. General characteristics............................................................................................................................................... 6

2. Accessories supplied with the drill ........................................................................................................................ 7

3. Accessories to be ordered separately ................................................................................................................... 9

4. Spindle advance lever ................................................................................................................................................ 13

5. Motor ON/OFF switch (EMERGENCY) ...................................................................................................................14

6. LED worklights ON/OFF switch............................................................................................................................... 14

7. LED indicator.................................................................................................................................................................. 15

8. "Drilling assistance" function................................................................................................................................... 15

9. Rechargeable battery ................................................................................................................................................. 16

9.1) Using the battery charger ......................................................................................................................................... 16

10. SR5000 coolant unit ................................................................................................................................................... 17

11. Preparing the drill ........................................................................................................................................................ 19

11.1) Assembling broach cutters with Quick push/turn shank.............................................................................. 19

11.2) Assembling broach cutters with Weldon shank................................................................................................20

11.3) Assembling spiral bits................................................................................................................................................. 21

11.4) Assembling terminations on DBG-F2 clamping device ................................................................................. 22

11.5) Assembly of DBG-F2 clamping device.................................................................................................................. 23

11.6) Fitting positioning templates ................................................................................................................................ 23

11.7) Fitting “double-sided” templates........................................................................................................................... 24

11.8) Clamping the drill to the rail web........................................................................................................................... 25

12. Drilling operation......................................................................................................................................................... 26

12.1) Drill fitted with broach cutter .................................................................................................................................. 26

12.2) Drill fitted with spiral bit............................................................................................................................................ 28

13. Alarms............................................................................................................................................................................... 29

14. SPA positioning plate.................................................................................................................................................. 30

15. Storing the drill ............................................................................................................................................................. 32

16. Maintenance .................................................................................................................................................................. 33

17. Return to

Cembre for overhaul............................................................................................................................... 35

Appendix “A”............................................................................................................................................................................... 35