728

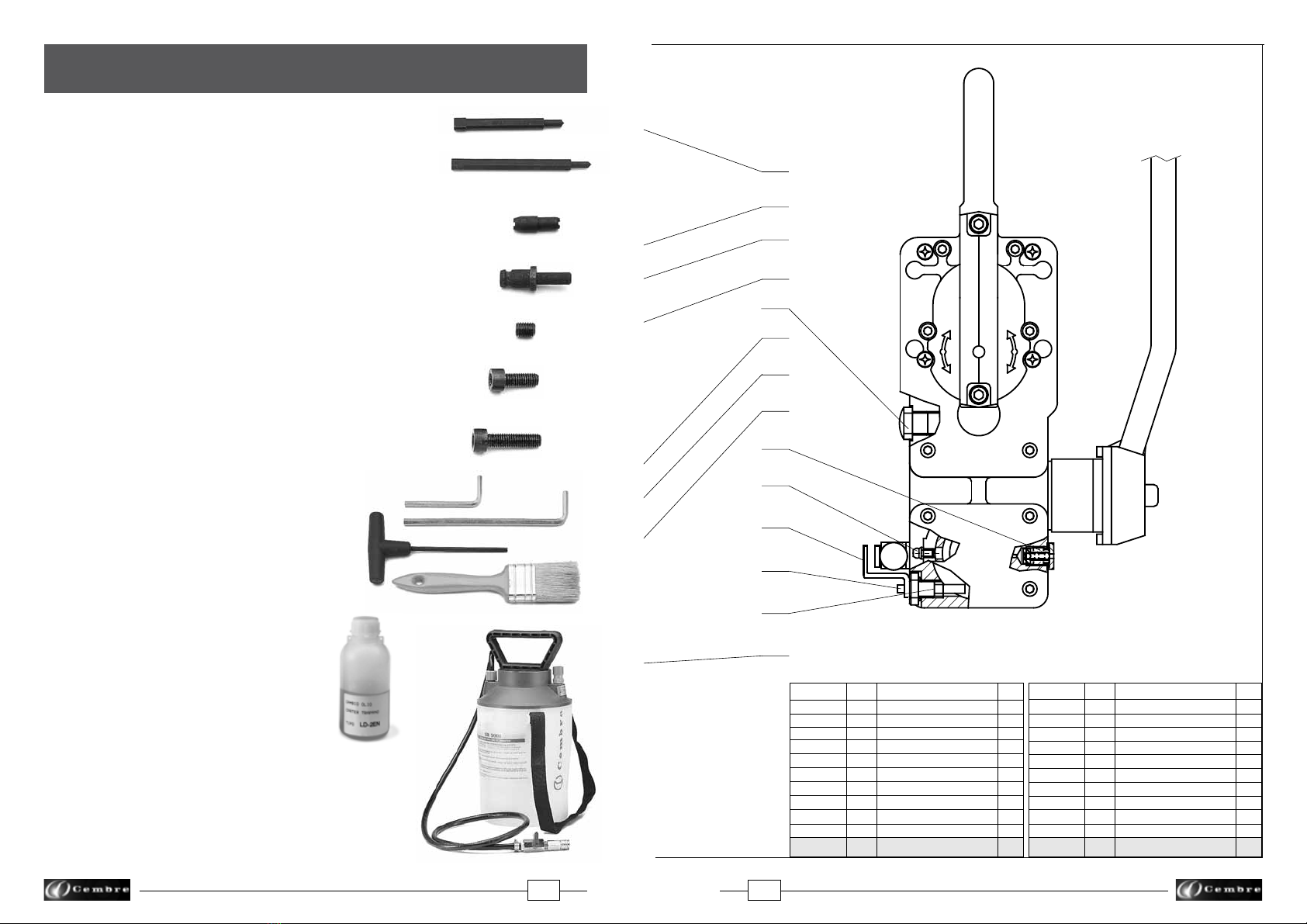

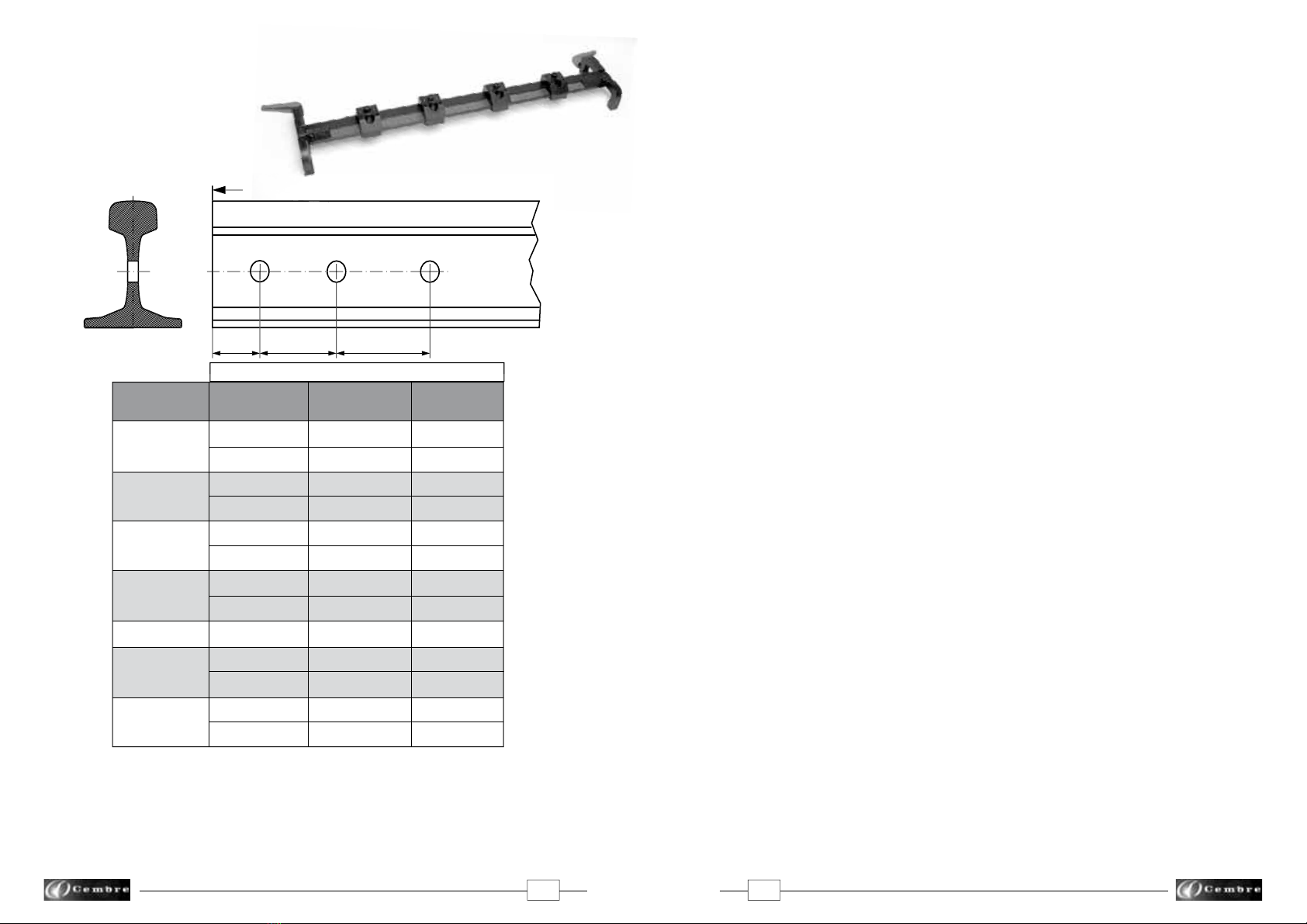

3.6) JOINT BAR POSITIONING GAUGES

Positioning gauges MRF-Y... for drilling joint bar

holes at pre-defined distances between rail end

and holes center lines.

2 21/32" 7 1/4" 5 1/2"

3 1/2" 6" 6"

2 21/32" 7 1/4" 5 1/2"

3 1/2" 4 3/4" 4 3/4"

2 23/32" 6" 7"

3 1/2" 6" 6"

3" 6" -

2 7/16" 5" -

2 7/16" 7" -

2 3/8" 7" -

2 3/4" 6 3/4" 6 3/4"

2 11/16" 5 1/2" 5 1/2"

3 1/2" 6" 6"

POSITIONING

GAUGE A B C

MRF Y10

MRF Y11

MRF Y12

MRF Y13

MRF Y14

MRF Y15

MRF Y16C

MRF Y10: suitable for drilling the following rails 100ARA-B, 115 and 119 LB RE

MRF Y11: suitable for drilling the following rails 100 ARA-B, 105 DL&W

MRF Y12: suitable for drilling the following rails 115, 119, 132, 136, 140 LB RE, 130 and 155 PS

MRF Y13: suitable for drilling the following rails 80, 90 LBASCE and 100ARA-A

MRF Y14: suitable for drilling the 85 LBASCE rail

MRF Y15: suitable for drilling the 130 LB RE and 136 LE.VAL rails

MRF Y: universal positioning gauge for all rail sizes

•

Note: other positioning gauge sizes available upon request.

B

APPENDIX “B”

Air noise (DIRECTIVE 2006/42/EC, Annexe 1, point 1.7.4.2, letter "u"):

–The continuous equivalent weighted level (A)

of noise pressure at the working place LpA is equal to .................................85,8 dB (A)

– The maximum value of instantaneous weighted noise

pressure C at the working place LpCPeak is lower than....................................130 dB (C)

– The level of noise force produced by the machine LWA

is equal to.....................................................................................................96,6 dB (A)

Protection of operators against risksof exposure to noise during work.

Cembre

drills type LD-2EY are designed and constructed according to EEC directives

80/1107 and 86/188 relating to the protection of operators against risks arising from ex-

posure to chemical, physical and biological agents during work, and with particular regard

to the risk of exposure to noise.

Thishas enabled a rangeof drills tobe manufactured for drillingrails and trackequipment,

at reduced noise levels.

The degree of exposure of an operator to noise produced from this equipment depends

on the duration of the loading times and the intervals between exposures, and finally on

the number of holes made within the space of one working day.

For example, an operator using the drill correctly for making holes 19 mm in diam., with

a type RCV 190 broach cutter on rails classified as UIC 60, quality 900, producing up to

400 holes/day, the daily personal exposure to noise, due solely to the use of the drill, is

less than 80 dB (A); under similar conditions producing 700 holes/day, the daily exposure

to noise would be 82.1 dB(A).

Since noise levels vary according to the many different operating conditions,

Cembre

engineers are available to give further details on the correct use of the drills.

Risks due to vibration (Directive 2006/42/EC, Annexe 1, point 2.2.1.1).

The weighted root mean square acceleration value to which the arms of an operator are

subjected when using the drill machine does not exceed 2,5 m/s2.

HOLES DISTANCES