Central Pneumatic 44923 Parts list manual

Other Central Pneumatic Nail Gun manuals

Central Pneumatic

Central Pneumatic Central Pneumatic Air Nailer/Stapler 2-in-1 Kit... User manual

Central Pneumatic

Central Pneumatic Contractor 97520 User manual

Central Pneumatic

Central Pneumatic 93496 User manual

Central Pneumatic

Central Pneumatic 92359 Installation manual

Central Pneumatic

Central Pneumatic 92917 User manual

Central Pneumatic

Central Pneumatic 93257 User manual

Central Pneumatic

Central Pneumatic 92917 Installation manual

Central Pneumatic

Central Pneumatic 68019 Installation manual

Central Pneumatic

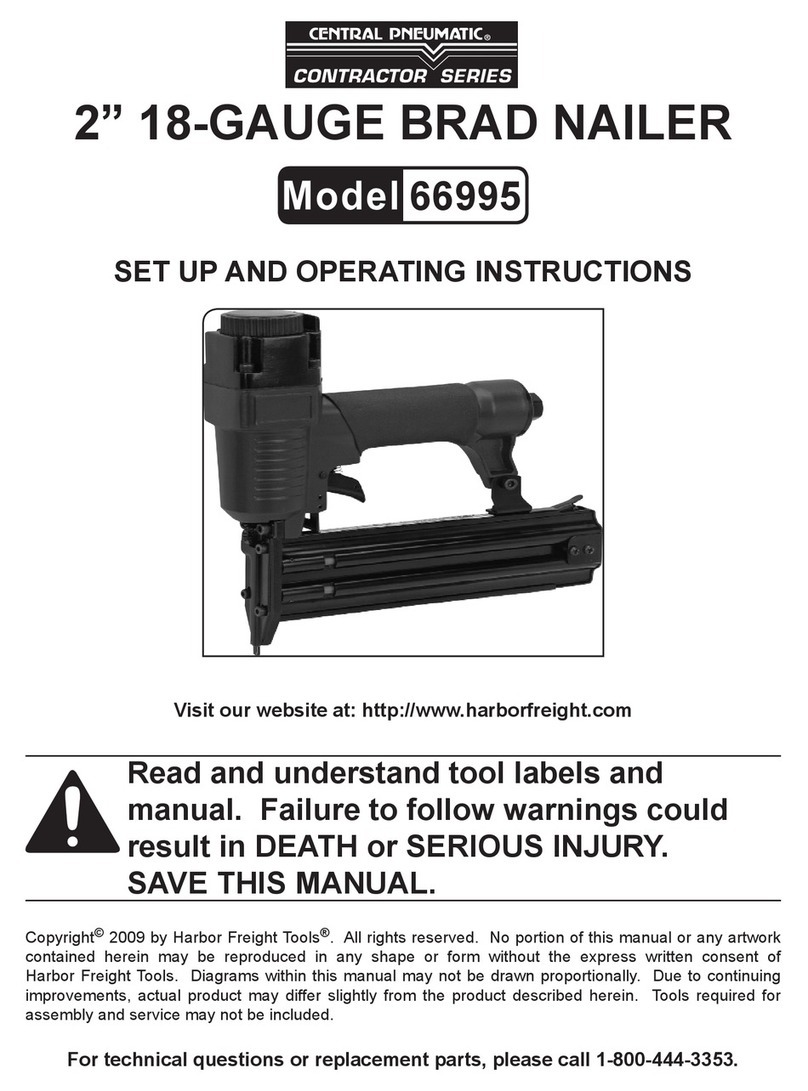

Central Pneumatic 66995 Installation manual

Central Pneumatic

Central Pneumatic 93496 User manual

Central Pneumatic

Central Pneumatic Contractor 97524 User manual

Central Pneumatic

Central Pneumatic 67100 Installation manual

Central Pneumatic

Central Pneumatic 93909 Installation manual

Central Pneumatic

Central Pneumatic 90193 User manual

Central Pneumatic

Central Pneumatic Contractor 97526 Parts list manual

Central Pneumatic

Central Pneumatic 40115 User manual

Central Pneumatic

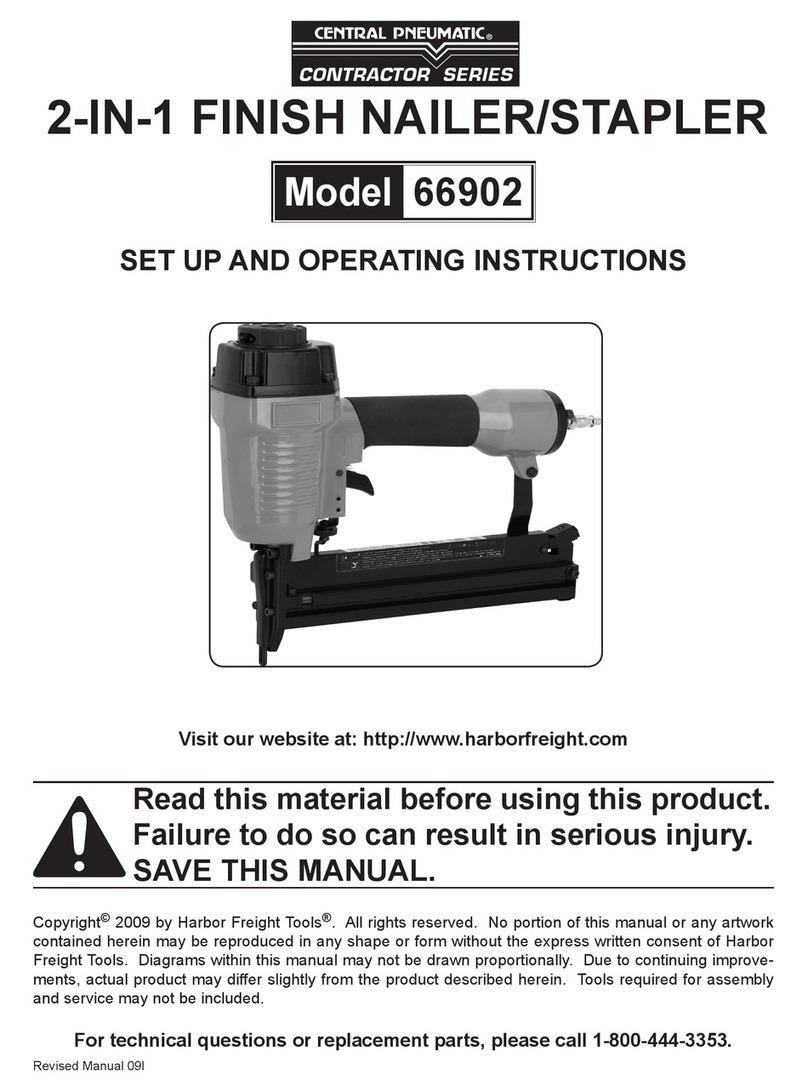

Central Pneumatic 66902 Installation manual

Central Pneumatic

Central Pneumatic 97586 User manual

Central Pneumatic

Central Pneumatic 95218 Parts list manual

Central Pneumatic

Central Pneumatic 98751 Installation manual

Popular Nail Gun manuals by other brands

Metabo HPT

Metabo HPT NR 3675DD Instruction and safety manual

EXTOL PREMIUM

EXTOL PREMIUM 8894580 Translation of the original user manual

DeWalt

DeWalt XR Li-Ion DCN680D2 Original instructions

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes