SKU 42332 For technical questions, please call 1-800-444-3353 PAGE 4

15. Guard against electric shock. Prevent body contact with grounded surfaces

such as pipes, radiators, ranges, and refrigerator enclosures.

16. Replacement parts and accessories. This product is to be repaired and

serviced only by a qualified technician. When this product is serviced, only

identical replacement parts should be used. Use of any other parts will void the

warranty. Only use accessories intended for use with this tool. Approved

accessories are available from Harbor Freight Tools.

17. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels if taking prescription medicine to determine if your judgement or reflexes

are impaired while taking drugs. If there is any doubt, do not operate the tool.

18. Use proper size and type extension cord. If an extension cord is required, it

must be of the proper size and type to supply the correct current to the

compressor without heating up. Otherwise, the extension cord could melt and

catch fire, or cause electrical damage to the tool. Check your air compressor’s

manual for the appropriate size cord. It is also possible that the use of an

extension cord may cause your circuit breaker to trip or your panel fuse to break.

If this happens, either use the compressor without an extension cord or find a

larger amperage circuit to use.

19. Maintenance. The maintenance outlined in the “Maintenance” section should be

performed regularly. For your safety, this product should be serviced or repaired

regularly only by a qualified technician.

20. Compressed air only. Never use combustible gas as a power source.

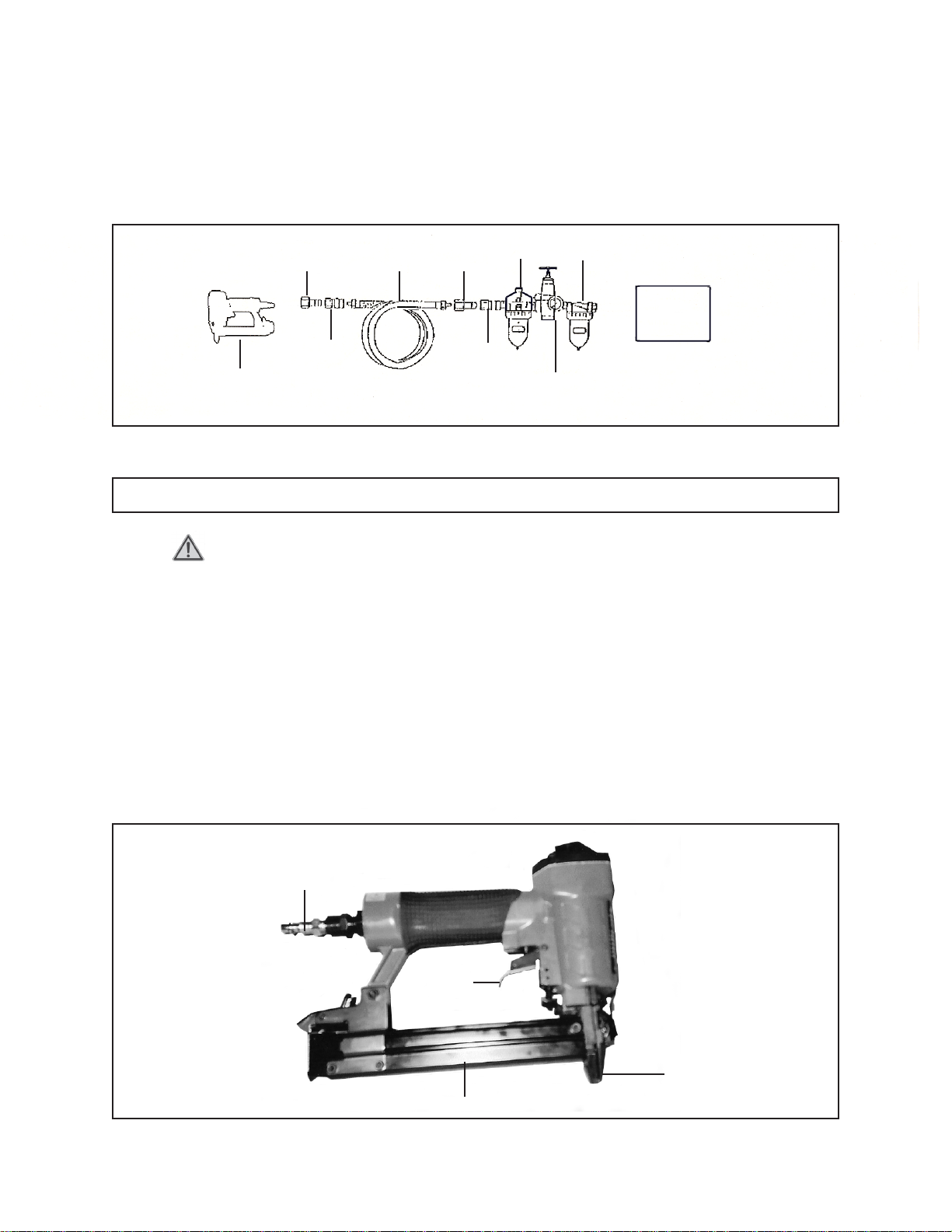

21. Do not load staples with the trigger or safety depressed. Unintentional firing

may occur. Do not load staples when the air hose is connected to the tool.

Always assume the tool contains staples.

22. Disconnect air supply before loading the Stapler. Before reloading (or making

any adjustments to) the Stapler, make sure the compressed air is disconnected.

23. Fire staples into an appropriate work surface only. Do not attempt to fire

staples into surfaces too hard to penetrate. Do not drive staples on top of other

staples, or at too steep an angle. Staples can ricochet, causing personal injury.

Never fire the Stapler into the air, or point it toward yourself or another person.

Always wear ANSI approved impact safety goggles during use, maintenance, and

reloading.

24. Do not fire staples too close to the edge of a workpiece. They may split the

workpiece and fly free, causing personal injury.