8

TrueComfort System

Features

This TrueComfort insulation machine is equipped with the following features. Before using this machine,

familiarize yourself with all the operating features and safety requirements. However, do not let familiarity

with this machine make you careless.

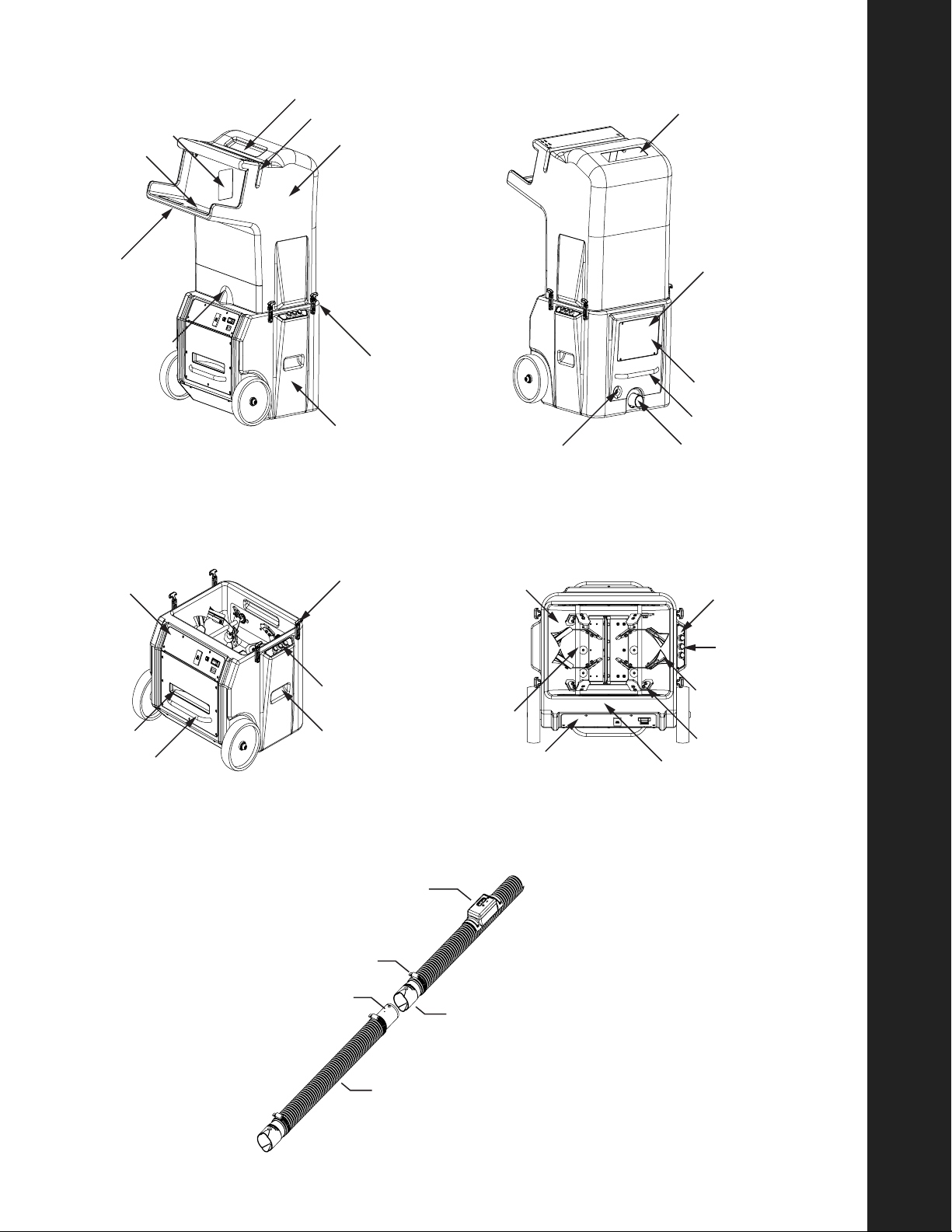

• Hopper (Fig 1) The top part of the machine which

has a built-in loading tray and contains the fiber glass

insulation. Note the key slot on the bottom right side of

the hopper that matches the key feature in the machine’s

base when assembled properly (Fig 4).

• Base (Fig 1) The lower part of the machine which

houses the rotating agitator blades, agitator motor,

blower motor, drive components and electrical system.

Note the base’s key feature on the side by the operator

panel; this key feature goes into the hoppers key slot

when assembled properly (Fig 4).

• Magnet, Safety Interlock (Fig 1) Located in both the

hopper and base components and is part of the safety

of this machine.

• Hopper Latch (Fig 1) Located on both the hopper

and base with a total of four latches. The latches

secure the hopper and base together for normal

operation.

• Bag Cutting Slot (Fig 1) This feature is molded into

the hopper and is used to assist in guiding the knife

when opening the bag.

• Knife Holding Tray (Fig 1) This feature is molded

into the hopper and should be used to hold the knife

when not in use.

• Window (Fig 1) There are two windows in the hopper.

These windows allow the operator to observe the flow

of material and assist in determining when to load the

next half bag of fiber glass insulation.

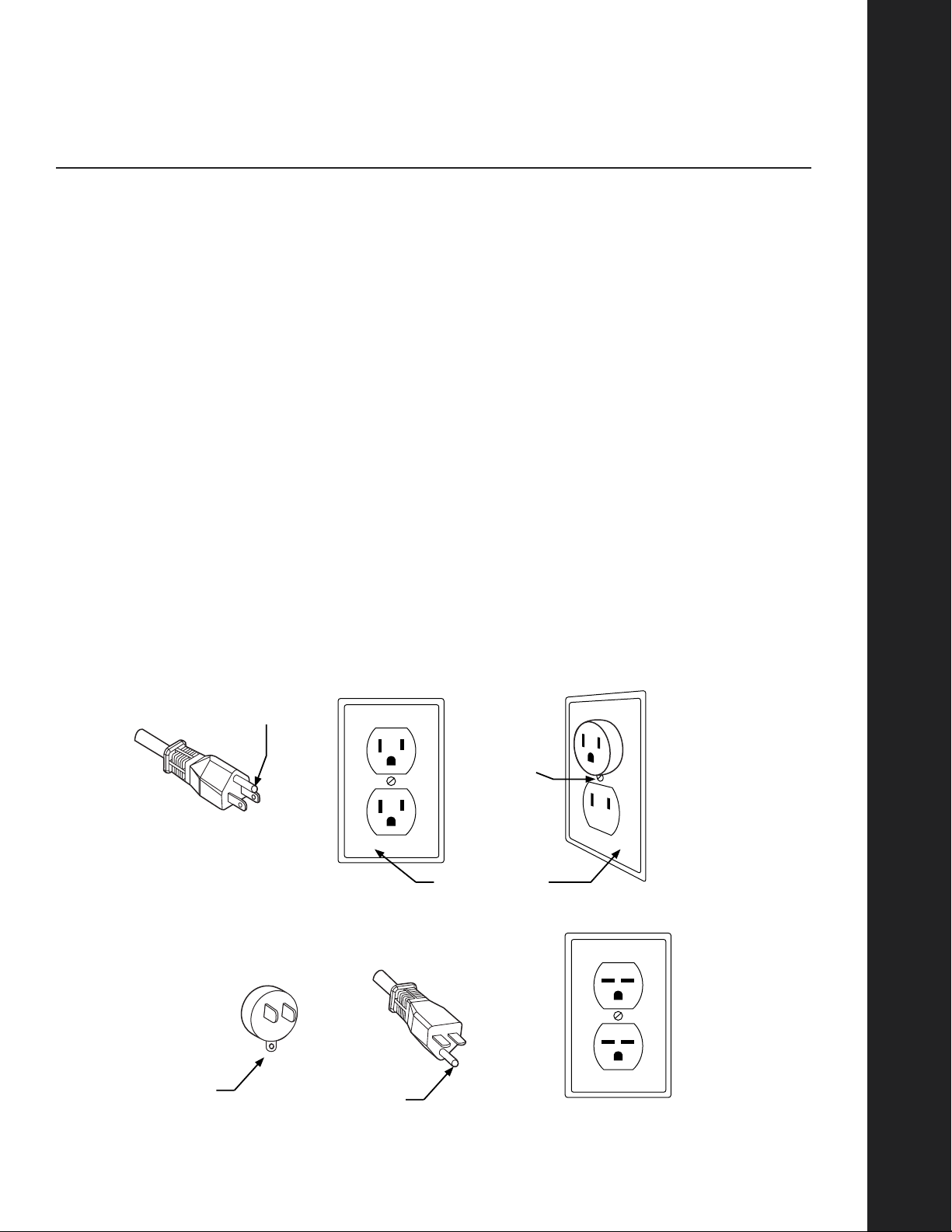

• Electrical Inlet (Fig 2) Located in the base of the

machine and where the power cord is to be plugged in.

Always plug this machine into 115 volt circuit rated at

15 amperes. Use only the supplied power cord.

• 2.5" Hose Outlet (Fig 2) Located in the base and

where the insulation hose is to be attached using the

quick connect feature.

• Handle(s) (Fig 2-3) There are a total of four handles

located in the base, two of which are molded into

the base and two others which are attached. These

handles are to be used for lifting the base in and out

of the transportation vehicle. These handles are not

intended for securing the base during transportation.

• Access Panel (Fig 2) This is located in the base

and is an access cover for the following; 2.5" outlet

interconnect, agitator bearings, electrical connections

and serial number.

• Electrical Panel (Fig 3) This panel is mounted to

the base and houses the following: time delay relay,

blower relay, main circuit breaker, agitator circuit

breaker, GFCI, hour meter.

• Operator Panel (Fig 3) This panel is mounted to the

base and houses the following: “on” / “off” switches

for operation of the entire machine and the ready light.

(Not shown)

• Agitator Basin (Fig 4): This is part of the base and

houses the rotating agitators. It also has an opening

at the bottom which allows the insulation to flow into

the airlock.

• Agitator(s) (Fig 4) There are two agitators located

within the base. They rotate at a moderate speed

to condition the fiber glass insulation material to the

desired density.

• Agitator Paddles (Fig 4) These are located on the

agitator within the base. They are attached to each

agitator blade and are made of rubber. There are two

different styles to help facilitate both the conditioning

and production of the fiber glass insulation material.

• Airlock (Fig 4) Located in the bottom of the base and

below the agitator(s). This part of the system is used to

meter the proper amount of conditioned insulation into

the air stream of the blowing hose.

• 2.5" Hose (Fig 5) This is a separate part of the

system which attaches to the outlet of the base. The

TrueComfort machine is supplied with two 50' sections

of blowing hose. The two sections can be coupled –

for a total of 100’ – using supplied couplings.

Features