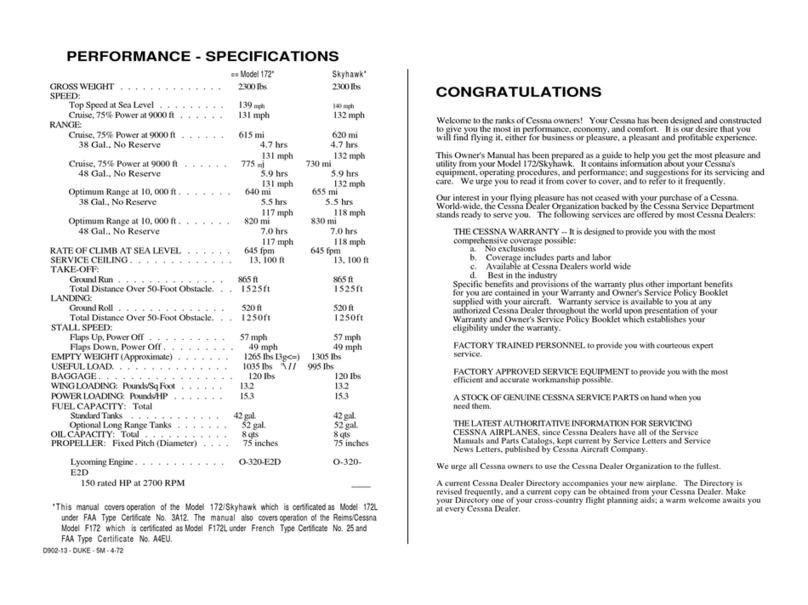

PERFORMANCE-

UROII

W&IUHT:

TUt·ott

• • .

.•.•..

l.andl"1

•.........

.'1:&0.

DEIT

POWER MIXTURE:

Top

ep.td

.1

Sea Level • . .

Crill...

nil

Power

at

5500

ft

•

!tAHOE. NORMAL LEAN MIXTURE:

Crill

••

,

711%

Power

at

5500

it

.

&&2

Pound"

No

Reserve

Crill

..

,

75%

Power

at

5500

ft

788 Pounds,

No

Reserve

Optimum

Range

at

10,000

ft

552 Pounds,

No

Reserve

Optimum

Range

at

10,000

ft

768 Pounds,

No

Reserve

RATE

OF

CLIMB

AT

SEA

LEVEL:

Twin Engine . • .

Front

Engine Only

Rear

Engine Oniy •

SERVICE CEILING:

Twin Engine . . .

Front

Engine Only

Rear

Engine

Only.

TAKE·OFF:

Ground Run

•.......•...

Total

Distance

Over 50- Foot

Obstacle

LANDING:

Oround Roll • . • . • • • • . • • .

Tolal

Distance

Over

50-Foot

Obstacle

IITALL

SPEED:

P'lapa

UP.

Power

Off • . •

..

lap.

Down,

Power

Off • .

&MPTY WEIGHT (Approximate)

UIIFUL

LOAD

••.•.••

BAOOAOE ALLOWABLE

•..•

WINO

LOADING: Pounds!Sq Foot

POW&R LOADING:

Pounds/HP

.

rUEL

CAPACITY: Total

••

ndllrd Tanks

...•.•

Super

4630lbs

4400

lb.

199

mph

190 mph

755 ml

4.0

hrs

189

mph

1060

mI

5.6

hra

189 mph

925

mi

6.1

hra

150 mph

1285

mi

8.6

hra

150

mph

1100 fpm

235

[pm

320 fpm

18,000

ft

5100

ft

7100

ft

1000

ft

1675

ft

700

it

1650

ft

80 mph

70 mph

2695lbs

1935

lbs

3651bs

22.9

11.0

4100

It.

4100

II

..

200

nllilo

192

••

'JlIo

765 ml

4.0

hr.

191 mph

1070 m!

5.6

hra

191

mph

1000

m!

7.0

hrs

143

mph

1390 m!

9.7

hrs

143 mph

1300 fpm

360 fpm

450 fpm

20,500

ft

8200

ft

10,200

it

800

it

1435

ft

700 ft

1650

ft

16 mph

67 mph

2695lbe

15051bs

3651bs

20.1

10.0

CONGRATULATIONS

......

.

Welcome to the

ranks

of

Cessna

owners! Your

Cessna

has

been designed

and

constructed

to give you the

most

in

performance,

economy, and

com-

fort.

It

is

our

desire

that you will find flying

it,

either

for

business

or

pleasure,

a

pleasant

and prOfitable

experience.

This

Owner's

Manual

has

been

prepared

as

a guide to help you

get

the

most

pleasure

and

utility

from

your Super

Skymaster.

It

contains

infor-

mation about your

Cessna's

eqUipment,

operating

procedures,

and

per-

formance;

and

suggestions

for

its

servicing

and

care.

We

urge

you to

read

it

from

cover

to

cover,

and

to

refer

to

it

frequently.

Our

interest

in your flying

pleasure

has

not

ceased

with your

purchase

of

a

Cessna.

World-wide,

the

Cessna

Dealer

Organization backed by the

Cessna

Service

Department

stands

ready

to

serve

you. The following

services

are

offered

by

most

Cessna

Dealers:

FACTORY TRAlNED PERSONNEL to

provide

you

w.ith

courteous

expert

service.

FACTORY APPROVED SERVICE EQUIPMENT to

provide

you

with the

most

efficient

and

accurate

workmanship

possible.

A STOCK

OF

GENUINE CESSNA SERVICE PARTS

on

hand

when you need them.

THE LATEST AUTHORITATIVE lNFORMATION FOR SERV-

IClNG CESSNA AIRPLANES,

since

Cessna

Dealers

have

all

of

the

Service

Manuals

and

Parts

Catalogs, kept

current

by

93

gal.

93 gal.

With Optlona.i Auxiliary Tanks 131

gal.

131

gal.

OIL

CAPACITY

•......

5

gal.

5

gal.

PROPILLERS:

Constant

Speed,

f'IIIl

....

Iherlng

(DIameter)

76

inches 76ln('!)tlK

.HWHE'I

Twl' ConlilMlnlal

Fuel

Injection Engines IO-360-C 10-360-1:

110

filed

DHP

at

2800 RPM

""'1

_1111"_111101

terVice

ceiling

increases

400

feet

for

each

30

minutes

of

m~ht.

.."

tMI,

11,14"111011

of

the

Super

Skymaster

which

is

certificated

as

Modef

33)f

undel

fM

Ijflll

eft

II

I I

the

""nUll

Iiso

covers

operation

of

the

F33)

which

is

cPoltilicatoo

8S

Modal

IHII

ulld"

"'

f\i:1:1l1t.,ICIII

!h.

f337,

manufactured

by

Reims

Avialion

SA.

Reims

(MaIne).

Franc."

II

Id,IIUul

Iff'

tlC.,1

Ihlt

some

equipment

designated

in

this

manual

as

opllonal

un

Ihl

5u~.,

"1

•

"'~I

Oft

III,

F337,

All

Super

Skymaster

inlormation

in

this

manual

p.rl.1I1I

In

11

••

1111

COPYRIUIU

"l'

II.H

Cessna Alrcrlfl CampI""

UIA

Wichita,

Klnl

..

Service

Letters

and

Service

News

Letters,

published

by

Cessna

Aircraft

Company.

We

urge

all

Cessna

owners

to

use

the

Cessna

Dealer

Organization

to the

fullest.

A

current

Cessna

Dealer

Directory

accompanies

your new

airplane.

The

Directory

is

revised

frequently,

and

a

current

copy can be obtained

from

your

Cessna

Dealer.

Make your

Directory

one

of

your

cross-country

flight planning

aids;

a

warm

welcome

awaits

you

at

every

Cessna

Dealer.

~

I