Foreword

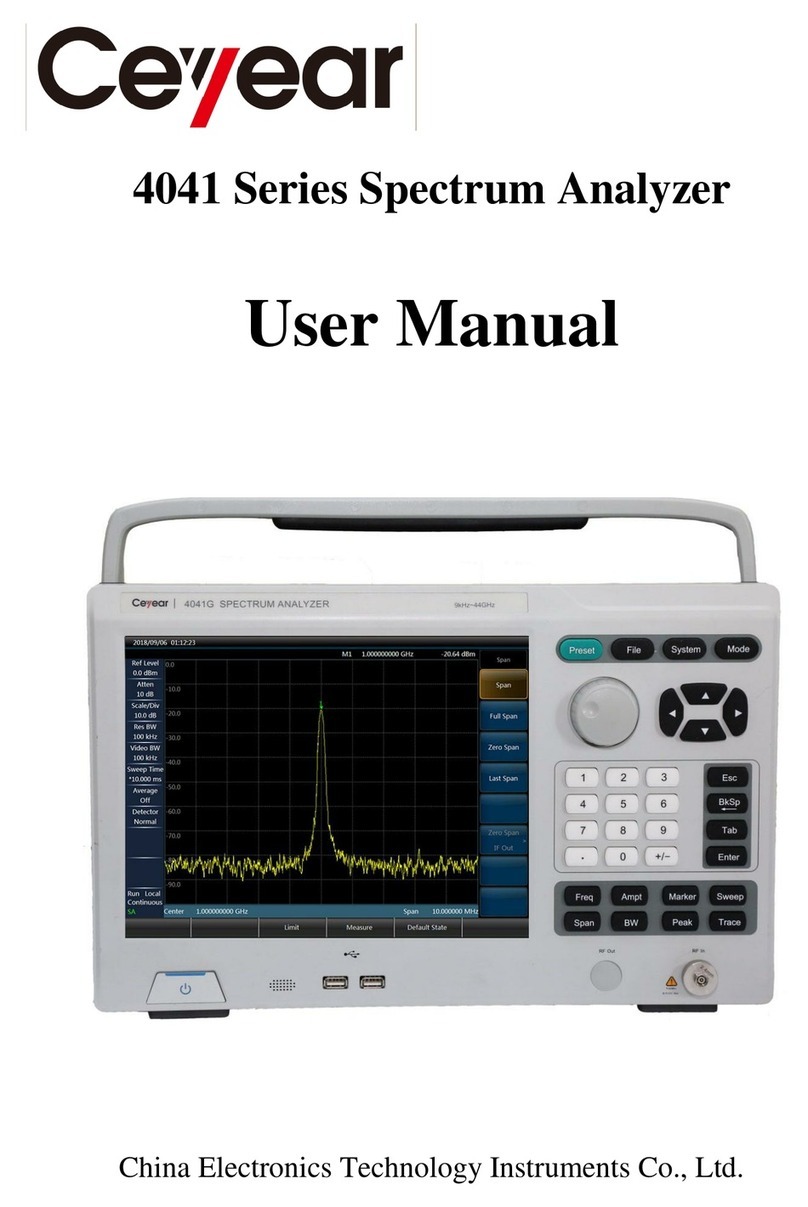

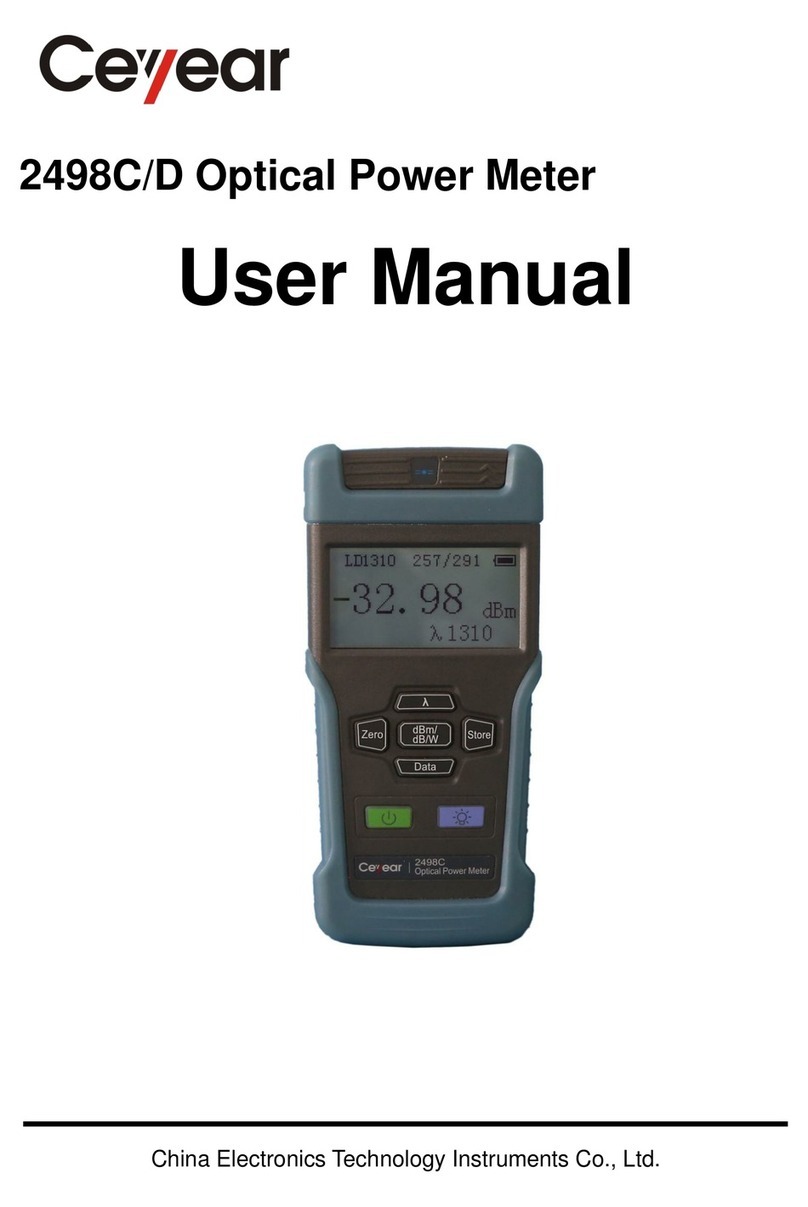

Thank you for choosing the

2348 series microwave power

meter developed and

manufactured by China

Electronics Technology

Instruments Co., Ltd. (CETI).

Our product is high-end,

precise and sophisticated, and

embraces a high cost

performance among the

competitors of the same class.

We are devoted to providing for

you high-quality products and

first-class after-sales service

with your most concerns and

demands in mind. Our

consistent aim is providing

excellent quality and good

service, and this is our sincere

commitment for all users.

Manual No.

AV2.715.1009/1010/1005/1006

SC

Version

A.1 2017.11

China Electronics Technology

Instruments Co., Ltd.

Manual Authorization

This manual may be subject to

change without notice. CETI

reserves all the rights to the

final explanation for all the

information and terminologies

referred to in this manual.

This manual is the property of

CETI. Without CETI's

permission, any organizations

or individuals shall neither

alter/temper nor

duplicate/transmit this manual

for profits; otherwise, CETI

reserves the right to pursue any

liabilities therefrom.

Product Warranty

The warranty period of this

product is 18 months from the

date of delivery. Instrument

manufacturer will repair or

replace the damaged parts

according to the user's

requirements and actual

situation in the warranty period.

The specific maintenance

matters should be subject to

the contract.

Product Quality

Certification

This product is certified to fulfill

the standards indicated in this

manual from the day of delivery.

Calibration measurements

have been carried out based on

national standards. Related

information is available to the

user for reference.

Quality/Environmental

Management

The quality and environmental

management systems have

always been implemented

during development,

manufacturing and test of this

product. China Electronics

Technology Instruments Co.,

Ltd. is properly qualified and

certified by ISO 9001 and ISO

14001 management system

standards.

Safety Precautions

CAUTION indicates an

important information rather

than danger. It reminds the

user to be cautious of a certain

operation process, operation

method or the similar. Failure to

follow the rules or operate

correctly may cause the

damage to the instrument or

loss of important data. The

conditions indicated by

CAUTION should be fully

understood and met before the

next operation.

NOTE indicates an information

prompt. It reminds the user to

pay attention to the instrument

or a certain operation process,

operation method or the similar,

so as to guide the instrument

operator to correctly use the

instrument.