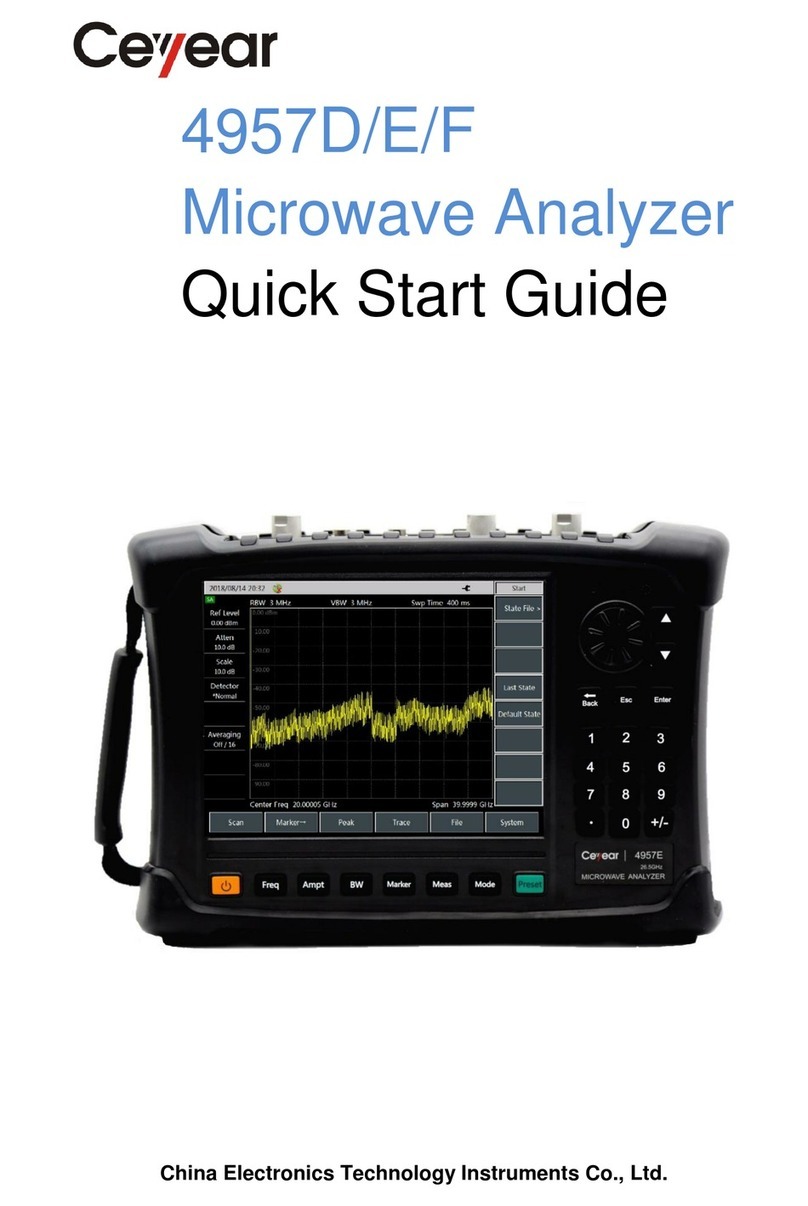

Working principle

The 4024 series spectrum analyzer consists of 4 mutually independent function modules with standard

interfaces, namely microwave/millimeter-wave frequency conversion module, frequency synthesis

module, IF signal processing module, and data processing, display and control module. Such a design

facilitates maintenance of the main unit and replacement of the parts, and also significantly reduces the

re-debugging workload of the main unit after the module replacement. The hardware scheme of the main

unit is as shown in Fig. 1.

Fig. 1 Diagram of Hardware of the Main Unit

2.1 Microwave/Millimeter-Wave Frequency Conversion Module

It is mainly used for receiving and down-conversion of the input signals of the microwave and

millimeter-wave frequency band. The input signals will enter the frequency conversion module through

the blocking module and 50 dB programmable step attenuator. The RF signals of 9kHz ~ 20 GHz and

broadband local oscillator signals of 6 GHz ~ 12 GHz (or its second harmonic) are mixed to produce

three second IF signals, namely 6,540.25 MHz of the first band (RF frequency is 9 kHz ~ 5.35 GHz),

1,740.25 MHz of the second band (RF frequency is 5.35 GHz ~ 13 GHz) and 3,340.25 MHz of third band

(RF frequency is 13 GHz ~ 20 GHz), and then output 140.25MHz IF signal to the IF channel plate

through down-conversion of the third-stage mixer. The signals above 20 GHz frequency band are mixed

with the first LO signal after the preamplifier and subsection switching filter to produce first IF signal (5

GHz ~ 16.5 GHz).The first IF signal and RF signals of 9kHz ~ 20 GHz are switched into the

second-stage mixer after switching by a single-pole double-throw switch, and the frequency conversion

scheme is the same as the 5 GHz ~ 16.5 GHz. The microwave/millimeter-wave frequency conversion

module directly affects the frequency conversion loss, noise factor, image frequency and off-band signal

suppression and gain compression of the main unit, which consists of the broadband

microwave/millimeter-wave switch, low-noise broadband preamplifier, high performance broadband

microwave/millimeter-wave mixer, microwave/millimeter-wave switch filter module, low power

consumption LO amplifier and multiplying circuit and microwave switch filter module.

2.2 Frequency Synthesis Module

Microwave/millimeter-

wave frequency

mable

-stage

-stage

Frequency synthesis

module

the second

IF signal processing

module

Data processing, display and

control module

local oscillators

-stage

Millimeter-wave

downconverter