CG emotron TSA Series User manual

Emotron TSA

Softstarter

Instruction manual

English

Valid from Software version 1.27

Emotron TSA softstarter

INSTRUCTION MANUAL - ENGLISH

Valid from Software version 1.27

Document number: 01-5980-01

Edition: R2

Date of release: 28-01-2017

© Copyright CG Drives & Automation Sweden AB 2013-2017

CG Drives & Automation Sweden AB retains the right to change

specifications and illustrations in the text, without prior notification.

The contents of this document may not be copied without the explicit

permission of CG Drives & Automation Sweden AB.

CG Drives & Automation 01-5980-01r2 1

Safety instructions

Congratulations for choosing a product from CG Drives &

Automation!

Before you begin with the installation, commissioning or

powering up the unit for the first time it is very important

that you carefully study this instruction manual.

The following symbols can appear in this manual or on the

product itself. Always read these first before continuing.

Safety

The softstarter should be installed in a cabinet or in an

electrical control room.

• The device must be installed by trained personnel.

• Disconnect all power sources before servicing.

• Always use standard commercial fuses, slow blow e.g.

gl, gG types, to protect the wiring and prevent short

circuiting. To protect the thyristors against short-circuit

currents, superfast semiconductor fuses can be used if

preferred. The normal guarantee is valid even if superfast

semiconductor fuses are not used.

Operating and maintenance

personnel

1. Read the whole instruction manual before installing and

putting the equipment into operation.

2. During all work (operation, maintenance, repairs, etc.)

observe the switch-off procedures given in this

instruction as well as any other operating instruction for

the driven machine or system. See Emergency below.

3. The operator must avoid any working methods which

reduce the safety of the device.

4. The operator must do what he can to ensure that no

unauthorised person is working on the device.

5. The operator must immediately report any changes to

the device which reduce its safety to the user.

6. The user must undertake all necessary measures to

operate the device in perfect condition only.

Phase compensation capacitor

If a phase compensation capacitor is to be used, it must be

connected at the inlet of the softstarter, not between the

motor and the softstarter.

Installation of spare parts

We expressly point out that any spare parts and accessories

not supplied by us have also not been tested or approved by

us.

Installing and/or using such products can have a negative

effect on the characteristics designed for your device. The

manufacturer is not liable for damage arising as a result of

using non-original parts and accessories.

Emergency

You can switch the device off at any time with the mains

switch connected before the softstarter (both motor and

control supply voltage must be switched off).

General warnings

Alarms

Never disregard an alarm. Always check and remedy the

cause of an alarm.

NOTE: Additional information as an aid to avoid

problems.

CAUTION!

Failureto followtheseinstructions canresult

in malfunction or damage to the softstarter.

WARNING!

Failure to follow these instructions can result

in serious injury to the user in addition to

serious damage to the softstarter.

!

WARNING!

Make sure that all safety measures have

been taken before starting the motor in order

to avoid personal injury.

WARNING!

Never operate the softstarter with the front

cover removed.

WARNING!

Make sure that all safety measures have

been taken before switching on the power

supply.

2CG Drives & Automation 01-5980-01r2

CG Drives & Automation 01-5980-01r2 3

Contents

Safety instructions......................................... 1

Contents.......................................................... 3

1. Introduction..................................................... 5

1.1 Delivery and unpacking ............................................ 5

1.2 Using of the instruction manual............................... 5

1.3 Warranty .................................................................... 5

1.4 Type code number..................................................... 5

1.5 Standards .................................................................. 6

1.5.1 Product standard for EMC ........................................ 6

1.6 Dismantling and scrapping....................................... 6

1.6.1 Disposal of old electrical and electronic

equipment ................................................................. 6

1.7 Glossary ..................................................................... 7

1.7.1 Abbreviations and symbols....................................... 7

1.7.2 Definitions.................................................................. 7

2. Mounting......................................................... 9

2.1 Installation in a cabinet ............................................ 9

2.1.1 Cooling ....................................................................... 9

2.2 Mechanical specifications and drawings .............. 10

2.3 Mounting schemes.................................................. 13

3. Connections................................................. 15

3.1 Mains and motor connections ............................... 15

3.1.1 Busbar distances on Emotron TSA softatarter...... 19

3.1.2 Cable covers ............................................................ 19

3.2 Board layout and connectors ................................. 20

3.3 Control signal connections ..................................... 22

3.4 Wiring examples ...................................................... 23

4. Application guidelines ................................ 31

4.1 Softstarter dimensioning according to AC-53b..... 31

4.2 Applications rating .................................................. 31

4.3 The Application Functions List ............................... 33

4.4 Special conditions................................................... 36

4.4.1 Small motor or low load.......................................... 36

4.4.2 Ambient temperature below 0°C (32°F) .............. 36

4.4.3 Pump control with softstarter and AC drive

together ................................................................... 36

4.4.4 Starting with counter-clockwise (reverse) rotating

loads......................................................................... 36

4.4.5 Running motors connected in parallel................... 36

4.4.6 Running motors linked together ............................ 36

4.4.7 Heat dissipation in cabinets................................... 36

4.4.8 Insulation test on motor ......................................... 36

4.4.9 Operation above 1,000 m (3280 ft) ...................... 36

4.4.10 Aggressive environment conditions....................... 36

4.4.11 IT earthing system................................................... 37

4.4.12 Earth fault relay....................................................... 37

4.4.13 Other control voltage .............................................. 37

5. Getting started............................................. 39

5.1 Check list ................................................................. 39

5.2 Mains and motor connection ................................. 39

5.2.1 Connect the mains cables...................................... 39

5.2.2 Connect the motor cables ...................................... 39

5.2.3 Connect the control supply voltage ....................... 39

5.3 Default toggle loop.................................................. 40

5.4 Remote I/O operation............................................. 40

5.5 Control panel operation.......................................... 41

6. Operation via the control panel.................. 43

6.1 Display ..................................................................... 43

6.2 LED indicators ......................................................... 44

6.3 Control keys............................................................. 44

6.4 Function keys .......................................................... 45

6.4.1 +/- key function....................................................... 45

6.4.2 Jog key function....................................................... 45

6.5 Toggle and Loc/Rem Key ....................................... 46

6.5.1 Toggle function........................................................ 46

6.5.2 Loc/Rem function ................................................... 47

6.6 The menu structure ................................................ 47

6.6.1 The main menu ....................................................... 48

7. Main features............................................... 49

7.1 Setting Start, Stop and Run functions................... 49

7.1.1 Start and stop control ............................................. 49

7.1.2 Start and stop methods.......................................... 49

7.1.3 Jog functions ........................................................... 50

7.1.4 Start/Stop signal priority ........................................ 50

7.1.5 Setting motor data .................................................. 50

7.1.6 Process information................................................ 50

7.2 Working with parameter sets ................................. 51

7.2.1 Selection of parameter sets ................................... 51

7.2.2 Configuration of parameter sets ............................ 52

7.2.3 Handling motor data in parameter sets ................ 52

7.2.4 Using the control panel memory ............................ 52

7.3 Applying limitations, alarms and autoreset........... 55

7.3.1 Alarm types and actions ......................................... 55

7.3.2 Alarm settings.......................................................... 55

7.3.3 Alarm indications .................................................... 55

7.3.4 Load monitor function ............................................ 56

7.3.5 Reset and autoreset ............................................... 60

7.4 Programmable I/O .................................................. 61

7.5 Remote control functions ....................................... 61

7.5.1 Default settings of the Run/Stop/Reset

functions.................................................................. 61

7.5.2 Enable and Stop functions ..................................... 62

7.5.3 Level / Edge operation after reset......................... 62

7.6 Logical functions ..................................................... 63

7.6.1 Jog speed at Start and /or Stop............................. 63

8. Functionality................................................. 67

8.1 Preferred View [100]............................................... 69

8.1.1 1st Line [110].......................................................... 69

8.1.2 2nd Line [120] ........................................................ 69

8.2 Main Setup [200].................................................... 69

8.2.1 Operation setup [210] ............................................ 69

4CG Drives & Automation 01-5980-01r2

8.2.2 Remote signal Level/Edge [21A] ........................... 72

8.2.3 Motor Data [220] .................................................... 73

8.2.4 Motor protection [230] ........................................... 76

8.2.5 Parameter set handling [240]................................ 80

8.2.6 Autoreset [250]....................................................... 83

8.2.7 Serial Communication [260] .................................. 86

8.3 Process [300].......................................................... 89

8.3.1 View Process Value [310]....................................... 89

8.3.2 Process Settings [320] ........................................... 89

8.3.3 Start setting [330]................................................... 91

8.3.4 Stop Setting [340]................................................... 94

8.3.5 Jog [350].................................................................. 97

8.4 Load Monitor and Process Protection [400]......... 98

8.4.1 Load Monitor [410]................................................. 98

8.4.2 Process protection [420]...................................... 103

8.4.3 Mains Protection [430]......................................... 104

8.5 I/O [500]................................................................ 106

8.5.1 Analogue Input [510]............................................ 106

8.5.2 Digital Inputs [520]............................................... 108

8.5.3 Analogue Output [530] ......................................... 109

8.5.4 Relays [550] .......................................................... 112

8.5.5 Virtual I/Os [560] .................................................. 115

8.6 Logical Functions and Timers [600] .................... 116

8.6.1 Comparators [610] ............................................... 116

8.6.2 Logic outputs [620]............................................... 121

8.6.3 Timers [630].......................................................... 124

8.6.4 SR Flip-flops [640] ................................................ 125

8.6.5 Counters [650] ...................................................... 127

8.6.6 Clock Logic [660] .................................................. 128

8.7 Operation/Status [700] ........................................ 129

8.7.1 Operation values [710]......................................... 129

8.7.2 Status [720] .......................................................... 131

8.7.3 Stored Values [730].............................................. 134

8.7.4 Real time clock settings [740] ............................. 134

8.8 View Trip Log [800] ............................................... 135

8.8.1 Trip Message Log [810]........................................ 135

8.8.2 Trip Messages [820] - [890]................................. 136

8.8.3 Reset Trip Log [8A0] ............................................. 136

8.9 System Data [900]................................................ 136

8.9.1 TSA Data [920]...................................................... 136

9. Serial communication............................... 139

9.1 Modbus RTU .......................................................... 139

9.2 Parameter sets...................................................... 139

9.3 Motor data ............................................................. 140

9.4 Start and stop commands .................................... 140

9.5 Process value ........................................................ 140

9.6 Description of the EInt formats ............................ 141

10. Softstarter theory...................................... 143

10.1 Background theory................................................ 143

10.2 Reduced voltage starting...................................... 145

10.3 Other starting methods......................................... 147

10.4 Use of softstarters with torque control................ 148

11. Troubleshooting, Diagnoses and

Maintenance .............................................. 149

11.1 Trip conditions, causes and remedial action ...... 149

11.1.1 Technically qualified personnel............................ 149

11.1.2 Opening the softstarter......................................... 149

11.2 Maintenance ......................................................... 149

11.3 Troubleshooting list............................................... 150

12. Options........................................................ 155

12.1 External control panel........................................... 155

12.2 EmoSoftCom.......................................................... 155

12.3 I/O Board ............................................................... 155

12.4 PTC/PT100 ............................................................ 155

12.5 Serial communication and fieldbus ..................... 155

13. Technical data............................................ 157

13.1 General electrical specifications.......................... 160

13.2 Semi-conductor fuses........................................... 160

13.3 Environmental conditions..................................... 161

13.3.1 Derating at high temperature............................... 161

13.3.2 Derating at high altitude....................................... 162

13.4 Control power- and I/O signal connectors........... 163

Index ........................................................... 165

Appendix 1: Menu List............................... 167

Appendix 2: Trip message communication

data............................................................. 197

CG Drives & Automation 01-5980-01r2 Introduction 5

1. Introduction

The Emotron TSA softstarter is intended for controlling the

start and stop of standard three phase asynchronous motors.

A built-in powerful digital signal processor (DSP) gives the

softstarter high performance and very good control of the

starting and stopping of the application.

Several options are available, listed in chapter 12. page 155,

that enable you to customize the softstarter for your specific

needs.

Users

This instruction manual is intended for:

• installation engineers

• maintenance engineers

•operators

• service engineers

Motors

The softstarter is suitable for use with standard 3-phase

asynchronous motors. Contact your supplier for details.

1.1 Delivery and unpacking

Check for any visible signs of damage. Inform your supplier

immediately of any damage found. Do not install the

softstarter if damaged.

Check that all items are present and that the type number is

correct.

1.2 Using of the instruction

manual

Check that the software version number on the first page of

this manual matches the software version in the softstarter.

See chapter 8.9.1 page 136.

With help of the index and the table of contents it is easy to

track individual functions and find out how to use and set

them.

The Quick Start Guide can be put in a cabinet so that it is

always easy to access in case of an emergency.

1.3 Warranty

The warranty applies when the equipment is installed,

operated and maintained according to instructions in this

instruction manual. Duration of warranty is as per contract.

Faults that arise due to faulty installation or operation are

not covered by the warranty.

1.4 Type code number

Fig. 1 gives an example of the type code numbering used for

the Emotron TSA softstarter. This identification will be

required for type specific information when mounting and

installing. The code number is located on the product label,

on the right side of the unit (when viewed from the front).

Fig. 1 Type code number

NOTE: Read this instruction manual carefully before

installing, connecting or working with the softstarter.

TSA 52 -016 -23 N N N —AA—

Position number:

1 2 3 4 567891011

Ta b l e 1

Position Configuration Description

1Type TSA

2 Main supply voltage 52 = Max 525 V mains

69 = Max 690 V mains

3 Current rating

016 = 16 A

-

- 1K8 = 1800 A

4 Control voltage 23=230 V

5 Option position 1

N=No option

P=PTC/PT100

I=I/O board

6 Option position 2

N=No option

P=PTC/PT100

I=I/O board

7Communication

option

N=No option

A=Profinet IO 1-port

B=Profinet IO 2-port

D=DeviceNet

E= EtherCAT

G=EtherNet/IP 2-port

M=Modbus/TCP

P=Profibus

R=RS485

U=USB

8 Supply type

—=Standard (Grounded

net)

I=IT-net (EMC not fulfilled)

9Brandlabel A=Standard

10 Software A=Standard software

11 Standard —=CE approved

U=UL/cUL approved

6Introduction CG Drives & Automation 01-5980-01r2

1.5 Standards

The softstarters described in this instruction manual comply

with the standards listed in Table 2. For the declarations of

conformity and manufacturer’s certificate, contact your

supplier for more information or visit www.emotron.com or

www.cgglobal.com.

1.5.1Product standard for EMC

The Emotron TSA softstarter complies with the product

standard EN(IEC) 60947-4-2: 2007. The standard

Emotron TSA softstarters are designed to meet the EMC

requirements according to:

Category C1 - Emotron TSA -frame sizes 1 & 2

Category C2 - Emotron TSA -frame sizes 3 & 4 .

1.6 Dismantling and scrapping

The enclosures of the Emotron TSA softstarters are made

from recyclable material such as aluminium, iron and

plastic. Each softstarter contains a number of components

demanding special treatment. The circuit boards contain

small amounts of tin and lead. Any local or national

regulations in force for the disposal and recycling of these

materials must be complied with.

1.6.1Disposal of old electrical and

electronic equipment

This symbol on the product or on its

packaging indicates that this product shall be

taken to the applicable collection point for the

recycling of electrical and electronic

equipment. By ensuring this product is

disposed of correctly, you will help prevent potentially

negative consequences for the environment and human

health, which could otherwise be caused by inappropriate

waste handling of this product. The recycling of materials

will help to conserve natural resources. For more detailed

information about recycling this product, please contact the

local distributor of the

product.

Ta b l e 2 St a n d a r d s

Market Standard Description

European

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

WEEE Directive 2002/96/EC

All

EN 60204-1 Safety of machinery - Electrical equipment of machines

Part 1: General requirements.

EN(IEC)60947-4-2:

2007

Contactors and motor starters

Part 3: EMC requirements and specific test methods.

EMC Directive: Declaration of Conformity and CE marking

EN(IEC)60947-4-2:

2007

Contactors and motor starters

Safety requirements - Electrical, thermal and energy.

Low Voltage Directive: Declaration of Conformity and CE marking

IEC 60721-3-3 Classification of environmental conditions. Air quality chemical vapours, unit in

operation. Chemical gases 3C3, Solid particles 3S1.

DNV-GL DNV-GL Marine standard

North & South

American

UL508C UL Safety standard for Power Conversion Equipment.

UL 840 UL Safety standard for Power Conversion Equipment.

Russian EAC For all sizes

CG Drives & Automation 01-5980-01r2 Introduction 7

1.7 Glossary

1.7.1Abbreviations and symbols

In this manual the following abbreviations are used:

1.7.2Definitions

In this manual the following definitions are used:

*) Calculation of nominal motor torque:

Table 3 Abbreviations

Abbreviation/

symbol Description

CP Control panel, the programming and

presentation unit on the softstarter

CB Control board

I2t The amount of energy losses, heating up the

motor.

PTC

Positive Temperature Coefficient

(temperature sensor, also known as

thermistor)

PB-PTC Power board PTC input

RMS Root Mean Square value

FLC Full Load Current

DOL Direct On-Line

EInt Communication format

UInt Communication format (Unsigned Integer)

Int Communication format (Integer)

Long Communication format (Integer Long)

SELV Safety Extra Low Voltage

The function cannot be changed in run mode

Table 4 Definitions

Name Description Unit

In_soft Nominal softstarter current [Arms]

In_mot Nominal motor current [Arms]

Pn_soft Nominal softstarter power [kW] or [hp]

Pn_mot Nominal motor power [kW] or [hp]

TnNominal motor torque* [Nm] or [lb.ft]

nn_mot Nominal speed of motor [rpm]

cosϕnNominal motor power factor (dimensionless)

U 3-phase mains supply voltage [Vrms]

Un_mot Nominal motor voltage [V]

TnNm[]

9550 PnmotkW[]×

nnmotrpm[]

-----------------------------------------------

=

Tnlbft[]

5252 Pnmothp[]×

nnmotrpm[]

----------------------------------------------

=

8Introduction CG Drives & Automation 01-5980-01r2

CG Drives & Automation 01-5980-01r2 Mounting 9

2. Mounting

This chapter describes how to mount the Emotron TSA

softstarter. Before mounting it is recommended that the

installation is planned out:

• Be sure that the softstarter suits the mounting location.

• The mounting site must support the weight of the

softstarter.

• Will the softstarter continuously withstand vibrations

and/or shocks?

• Consider using a vibration damper.

• Check ambient conditions, ratings, required cooling air

flow, compatibility of the motor, etc.

• Do you know how the softstarter will be lifted and

transported?

Make sure that the installation is performed in accordance

with the local safety regulations, and in accordance with

DIN VDE 0100 for setting up power installations.

Care must be taken to ensure that personnel do not come

into contact with live circuit components.

2.1 Installation in a cabinet

When installing the softstarter:

• Ensure that the cabinet will be sufficiently ventilated

after the installation.

• Keep the minimum free space, as listed inTable 5.

• Ensure that air can flow freely from the bottom to the

top.

The Emotron TSA softstarters are delivered as enclosed

versions with front access cover. The units have top and

bottom entry for cables etc., see Chapter 3. page 15.

2.1.1 Cooling

WARNING!

Never operate the softstarter with the front

cover removed.

NOTE: When installing the softstarter, make sure it does

not come into contact with live components. The heat

generated must be dispersed via the cooling fins to

prevent damage to the thyristors (free circulation of air).

Table 5 Minimum free space

TSA

Frame size

Minimum free space

mm (in)

above* below at side

1

100

(3.9)

100

(3.9) 0

2

3

4

*) Above: Cabinet roof to softstarter or softstarter to softstarter

10 Mounting CG Drives & Automation 01-5980-01r2

2.2 Mechanical specifications and drawings

*) H1 = Height of enclosure.

H2 = Total mounting height of unit.

H3 = Total height including Cable covers.

Emotron TSA frame size 1 - 2

Fig. 2 Dimensions for Emotron TSA frame size 1 and 2.

Fig. 3 Dimensions for Emotron TSA frame size 1 and 2,

bottom view.

Ta b l e 6

TSA

Frame

size

Dimensions*

H1/H2/H3 x W x D

[mm (in)]

Mounting

position

[Vertical/

Horizontal]

Weight

[kg(lb)]

Connection

busbars and

pressnut

dimension

[mm (in)]

PE

screw Cooling

system Protection

class

1246/296/340 x 126 x 188

(9.7/11.7/13.4 x 5 x 7.4)

Vertical 5.5

(12.1) 15 x 2

(0.59 x 0.08)

M6 connection

M5

Convection

IP20

2

Vertical/

Horizontal

5.7

(12.6) Fan

3285/323/380 x 196 x 235

(11.2/12.7/14.9 x 7.7 x 9.3)

13

(28.7)

20 x 5

(0.8 x 0.20)

M10 connection

M8 Fan IP20

4378/411/514 x 254 x 260

(14.9/16.2/20.2 x 10 x 10.3)

23.5

(51.8)

40 x 10

(1.6 x 0.39)

Ø 13 connection

M8 Fan IP20

H1 H2

WD

H3

188 (7.4)

CG Drives & Automation 01-5980-01r2 Mounting 11

Emotron TSA frame size 3

Fig. 4 Dimensions for Emotron TSA frame size 3.

Fig. 5 Dimensions for Emotron TSA frame size 3, bottom

view.

H1 H2

196 (7.7) 235 (9.3)

H3

235 (9.3)

12 Mounting CG Drives & Automation 01-5980-01r2

Emotron TSA frame size 4

Fig. 6 Dimensions for Emotron TSA frame size 4 .

Fig. 7 Dimensions for Emotron TSA frame size 4, bottom

view.

H1 H2

254 (10) 260 (10.3)

H3

260 (10.3)

CG Drives & Automation 01-5980-01r2 Mounting 13

2.3 Mounting schemes

Emotron TSA frame size 1 - 2

Fig. 8 Hole pattern for Emotron TSA frame size 1 and 2.

Emotron TSA frame size 3

Fig. 9 Hole pattern for Emotron TSA frame size 3.

Emotron TSA frame size 4

Fig. 10 Hole pattern for Emotron TSA frame size 4.

On our websites www.cgglobal.com and www.emotron.com

it is possible to download a full-size template for positioning

of the fixing holes.

104.5 (4.1)

11(0.43)

273(10.7)

Ø 6,5 (x 4)

11

(043)

170(6.7)

13(0.51)

303(12)

10

Ø 13

Ø 7 (x 4)

(039)

4

25

,

5

220(8.7)

17(0.67)

390(1.4)

Ø 7 (x 4)

11

Ø 13

(043)

14 Mounting CG Drives & Automation 01-5980-01r2

CG Drives & Automation 01-5980-01r2 Connections 15

3. Connections

The installation description in this chapter follows the EMC

standards and the Machinery Directive.

If the softstarter is temporarily stored before being

connected, please check the technical data for environmental

conditions section 13.3, page 161. If the softstarter is moved

from a cold storage room to the location where it is to be

installed, condensation could appear on the unit. Allow the

softstarter to become fully acclimatised and wait until any

visible condensation has evaporated before connecting any

supply voltages.

Cables

Dimension the mains and motor cables according to local

regulations and the nominal current of the motor. It is

possible to use either copper or aluminium cables.

It is not necessary to use shielded motor cables together with

the Emotron TSA softstarter. This is due to its very low

radiated emissions.

Neither is it necessary to use shielded mains supply cables

for the Emotron TSA softstarter.

For control signal cables it is not mandatory to use shielded

cables to fulfil the EMC regulations (section 1.5, page 6) but

it is recommended in general to avoid disturbances.

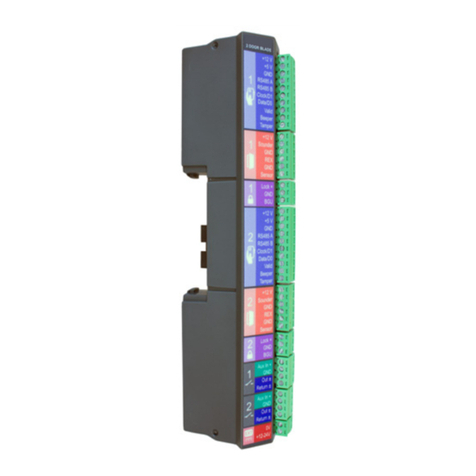

3.1 Mains and motor

connections

Fig. 11 Mains, motor and control supply voltage connection

NOTE: The Emotron TSA control-board is equipped with a

ground plane to which shielded cables can be

connected (see Fig. 17 on page 21).

NOTE: For UL-approval use 75°C copper wire only.

100 - 240 VAC

16 Connections CG Drives & Automation 01-5980-01r2

Emotron TSA frame size 1 - 2

Fig. 12 Mains and motor connections for Emotron TSA Size 1-2.

1. 3-phase mains supply connection, L1, L2, L3

2. Protective earth (PE) connection for mains supply

3. Motor power supply connection T1, T2, T3

4. Motor earth, connection

PE

T1 T2 T3

L1 L2 L3

L1 L2 L3

T1 T2 T3

3

4

2

1

WARNING!

Leakage current may occur from the

thyristors when a 3-phase mains supply is

connected. Full voltage can be detected if no

motor is connected.

Table 7 Tightening torque for bolts [Nm (Lb-in)].

TSA

Frame size

Tightening torque for bolts

[Nm (Lb-in)]

Motor or mains

cables PE cable

1 8 (70) 5 (44)

2 8 (70) 5(44)

This manual suits for next models

1

Table of contents

Other CG Controllers manuals