Chamberlain DH Quick start guide

Other Chamberlain Accessories manuals

Chamberlain

Chamberlain Protector System 770E User manual

Chamberlain

Chamberlain CPS-UN4 User manual

Chamberlain

Chamberlain 915GA User manual

Chamberlain

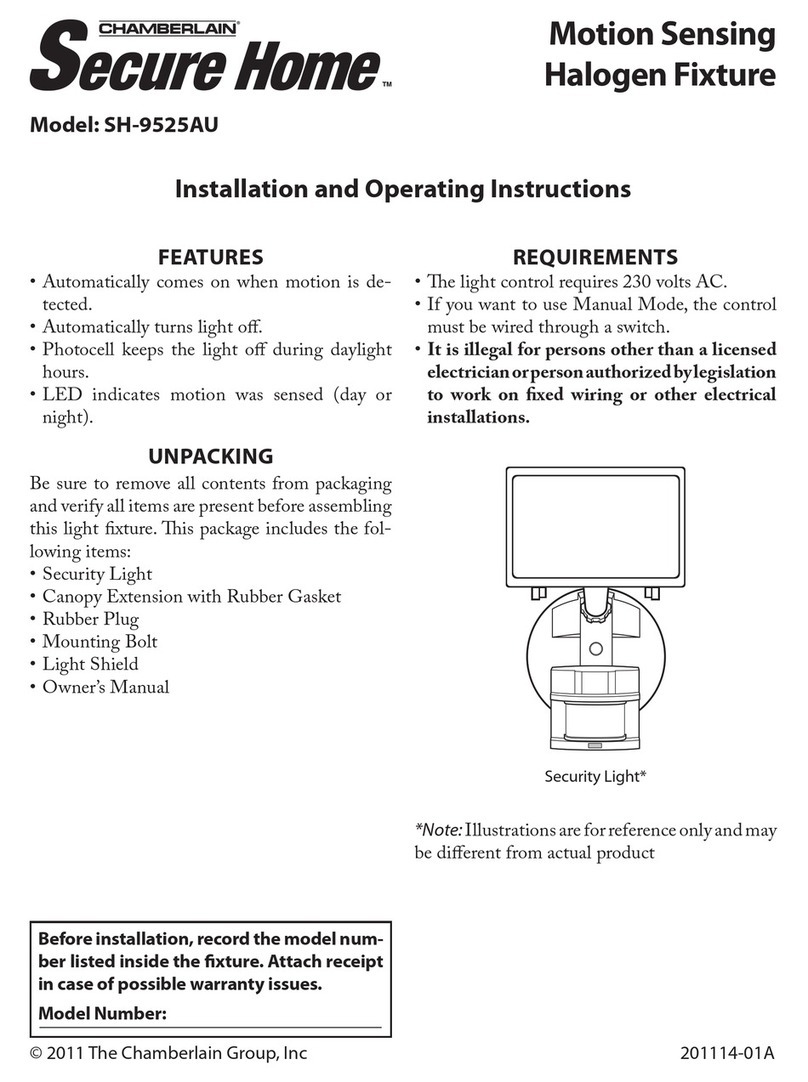

Chamberlain Secure Home SH-9525AU User manual

Chamberlain

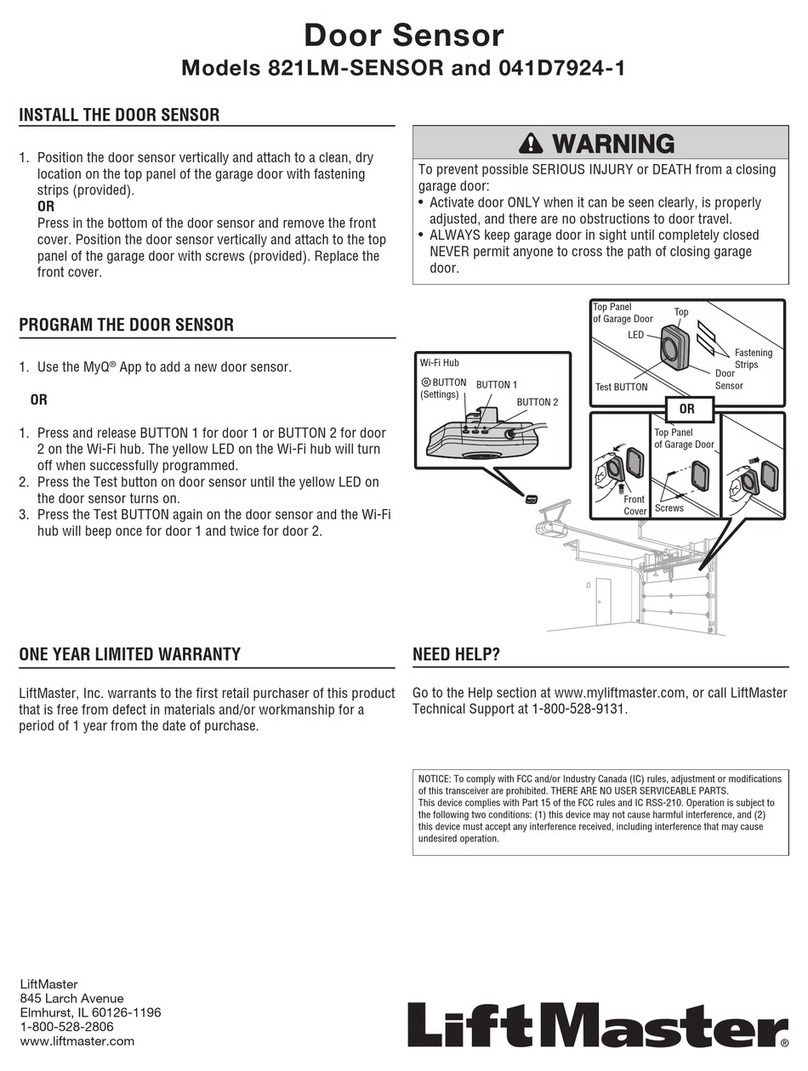

Chamberlain 821LM-SENSOR User manual

Chamberlain

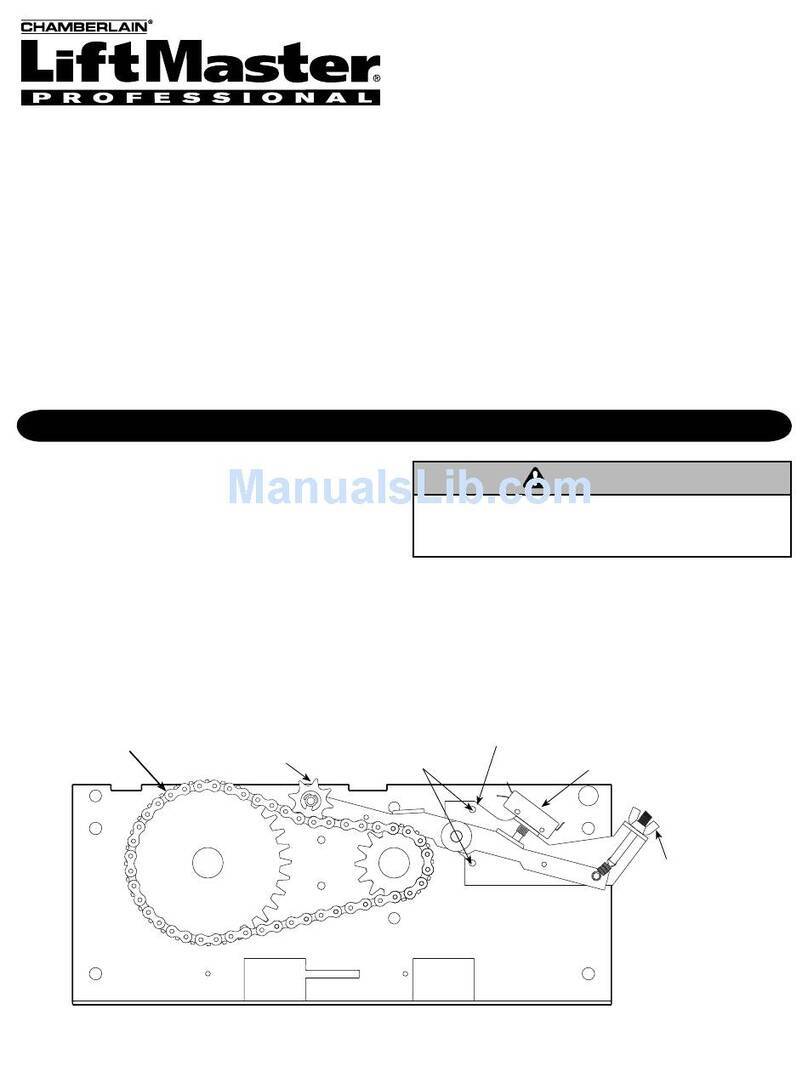

Chamberlain DH Installation and operating instructions

Chamberlain

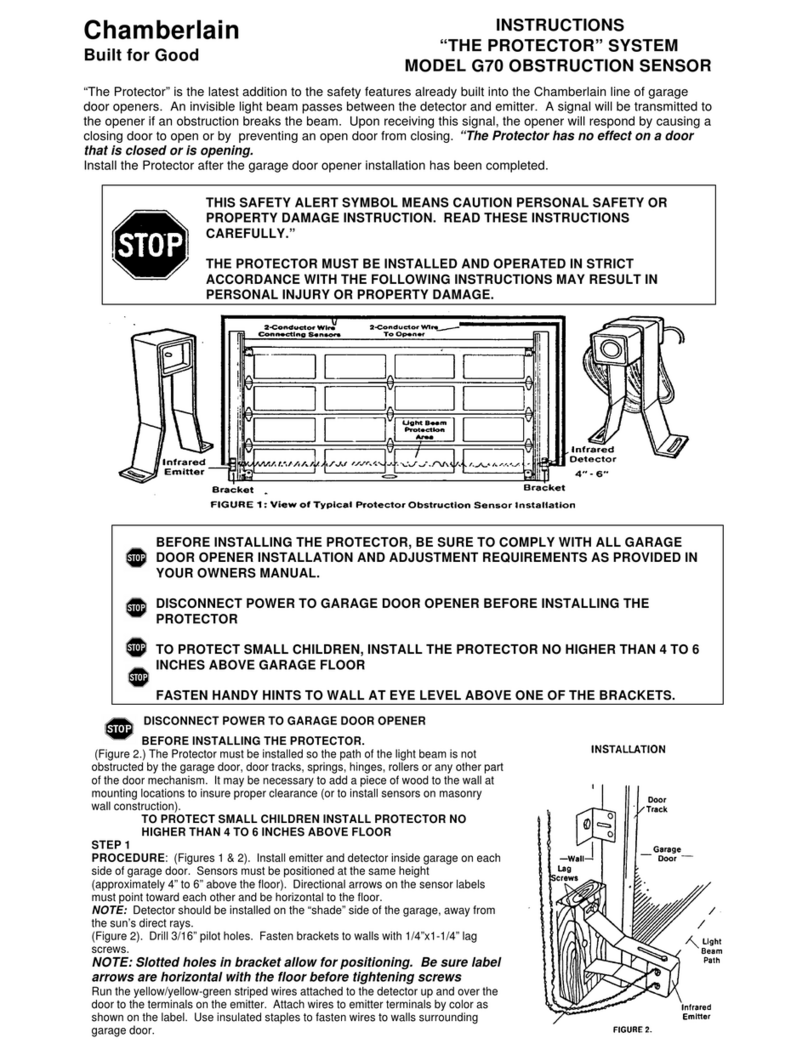

Chamberlain The Protector G70 User manual

Chamberlain

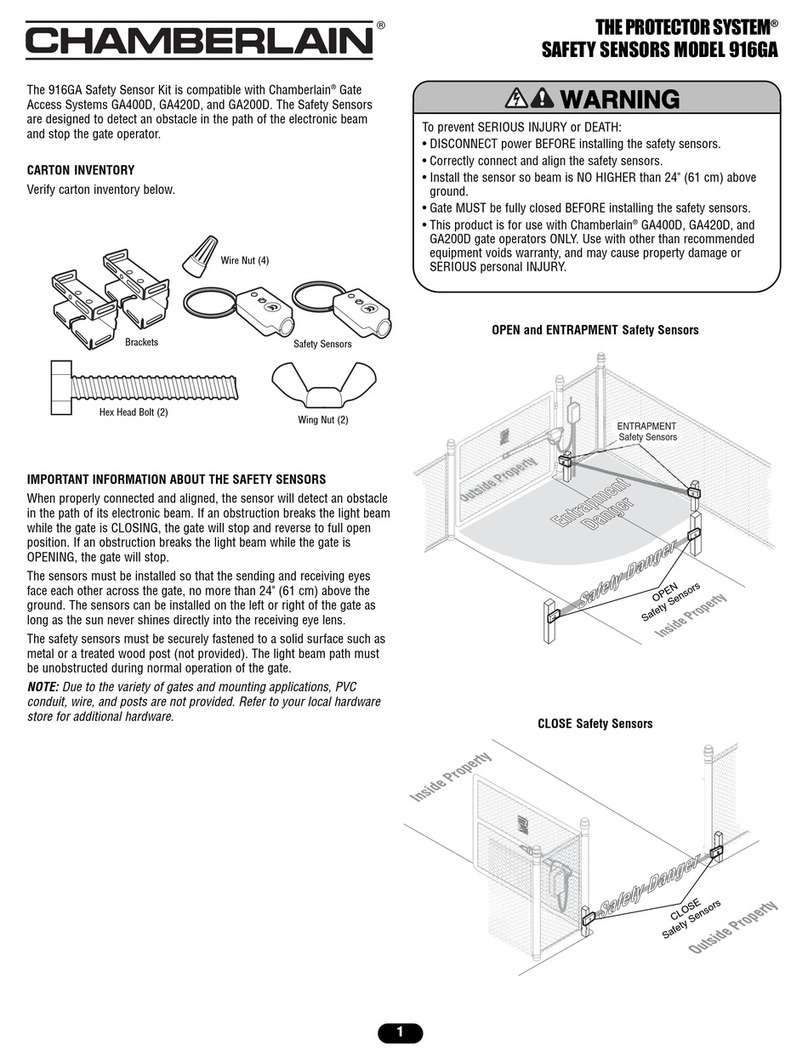

Chamberlain 916GA User manual

Chamberlain

Chamberlain LMTBUL User manual

Chamberlain

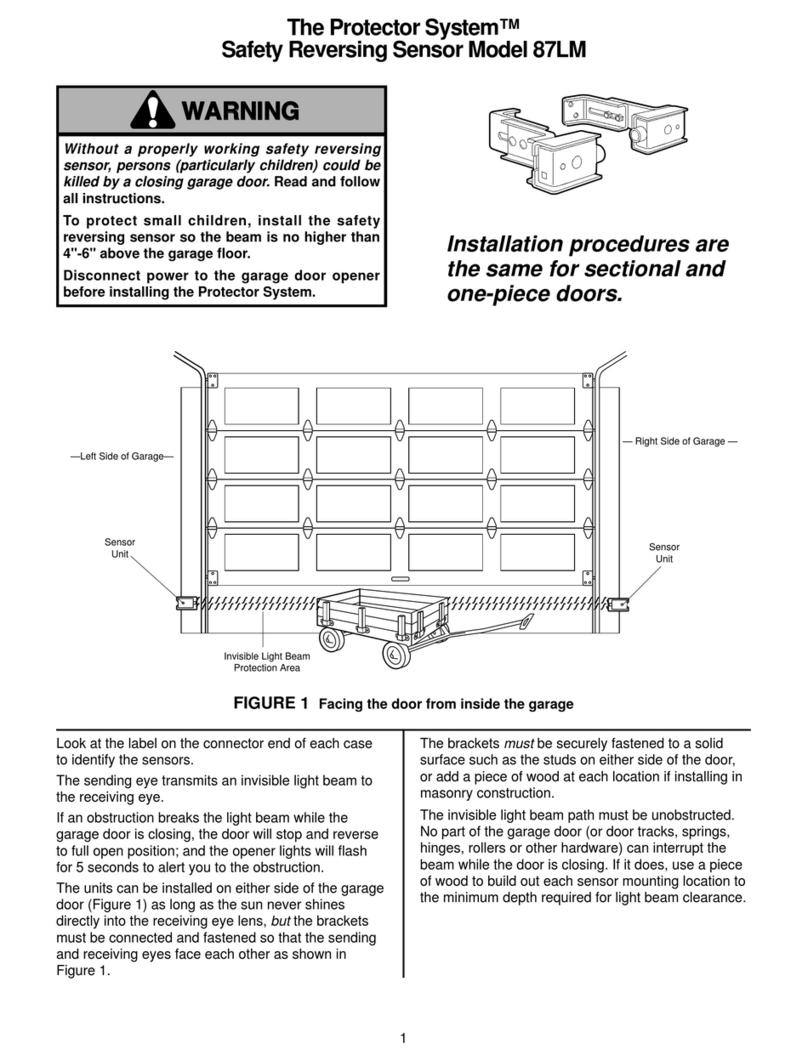

Chamberlain Protector 87LM User manual

Chamberlain

Chamberlain PROFESSIONAL TCLS1E User manual

Chamberlain

Chamberlain PIRV400R User manual

Chamberlain

Chamberlain 771ANZ User manual

Chamberlain

Chamberlain 771E User manual

Chamberlain

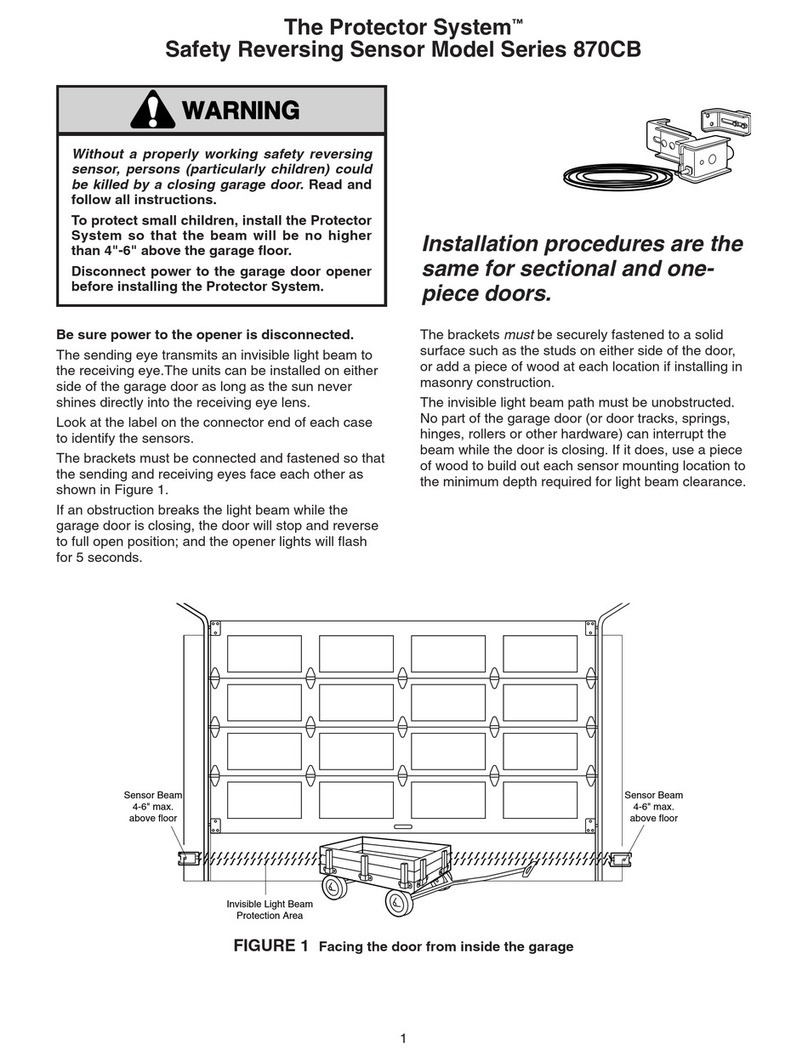

Chamberlain 870CB Series User manual

Chamberlain

Chamberlain LMRRU User manual

Chamberlain

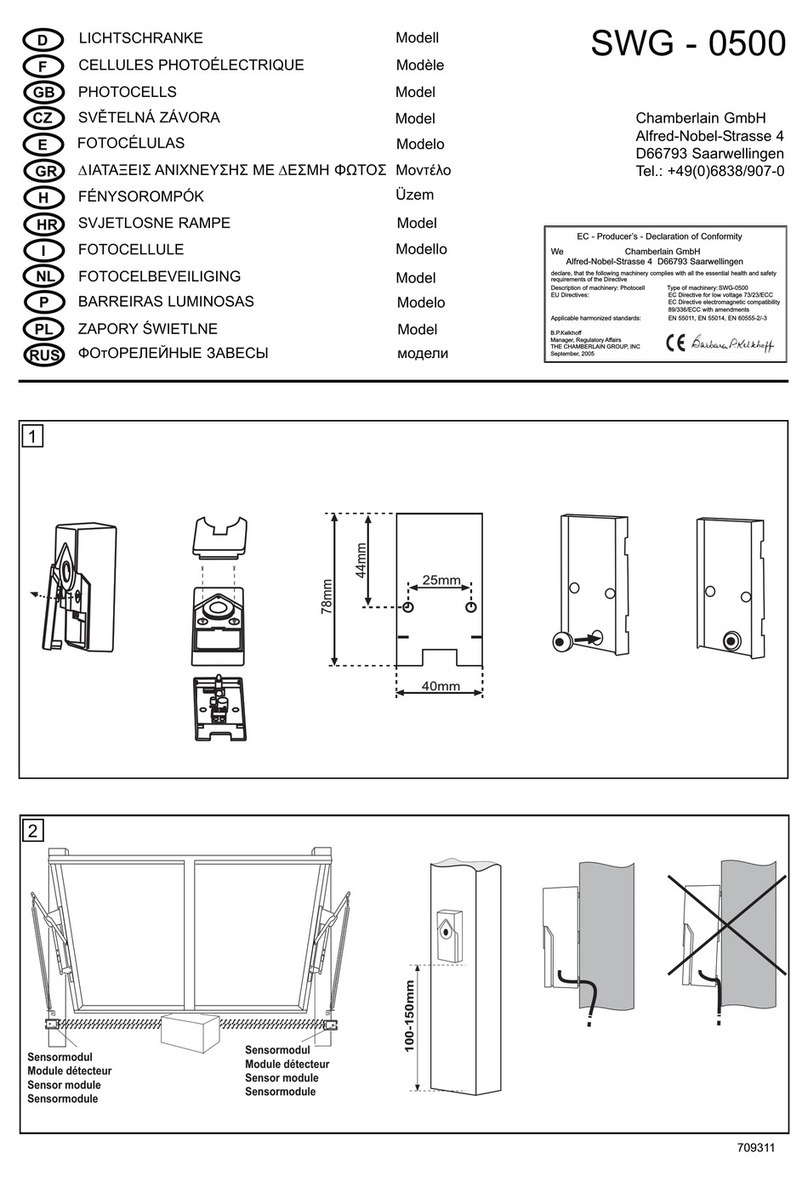

Chamberlain SWG-0500 User manual

Chamberlain

Chamberlain THE PROTECTOR SYSTEM 916GA User manual

Chamberlain

Chamberlain 41C4672 Guide

Chamberlain

Chamberlain PIR2300R User manual