,IFT-ASTER )NTERNET 'ATEWAY .OT 0ROVIDED

4O PROGRAM THE OPERATOR TO THE ,IFT-ASTER )NTERNET 'ATEWAY

0ROGRAM USING THE LEARN BUTTON ON THE OPERATORgS CONTROL BOARD 0ROGRAM USING THE RESET BUTTON ON THE OPERATOR

#ONNECT THE ETHERNET CABLE TO THE ,IFT-ASTER )NTERNET 'ATEWAY AND THE

ROUTER

#ONNECT POWER TO THE ,IFT-ASTER )NTERNET 'ATEWAY

#REATE AN ONLINE ACCOUNT BY VISITING WWWMYLIFTMASTERCOM

2EGISTER THE ,IFT-ASTER )NTERNET 'ATEWAY

5SE AN INTERNET ENABLED COMPUTER OR SMARTPHONE TO ADD DEVICES 4HE

,IFT-ASTER )NTERNET 'ATEWAY WILL STAY IN LEARN MODE FOR THREE MINUTES

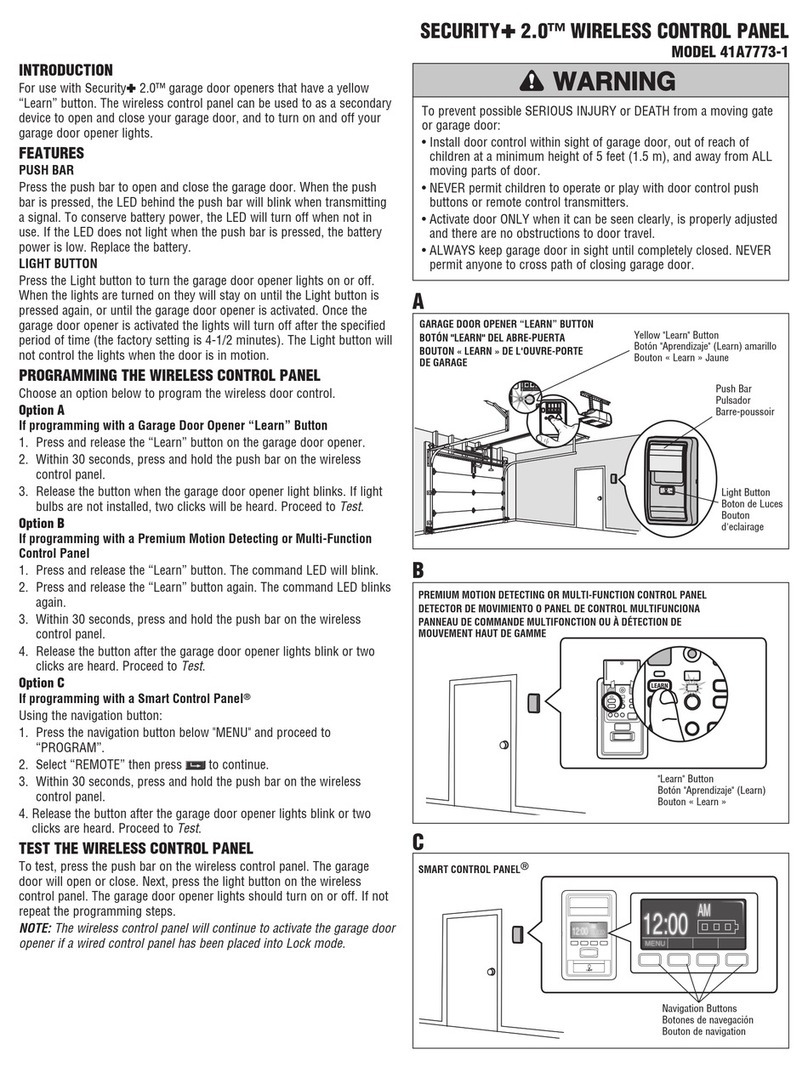

0RESS THE ,EARN BUTTON TWICE ON THE PRIMARY OPERATOR THE OPERATOR

WILL BEEP AS IT ENTERS LEARN MODE 4HE ,IFT-ASTER )NTERNET 'ATEWAY WILL

PAIR TO THE OPERATOR IF IT IS WITHIN RANGE AND THE OPERATOR WILL BEEP IF

PROGRAMMING IS SUCCESSFUL

#ONNECT THE ETHERNET CABLE TO THE ,IFT-ASTER )NTERNET 'ATEWAY AND THE

ROUTER

#ONNECT POWER TO THE ,IFT-ASTER )NTERNET 'ATEWAY

#REATE AN ONLINE ACCOUNT BY VISITING WWWMYLIFTMASTERCOM

2EGISTER THE ,IFT-ASTER )NTERNET 'ATEWAY

5SE AN INTERNET ENABLED COMPUTER OR SMARTPHONE TO ADD DEVICES 4HE

,IFT-ASTER )NTERNET 'ATEWAY WILL STAY IN LEARN MODE FOR THREE MINUTES

%NSURE GATE IS CLOSED

'IVE THE OPERATOR AN /0%. COMMAND

7ITHIN SECONDS WHEN THE GATE IS AT THE OPEN LIMIT PRESS AND

RELEASE THE RESET BUTTON TIMES ON PRIMARY GATE TO PUT PRIMARY

OPERATOR INTO (IGH "AND ,EARN -ODE THE OPERATOR WILL BEEP AS IT

ENTERS LEARN MODE 4HE ,IFT-ASTER )NTERNET 'ATEWAY WILL PAIR TO THE

OPERATORIFITIS

4HE STATUS AS SHOWN BY THE ,IFT-ASTER )NTERNET 'ATEWAY APP WILL BE EITHER hOPENv OR hCLOSEDv 4HE GATE OPERATOR CAN THEN BE CONTROLLED THROUGH THE

,IFT-ASTER )NTERNET 'ATEWAY APP

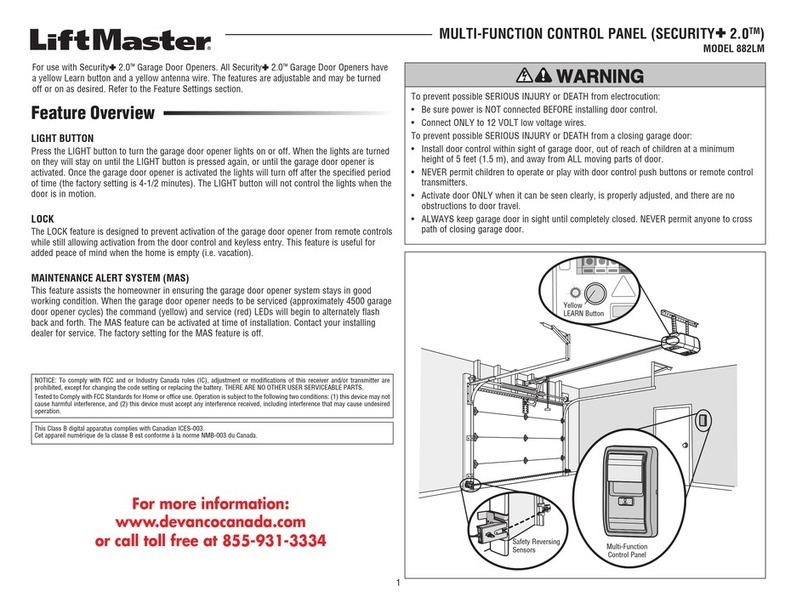

%RASE !LL #ODES

0RESS AND RELEASE THE ,%!2. BUTTON OPERATOR WILL BEEP AND GREEN 8-)44%2 ,%$ WILL LIGHT

0RESS AND HOLD THE ,%!2. BUTTON AGAIN UNTIL THE GREEN 8-)44%2 ,%$ FLASHES AND THEN RELEASE THE BUTTON APPROXIMATELY SECONDS !LL REMOTE

CONTROL CODES ARE NOW ERASED

4O 2EMOVE AND %RASE -ONITORED %NTRAPMENT 0ROTECTION $EVICES

2EMOVE THE ENTRAPMENT PROTECTION DEVICE WIRES FROM THE TERMINAL BLOCK

0RESS AND RELEASE THE /0%. ,%&4 AND /0%. 2)'(4 BUTTONS SIMULTANEOUSLY 4HE HANDING DIRECTION ,%$ WILL REMAIN SOLID 4HE OTHER DIRECTION ,%$ WILL

BEGIN FLASHING ENTERING SETUP MODE

0RESS THE /0%. ,%&4 AND /0%. 2)'(4 BUTTONS SIMULTANEOUSLY TO EXIT

#ONSTANT 0RESSURE /VERRIDE #0/

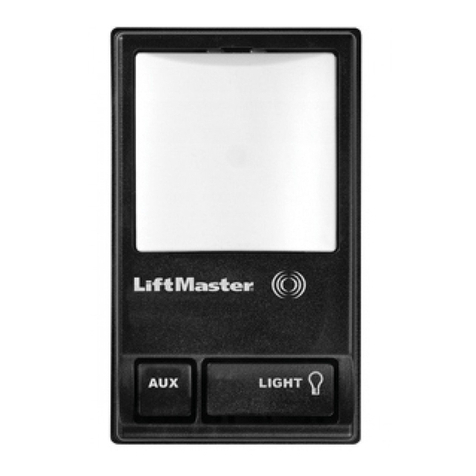

#ONSTANT 0RESSURE /VERRIDE IS FOR USE WITH +07 AND +07 KEYPADS NOT PROVIDED 4HE +07+07 WIRELESS COMMERCIAL KEYPADS ARE SECURITY

KEYPADS AND CAN ONLY BE PROGRAMMED TO /.% GATE OPERATOR SEE THE +07+07 MANUAL FOR COMPLETE PROGRAMMING INSTRUCTIONS

4HE #ONSTANT 0RESSURE /VERRIDE FEATURE IS INTENDED TO TEMPORARILY OVERRIDE A FAULT IN THE ENTRAPMENT PROTECTION SYSTEM IN ORDER TO OPERATE THE GATE UNTIL THE

EXTERNAL ENTRAPMENT PROTECTION DEVICE IS REALIGNED OR REPAIRED 5SE THE FEATURE ONLY IN LINE OF SIGHT OF THE GATE WHEN NO OBSTRUCTIONS TO TRAVEL ARE PRESENT

%XTERNAL ENTRAPMENT PROTECTION DEVICES INCLUDE ,IFT-ASTER MONITORED PHOTOELECTRIC SENSORS AND ,IFT-ASTER MONITORED WIRED AND WIRELESS EDGE SENSORS "E

SURE TO REPAIR OR REPLACE THESE DEVICES PROMPTLY IF THEY ARE NOT WORKING PROPERLY

4O USE #ONSTANT 0RESSURE /VERRIDE

%NTER A VALID DIGIT 0).

0RESS AND HOLD FOR SECONDS TO ENTER #0/ #ONTINUE TO HOLD TO KEEP THE OPERATOR IN MOTION ! CONTINUOUS TONE WILL SOUND UNTIL LIMIT IS MET ANDOR

IS RELEASED

4HE OPERATOR WILL STOP WHEN EITHER THE OPERATOR REACHES A LIMIT OR THE USER RELEASES

2EINSTALL THE #OVER

2EPLACE THE OPERATOR COVER OR ELECTRICAL BOX COVER IF APPLICABLE