Champion Sidecars DAYTONA 2+2 User manual

1

CHAMPION SIDECARS

DAYTONA 2+2, LEGEND AND ESCORT

OWNERS MANUAL

(HARLEY DAVIDSON SIDECAR GENERAL INSTRUCTION)

Champion Sidecars Inc.

11841 Monarch Street

Garden Grove, CA 92841

(800)875-0949 (sales)

(714)847-0949 (customer service)

(714)375-5668 (parts)

(714)847-1539 (fax)

http://www.champion sidecars.com (web site)

2

TABLE OF CONTENTS

SPECIFICATIONS------------------------------- 3

Information on tire size, wheel bearings, brake pads

tire air pressure, T.I.L.T. actuator and information

regarding the removal and re-installation of your

sidecar.

GENERAL------------------------------------- 4

Drawing of frame and suspension parts inc frame

and suspension parts list

ELECTRICAL----------------------------------- 5

Wiring harness pin location and color call out for

wiring harness installation to motorcycle.

Wiring of fuse link, ground, clock and accessories. 6

brake lights, running lights, right turn signal,

and back up light.

wiring of canopy switch (Daytona Sidecar)

T.I.L.T. electrical installation.

Wiring instructions Legend Sidecar

INSTALLATION OF REAR SUB FRAME--------------- 7

CONTINUED INSTALLATION OF SUB FRAME--------- 8

INSTALLATION OF UPPER FRONT MOUNT------------ 9

INSTALLATION OF LOWER FRONT MOUNT------------ 9

BRAKES--------------------------------------- 10

PREPARATION AND MOUNTING OF SIDECAR TO

MOTORCYCLE----------------------------------- 10

This section covers all aspects of installing the

sidecar to the motorcycle including helpful hints for

pre installation.

Mounting of sidecar continued. This section includes 11

instructions on wheel lead, toe in, and torque specs.

Mounting of sidecar continued to include diagram 12

showing the correct frame height and location of

measurement points for the Daytona, Legend and Escort

sidecar installation.

Mounting of sidecar continued. Diagrams showing 13

hardware used in the installation of the Daytona,

Legend and Escort sidecar. This section also covers

some information regarding the chrome struts.

STEERING DAMPER ------------------------------- 14

Photo showing installation of steering damper

DRIVING A SIDECAR------------------------------ 15

Helpful hints and safety precautions for the first

time sidecar rider and sidecar passenger.

Also information regarding what to expect when you take

your sidecar for its first ride.

3

4

Escort (E) Daytona (D) Legend (L)

SPECIFICATIONS

TIRE (E)(D) ----- 145SR13 DUNLOP

Tire (L) ----- 130 x 90 x 16"

WHEEL (E)(D) ----- #22-3511 4 x 100 modified to 4 x 4

Wheel wire (L) ----- Wire 16"x3"84 up FXST

Wheel alloy (L) ----- Alloy 10 spoke HD #43345-87

WHEEL BEARINGS (E)(D) ----- #L44643 bearings L44610 race

WHEEL BEARING SEAL(E)(D) ----- #AD7128EO

BRAKE PADS(E)(D) ----- #220018 Brembo

SHOCK Progressive ----- Escort#6602-007 Daytona#6602-011

T.I.L.T. ACTUATOR (All) ----- 20A at 1500 lbs.

CARE AND MAINTENANCE

PAINT Champion uses only PPG paint products for maximum quality and finish.

Your sidecar is painted using only base coat/clear coat urethane finishes.

This finish is hand polished at the factory and requires very little

maintenance except normal wash and wax. It is advisable not to wax your

sidecar for roughly three to four weeks after receiving it in order for the

paint to cure thoroughly.

WHEEL BEARING MAINTENANCE The wheel bearings used on your sidecar are

automotive grade tapered wheel bearings. It is advisable to check the wheel

bearing adjustment periodically, and to clean and re-pack the bearings

roughly every 3000 miles. These bearings and seals are available at most

automotive part stores.

TIRE AND TIRE AIR PRESSURE The tire used on your Daytona or Escort sidecar

is manufactured by the Dunlop Tire Co. and is available at most tire

centers. This tire is manufactured to automotive stress and wear factors

that are much higher then those you will ever experience with your sidecar.

There is a good chance that through normal use of your sidecar you will

never wear out the tire tread, but you must inspect the tire periodically

for air pressure, dry rot and sidewall damage. The manufacturer recommended

air pressure for this tire is 28 lbs. psi, but because of the light duty

application this tire is being used for, you may want to experiment with

the tire pressure to enhance the suspension comfort.

Tire pressure for the legend should be maintained at 40 PSI.

SHOCK SUSPENSION The shock suspension used on the Daytona, Legend and the

Escort sidecar are manufactured by Progressive Suspension. Progressive

Suspension has a reputation for manufacturing high quality aftermarket

motorcycle shocks and springs. Although the sidecar is shipped to you from

the factory with the shock spring set at it’s softest setting, there are a

total of five performance adjustments you can set your shock spring at.

SIDECAR REMOVAL AND REINSTALLATION To remove the sidecar from the

motorcycle first remove the two ½" bolts connecting the struts to their

upper eye mounting positions. Be sure to have someone support the

motorcycle as you remove the last of the ½" bolts . Now with the side stand

in it’s down position lean the motorcycle to the left so it rests on the

side stand. Now with the sidecar frame supported with a jack or dolly

remove the two lower 5/8" bolts connecting the lower mounting positions.

5

Disconnect the wiring harness plug, brake quick coupler, and steering

damper if you are using one. Now slide the sidecar away from the

motorcycle. (IMPORTANT NOTE)( UNLESS IT IS YOUR INTENT TO RE-ALIGN THE

SIDECAR DO NOT LOOSEN ANY OF THE JAM NUTS OR PINCH BOLTS DURING REMOVAL OF

6

7

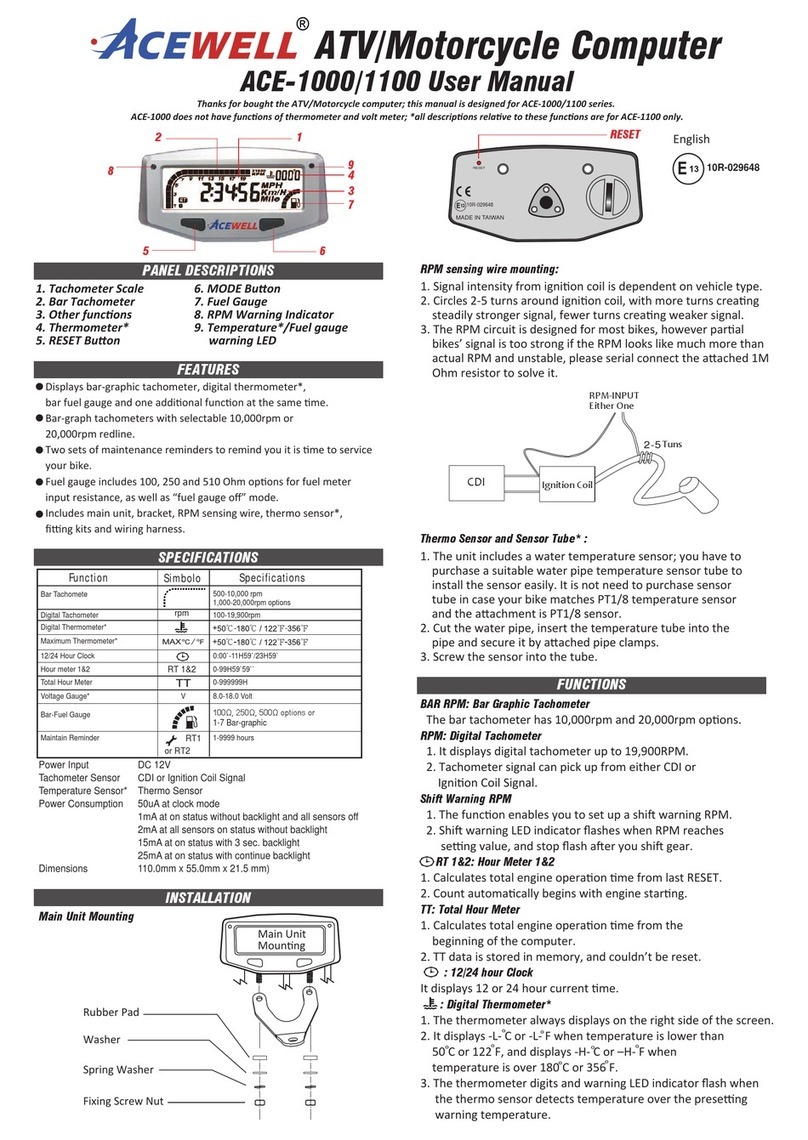

ELECTRICAL

SIDECAR POWER CONNECTOR (sidecar side)

Motorcycle Wiring Diagram Code (Escort, Daytona)

Pin # Description Color Gauge

1 Clock Green 22

2 Accessory Red 18

3 Ground Black 18

4 Brake Light Red 22

5 Running Light White 22

6 Right Turn Signal Yellow 22

7 Backup Utility Blue 22

8 Canopy Switch on Bike Orange 22

9 TILT (all models) Yellow 14

10 TILT (all models) Pink 14

TILT Switch Wiring Colors (all models)

Positive Battery (+) Red 14

Negative Battery (-) Black 14

Harness Yellow 14 Yellow 14

Harness Pink 14 Purple 14

WIRING LEGEND SIDECAR - red (stop), green (running), black (- battery)

Wiring Description (Most applications require the removal of the seat.)

* Fuse link When connecting wires directly to the positive terminal

of the battery always use a fused connection to prevent fire or

damage to motorcycle and sidecar if a short occurs.

* Ground The ground wire should be connected directly to the battery

ground or negative terminal or to another suitable frame ground. The

ground connection on the sidecar is not connected to the sidecar

frame, however the sidecar frame is connected to the motorcycle

frame. * Clock The clock signal is used for supplying constant power to

the backup circuit of a stereo. This should be connected directly to the

positive terminal of the battery or any other wire that is always live . IF

you are not installing a stereo in the sidecar this wire can be left

disconnected.

* Accessories This should be attached to the switched accessory terminal of

your bike. If you are already using this circuit, it would be advisable to

8

use the accessory terminal to control a relay that feeds this. This will

prevent overloading the accessory circuit on your bike.

* Brake Lights, Running Lights, Right Turn Signal, Backup light

These wires need to attach to the corresponding signal from the motorcycle.

There are several ways to do this. The first method is to remove the seat

and locate the corresponding wires with the use of a test light. The second

method although more expensive is to install a Station 9 from Kriss

Industries, where most of the wires to the sidecar can be isolated and

fused. If you do not have a reverse gear on your motorcycle the sidecar

backup light makes a very useful utility light when wired to a positive

battery connection and to a switch.

We suggest that you remove the right turn signal bulbs from your motorcycle

and cover the appropriate terminals with a small piece of electrical tape;

then replace the bulbs. This will prevent any confusion by following

motorists that could result from having two signals flashing, especially at

night when the extra signal appears to be in the center of the vehicle. If

you remove the sidecar, remember to put the bulbs back to their original

condition.

* Canopy Switch on Bike (Daytona Sidecar) This goes to a momentary switch

installed anywhere on the bike to open the canopy latch. It is recommended

that the power to this switch comes from switched power on the bike , thus

only allowing the canopy to be opened when the bike is switched on.

* TILT There are a total of 6 wires involved in the TILT system. The red

and black wires of the second harness need to go to the positive and

negative terminal of the battery respectively.. This is because of the high

current draw. The switch is momentary only and therefore cannot cause

unnecessary drain on the battery. You must run the power for this through a

20 amp fuse. The yellow and purple wires from the switch are connected

directly to the yellow and pink wires from the harness using the butt

connectors provided.

Mount the switch in a convenient location on the left side of your fairing.

The switch should be mounted so that moving it to the left or away from the

sidecar causes the sidecar to lift and the motorcycle to lean to the left.

Moving the switch to the right or toward the sidecar should cause the

sidecar to lower and cause motorcycle to lean to the right.

WIRING LEGEND SIDECAR

The wiring of the legend sidecar can be accomplished by first removing the

seat of your motorcycle and with the use of a test light locate the brake

light wire connection , the tail light wire connection and the battery

positive terminal. Now using the hardware supplied connect the red wire

from the sidecar harness to the motorcycle brake light connection, the

black wire to the negative battery post and the green wire to the

motorcycle tail light connection. If you have ordered other accessories

9

such as driving light, interior light etc. it will be necessary to locate

you motorcycle accessory lead or positive battery terminal for this

connection. (NOTE) Remember to use a fused connection if you are connecting

to the battery. And if you are connecting to your motorcycle accessory lead

it may be necessary to use a larger amperage fuse.

10

1996 - 1997 Harley Davidson FLH Hardware Instructions

Figure 1

1. Remove the seat.

2. Remove the right side passenger and driver foot rest.

(Allen hex head bolt)

3. Remove the front lower crash bar bolt.

4. Remove the saddlebag crash bar upper mount.

5. Take the rear mount Fig 1 and starting with the

passenger foot rest put the bolts in place from the center

out. Leave the bolts loose until the lower rear and upper

rear mounts are connected together Fig 3 # 2 and all the

bolts are in place.

6. Now install the lower rear mount to the frame rails as

shown in Fig #2 . Now tighten all bolts to the upper rear

mount and the lower rear mount.

If you are installing the sidecar to a FLHTCU with

front lower leg guards it will be necessary to remove

the right side. (This part will not be reinstalled)

1. Number 1 of (figure 2) shows the location of crash bar

mount located under the seat (position the mount under

the factory crash guard). Figure 2

2. Number 2 of (Figure 1) shows the

location of the mount to the foot rest bolt.

3. # 1 and # 2 of (figure 2) shows the

location of the lower rear sub frame to the

motorcycle frame. Take notice of the

clamp location and the bolts supplied by

Champion.

4. Number 2 of (figure 3) shows the bolt

supplied by Champion that is used to

connect the upper rear and lower rear sub-

frame together.

11

Figure 3

Figure 4

(1996-1997)

Lower Front Mount (figure 4)

Remove the two socket head cap screws

holding the right floorboard. Remove the

bolt holding the bottom of the crash guard.

Install the mount between the crash guard

and the frame and replace the crash guard

bolt Align the mount slots with those for

the floorboard and replace the floorboard.

Now tighten all bolts .

12

98 - 2000 FLH REAR MOUNT

(FIG 2)

(FIG 3)

(FIG 4)

1. Number 3 of (figure 2) shows location of crash bar mount

located under the seat (position under factory crash guard).

2. Number 2 of (Figure 2) shows location of mount to foot

rest bolt.

3. Number 1 of (figure 2) shows the location of the 7/16"

bolt supplied by Champion installed to open threaded in bike

frame.

4. Number 1 of (figure 3) shows ½" bolt supplied by Champion used to connect part A & B of the rear sub-

frame.

5 # 1 and # 2 of (Figure 4) shows the two clamps and bolts connecting

the lower rear mount to the bike frame.

02/03 REAR MOUNT

13

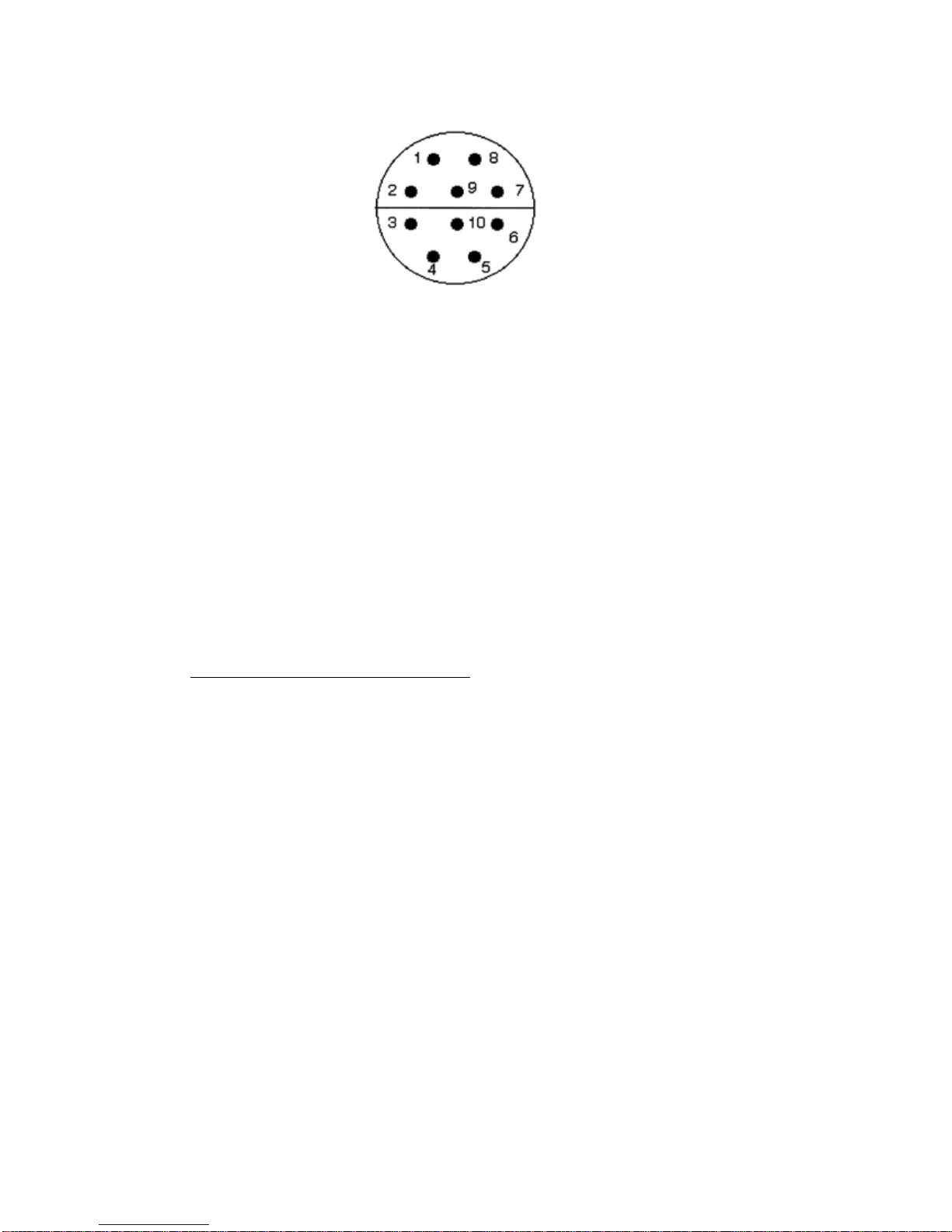

Upper Front Mount (1984 through 2003)

(FIG 5)

Eye Clamp Assembly

Install the strap clamp (figure 5) as high as possible on the

right side vertical frame tube. Do not tighten the eye bolt at

this time . Note: Be sure to install the two 1/4 bolts from the

rear with the nuts facing forward to allow sufficient

clearance between the volt heads and the engine.

(FIG 6)

Remember the engine moves

when it is running and if the

clamp bolts are too close it

could damage the head finish.

(FIG

7)

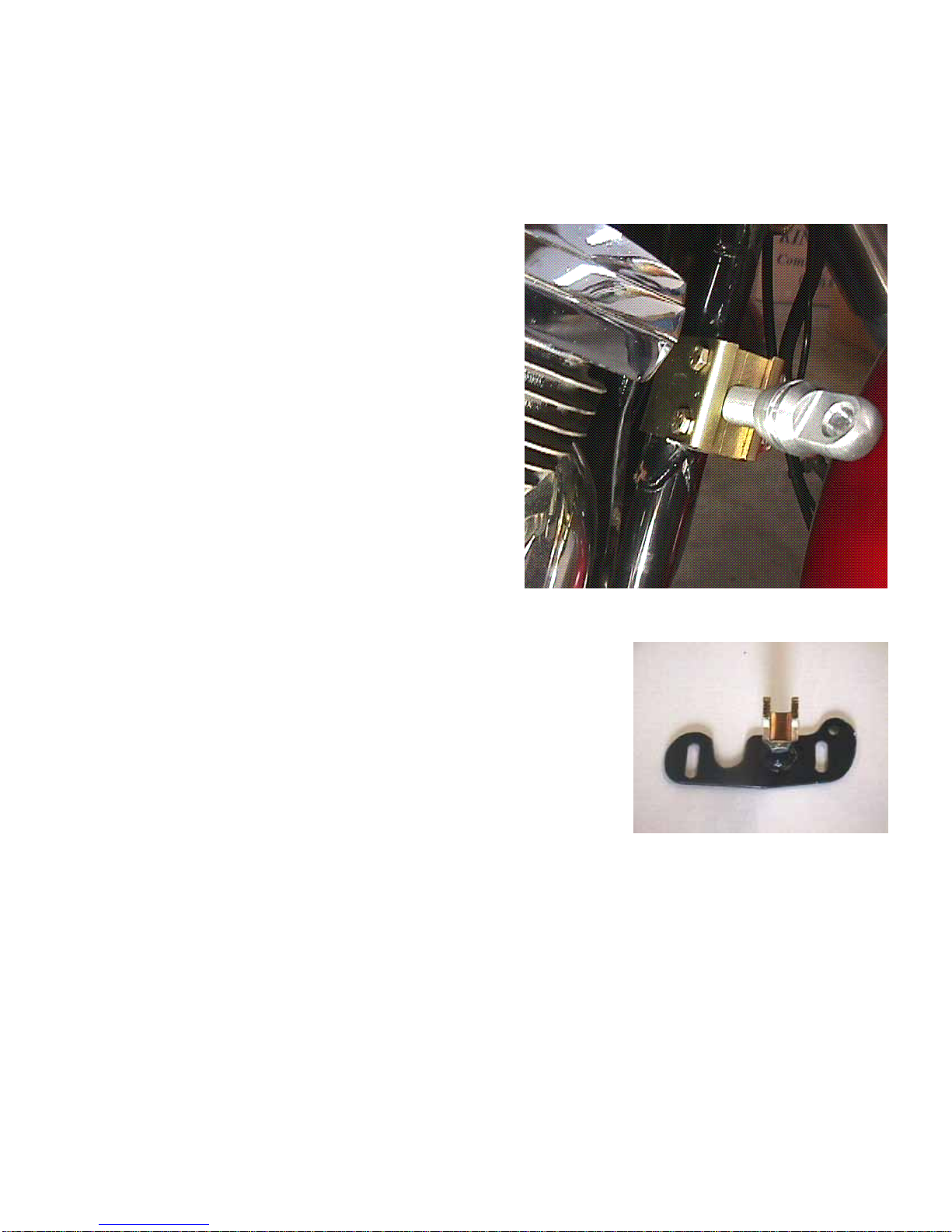

Lower Front Mount (figure 7 & 8)

Remove the two socket head cap screws holding the right floorboard.

Remove the bolt holding the bottom of the crash guard. Install the mount

between the crash guard and the frame and replace the crash guard bolt

Align the mount slots with those for the floorboard and replace the

floorboard. Now tighten all bolts .

(FIG 8)

14

(Fig 9)

BRAKES (IF EQUIPPED) Locate the rear brake

master cylinder usually located near the

rear brake pedal. The brake connection is

accomplished by removing the existing banjo

bolt connecting the rear brake line to the

rear master cylinder and replacing it with a

longer double banjo bolt supplied by

Champion. The double banjo bolt will go

through both the new brake quick coupler

banjo end and the existing brake cable banjo

end shown (Figure 9). ( be sure to use new

crush washers between all banjo fittings and

connecting surfaces). The brake cable to the

sidecar is aircraft quality steel braided

hose with a quick disconnect coupler. This

coupler is sealed in both directions to prevent any brake fluid from

leaking out. Because your Harley Davidson uses DOT 5 brake fluid from the

factory and because DOT 5 brake fluid is not compatible with the brakes

used on your sidecar it will be necessary to drain and refill the rear

brake system with DOT 4 brake fluid and re-bleed the motorcycle rear brake

system. The sidecar is shipped without any brake fluid so it will be

necessary to replace the fluid with DOT 4 brake fluid and bleed the brake

system before riding the sidecar combination. Also at any time the rear

brake pedal feels spongy or softer than normal, the sidecar brake line

should be bled and checked.

(NOTE) It is recommended to bleed the brakes every 3rd. or 4th time the

sidecar is removed.

PREPARATION AND MOUNTING PROCEDURES

ATTACHING THE SIDECAR

Mounting the sidecar should be done on a level even floor surface. The

sidecar frame should be supported at the front and rear cross member on 4x4

blocks or stands adjusted to a length of six and a half inches for the rear

and seven and a half inches in the front for the Daytona and Escort (Figure

L). If the sidecar you are installing is our Legend sidecar the front

measurement should be nine inches and the rear measurement is seven and

three quarter inches Figure L-1. If you have T.I.L.T. installed on the

sidecar, retract the wheel to ensure the wheel does not support the weight

of the sidecar. Slide the front and rear mounting hardware into the sidecar

frame. To ease adjustments, excess powder coat may have to be trimmed off

the leading edge of the tubes before being inserted into the frame tubes.

For the Escort and Daytona installation the front uses the 45 degree boss

and 45 degree clamp while the rear uses the 70 degree boss and 70 degree

clamp. For the Legend sidecar front hardware installation the offset clamp

15

will slide into the sidecar frame first and then install the 45 degree

clamp and 45 degree boss to the offset clamp. The rear mounting hardware

will use a 70 degree clamp and a 70 degree boss.

THE SIDECAR) To reinstall the sidecar reverse the process.

16

The motorcycle ride height should be adjusted to simulate your current

riding height. This can usually be accomplished by removing all the air

from your rear shocks to a close approximation of bike height with a rider

on it.

Wheel the motorcycle alongside the sidecar in preparation for an average 60

inch MC wheel to SC wheel measurement. Use two jack stands to balance the

motorcycle. One should be placed under each rear bag guard and adjusted to

just balance the motorcycle not support it as full weight should be on the

suspension. A false setting of the frame or MC suspension will require you

to readjust the alignment settings just when you think everything is

completed.

The wheel lead should be set at approximately 9 ½" as per the diagram

(Figure M location C). The toe in measurement (Figure M ) should be

approximately 1" less at location B then location A . This measurement can

easily be accomplished using a long straight edge supported off the ground

about 4" and resting against the sidecar tire. The straight edge should be

5' to 6' long. If you do not have a long straight edge, a 6' flourescent

bulb will work fine.

Engage the lower rear mount insert then snug up the 5/8" through bolt. Do

the same for the front lower mount. All the half inch fasteners should be

final torque to 80 ft lbs. at this time. After you have torqued the half

inch pinch bolts to 85 ft. lbs., you should now install the rear strut and

front strut from the sidecar frame eye to the upper rear mount eye. It may

be necessary to rotate the eyes on the frame and the upper mounts slightly

for strut installation (only turn the top front frame eye clockwise for

this adjustment). After the pinch bolts have been torqued and struts

installed, you should remove the supports holding the sidecar at its

correct height. This will assure that the sidecar remains level after

installation. The motorcycle should be set up so that it leans away from

the sidecar. (ie, the upper part of the rear wheel) should be about 1/4"

further away from the SC than the bottom of the MC wheel. The lean out or

lean in of the motorcycle is accomplished by adjusting the struts only. If

you have the optional TILT (trimming device) it is a good idea to first

lower the sidecar to its full down position and then raise it one inch to

do the final strut adjustment. This will allow three inches of up

adjustment and one inch of down adjustment. NOTE If the sidecar does not

drift left or right at a cruising speed of approximately 50 mph and with

the passenger weight that would normally be in the sidecar , you have

adjusted the lean of the motorcycle correctly. If the motorcycle drift’s to

the right and the toe in has been checked and found to be correct adjust

the struts and lean the motorcycle to left in small increments and vice-

versa if it pulls to the left.

RE-Check Ensure that all fasteners have been torqued to the correct

values. Do not forget the jam nuts in the struts or frame mounts! Bleed

the brake system and check SC brake operation with the SC wheel lifted off

17

the ground. ---Enjoy!---

18

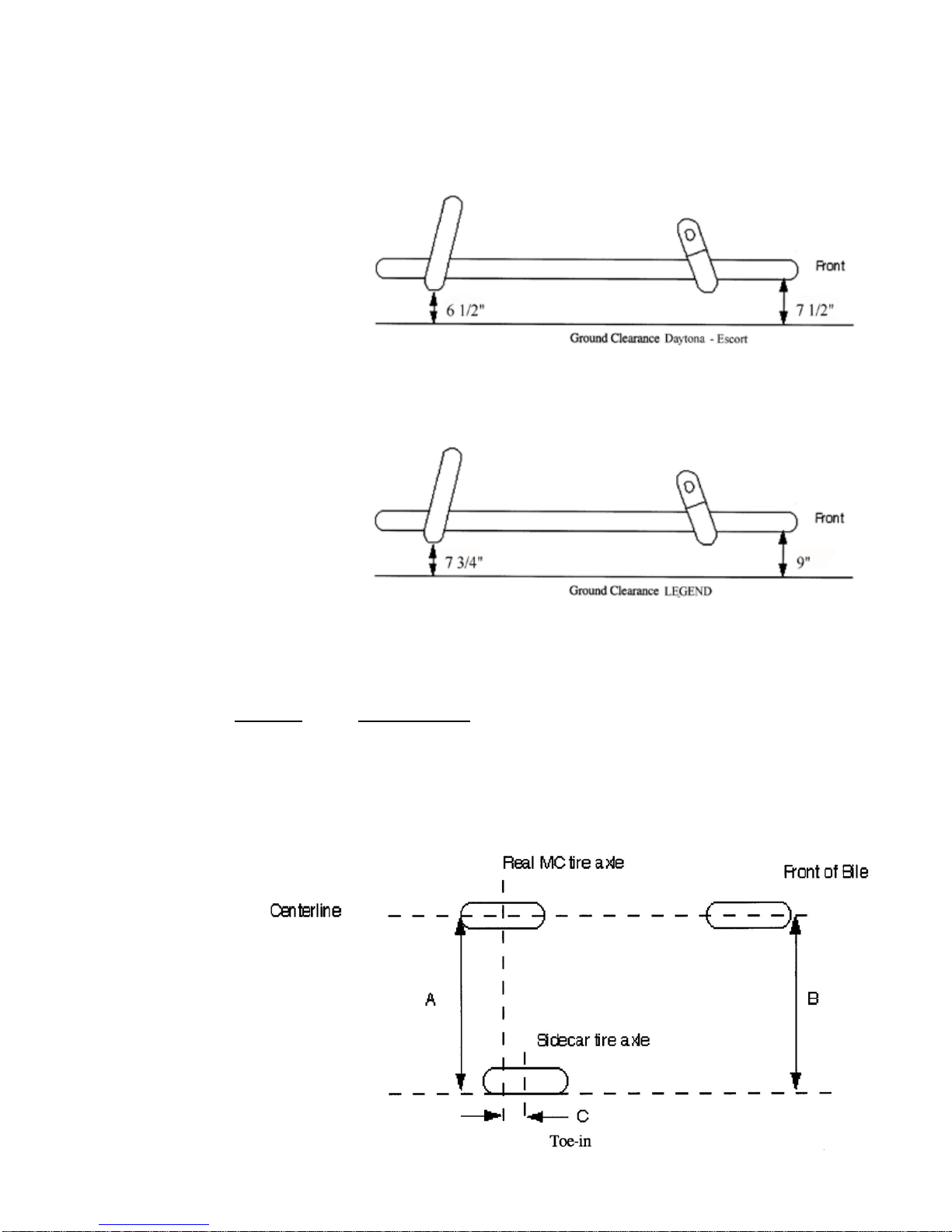

Figure L, is showing the correct frame height and location of measurement

points for the Daytona and the Escort sidecar installation.

(Fig L)

Figure L-1, is showing the correct frame height and location for

measurement points for the Legend sidecar installation.

(Fig L-1)

Figure M is showing the correct measurement points for toe in and wheel

lead for the Daytona Legend and Escort sidecar.

Harley Davidson toe in and wheel lead specifications.

Toe in measurement at Figure (B) should be approximately 1" less then at

Figure (A).

Wheel lead Figure (C) should be approximately 9 ½"

Also the measurement at Figure A should be approximately 54".

(Fig M)

19

20

Chrome Struts

Push the outer sleeve

downward with a slight twisting

to free it from the retaining

O Ring. This will allow access to

the jam nut. (keep O ring lubricated)

This manual suits for next models

2

Table of contents

Popular Motorcycle Accessories manuals by other brands

kellermann

kellermann Bullet Atto RB installation manual

SCORPION

SCORPION EHA-95 Fitting instructions

Crivit

Crivit SP-56 owner's manual

KTM Power Parts

KTM Power Parts 69109945000 Information

Paaschburg & Wunderlich

Paaschburg & Wunderlich HIGHSIDER CNC FRAME-R1 Mounting and safety instructions

Dynojet

Dynojet Power commander V installation instructions