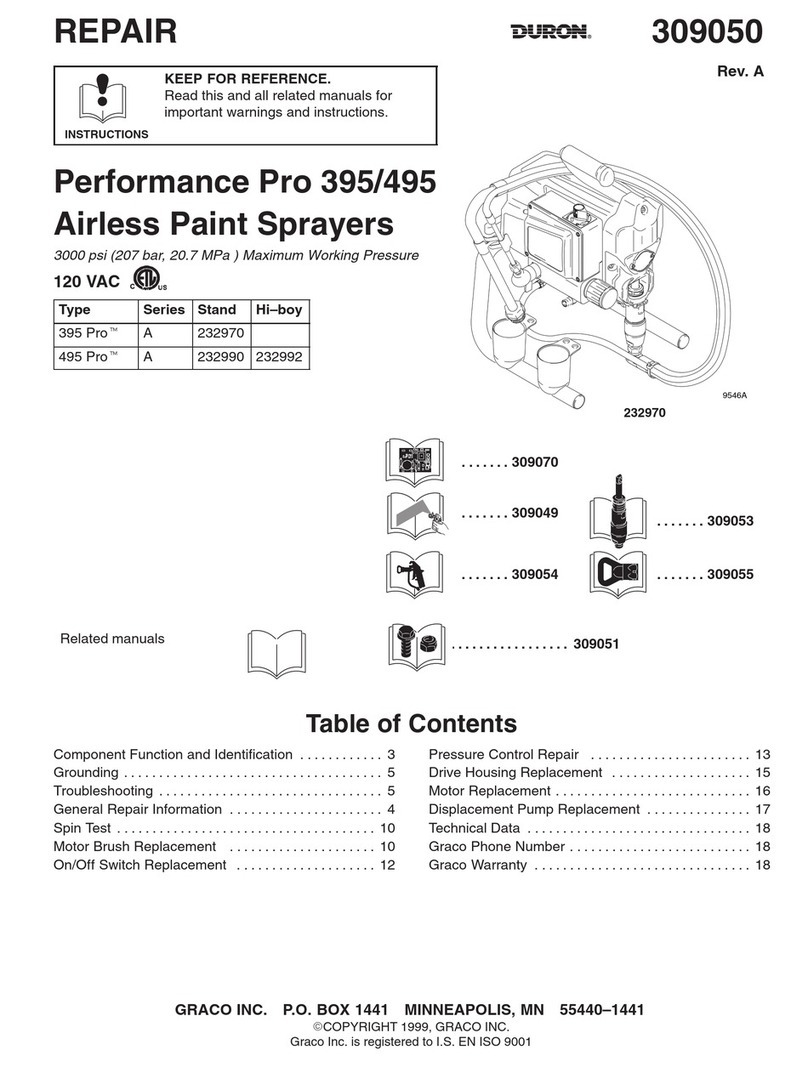

PowerFLO"" 7800 Series “‘§.?‘ "“‘°

12 Volt DC Motor-Driven Diaphragm Pumps itt

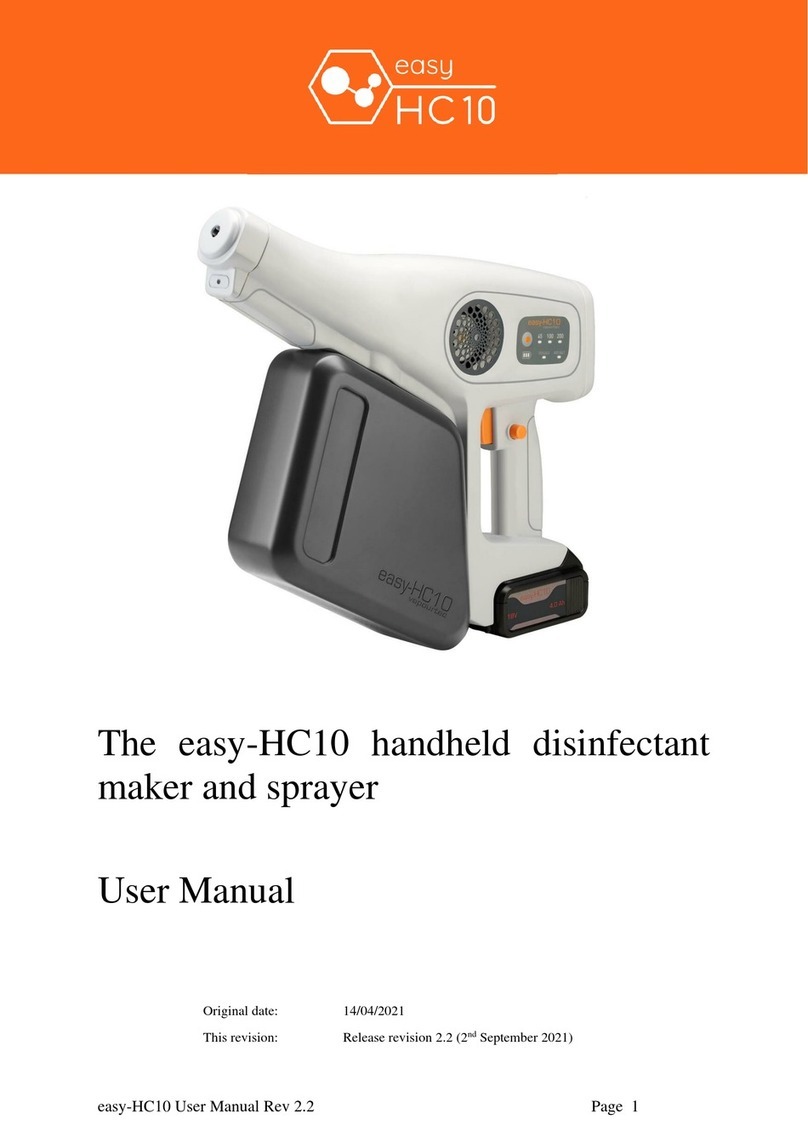

Tempe aéQé

-‘~

-4»I

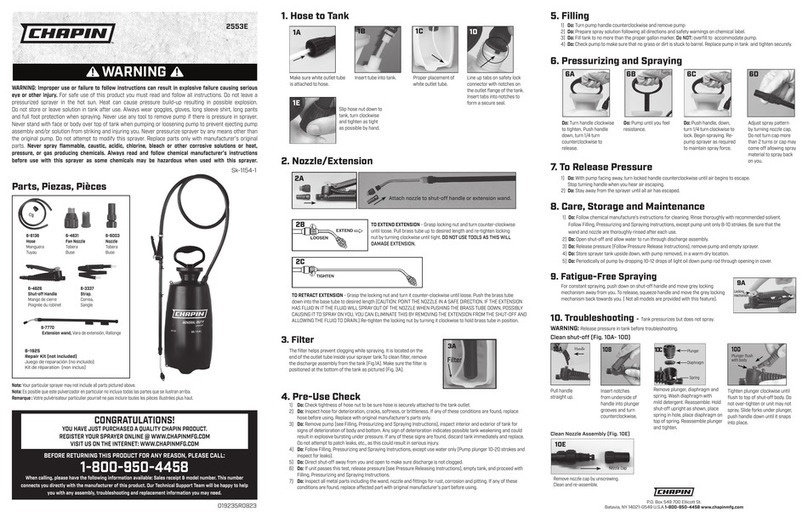

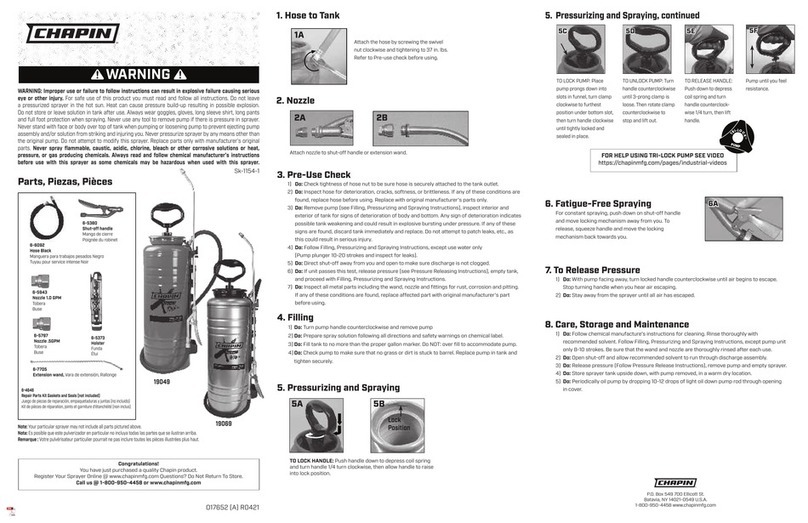

130 Recommended

Shell Temperature

A

V___

40

.-

I

9Amps

I

0::0

coO

E‘>....._O

6-___.

R30

60 010 20 30 40 50 80 70

Time (Minutes)

Approximate values, actual values will vary with ambient temperature.

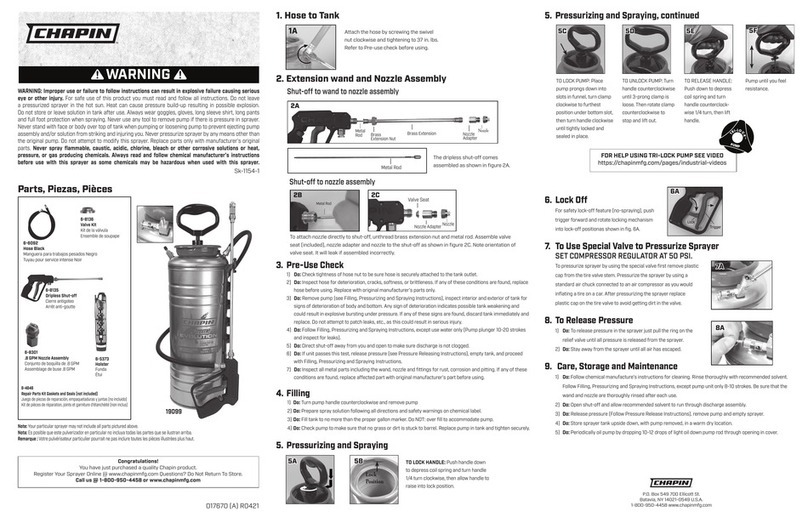

M0del= 7802= 2-2 GPM Pressure Sensing Demand Switch —

TePower eries 7pump is contro eyauit-in pressure

hFLOS' 800 'lldb b'l'

S|JeClflC3tIOl‘lS —sensing demand switch. When afaucet or valve is opened down stream of

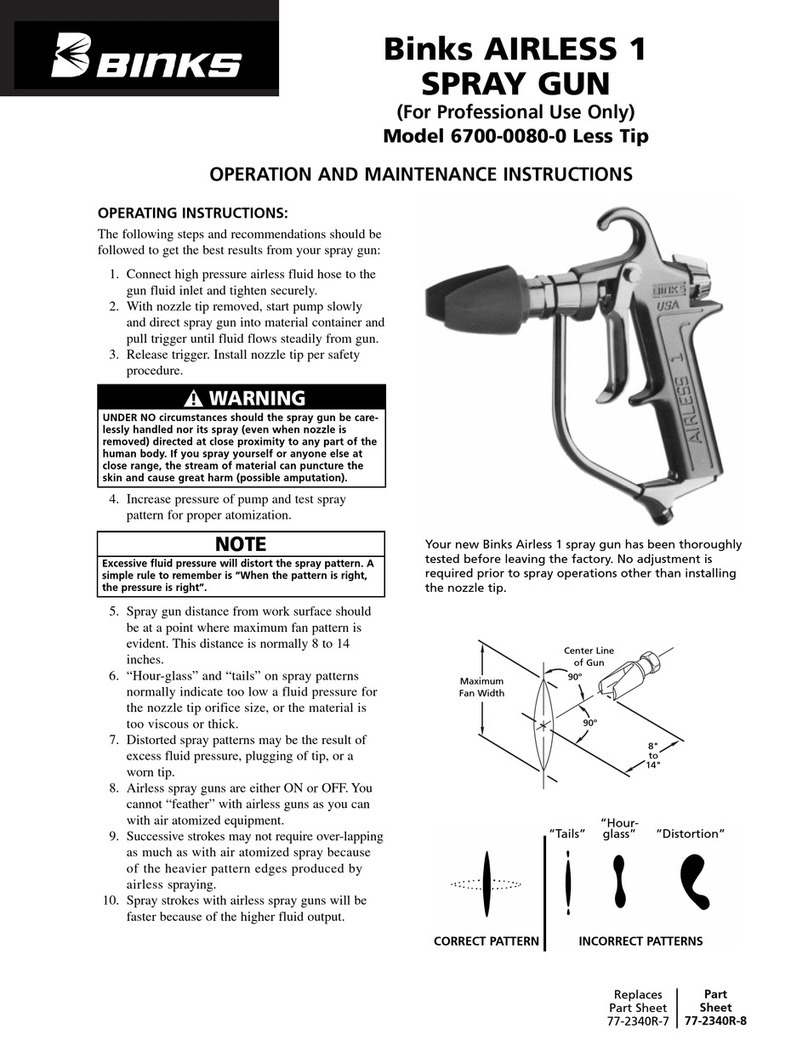

"'°t°'= the W35’ "“‘ii€Fie§i?é”v“i-,i1§’EitZ“i§Zaii§12g §'§§sEi‘3R§Z§‘ZZ‘§ti§‘?n"i¥i' the

Type: 12 \/DC’ permanent magnet’ totauy enc|°sed' n0n'Vent"ated p8rr111\/i;at>ffa'u\t\t>matica|ly. The pressure switcra actuates in response togthe

Leadsi 16 AWG, 12” r009 pump outlet pressure at apredetermined and preset pressure. The pump

Duty Qygie; 599 Heat Rise graph label indicates the piedetermmed ON and OrFFhpr(ee\isures. Typically, rihe OFF

tetppetetete ttptte Meter te pet eeptppee with tpettpet §l€t§tie'?§i°§é’t}’§iQif$a?‘v§i§@Fi%t?2£§QnsZ to tiepéifiéteiistiéi Si iii;

Pt°te¢tt°"- For “Stet safety’ Optimal performance’ and system in which the pump is installed, the flexibility and length of the

maX|ml-lm motor "re, the m0t0r 5Urrat_3‘a temperature 5h_°U|d tubing, the faucet or valves and the duration that they are open; these

not exceed 15O°F (66°C) (See Heat Rlse graph above r|9ht)- pressure settings may vary. Therefore, variation in pressure setting is

expected with use and over time.

Pump:

Type: 3chamber positive displacement diaphragm pump, self A-.-

- - -djusting the Pressure Switch:

p'!'T“'“9.' Ca_pab'e of bemg run dry’ demand or bypass modet Should the pressure switch OFF setting vary with use and time to an

C_erttf'cat'On5- NSF Standard 58 unsuitable value, it may be adjusted for optimum performance. Turn the

Liquid Temperature: 140°F (6O°C) Max. setscrew clockwise to increase the OFF pressure setting and counter

Priming Capabilities: 14 feet (4 m) clockwise to decrease. The screw should not be adjusted more tfhan one

ivi p;59 PSI half turn without consulting the Factory. Excessive adjustment 0the

ax ressure ..-pressure switch could cause low system pressure, rapid cycling ON/OFF

met/Outiet Ports‘ 7802' QUICK Attach operation, and reduced pump and motor life. Damage may occur. The

Mater-iais of construction; Warranty does not cover improper adjustment of the pressure switch.

Housing: Polypropylene Diaphragm: Santoprene

Valves: Viton Fasteners: Stainless steel

Weight: 6lbs (2.7 kg) Servicing —

Every Year: Check system against operating standards.

Every 2-3 Years: We recommend replacing the diaphragm and

Installation and Operation Precautions -checking against operating standards.

1. The pump is equipped with apressure sensing demand switch that

controls the maximum operating pressure.

2. gdgétrigii, never subject the pump to pressures above 125 PSI *Important return safety instructions:

3_ AS iooo as more is iriior Water pressure, mo oomo Wiii not Sioo Whenyou return your pump for warranty or repair, you must always do the

forward flow of water even if the motor is turned off. Be sure the r°"°W'n9- _..

System has oosirivo moans or Siiorririo off Woror 5oooii,_ 1. Flush chemical residue from the pump (best done in the eld).

4. Do not operate pump in an explosive environment. Arcing from the 2- T39 pump WM‘ type of .ch?m'Ca|5 haV'n.9 been sprayed-

motor brushes, switch or excessive heat from an improperly cycled 3- mdude Comptete de5Cr'Pt'°0 of °Perat'°" prpptem, Such as how Pump

moror may cause on oXoio5ioo_ was used, symptoms of malfunction, etc. Since pumps can contain

5_ Do riot ioooro me oomo motor rioor iow temperature oiosrios or residues of toxic chemicals these steps are necessary to protect all the

oomousiioio mororiaii -i-he Sorrooo romoorororo or mo motor may people who handle return shipments, and to help pinpoint the reason for

exceed 2500': (12OoC)_ th8 breakdown.

6. Do not pump gasoline or other ammable liquids. Pump head

materials are designed for use with water only. Do not use with

petroleum products.

7. Do not assume uid compatibility. If the uid is improperly

matched to the pumps’ elastomers, aleak may occur.

8. To prevent electrical shock, disconnect power before initiating any

work. In the case of pump failure, the motor housing and/or pump

uid may carry high voltage to components normally considered

safe. Therefore, always consider electrical shock hazard when

working with and handling electrical equipment. If uncertain,

consult an electrician. Electrical wiring should only be done by a

qualied electrician per local and state electrical codes. -

CHAPIN INTERNATIONAL, INC. P.0.BOX 549 700 ELLICUTT ST. BATAVIA, NY1402l-0549 www.chapinmfg.cnm 800-050-4458