Charder MS2500 User manual

0

MS-2500

Dual Slope type

SERVICE MANUAL

TABLE OF CONTENTS

PRECAUTIONS...................................................................................................................................1

GENERAL INFORMATION..................................................................................................................1

GENERAL INSPECTION.....................................................................................................................1

TROUBLESHOOTING.........................................................................................................................1

SPECIFICATION..................................................................................................................................2

PANEL / OVERLAY..............................................................................................................................3

ERROR MESSAGE..............................................................................................................................4

WIRING................................................................................................................................................6

LCD FORMAT......................................................................................................................................7

CONTROL PANEL...............................................................................................................................8

LOAD CELL .........................................................................................................................................9

ZERO COUNT ADJUSTMENT (Dual slope model)............................................................................10

TROUBLESHOOTING TREE.............................................................................................................12

MS2500 SERVICE MENU CONFIGURATION...................................................................................13

DEFAULT COMPANY SETTINGS.....................................................................................................14

CALIBRATION PROCEDURE ...........................................................................................................15

PRINT FUNCTION INSTRUCTION....................................................................................................17

USING PRINT FUNCTION.................................................................................................................18

SCHEMATICS—MAIN BOARD CH-0733..........................................................................................21

LAYOUT—MAIN BOARD CH-0733 ...................................................................................................24

SCHEMATICS-POWER BOARD CH-0689........................................................................................25

LAYOUT—POWER BOARD CH-0689...............................................................................................25

SCHEMATICS- JUNCTION BOARD (CH-0525)................................................................................26

LAYOUT—JUNCTION BOARD (CH-0525)........................................................................................26

MS 2500 PARTS & ASSEMBLY........................................................................................................27

DP2701, NP- 4444 INDICATOR PARTS & ASSEMBLY....................................................................28

INSTRUCTION FOR CHARGING AND CONNECTING ....................................................................30

INSTRUCTION FOR REPLACING BATTERY...................................................................................31

GRAVITY COMPENSATION .............................................................................................................32

1

PRECAUTIONS

READ the service manual BEFORE operating or servicing this equipment.

FOLLOW the instructions carefully.

Keep this manual for future reference.

Don’t allow untrained personnel to operate, clean, inspect, maintain, service or tamper

with this equipment.

ALWAYS DISCONNECT this equipment from the power source before cleaning or

performing maintenance.

Note: If the unit has been stored or transported to below freezing temperature, let the

unit to warm up to room temperature before turning on power.

PAY SPECIAL ATTENTION TO ALL “WARNING” SYMBOLS

GENERAL INFORMATION

Before connecting or disconnecting any internal electronic components or

interconnecting wiring between electronic components, always remove power and wait

at least 30 seconds. Ignoring any of these precautions could damage or cause

destruction to the equipments.

GENERAL INSPECTION

Inspect the scale assembly by checking the following:

Are there any unusual wear points, paths, or marks on the weighing Surface?

Is the instrument cable damaged or binding the scale?

Has any debris or material built up under or around the platform that could inhibit

movement?

Visually inspect the load cells and levelling feet for signs of unusual wear.

TROUBLESHOOTING

GENERAL:

If the scale does not operate properly, find out as mush as possible about the problem.

Determine whether the problem is constant or intermittent. Be aware that problems

can be caused by mechanical or electrical influences.

While troubleshooting MS 2500 scale, check for the following:

Water

Corrosive materials

Uneven floor

Strong vibrations or wind currents

Physical damage to the scale platform or housing.

IMPORTANT ELECTRICAL WARNING

2

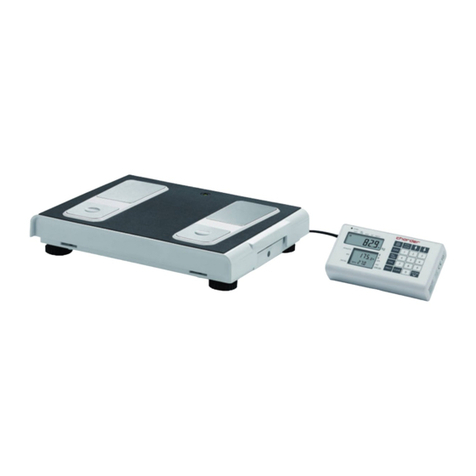

SPECIFICATION

Model MS 2500

Capacity

300kg x 0.1kg/ 660lb x 0.2lb

Weight Unit

Kg / lb

LCD Display

1.0 inch LCD display with 5 and 1/2 digits

Dimensions

Platform size: 550(L) x 550(W) x 50(W) mm

Key Functions

ON/OFF, UNIT , HOLD/BMI , TARE

Zero count

2000~9000

Span count

10000~13000 (200kg)

Power Supply

AAA Battery x 6 / AC adapter 15V 300mA

Operation

Temperature 5℃

℃℃

℃/ 35℃

℃℃

℃

3

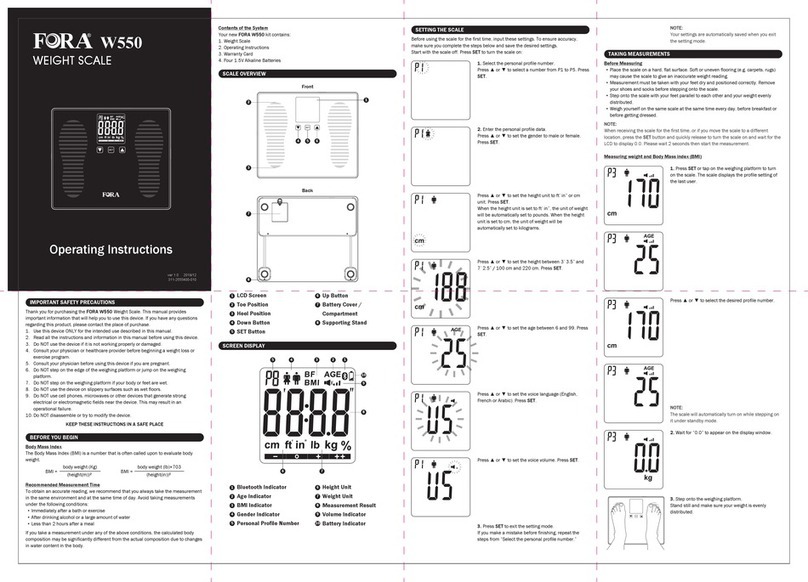

PANEL / OVERLAY

1. NP 4444

4

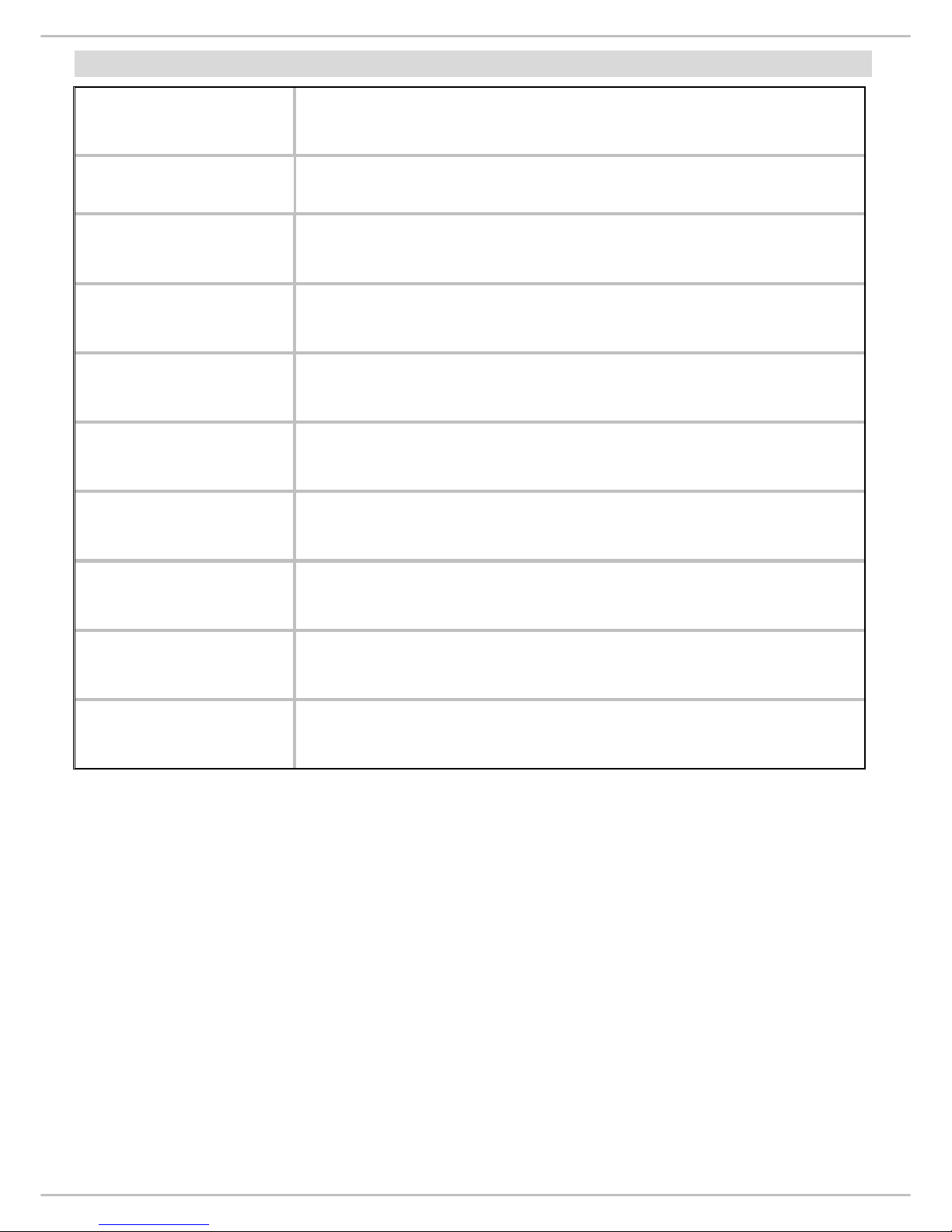

ERROR MESSAGE

Error Message Description Solution

Nothing appears on the

display after pushing

ON/OFF key.

1. Check display.

2. Disassemble indicator.

3. Check wires and control panel.

(refer P.7 & P.9)

Can’t switch on scale

using AAA battery. Battery housing wires are

disconnected or broken. (refer P.7)

Can’t switch on scale

using AC adaptor.

1. AC adaptor damaged.

→Replace adaptor.

2. AC jack wires are disconnected.

(refer P.7)

Low battery indication.

1. Check battery voltage (>6V) and

if needed replace new battery for

operation.

2. If the problem still persists

inspect soldering of controller

PCB or replace the controller

PCB.

Scale zeroed under its

initial balance.

1. Check the load cell and its wiring

(refer P.7).

2. Replace load cell, then re-

calibrate the scale. (for re-

calibrating refer P.17)

Scales zeroed exceed its

initial balance.

1. Remove the weight from scale.

2. Check the load cell’s resistance.

(See P.11)

3. If you change the load cell,

please re-calibrate the scale.

(refer P.17)

Overload 1. Remove the weight from scale.

Overload: Maximum capacity + 9d

EEPROM data incorrect.

1. Check IC3 is soldered or

not.

(Refer P.26 Bottom overlay)

2. Replace controller PCB.

3. Re-c

alibrate the scale. (refer

P.17)

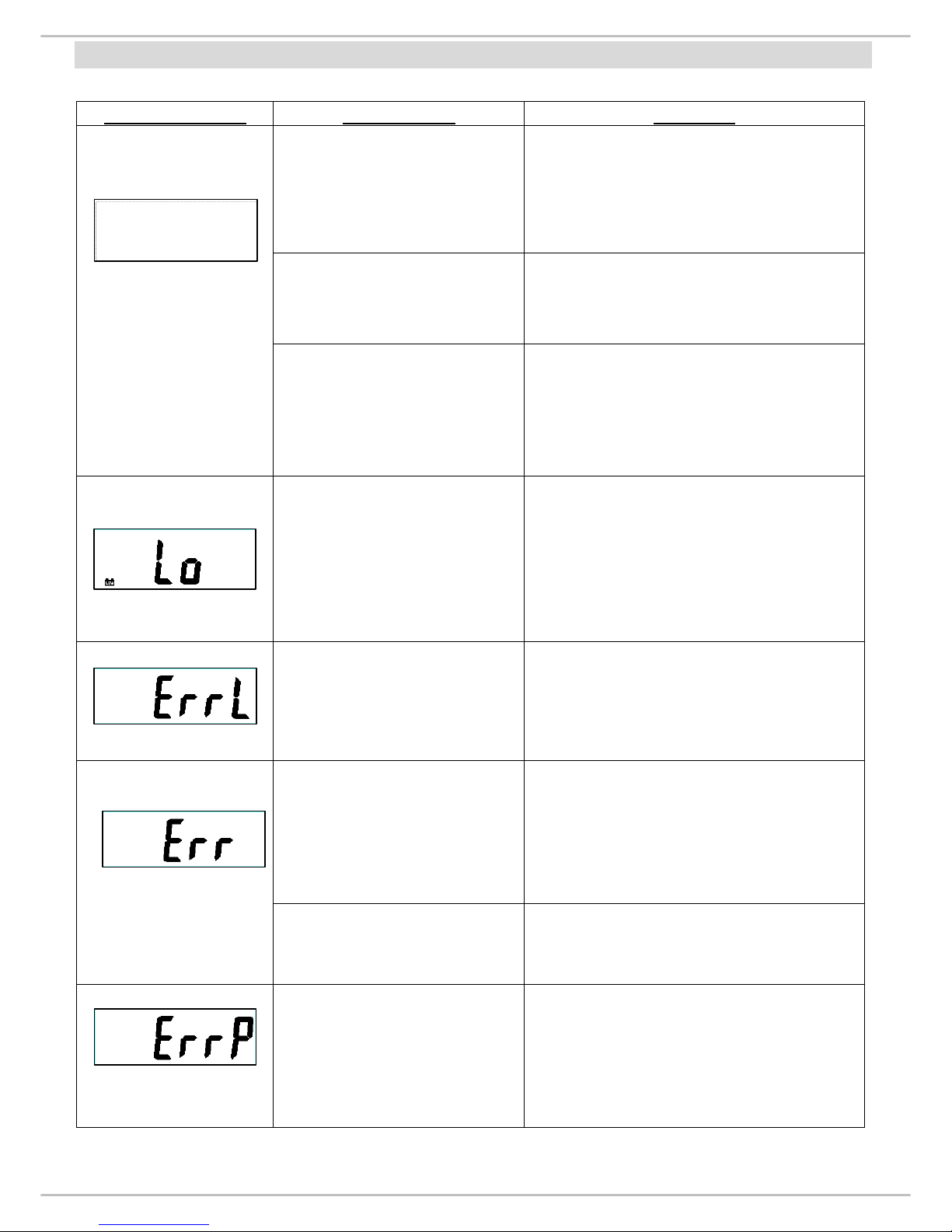

5

Error Message Description Solution

No weighing.

1. Check the load cell wires are

well and connected to the

correct points. (refer P.7)

2. Check resistan

ces of load cell.

(refer P.11)

3. If you change the load cell,

please re-calibrate the scale.

(refer P.17)

The scale shows non-

complete segments when

power on. Check LCD pin. (refer P.8)

No Current.

1. Check parameters of RS232

interface and pin out. (refer P.19)

2. RS232 wire is disconnected.

(refer P.7)

Count error (too high)

1. Check the load cell wires are

well and connected to the

correct points. (refer P.7)

2. Check load cell for proper bridge

resistances. (refer P.11)

3. Replace load cell, then re-

calibration the scale. (refer

P.17)

Zero count is more than

calibration range (i.e.

10%) while power on.

1. Make sure that the scale

platform doesn’t have any kind

of weight on it.

2. Check the load cell wires are

well connected to the correct

points. (refer P.7)

Re-calibrate the scale. (refer

P.17)

Zero count is less than

calibration range (i.e.

10%) while power on.

1. Make sure that there is no

blocking object (like

paper/plastic sheet or heavy

layer of dirt/dust) between

upper platform of the scale and

the platform on which load cell

is fitted.

2. Check the load cell wires are

well connected to the correct

points. (refer P.7)

3. Re-calibrate the scale. (refer

P.17)

6

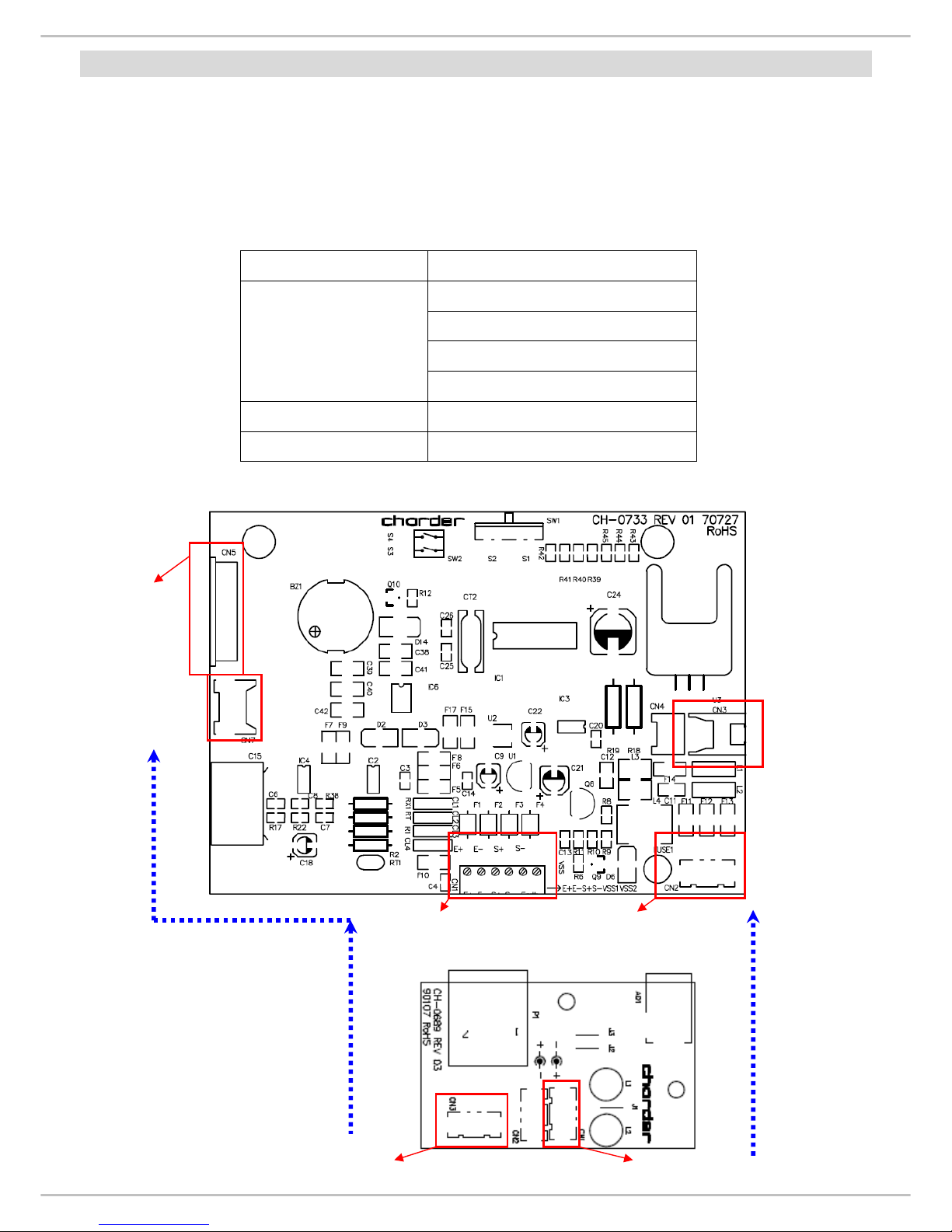

WIRING

ACTION:

1. Remove battery from the scale.

2. Un-screw the lower housing.

3. Remove upper housing.

4. Make sure that all wire connectors are well and that no insulation material is

touching the soldering contacts.

5. Make sure that all wires are connected to the correct points.

Wiring Connector

RED (solder pad “E+”)

WHITE (solder pad “S+“)

YELLOW (solder pad “S-”)

Load cell wiring

(from junction board to

main board)

BLACK (solder pad “E-“)

Battery Wiring CN 3

Power Wiring CN 2

Main Board (CH-0733)

Power Board (CH-0689)

RS 232

connector

Control panel

connector

Load cell

connector Power board

connector

Battery

connector

AC Jack connector (CN 1)

RS 232

connector

7

LCD FORMAT

ACTION:

Problem- The scale shows non-complete segments when power on.

Solution:

•Turn off the scale and take out the batteries from the scale.

•Check LCD pin. (Please refer to above LCD FORMAT)

For instance, if the top left arrow (S1) disappears, then check pin 1 and pin 4.

•Check whether LCD pins are soldered properly or not.

8

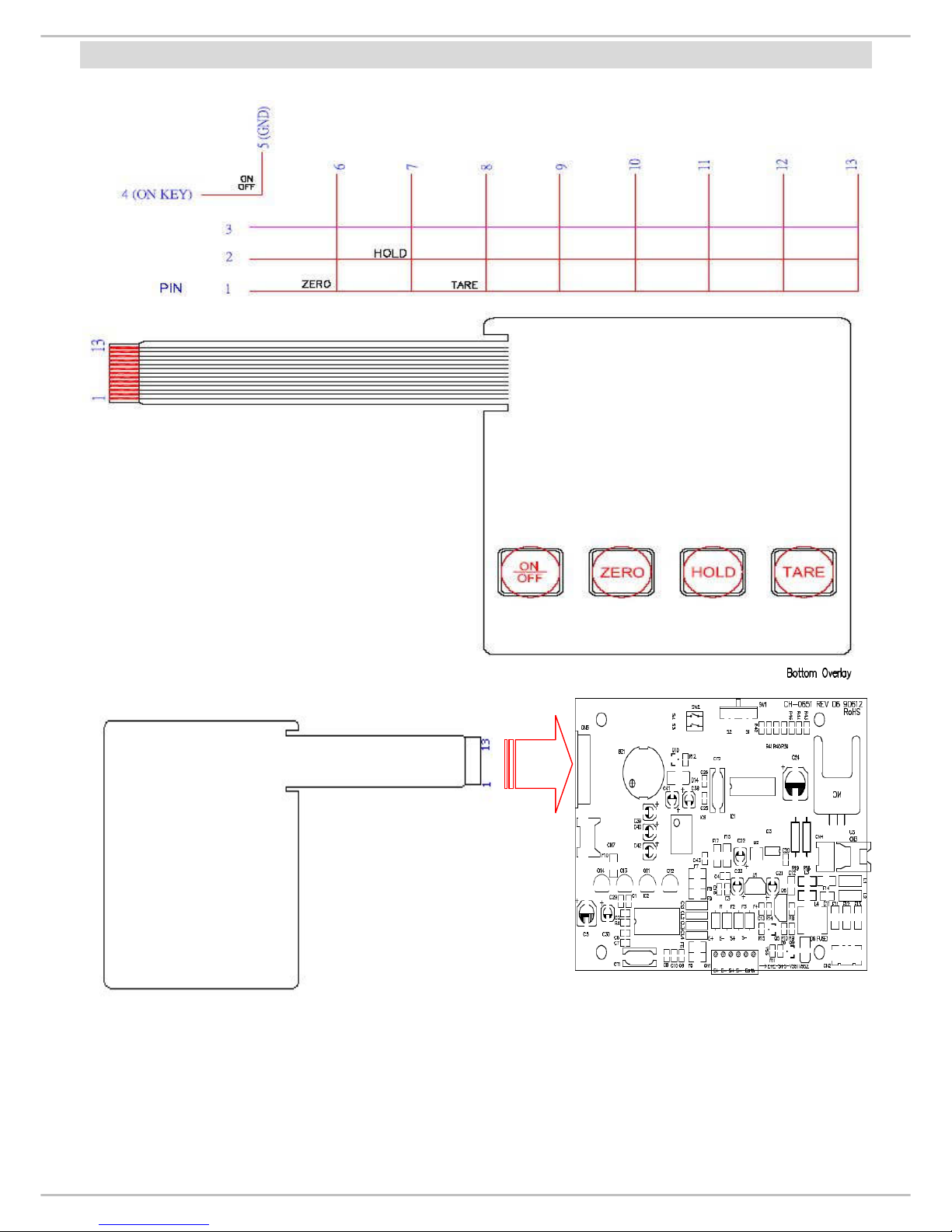

CONTROL PANEL

1. NP4381 (300kg Capacity)

1. Control panel switch damaged.

2. Use multi-meter to measure voltage current of control panel.

3. Reconnect control panel switch.

Make sure that control panel is connected to the correct housing (CN5).

4. If problem persists, replace a new control panel.

9

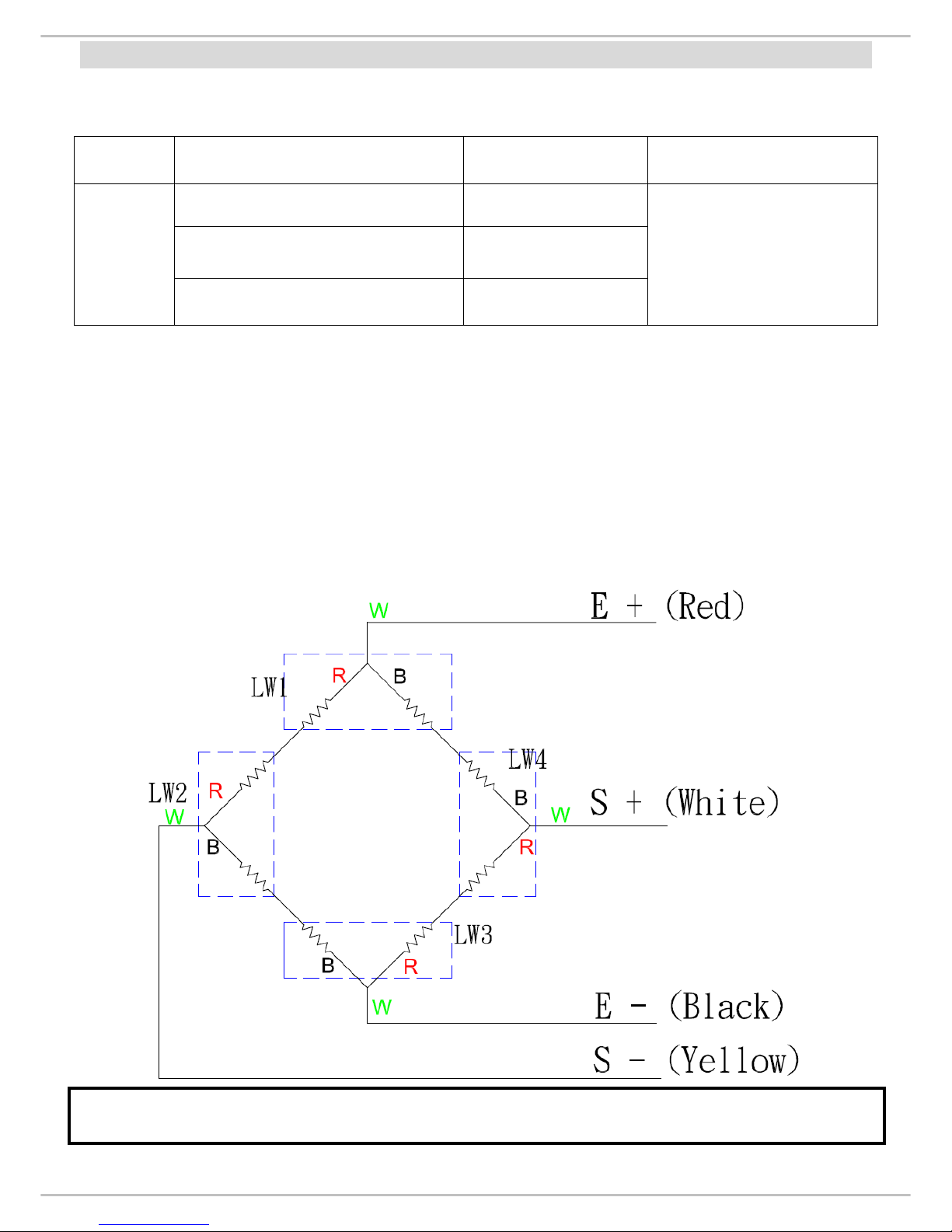

LOAD CELL

Check load cell for proper bridge resistances as below.

MODEL

MEASURING POINTS RESISTANCE REMARK

+E (Red) to -E (Black)

690 ohms minimum

+E (Red) to +S (White)

345 ohms minimum

AL1420A

- E (Black) to +S (White)

345 ohms minimum

Each resistant on load

cell should be same

and the tolerance <

1000 ohms.

ACTION:

1. Remove power (adaptor pin) from the system, check load cell for proper

resistances.

2. If load cell fails the above tests, replace load cell.

3.

If load cell passes the above tests and has no visible damage, please re-calibrate

the scale.

If any of the 4 load cells is broken or damaged, the complete set (all 4 load cells) of load cells

need to be changed.

10

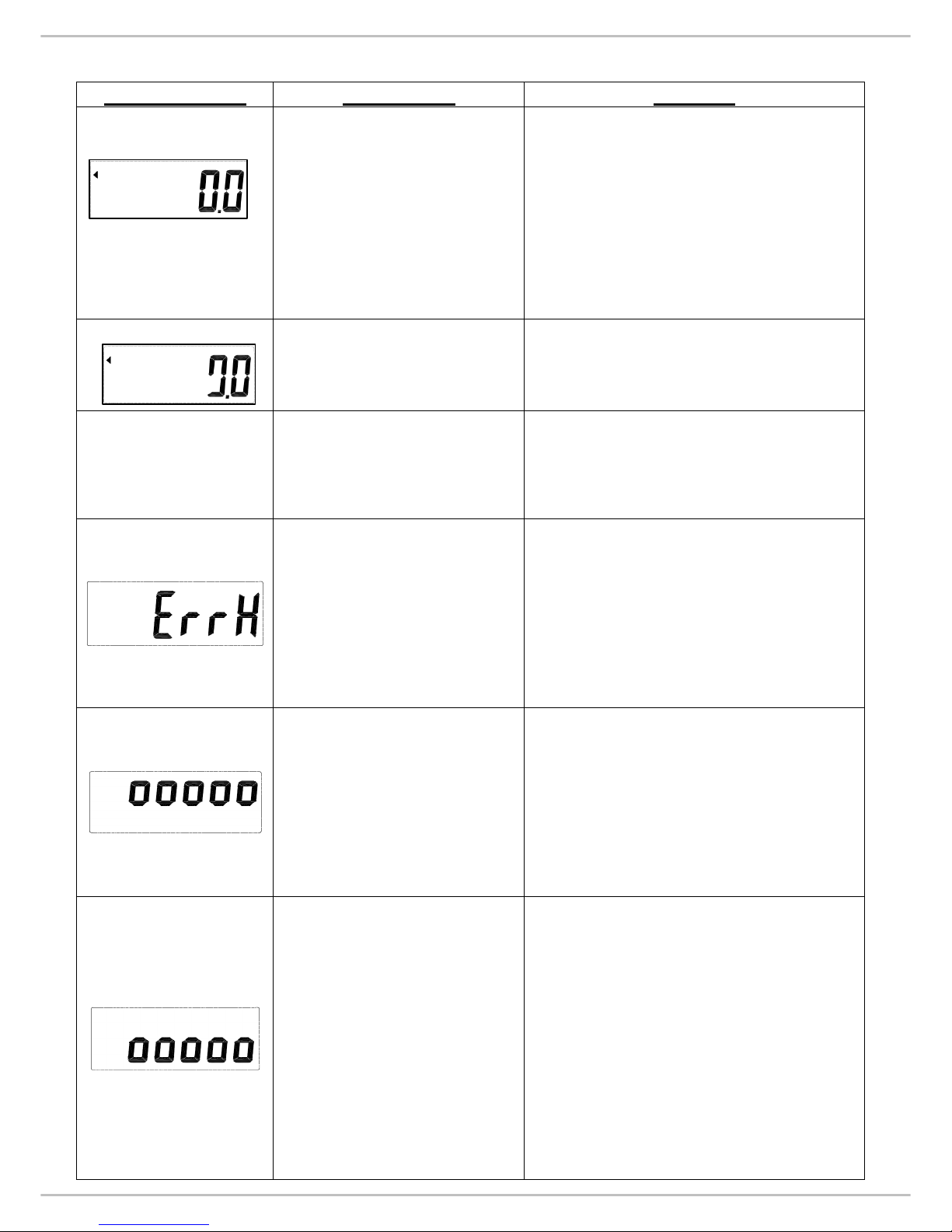

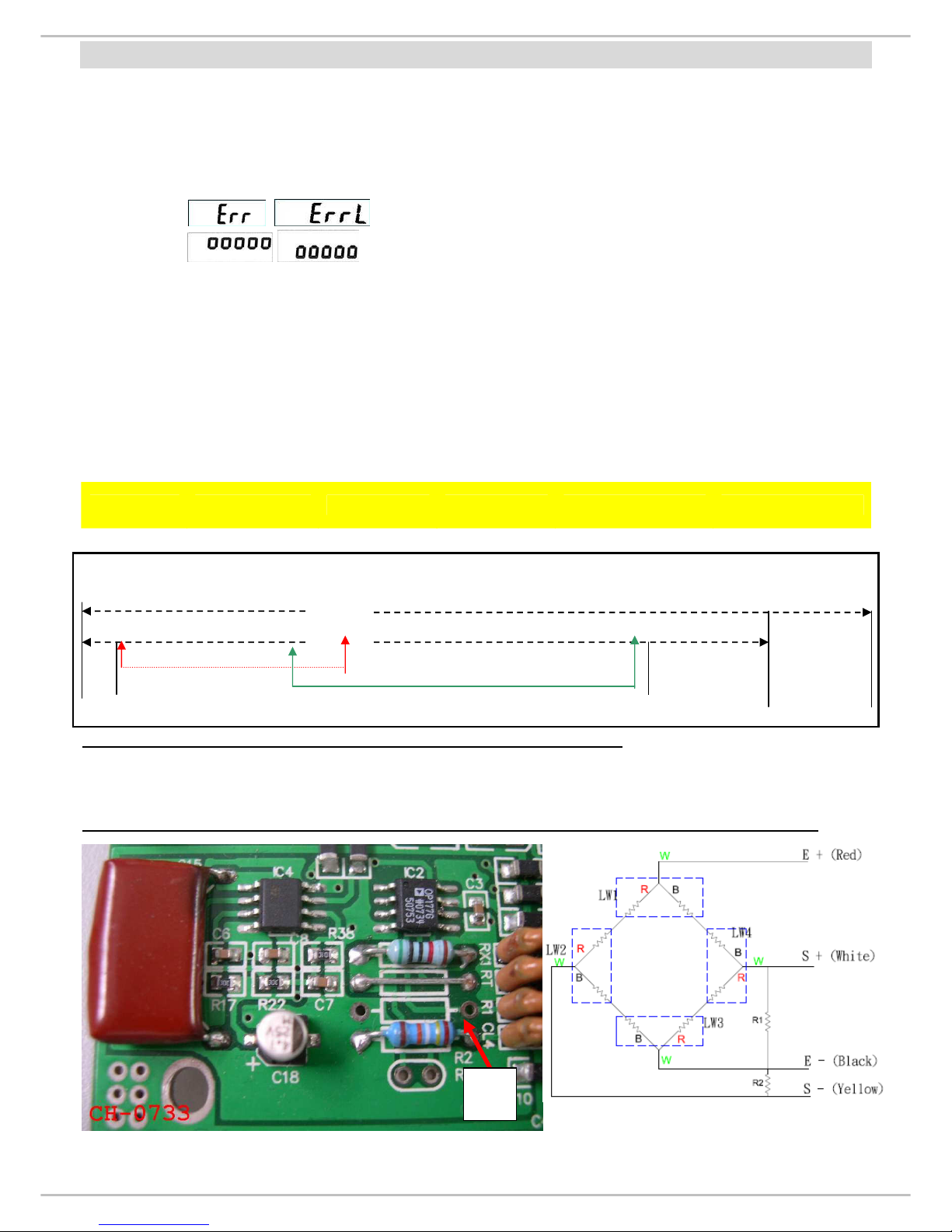

ZERO COUNT ADJUSTMENT (Dual slope model)

•Why should I adjust ZERO count?

Situations in which ZERO count need to get adjusted

oLoad cell damaged because of over load; beyond scale’s capacity.

oMain board has been replaced.

oBecause of rough handling of scale, the ZERO count move out of range.

oLoad cell has been replaced.

o/ message displays on the display.

o/ message displays on the display.

•How to quick check ZERO Count?

Please refer to Calibration procedure on P.17

*Only Non-Approved models need to adjust Zero Count. Approved Models don’t need any such

adjustment.

Range Chart: ZERO count must be within the range (6000~12000), if it’s out of this range it

need to be adjusted.

SPAN Count Range

MODEL ZERO Count

Range 200kg 500kg ZERO control

(R2) PCB Board

MS 2500 2000~9000 10000~13000 12500~16500

200K CH-0733

Total Internal count of MS3800 (Dual slope) is 65535, but the overload is been set at

65000(company settings).

65535

65000

Overload

←2000 ~9000(zero) +10000~13000(span 200kg) =12000~22000 →Safety range

+12500~16500(span 500kg) =14500~25500

When ZERO count is out of range, there can be two possibilities:

1. ZERO count value is below the lower limit i.e. 2000

2. ZERO Count value is above the upper limit i.e. 9000.

Please adjust R1/R2 on the main board, to bring the ZERO count value in the range limit.

R1

R2

11

R1-If ZERO count is less than 2000, put resistor at R1 to increase the ZERO count value.

R2- If ZERO count is more than 9000, put resistor on R2 to decrease the ZERO count value.

ZERO Count Adjustment Procedure:

1. ZERO count value is below the lower limit i.e. 2000.

•If there is any resistor at R2, please remove it.

•Check the zero count. If the ZERO Count value is between (2000~9000), stop the

procedure, ZERO Count value is successfully adjusted.

•If the count is still below 2000, use metal resistor 100K on the R1, then check the ZERO

count, if the count moves over 9000, change the resistor to 50K or below, until the zero

count comes under the ZERO Count range.

2. ZERO Count value is above the upper limit i.e. 9000.

•If the ZERO count is above 9000, use metal resistor 100K on the R2, then check the

zero count, if the count is still over 9000, change the resistor to 150K or above, until the

ZERO count comes under 9000 and between ZERO count range.

*After determining the required resistor, solder it

.

12

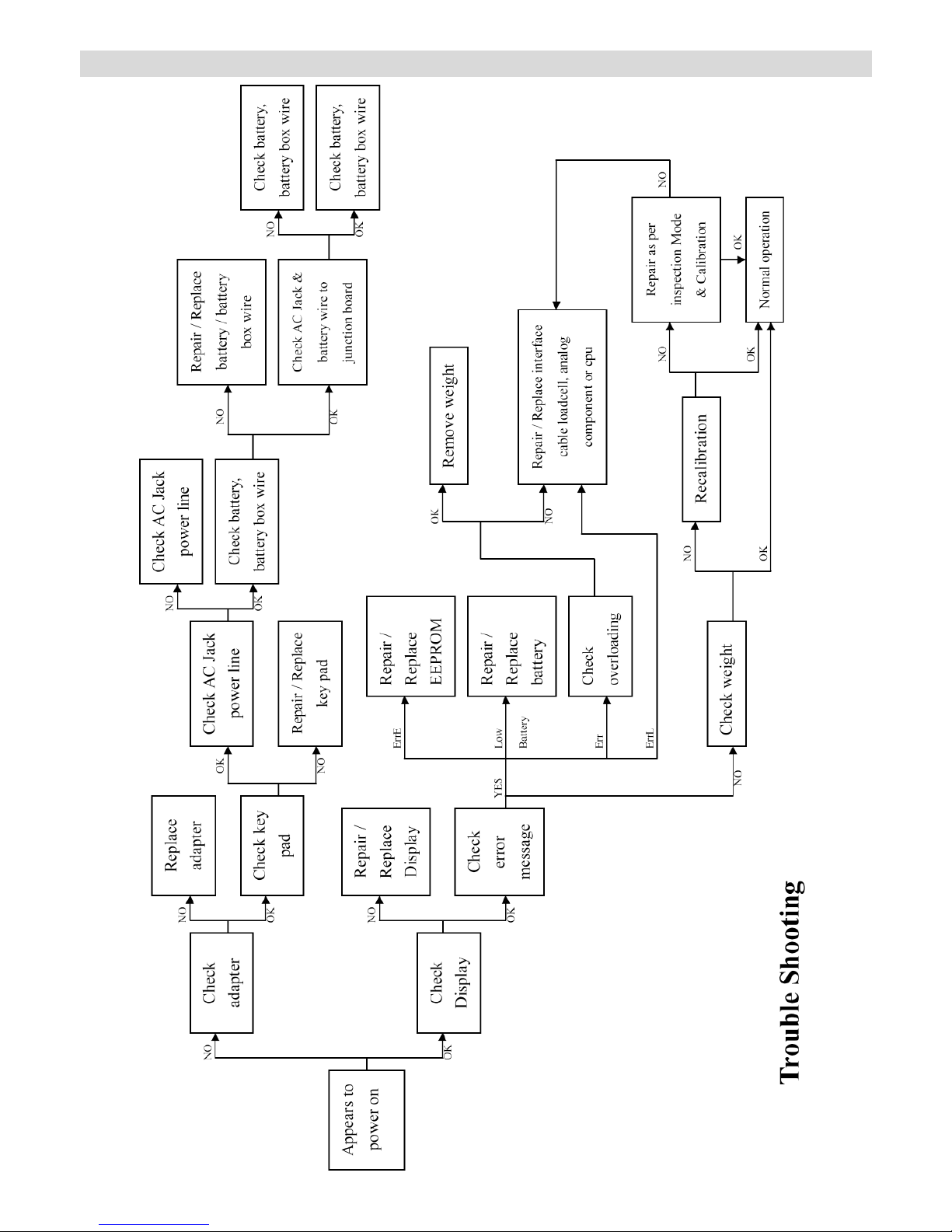

TROUBLESHOOTING TREE

13

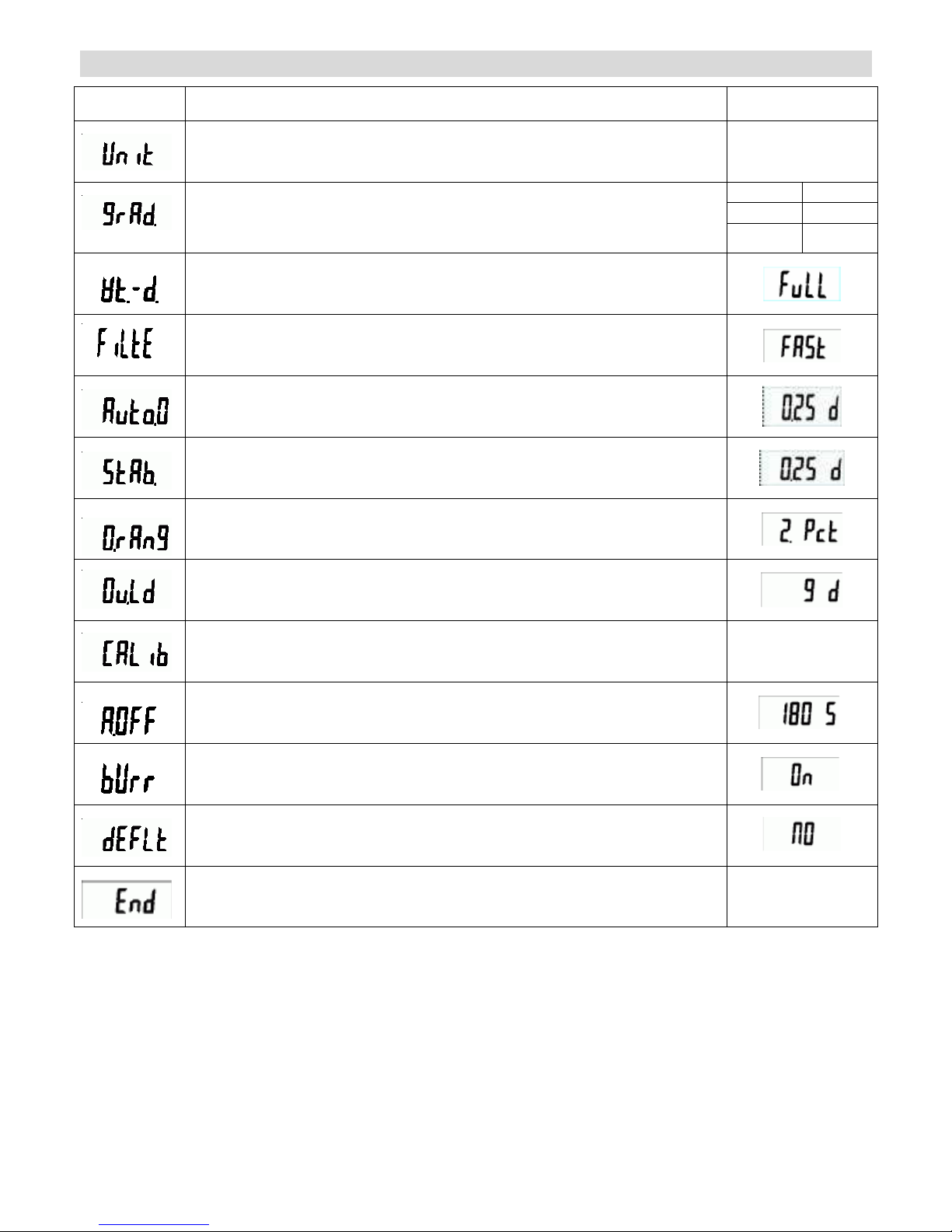

MS2500 SERVICE MENU CONFIGURATION

Press [UNIT 4key display] for 3 seconds without release to enter program setting mode.

First SETUP will appear, and then it will change to “UNIT” automatically.

Press [TARE 4key display] to switch to next function. Program flow is like

Press [HOLD/BMI 4key display] to enter function flow. Program flow is like

To confirm desired setting press [TARE 4key display] to go back to main menu.

To save all changed setting, please switch to END and press [HOLD/BMI 4key display] to save and then scale will restart.

Example- Press SEMI AUTO TARE key 3 times when display shows press HOLD key to enter into the

feature settings, and then press HOLD key to move between and if you want to

select , Press SEMI AUTO TARE key again, after the selection is made will display back automatically.

*Please press SEMI AUTO TARE key until displays on the screen, and then press HOLD key, to apply the

changes. Display will show ; means changes has been applied successfully.

enter

200kg

14

DEFAULT COMPANY SETTINGS

Function

Description Default

(Units): Kg , st , lb

Kg/lb

300Kg 600kg

3000 d 3000d

(Graduations): Setting division, max capacity and

graduation.

300.1 600.2

(Weight Section Division): Setting weight section division

(Filter): Fast/ Normal/ Slow

(Auto Zero Tracking): 0.25d/ 0.5d/ 1d/ 3d/ OFF

(Stable Range): 0.25d/ 0.5d/ 1d/ 3d/ OFF

(Zero Range): 2% (or 100%)

(Overload Range): 9d (or 2%)

(Calibration Set): The method of calibration setting

(Auto off Time): 120 sec/ 180 sec/ 240 sec/ 300 sec/ OFF

(Buzzer): ON/OFF

(Default Setup)

(Save setting)

15

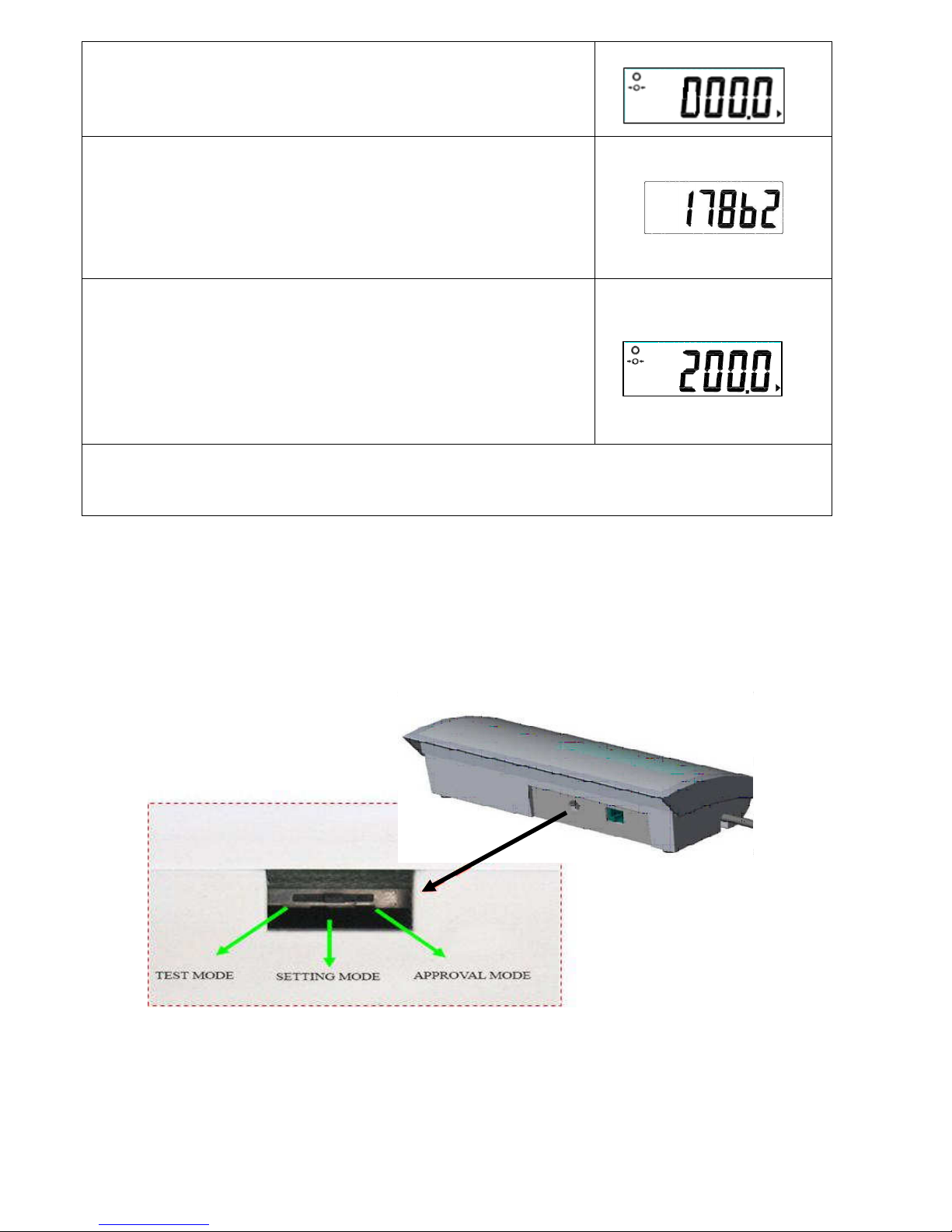

CALIBRATION PROCEDURE

To calibrate the scale, please turn off the scale and move Calibration pin to center

(refer P.14).

Operation Display

Turn the scale on using the ON/OFF key.

Press UNIT key for 3 seconds and SETUP will show

shortly. UNIT will appear on the display.

Press the TARE key repeatedly until the “CAL ib”

symbol is displayed.

Press the HOLD/BMI key.

Press the TARE key. The triangle [ ] will display in

the upper left corner (for “kg” calibration weight).

(If the calibration weight is “lb”, please press TARE key

again and the triangle [ ] will display in the lower left

corner.)

Press the HOLD/BMI key repeatedly until the “CAL 0”

symbol is displayed.

Press the TARE key, the display will show the present

ZERO Count value (6000~12000).

Then press the UNIT key.

Press the HOLD/BMI key.

Press the TARE key.

Enter the calibration weight (ex: 200kg). Press TARE

key and HOLD/BMI key to set your weight.

16

Confirm by pressing the UNIT key and the number on

the display will be 000.0

Place calibration weight on the centre of the scale

plate, and the display will show SPAN Count value

(15000~20000). Press the HOLD/BMI key. The

adjustment process is started.

When the adjustment is finished successfully, the

scale is automatically switched over to the weighing

mode again and the calibration weight will be

displayed.

Remove the calibration weight from the scale.

Turn off the scale and then start the scale again.

Calibration pin is at the back of indicator.

17

PRINT FUNCTION INSTRUCTION

PARAMETERS OF RS232 INTERFACE

Set parameters of the scale interface on the connected device. It is not possible to

change the scale parameters.

BAUD RATE: 9600 bps

PARITY CHECK: no

DATA LENGTH: 8 bits

STOP BIT: 1 bit

HANDSHAKE: no or Xon/Xoff

DATA CODE: ASCII

ACTION:

1. Make sure that all wires are connected to the correct points.

2. Check parameters of RS 232 transfer cable interface.

3. Use your PC to output the data to check whether RS 232 transfer cable is okay or not.

PIN 2--TXD

PIN 3--RXD

PIN 5--GND

PIN 2--TXD

PIN 3--RXD

PIN 5--GND

18

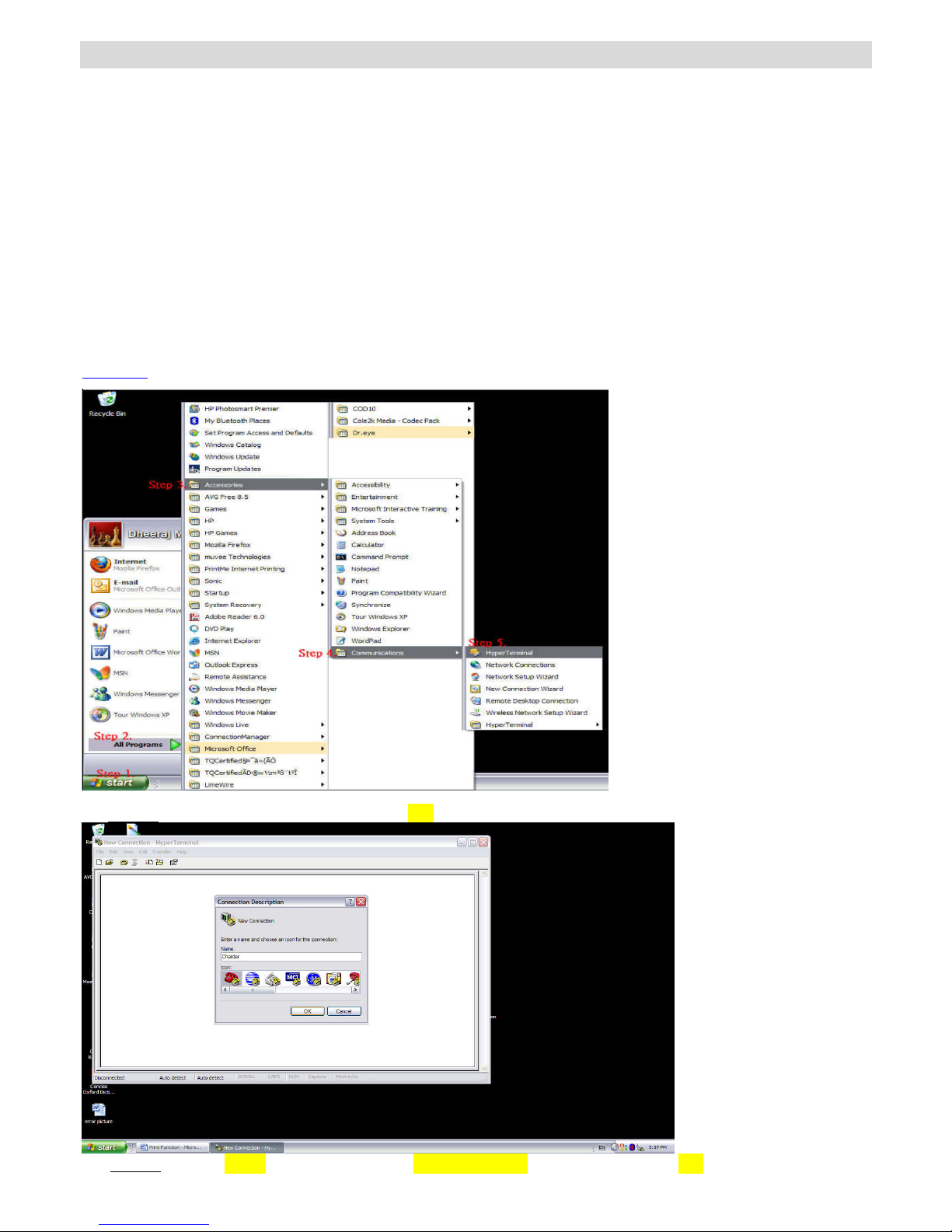

USING PRINT FUNCTION

Print function is only available for some specific models, please make sure whether the model has

print function or not.

A. Using Printer to print out the results.

You can print through PC simply press P on keyboard after weighing and taking BMI.

B. Using Computer to print out the results.

After taking the weight and BMI, please follow instruction below to print the results:

1. Start Hyper Terminal

Step.1- Click on Start Button.

Step.2- Go to All Programs.

Step.3- Select Accessories.

Step.4- Find Communications.

Step.5- In Communications section click on HyperTerminal.

Step1~5

Step.6-Name the connection and click OK Button

Step.7- Select COM (1, 2, 3…4) under Connect Using Section and press OK.

19

Step.8- Set Port Settings

•Set up as below:

BAUD RATE: 9600 bps

DATA BITS: 8 bits

PARITY : None

STOP BITS: 1 bit

FLOW CONTROL: NONE or Xon/Xoff

•Click OK button to complete the setting.

Other manuals for MS2500

3

Table of contents

Other Charder Scale manuals

Charder

Charder MS4400 User manual

Charder

Charder MS5750 User manual

Charder

Charder MS 5900 User manual

Charder

Charder MS6110 User manual

Charder

Charder MS4980 User manual

Charder

Charder R460 User manual

Charder

Charder MS3400 User manual

Charder

Charder W310 User manual

Charder

Charder MS 4940 User manual

Charder

Charder MS 3850 User manual

Charder

Charder MS4201 User manual

Charder

Charder MS2500 User manual

Charder

Charder MS3450 User manual

Charder

Charder MS-3500 User manual

Charder

Charder MHS2510I User manual

Charder

Charder R260 User manual

Charder

Charder MS6110 User manual

Charder

Charder MBF6000 User manual

Charder

Charder MS3400-1 User manual

Charder

Charder MS5461 User manual