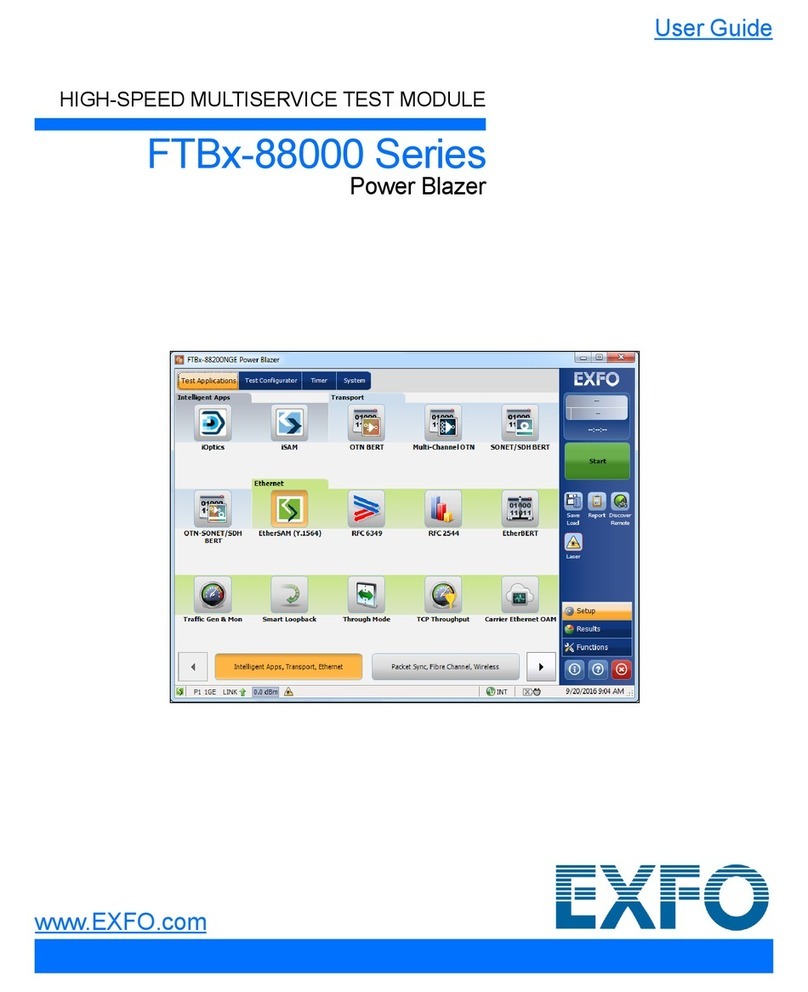

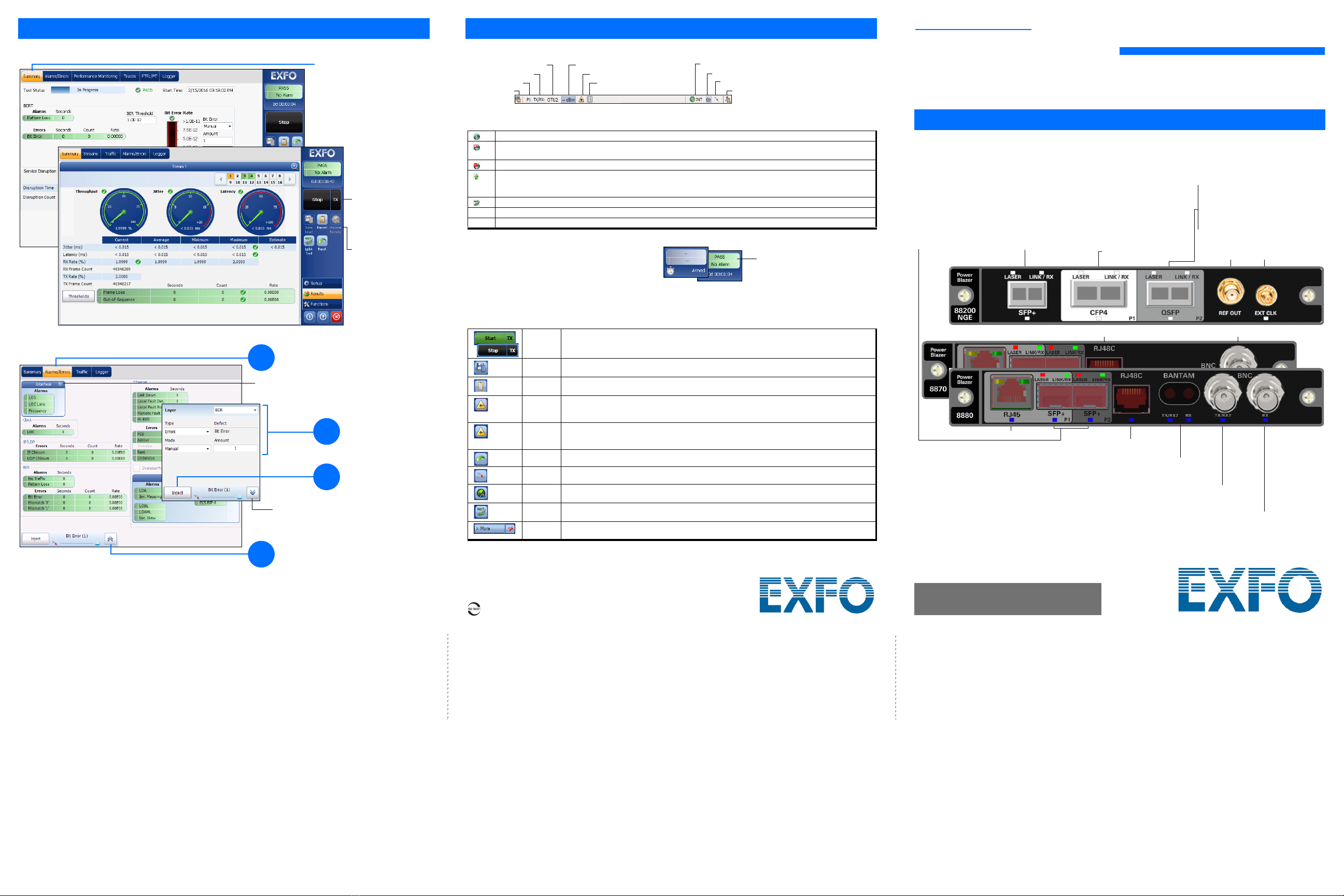

FTBx-88000 Series

Power Blazer and NetBlazer

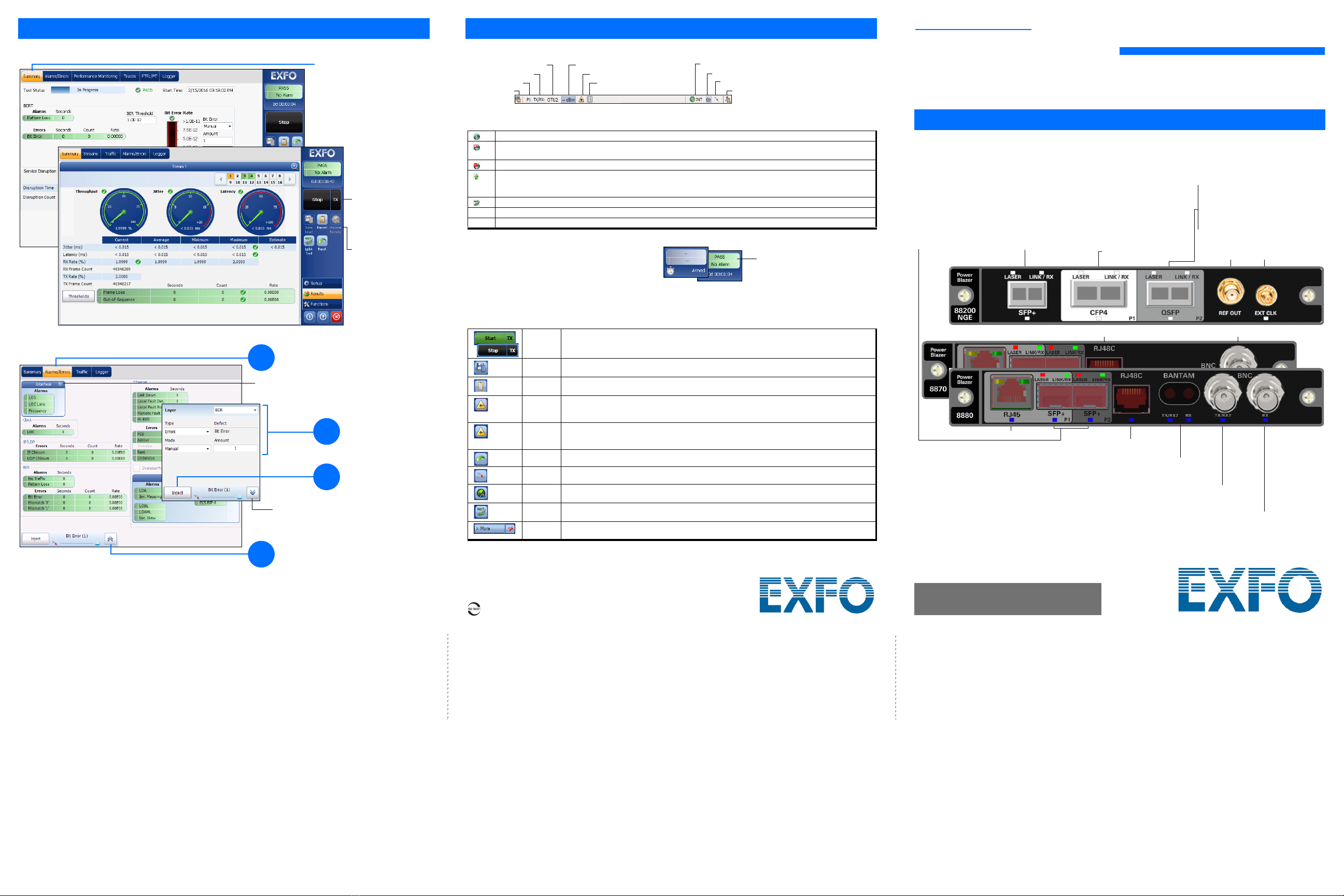

Getting Results

The Summary tab is automatically

displayed once the test is started.

Select a tab to get additional test

results.

Alarm/Error Injection

Test control buttons are

reconfigured according

to the test application

and status.

The Stop button is

displayed when the

test is running.

1Tap the Alarms/Errors tab.

3

Tap Inject.

Gives more information on this alarms/errors group.

Hides the alarm/error selection.

Status Bar

Additional Status Bar Symbols:

Test Control Buttons

Connection established between two testing units in Dual Test Set (DTS), EXFO|Worx Interop, or in Loop Up mode.

Connection not established between two testing units in Dual Test Set (DTS), EXFO|Worx Interop, or in Loop Up

mode.

Remote unit is busy (locked) in EXFO|Worx Interop operation mode.

LINK: Port link

PTP: 1588 PTP, PTP Frames

ESMC: SyncE, ESMC Frames

Loopback Tool (Only available with 8870/8880)

(BTS) CPRI, Base Station emulation mode

(RRH) CPRI, Remote Radio Head emulation mode

Start

Stop

TX

Starts test. Available when the test is not running.

Stops test. Available when the test is running.

Enables traffic generation and starts test. Available with Traffic Gen & Mon and eCPRI BERT.

Save

Load

Saves, loads, imports, exports, and deletes configuration file(s). Available when the test is not

running.

Report Saves, opens, imports, exports, and deletes test report(s). Available when the test is running or

stopped, but the report generation (save) is only possible when the test is stopped.

Laser (on) Indicates that the laser control is on (for at least one lane for parallel interface); the laser button

has a red border. Tapping this button will turn off the laser (for all lanes for parallel interface). Only

available with optical ports.

Laser (off) Indicates that the laser control is off (for all lanes for parallel interface). Tapping this button will

activate the laser immediately by emitting an optical laser signal (on all lanes for parallel

interface). Only available with optical ports.

Reset Clears results, statistics, and logger content. Available when the test is running.

Inject Injects alarms/errors based on settings from the Inject button from the Results - Alarms/Errors tab.

Discover

Remote

Discovers and connects to a remote module that loops back the traffic via Smart Loopback or

Dual Test Set (DTS).

Lpbk Tool Loops back the Ethernet frames/packets that are received on the port unused by the main test

application. Only available with 8870/8880.

More/

Less

The More/Less button appears when there is not enough room to display all available test control

buttons.

Tes t

Direction

Pattern Synchronization

Power Clock

Laser

Remote Control

Inject

Non-default OH

Interface/Signal

Port

Global Indicator Tap anywhere within the global

indicator area to view the

maximized view of these

indicators.

The global indicator displays the pass/fail verdict,

global alarm, timer, and/or test duration.

2Tap to select an alarm/error.

4

Select the alarm/error to

be injected and its

parameters.

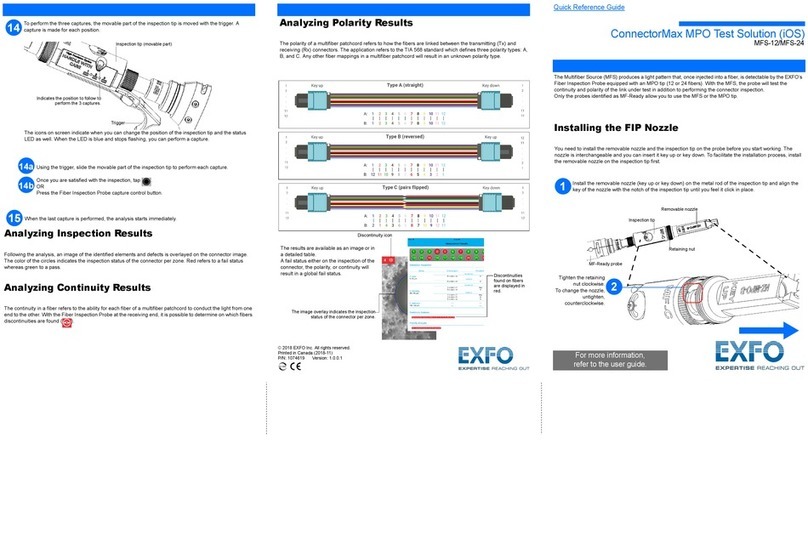

Quick Reference Guide

HIGH-SPEED MULTISERVICE TEST MODULE

© 2020 EXFO Inc. All rights reserved.

Printed in Canada (2020-02)

P/N: 1079326 Version: 9.0.0.1 For more information,

refer to the user guide.

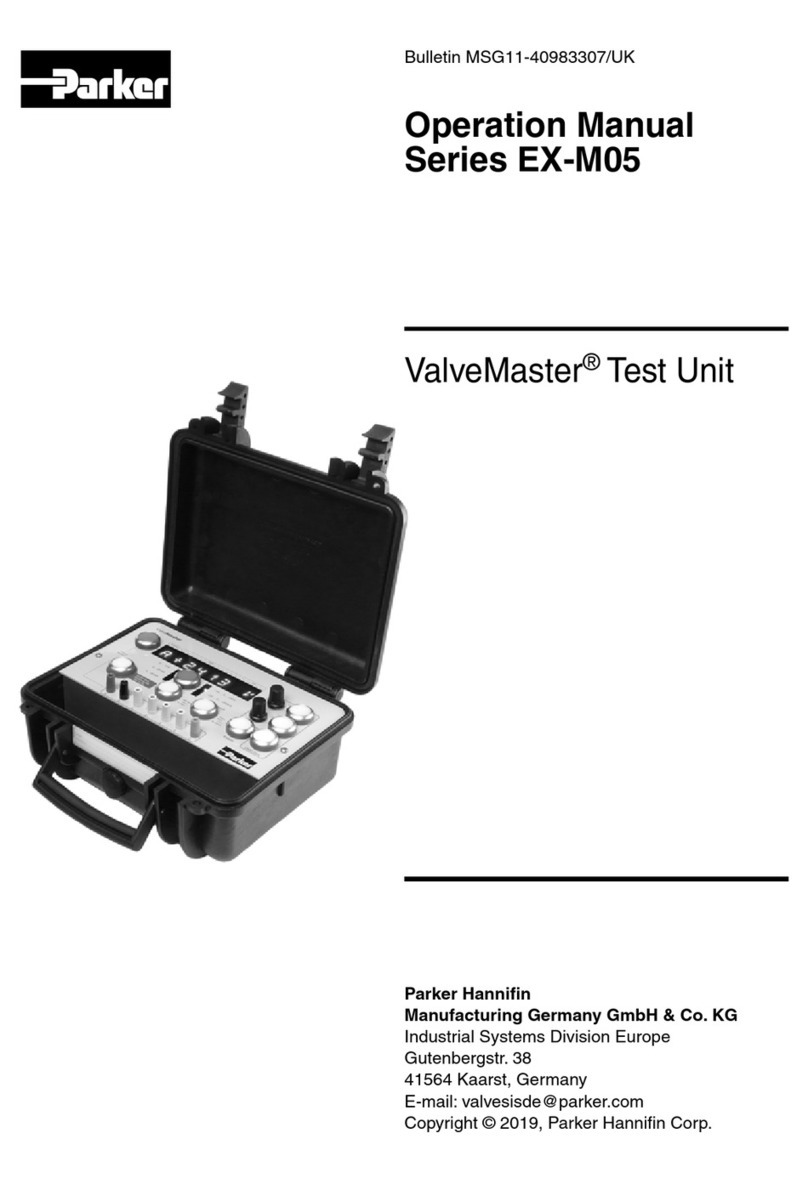

Physical Interfaces

TX: E1/2M, E3/34M, DS3/45M, STS-1e/STM-0e/52M, E4/140M, STS-3e/STM-1e/155M

RX2: DS3, 2 MHz, 10 MHz

Clock OUT: DS1/1.5M, E1/2M, 2MHz

Ethernet 10/100/1000 Mbit/s electrical

TX and RX: DS1/1.5M, E1/2M

RX2: DS1/1.5M

Clock IN/OUT: DS1/1.5M, E1/2M, 2MHz

E1/2M, E3/34M, DS3/45M, STS-1e/STM-0e/52M, E4/140M, STS-3e/STM-1e/155M, 1PPS, 2 MHz

Clock IN: DS1/1.5M, E1/2M, 2MHz, 10MHz, 1 PPS

DS1/1.5M, E1/2M, 1PPS, 2 MHz, 10 MHz

Clock IN/OUT: DS1/1.5M, E1/2M, 2MHz

External Clock:

DS1/1.5M, E1/2M,

2MHz, 1PPS

Reference

Output

QSFP+:

QSFP28:

QSFP56:

Ethernet 40 Gbit/s

OTU3e2, OTU3e1, OTU3

Ethernet 100 Gbit/s

OTU4

Ethernet 100 Gbit/s

1. Available on P1 for 88200NGE and on P2 for 8870/8880

2. Available on 88200NGE

Ethernet 100 Gbit/s

OTU4

Ethernet 100 Mbit/s, 1000 Mbit/s, 10 Gbit/s optical

Ethernet 10/100/1000 Mbit/s electrical (using active copper SFP)1

Fibre Channel 1X, 2X, 4X, 8X, 10X, 16X2

CPRI 1.2, 2.4, 3.1, 4.9, 6.1, 9.8, 10.1 Gbit/s

OBSAI 1.5, 3.1, 6.1 Gbit/s

OC-1/STM-0, OC-3/STM-1, OC-12/STM-4, OC-48/STM-16, OC-192/STM-64

OTU1, OTU2, OTU1e, OTU2e, OTU1f, OTU2f

Connect the signal to the corresponding interface on the module. For optical port, insert an EXFO supported

transceiver into the port’s slot then carefully connect optical fiber cables to the transceiver IN (RX) and OUT (TX)

ports.

DS1/1.5M, E1/2M Clock IN: DS1/1.5M, E1/2M, 2MHz, 1 PPS