17

Mōveo™ XP

4- TROUBLESHOOTING

4.1 MŌVEO™ XP TROUBLESHOOTING

A. General - Electronic

1. Information in this section with respect to

1. Information in this section with respect to

electronic components is intended to help

electronic components is intended to help

with troubleshooting the controller, actuators

with troubleshooting the controller, actuators

and wiring.

2. Procedures are provided to determine

2. Procedures are provided to determine

whether electrical components need to be

whether electrical components need to be

replaced.

3. Once it has been determined that a particular

3. Once it has been determined that a particular

part requires replacement, use only parts

part requires replacement, use only parts

obtained from Chattanooga Group.

obtained from Chattanooga Group.

B. General - Replacement Components

B. General - Replacement Components

1. Critical component replacement parts for

1. Critical component replacement parts for

the table are available as subassemblies only.

the table are available as subassemblies only.

Individual components of these

Individual components of these

subassemblies will not be made available by

subassemblies will not be made available by

Chattanooga Group.

C. General - Tests and Repair Procedures

C. General - Tests and Repair Procedures

1. Certain tests and repair procedures may

1. Certain tests and repair procedures may

require the use of special tools and/or fixtures.

require the use of special tools and/or fixtures.

These will be listed at the particular test

These will be listed at the particular test

where they are required. Testing with any

where they are required. Testing with any

other special tool or fixture other than those

other special tool or fixture other than those

stated could give erroneous readings or test

stated could give erroneous readings or test

results. Always perform the test exactly as

results. Always perform the test exactly as

stated to ensure accurate results.

stated to ensure accurate results.

2. Test equipment settings will be listed for each

2. Test equipment settings will be listed for each

test performed prior to the respective

test performed prior to the respective

test. This will ensure the test is performed to

test. This will ensure the test is performed to

Chattanooga Group standards and enable

Chattanooga Group standards and enable

proper readings.

D. Tools, Fixtures, and Equipment Required.

D. Tools, Fixtures, and Equipment Required.

• 1/4" Combination Wrench

• 7/16" Combination Wrench

• 9/16" Combination Wrench (2)

• 17mm Combination Wrench

• 3/8" Combination Wrench

• 6mm Allen Wrench

• 1/8" T-handle Allen Wrench

• Wire Cutters

• #20 TORX Wrench

• Flat Head Screwdriver

• #2 Phillips Head Screwdriver

• #1 Phillips Head Screwdriver

• Small Flat Head Screwdriver

Inspect the cushions of the table to verify they are

Inspect the cushions of the table to verify they are

in good condition, without rips or tears.

in good condition, without rips or tears.

With the caster lock bar in the horizontal position,

With the caster lock bar in the horizontal position,

verify all 4 casters move freely. Press the caster bar

verify all 4 casters move freely. Press the caster bar

down toward the foot end of the table and verify

down toward the foot end of the table and verify

only the wheel at the head end on the controller

only the wheel at the head end on the controller

side locks and the other 3 move freely. Press the

side locks and the other 3 move freely. Press the

caster lock bar toward the head end of the table

caster lock bar toward the head end of the table

and verify all of the casters are locked.

and verify all of the casters are locked.

Using the hand controller, raise the table to

Using the hand controller, raise the table to

full height. Lower the table below the brake

full height. Lower the table below the brake

connecting rod. Press the tilt up button on the

connecting rod. Press the tilt up button on the

hand controller and verify the table will not tilt

hand controller and verify the table will not tilt

when the height is below the connecting rod.

when the height is below the connecting rod.

Raise the height of the table above the connecting

Raise the height of the table above the connecting

rod and verify the table will tilt forward.

rod and verify the table will tilt forward.

Lower the table with the table tilted forward and

Lower the table with the table tilted forward and

verify the table will not go below the connecting

verify the table will not go below the connecting

rod in the tilted position. Lower the tilt on the

rod in the tilted position. Lower the tilt on the

table and verify the table will continue down past

table and verify the table will continue down past

the connecting rod.

Press the handle bar lever on the head section of

Press the handle bar lever on the head section of

the table. Verify the head section moves up and

the table. Verify the head section moves up and

down when the lever is pressed. Release the lever

down when the lever is pressed. Release the lever

and verify the table locks into place.

and verify the table locks into place.

Pull down on the Foot Plate lock knobs and verify

Pull down on the Foot Plate lock knobs and verify

the foot plates lower. Check each of the foot plates

the foot plates lower. Check each of the foot plates

to verify that when the lever is released, the foot

to verify that when the lever is released, the foot

plate locks into place. While holding the foot plate

plate locks into place. While holding the foot plate

in one hand, press the lever of each foot plate

in one hand, press the lever of each foot plate

release and reposition the foot plate.

release and reposition the foot plate.

Remove the Key pins from both sides of the table.

Remove the Key pins from both sides of the table.

Verify the carriage consisting of the back rest and

Verify the carriage consisting of the back rest and

pelvic section slide freely. Insert the Key pins into

pelvic section slide freely. Insert the Key pins into

the same location on each side of the table and

the same location on each side of the table and

verify the carriage will not slide past the key pins.

verify the carriage will not slide past the key pins.

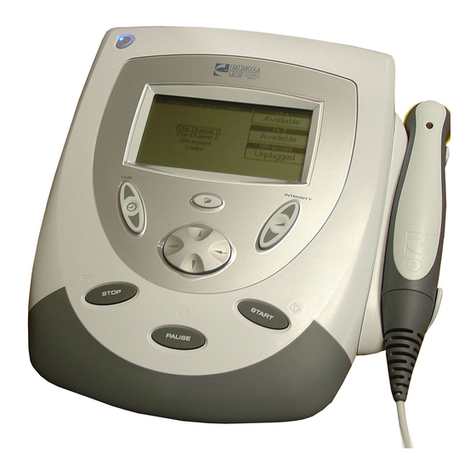

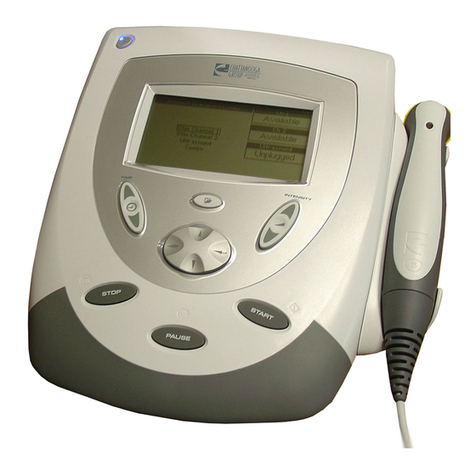

Inspect the casing of the controller for cracks or

Inspect the casing of the controller for cracks or

damage. Inspect the safety cover on the controller,

damage. Inspect the safety cover on the controller,

verify it closes properly and locks in place.

verify it closes properly and locks in place.

Remove the cover from the controller and inspect

Remove the cover from the controller and inspect

all of the cables plugged into the controller and

all of the cables plugged into the controller and

verify they are well seated. Inspect the terminal

verify they are well seated. Inspect the terminal

block and verify all of the screws holding the wires

block and verify all of the screws holding the wires

are secure.

If a battery is present, disconnect the battery

If a battery is present, disconnect the battery

from the controller and inspect the connections.

from the controller and inspect the connections.

Verify the condition of the battery and inspect for

Verify the condition of the battery and inspect for

corrosion.

4.2 VISUAL INSPECTION