check-all Valve EPIC User manual

CHEC

K

-ALL VALVE MFG. CO.

1800FullerRd.WestDesMoines,IA50265

PH:(515)224‐2301Fax:(515)224‐2326

ISO9001CERTIFIED

EPIC™

INSTALLATION & OPERATION Manual

WARNING:READALLOFTHESEINSTRUCTIONSBEFOREPROCEEDING.ONLYEXPERIENCEDPERSONNELSHOULDBEALLOWEDTOINSTALLORHANDLETHEENCLOSEDVALVE(S).ANYDAMAGE

RESULTINGFROMMISHANDLINGORIMPROPERINSTALLATIONISNOTCOVEREDBYTHEMANUFACTURER’SWARRANTY.FORWARRANTYDETAILS,REFERTOTHELATESTREVISIONOF

CHECK‐ALLVALVE®MANUFACTURINGCOMPANYMANUFACTURER’STERMSANDCONDITIONS(Form#160).SEEwww.checkall.comORREQUESTACOPYFROMTHEFACTORY.Form#106B

The EPIC™is an in-line spring loaded poppet-type

check valve that is designed to be simple, rugged, and

efficient in any flow orientation. It is streamlined so

that media flows through the valve over smooth

contoured surfaces with a minimum change in

direction. This minimizes the pressure drop across

the valve. The patent pending EPIC™features a

complete drop in Replaceable Insert that is

engineered for silent operation. The valve closes

quickly and smoothly to minimize fluid hammer.

The following instructions are meant as a guideline

only. They do not cover every situation and rely on

the common sense and expertise of the person

installing the valve. See also checkall.com/EPIC for

an Assembly/Disassembly video. In no way is

Check-All®liable for any damage to the valve, the

system, or for personal injury resulting from use of

these guidelines.

INSTALLATION

Prior to installation remove any end caps and inspect

the valve(s) for any damage, internal debris or loose

parts that may have occurred during shipment.

Orient the valve so the FLOW ARROW is pointing

in the direction of desired flow (Fig. 1). From the

closed position the POPPET moves away from the

SEAT in the direction of flow (Fig. 2).

Connect the valve inlet and outlet to the system.

Care should be taken to prevent disassembling

the valve body. After the valve has been installed

verify that it is properly supported to prevent

additional loading on the valve body.

To avoid personal injury, take appropriate

precautionary measures if the system contains

hazardous materials. Discharge, depressurize, and

drain the surrounding system prior to removing the

valve from service. If the media within the system is

colder or hotter than room temperature allow the

valve to return to room temperature before removing

from the system.

While holding the valve ends disconnect it from the

system. Care should be taken to prevent

disassembling the valve body.

Clean the valve to remove any thread sealant, tape,

debris and/or hazardous materials prior to

preforming maintenance, inspection and/or re-

installation.

Table 1

EPIC™Kits

Valve Part Number Replaceable Insert

Kit Part Number

EPIC-0125, all styles

EPIC-0250, all styles

EPIC-0375MP

EPIC-0375FT

EPIC-0375DF

EPIC-RKD

EPIC-0375FP

EPIC-0500MP

EPIC-0500DF

EPIC-0500FT

EPIC-RKF

EPIC-0500FP

EPIC-0750MP

EPIC-0750DF

EPIC-0750FT

EPIC-RKH

EPIC-0750FP

EPIC-1000MP

EPIC-1000DF

EPIC-1000FT

EPIC-RKI

EPIC-1000FP

EPIC-1250MP EPIC-RKJ

Scan here

for Online

Ordering

Insert kits come with

a replaceable insert,

insert o-ring, and

body o-ring

Fig. 2: Vertical Flow Up Orientation

(Example Only)

INLETENDOUTLET END

Fig. 1: Horizontal Orientation

(Example Only)

FLOWARRO

W

REMOVAL

CHEC

K

-ALL VALVE MFG. CO.

1800FullerRd.WestDesMoines,IA50265

PH:(515)224‐2301Fax:(515)224‐2326

ISO9001CERTIFIED

EPIC™

INSTALLATION & OPERATION Manual

WARNING:READALLOFTHESEINSTRUCTIONSBEFOREPROCEEDING.ONLYEXPERIENCEDPERSONNELSHOULDBEALLOWEDTOINSTALLORHANDLETHEENCLOSEDVALVE(S).ANYDAMAGE

RESULTINGFROMMISHANDLINGORIMPROPERINSTALLATIONISNOTCOVEREDBYTHEMANUFACTURER’SWARRANTY.FORWARRANTYDETAILS,REFERTOTHELATESTREVISIONOF

CHECK‐ALLVALVE®MANUFACTURINGCOMPANYMANUFACTURER’STERMSANDCONDITIONS(Form#160).SEEwww.checkall.comORREQUESTACOPYFROMTHEFACTORY.Form#106B

DISASSEMBLY

Orient the valve to the VERTICAL FLOW UP

position (Fig. 2). Hold the Inlet End and unthread

the OUTLET from the INLET and set aside (Fig. 3).

Remove the REPLACEABLE INSERT from the

INLET (Fig 3). Clean to remove any debris that may

be present. Inspect the SEAT (Fig. 2) for debris,

dings, scratches and/or tears. Replace as needed

(See Table 1 for Insert Kits).

Remove the INSERT O-RING from the INSERT

GROOVE (Fig. 3) and replace.

Remove the BODY O-RING from the BODY

GROOVE (Fig 3) and replace.

Clean the INLET and OUTLET to remove any

thread sealant, tape, debris and/or hazardous

materials that may be present.

ASSEMBLY

Orient the INLET to the VERTICAL FLOW UP

position. Insert the BODY O-RING into the BODY

GROOVE (Fig 3). Verify that the o-ring is positioned

correctly in the groove and is free from debris, dings,

scratches and/or tears.

Place the INSERT O-RING into the INSERT

GROOVE (Fig 3). Verify that the o-ring is

positioned correctly in the groove and is free from

debris, dings, scratches and/or tears.

Place the REPLACEABLE INSERT onto the

INLET face so that the YOKE goes inside of the

INLET and the POPPET is exposed (Fig 2 &3).

Note: The Replaceable Insert will self-center within

the INLET and OUTLET when assembled.

CAUTION: The Replaceable Insert can be

installed backwards which will prevent flow

and/or result in damage to the valve. VERIFY

THAT THE REPLACEABLE INSERT IS

INSTALLED CORRECTLY BEFORE

PROCEEDING.

Hold the INLET stationary in the VERTICAL

FLOW UP position. Tighten the two body

components to the appropriate torque for your

individual application requirements. (Fig 3). Note:

Thread lubricant may be required to prevent thread galling.

WARNING: DO NOT CHANGE THE VALVE

ORIENTATION UNTIL THE VALVE HAS

BEEN COMPLETELY ASSEMBLED.

CAUTION: Improper seating of components will

result in failure of the valve and/or diminish the

life of the Replaceable Insert and/or o-rings.

Scan here for Express Line homepage

Fig. 3: Expande

d

Assembl

y

Popular Control Unit manuals by other brands

Ei Electronics

Ei Electronics EIB600MRF instructions

Trinamic

Trinamic TMCM-1021 TMCL manual

Applanix

Applanix POS AVX 210 user guide

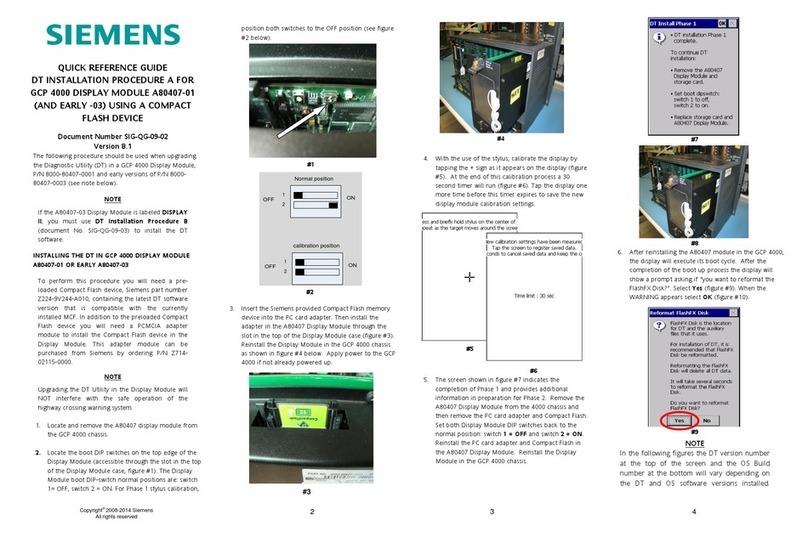

Siemens

Siemens A80407-01 Quick reference guide

Panasonic

Panasonic GPKS822H - COLOR CAMERA HEAD operating instructions

Siemens

Siemens SIRIUS ACT 3SU1803-3NB00-1AE1 Original operating instructions

Salto

Salto CU5000 quick guide

National Instruments

National Instruments NI 9214 manual

FARFISA INTERCOMS

FARFISA INTERCOMS PL10PED manual

Cooper Lighting

Cooper Lighting WaveLinx WOLC Wiring and installation manual

Bosch

Bosch Security Systems Blue Line A1-CC quick start guide

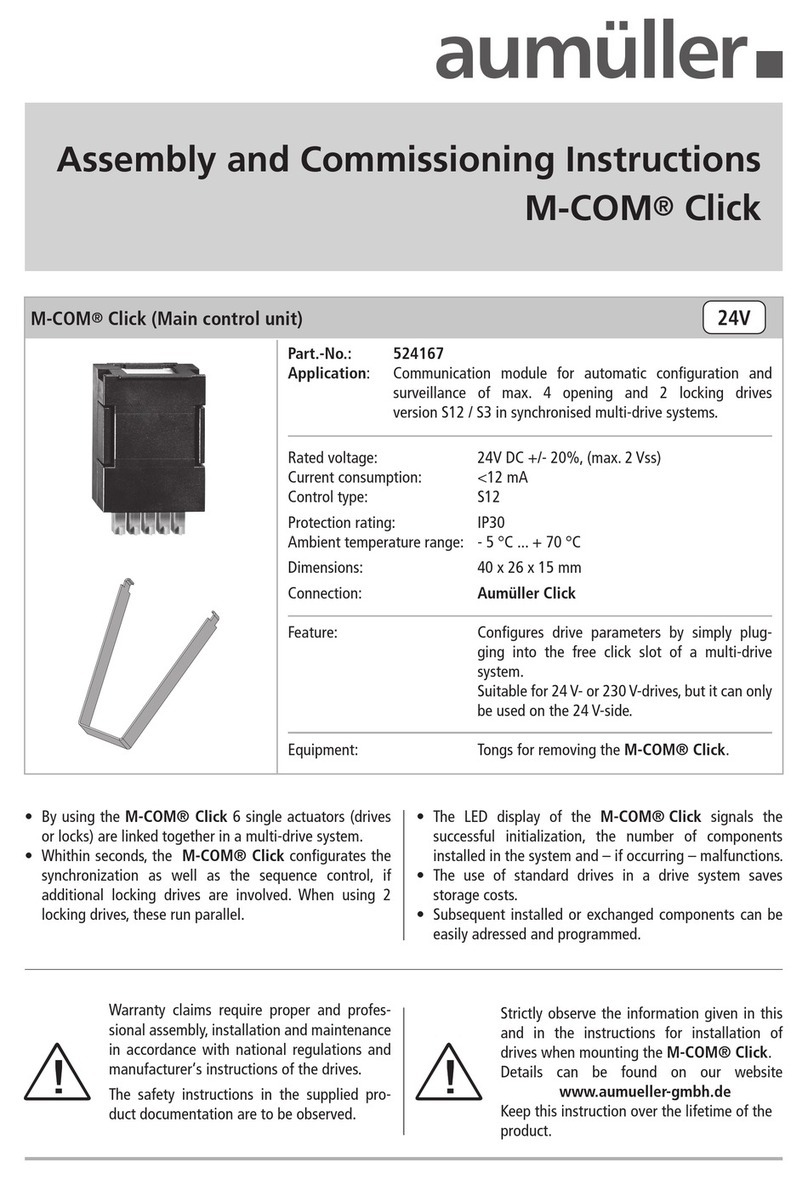

Aumuller

Aumuller M-COM Click Assembly and commissioning instructions