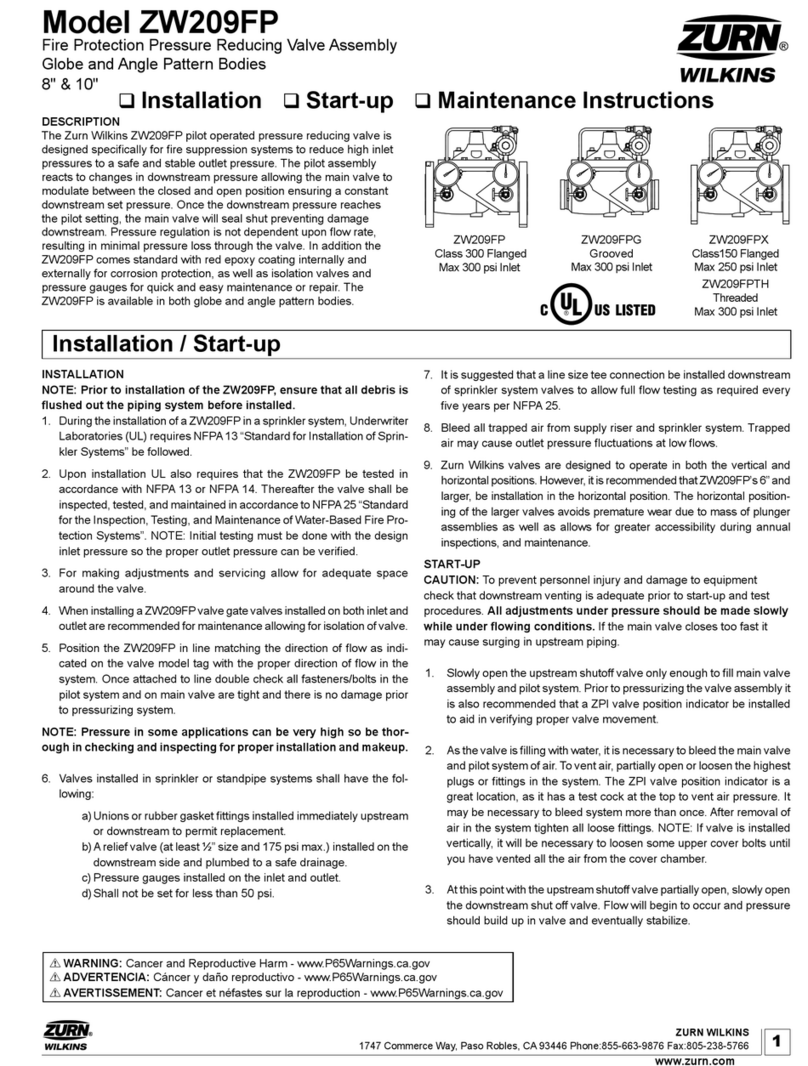

Installation Troubleshooting Maintenance Instructions

Model ZW204

Non-Modulating Float Valve

1 1/4", 1 1/2", 2", 2-1/2", 3", 4", 6", 8" & 10"

to the inlet of the main valve. Port A should be connected to the

main valve cover (or accelerator pilot cover if installing an 8 or

10 inch valve.)

Note: When mounting the oat pilot above the main valve,

verify pressure at the oat pilot is 5 psi or greater to ensure

proper operation.

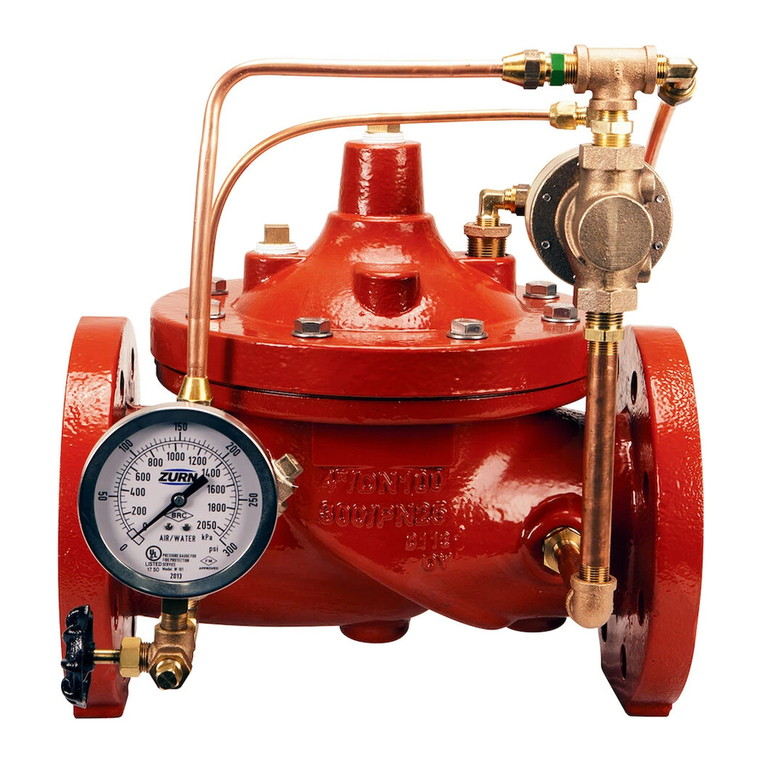

7. Zurn Wilkins valves are designed to operate in both the verti-

cal and horizontal positions. However, it is recommended that

ZW209 6” and larger, be installation in the horizontal position.

The horizontal positioning of the larger valves avoids premature

wear due to the mass of plunger assemblies as well as allows

for greater accessibility during annual inspections, and mainte-

nance.

START-UP

CAUTION: To prevent personnel injury and damage to

equipment check that downstream venting is adequate pri-

or to start-up and test procedures. If the main valve closes

too fast it may cause surging in upstream piping.

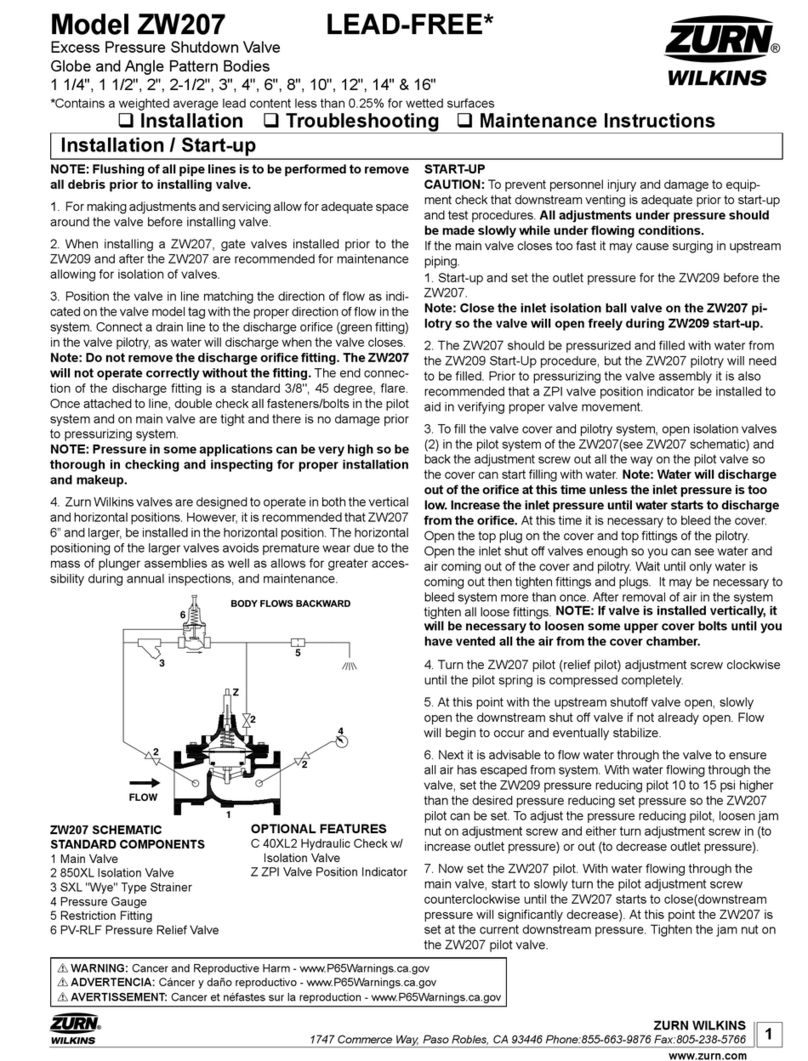

1. Open isolation valves (2) in the pilot system (see ZW204

schematics).

2. Slowly open the upstream shutoff valve only enough to ll

main valve assembly and pilot system. Prior to pressurizing the

valve assembly it is also recommended that a ZPI valve position

indicator be installed to aid in verifying proper valve movement.

3. As the valve is lling with water, it is necessary to bleed the

main valve and pilot system of air. To vent air, partially open or

loosen the highest plugs or ttings in the system. The ZPI valve

position indicator is a great location, as it has a test cock at the

top to vent air pressure. It may be necessary to bleed system

more than once. After removal of air in the system tighten all

loose ttings.

4. If valve is equipped with speed controls (O or L on ZW204

schematic) it is necessary to back out the set screw a minimum

of 3 turns from initial set point.

5. At this point with the upstream shutoff valve partially open,

slowly open the downstream shut off valve. Flow will begin to

occur and pressure should build up in valve and eventually

stabilize.

6. Next it is advisable to ow water through the valve to ensure all

air has escaped from system.

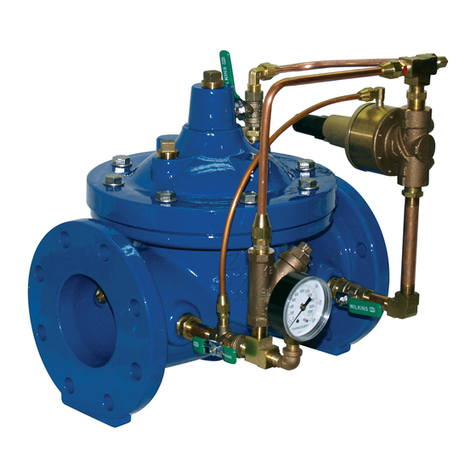

DESCRIPTION

The Zurn Wilkins Model ZW204 Non-Modulating Float Operated

Control Valve is an automatic control valve designed to be fully

open or fully closed in response to the position of the oat. The

oat ball will be placed in a tank where it will be raised or lowered

by the uid level. The valve will be fully open when the uid level is

at a preset low point and will fully close when the uid level is at a

preset high point. If the oat valve is being used to ow water out

of instead of into the reservoir, the oat pilotry can be congured

to have the valve fully open at a preset high point and fully closed

at a preset low point. If desired, switch line from port A to B on

the oat valve and plug port A. The Float Pilot valve is set up for

remote liquid level control as standard. With the VM option, the

oat pilot can be mounted on the valve.

NOTE: Flushing of all pipe lines is to be performed to remove

all debris prior to installing valve.

1. Install a control valve, orice, or other ow restricting device

downstream of the ZW204 if discharge pressure is greater than

20 psi. This will prevent the valve from exceeding maximum

ow, cavitating, or causing other damage to valve or system

from high water velocities.

2. For making adjustments and servicing allow for adequate space

around the valve before installing valve.

3. When installing a ZW204, gate valves installed on both inlet and

outlet are recommended for maintenance allowing for isolation of

valve.

4. Position the main valve in line matching the direction of ow as

indicated on the valve model tag with the proper direction of ow

in the system. Once attached to line, double check all fasteners/

bolts in the pilot system and on main valve are tight and there is

no damage prior to pressurizing system.

NOTE: Pressure in some applications can be very high so be

thorough in checking and inspecting for proper installation

and makeup.

NOTE: Upstream pressure should be at least 10 psi greater

than downstream hydrostatic pressure when valve is

closed.

5. The oat ball and rod assembly must be mounted in the verti-

cal position above the water in a tank or reservoir.

Note: A stilling well is required to surround the oat in

tanks or reservoirs which are subject to waves of any kind.

Verify oat has adequate clearance to move freely in all

oat positions.

6. Go to step 7 if installing a ZW204 with valve mounted pilot.

When installing a ZW204 with remote pilot, route tubing from

the main valve to the oat valve according to the schematic dia-

grams on page 3. Port P on the oat valve should be connected

Installation / Start-up

®

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766 1

www.zurn.com

®