CHESTER 626 TURRET MILL User manual

626 TURRET MILL

OPERATION MANUAL

Chester Machine Tools

Hawarden Industrial Park,

Hawarden,

Chester,

CH5 3PZ.

Tel: 01244 531631

Fax: 01244 531331

Email:[email protected]

Website: www.chestermachinetools.com

Page | 2

Page | 3

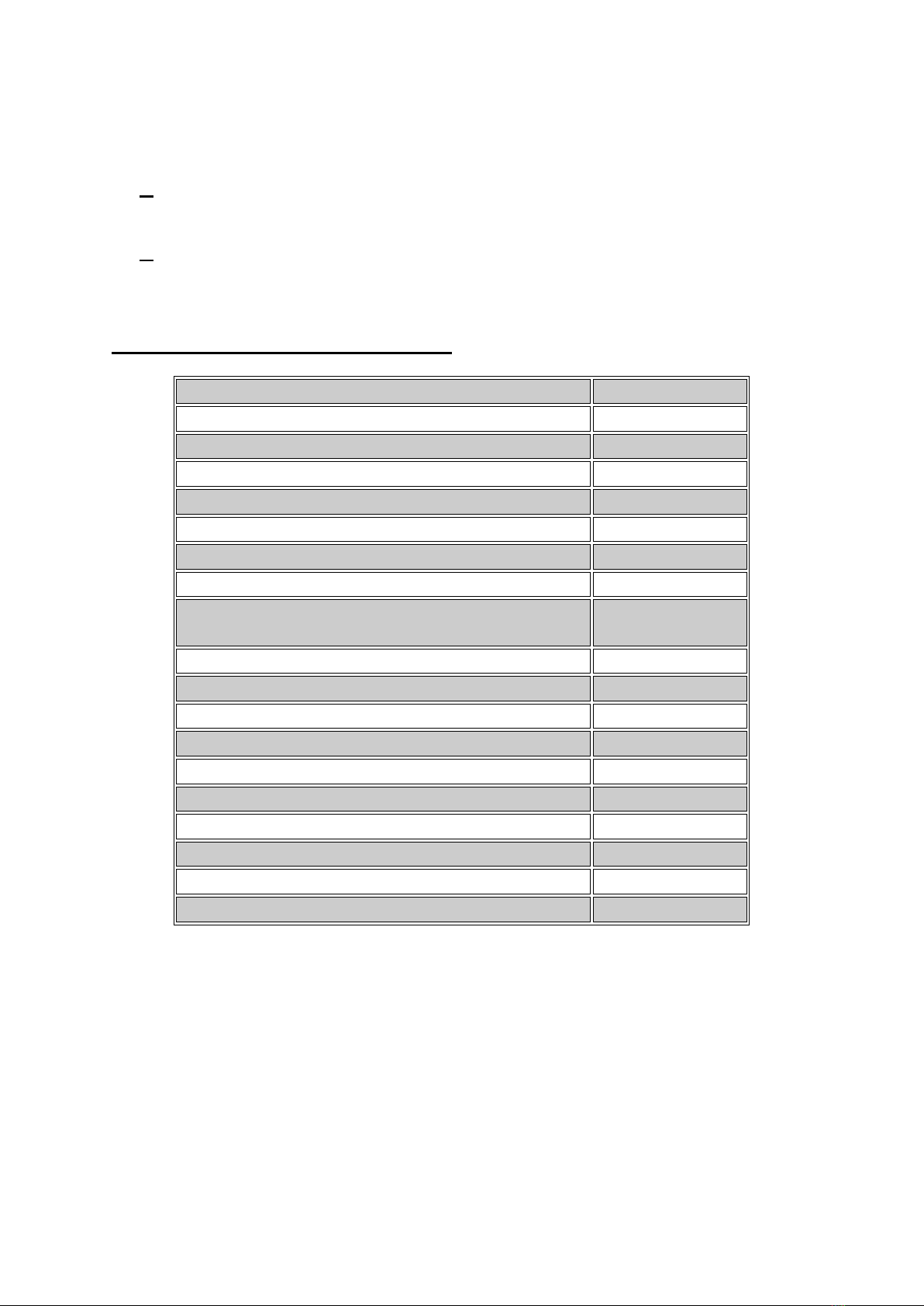

CONTENTS

1. Introduction

3

2. Health &

Safety

4 –5

3. Machine

Specification

6

4. Main

Applications &

Features

7-8

5. Wiring

Diagram

9

6. Part Diagrams

10-11

7. Part List

12-13

8. Inspection

Record

14

9. CE

Certificate

15

Page | 4

INTRODUCTION

Chester UK Limited is a specialist company that has been supplying the machine tool

industry for over 15 years. The Chester UK Head Office comprises of a 30,500 sq.ft factory complete

with offices and a showroom. Specialising in conventional machine tools, Chester has built a

reputation for quality and reliability, which is highly regarded in the machine tool industry and the

model engineering market.

There are several divisions within the company; Export, Education, Model Engineering & UK

Sales, all with dedicated sales personnel who are trained to answer your questions.

When buying from Chester you can be assured of a complete back-up service with

mechanical and electrical engineers that are available to give advice if required.

Stock is a large part of any business and Chester have always invested substantially in

building a large quantity of machines and spares, ready to satisfy customer requirements. Chester UK

has one of the largest stocks of conventional new machines and accessories within Great Britain.

Please take time to visit our website: www.chestermachinetools.com

Page | 5

HEALTH AND SAFETY

As with all machinery there are certain hazards involved with the operation and use of the

lathe. Using the machine with respect and caution will considerably lessen the possibility of person

injury. However, if normal safety precautions are overlooked or ignored, personal injury to the

operator may result.

This machine was designed for certain applications only. We strongly recommend that the machine is

not modified, and / or used for any application other than which it was designed. If you have any

questions relative to its application do not use the machine, until you have first been in contact

with Chester UK.

The lathe may not arrive with a power socket or plug. In the event of this happening, please inform

Chester UK on Tel: (01244) 531 631.

Safety rules for all tools

User

1. Wear correct apparel

No loose clothing, gloves, rings, bracelets or other jewellery to get caught in moving parts.

Non-slip footwear is recommended. Wear protective hair covering to contain long hair.

2. Always wear eye protection

Refer to ANSLZ87.1 standard for appropriate recommendations. Also use face and / or a dust

mask if the cutting operation is dusty.

3. Don’t overreach

Keep a proper footing and balance at all times.

4. Never stand on a tool

Serious injury could occur if the tool is tipped or if the cutting tool is accidentally contacted.

5. Never leave the tool running unattended

Turn power off. Leave tool until it comes to a complete stop.

6. Drugs, alcohol and medication

Do not operate the tool while under the influence of drugs, alcohol or any medication.

7. Make sure the tool is disconnected from the power supply

While motor is being mounted, connected or reconnected.

8. Always

Keep hands and fingers away from any moving parts.

9. Stop

The machine before moving chips.

10. Shut-off

Power and clean the lathe and work area before leaving the machine.

Use of the machine

1. Remove adjusting keys and wrenches

Form a habit of checking to see that keys and adjusting wrenches are removed from the tool

before turning it ‘on’.

2. Don’t force the tool

It will do the job better and be safer at the rate for which it was designed.

3. Use the right tool

Don’t force the tool or attachment to do a job for which it was not designed.

4. Secure work

Use clamps or a vice to hold work when practical. It’s safer than using your hands, and frees

both to operate the machine.

3

Page | 6

5. Maintain tools in top condition

Keep tools sharp and clean for the best and safest performance. Follow instructions

for lubricating and changing accessories.

6. Use recommended accessories

Consult Chester UK for recommended accessories. The use of improper accessories

may cause hazards.

7. Avoid accidental starting

Make sure the switch is in the ‘OFF’ position before plugging in power cord.

8. Stop

The machine before putting material in the vice.

9. Always

Have stock firmly clamped in the vice before starting the cut.

10. Ground all tools

If the tool is equipped with a three-prong plug, it should be plugged into a three-hole

electrical receptacle. If an adapter is used to accommodate a two-prong receptacle, the

adapter plug must be attached to a known ground. Never remove the third prong.

Adjustment

Make all adjustments with the power off. When assembling follow the manuals

instructions, this will ensure correct instruction and a safe structure.

Working environment

1. Keep the work area clean

Cluttered areas and benches invite accidents.

2. Don’t use in a dangerous environment

Don’t use power tools in damp or wet locations, or expose to rain. Keep the work area

well lit.

3. Keep children etc at a safe distance.

All children etc should be kept at a safe distance from the work area.

4. Don’t

Install & use this machine in an explosive dangerous environment.

Maintenance

1. Disconnect

Machine from the power source when making repairs.

2. Check damaged parts

Before further use of the tool, a guard or other part that is damaged should be

carefully checked to ensure that it would operate properly and perform its intended

function check for alignment of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation. A guard or

other part that is damaged should be properly repaired or replaced.

3. Disconnect tools

Before servicing and when changing accessories such as blades bits, cutters, etc.

4. To prevent

The corrosion of machined surfaces when a soluble is used as coolant, pay particular

attention to wiping dry the surfaces where fluid accumulates and does not evaporate

quickly, such as between the machine bed and vice.

Page | 7

Safety Device

1. Interlock switch on pulley cover. As soon as the pulley cover is open, the machine

will come to a stop with the function of this switch. Do not remove this switch

from the machine for any reason, and check it’s function frequently.

2. Interlock switch on cutting area. As soon as the pulley cover is open, the machine

will come to a stop with the function of this switch. Do not remove this switch

from the machine for any reason, and check it’s function frequently.

MACHINE SPECIFICATIONS

Drilling Capacity

32mm

End Milling Capacity

25mm

Face Milling Capacity

75mm

Table Size

156x745mm

Longitudinal Travel

365mm

Cross Travel

135mm

Max. Distance Spindle to Table

330mm

Distance between Spindle & Column

155mm

Head Tilt

45 deg Left or

Right

Knee Travel

330mm

T’ Slot Size

14mm

Number of Spindle Speeds

9

Spindle Speed Range

190 – 2100rpm

Spindle Stroke

80mm

Spindle Taper

MT3 or R8

Motor

1½hp

Supply

240volt or 415volt

Dimensions (WxDxH)

1085x990x1710mm

Weight

410Kgs

Page | 8

FEATURES AND MAIN APPLICATIONS

Features

The 626-turret mill is a compact vertical milling machine, easy to set up, with controls

designed for easier operation (dual hand wheels).

A practical machine that can be easily used for technical schools, small parts production, tool

rooms, R&D work, maintenance shops and even hobby use.

Ideally suited for many operations: conventional milling, compound angle milling, engraving,

drilling as well as jig boring.

The ‘ways’ are hand scraped for a perfect bearing alignment, as well as the table being

ground for a perfect square ness.

All high castings are made of a high strength material. They are aged for several months

before normalizing and tempering, to minimize deformation.

Installation

To set the machine on a solid concrete foundation, it is advisable to apply a little grout to

touch up any unevenness in the concrete in order to get a solid foundation at all points.

When setting the machine on a floor that has any surface irregularities, shims should be used

to correct.

Pre-lubrication

Thoroughly clean the machine with gasoline or kerosene, and then lubricate all the slide ways

with S.A.E. #10 & gears with S.A.E. #30 lubricant. Be sure the machine is lubricated

properly before starting.

Page | 9

Levelling

Set the machine by levelling the worktable lengthwise & crosswise, with a precision levelling

instrument (refer to the test readings in the attached test records).

Inspection

Inspect the machine with the attached original testing records for reference.

Switch box

The switch box is located on left side of the column, for the On – Off only.

Adjustment of the table feed travel

The table longitudinal and cross feed travel, can be set for any travel distance by simply

adjusting the stop set screws that are located in front of the table and at the right side of the

knee.

Adjustment of the table gib

The table is provided with a full-length tapered gib in the saddle with an adjustable screw at

each end. To take up gib, tighten the two screws until a slight drag is felt (when moving the

table by hand).

If the table is not tight enough, loosen the adjusting screw on the small end, and then tighten

on the big end.

If, after completing this process, you feel that the table gib is too tight, simply reverse the

above procedure.

Adjustment of saddle & knee gibs

To tighten the gibs, use the same method as previously described in the ‘Adjustment of the

table gib’.

Clamping the table, saddle & knee

When milling with the longitudinal table feed, it is advisable to clamp the knee with the

column and saddle, this will add rigidity to allow for heavier cuts with a minimum of

vibration.

The saddle-locking lever is located on the left hand side of the saddle (to the operator),

applying a clamping pressure will hold the saddle rigid.

The table clamping levers are located in front of the saddle, and should always be clamped

when a longitudinal movement is not required.

The knee-clamping lever is at the left side of the knee, leave this clamped at all times unless

the knee is in operation.

Removing the table

Remove the table as follows: hand-wheel, dial holder, turn the lead screw all the way, so that

it can be removed.

Page | 10

Then the table can be disassembled quite easily.

Mounting the motor & shifting the belts for speed

The motor is mounted on a plate hinged to the pulley housing. Release the belt setting unit by

turning the handle at the side of the motor, and then shift the belts to the required speed.

Retighten and use. A speed chart is supplied for your reference.

Quill lock & vertical feed

The handle at the right lower corner of the head is called the quill lock. When the vertical

feed is not in use, set the handle to lock the quill and make the head more stable.

The micrometer depth is graduated in inches. By utilizing these simple graduations, it is

possible to work accurately to different depths.

A lock nut under the micrometer nut, assures that the micrometer nut is secured.

Quill clutch of the vertical head

The vertical feed is controlled via a hand wheel at the front of the head, as well as a handle at

the right side of the head.

When the hand wheel is in use, tighten the clutch lock nut, or loosen for handle operation.

The hand-wheel for fine feeds, handle for fast feeds.

Vertical head and tee adapter

The vertical milling head can be tilted 90° on either side; this can be accomplished by

loosening the four locking bolts on the tee adapter.

Loosen the two set bolts on the adapter; you can then swivel the vertical milling head 120°,

tighten the bolts once the correct position is achieved.

The motor and milling head must tilt together, simply because the motor & head are suspend

on the same pulley housing.

Page | 11

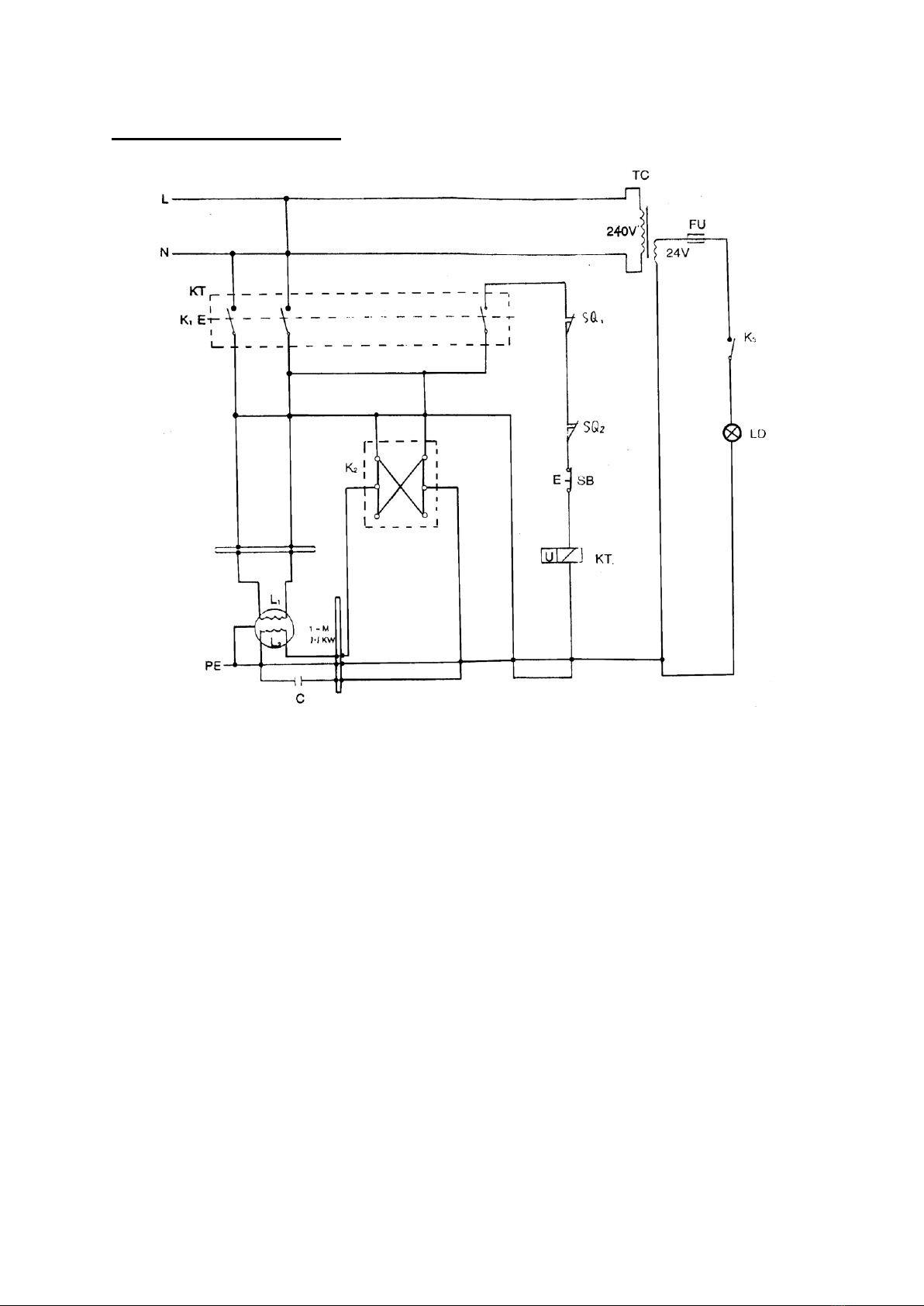

WIRING DIAGRAM

Page | 12

PART DIAGRAMS

Page | 13

Page | 14

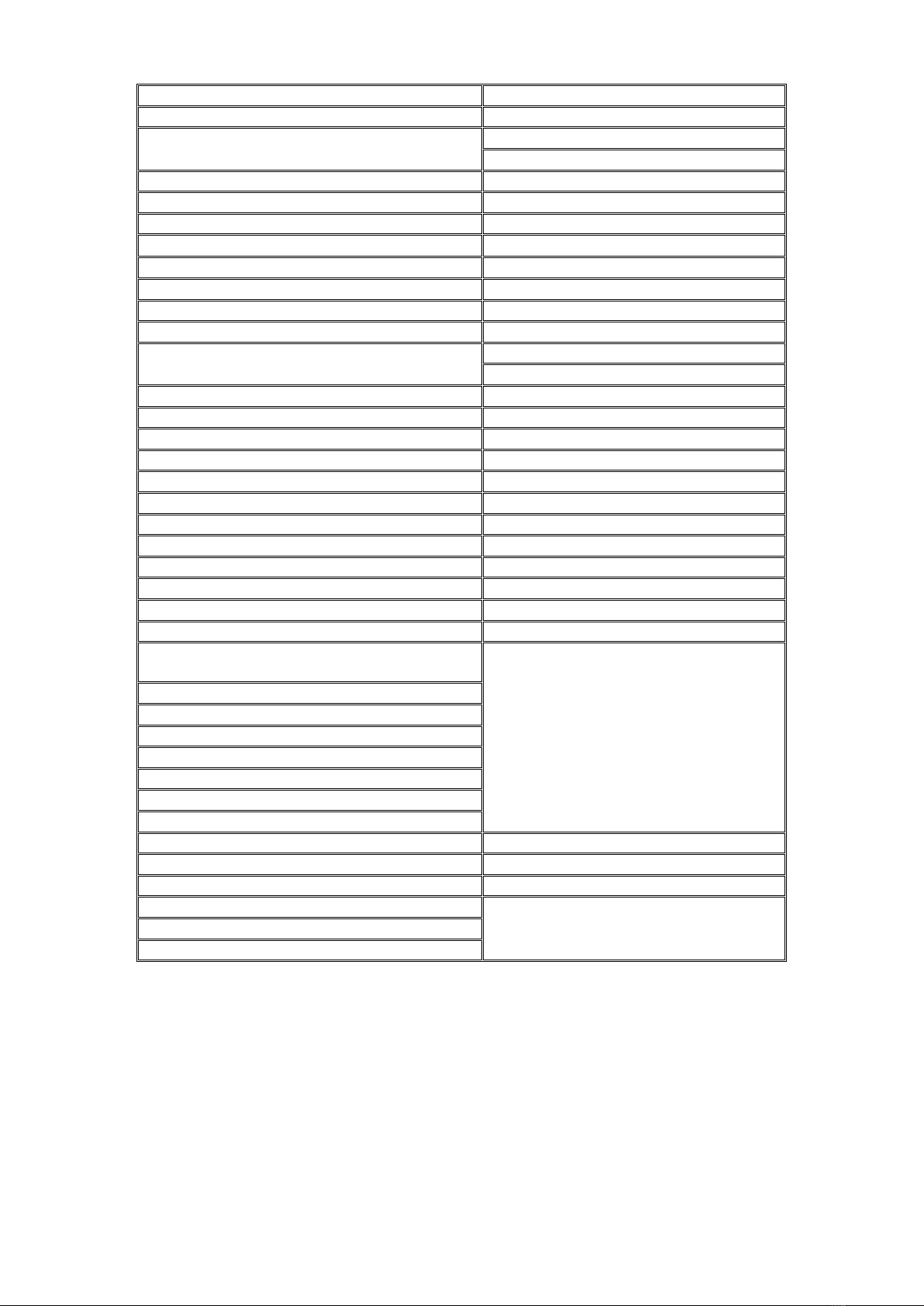

PARTS LIST

S/N P/N DESCRIPTION

S/N P/N DESCRIPTION

1. 250-S-IYT-1001 Vertical milling head

39. 250-S-IYT-M5x10 Screw

2. 250-S-IYT-1095 Belt housing cover

40. 250-S-IYT-T1089 Pulley cover supporting arm

3. 250-S-IYT-1005 Quill

41. 250-S-IYT-M5 Nut

4. 250-S-IYT-S-45-1010 Snap ring

42. 250-S-IYT-1016 Washer for bearing

5. 250-S-IYT-1007 Spring washer

43. 250-S-IYT-7207-1003 Bearing

6. 250-S-IYT-1002 Vertical Spindle

44. 250-S-IYT-6007zz-1003 Bearing

7. 250-S-IYT Cover

45. 250-S-IYT-6206z-1003 Bearing

8. 250-S-IYT-1008 Bearing adjusting nut

46. 250-S-IYT-1082 Bearing cover

9. 250-S-IYT-1009 Spindle sleeve

47. 250-S-IYT-R-75-1012 Snap ring

10. 250-S-IYT-1016 Pulley locking nut

48. 250-S-IYT-6009z-1011 Bearing

11. 250-S-IYT-1018 Spindle pulley

49. 250-S-IYT-1052 Thrust bearing

12. 250-S-IYT-1019 Quill pinion shaft

50. 250-S-IYT-1037 Spring

13. 250-S-IYT-1047-M5x10 Screw

51. 250-S-IYT-1020 Spring

14. 250-S-IYT-1036 Clutch worm gear

52. 250-S-IYT-E-19 Snap ring

15. 250-S-IYT-1039 Clutch

53. 250-S-IYT-M6x15-1038 Bolt

16. 250-S-IYT-1040 Clutch adjusting nut

54. 250-S-IYT-1076 Swivel arm

17. 250-S-IYT-1046 Clutch cover

55. 250-S-IYT-1075 Swivel stud

18. 250-S-IYT-1021 Pinion shaft seal

56. 250-S-IYT-R-35 Snap ring

19. 250-S-IYT-1032 Ball handles

57. 250-S-IYT-1079 Pulley pivot stud

20. 250-S-IYT-1028 Hand bar holder seat

58. 250-S-IYT-1080-58 Idle pulley

21. 250-S-IYT-1030 Handle bar

59. 250-S-IYT-1080-59 Motor pulley

22. 250-S-IYT-1051 Worm shaft

60. 250-S-IYT-1067 Motor mounting

23. 250-S-IYT-1053 Worm shaft sleeve

61. 250-S-IYT-1068 Motor suspending pivot

24. 250-S-IYT-1055 Nut for bearing

62. 250-S-IYT-1070 Motor mounting

25. 250-S-IYT-1056 Dial

63. 250-S-IYT-1072 Motor set unit handle

26. 250-S-IYT-1060 Dial positioning screw

64. 250-S-IYT-1071 Belt set unit

27. 250-S-IYT-1057 Hand wheel

65. 250-S-IYT-1071 Belt set unit

28. 250-S-IYT-1061 Handle

66. 250-S-IYT-1064 Vertical head adapter

29. 250-S-IYT-1048 Quill locking block

67. 250-S-IYT-1067-10Mx35 Screw

30. 250-S-IYT-1049 Quill locking bolt

68. 250-S-IYT-10M Bolt washer

31. 250-S-IYT-1042 Quill stop micro screw

69. 250-S-IYT-A35-1102 Vee belt

32. 250-S-IYT-1044 Micrometer nut

70. 250-S-IYT-10M Nut

33. 250-S-IYT-1045 Quill micro stop nut

71. 250-S-IYT-6003z-1081 Bearing

34. 250-S-IYT-1041 Quill stopper

72. 250-S-IYT-A32-1101 Vee belt

35. 250-S-IYT-8Mx20 Screw

73. 250-S-IYT-1HP4-POLE-1073 Motor

36. 250-S-IYT Bolt washer

74. 250-S-IYT-2006 Column

37. 250-S-IYT-1014 Draw bar

75. 250-S-IYT-2073 Table

38. 250-S-IYT-c5x15 Rivet

76. 250-S-IYT-2062 Table gib

Page | 15

S/N P/N DESCRIPTION

S/N P/N DESCRIPTION

77. 250-S-IYT-2059 Adjusting screw

115. 250-S-IYT-2089 Switch

78. 250-S-IYT-2082 Longitudinal bearing

116. 250-S-IYT-“x2”-2002 Bolt

bracket

117. 250-S-IYT-2097 Light

79. 250-S-IYT-2079 Longitudinal lead screw

118. 250-S-IYT-2069 Rubber sheet

80. 250-S-IYT-2084 Nut for bearing

119. 250-S-IYT-6Mx25 Bolt

81. 250-S-IYT-2080 Longitudinal feed nut

120. 250-S-IYT-6004z-2010 Bearing

82. 250-S-IYT-2081 5Mx25 Screw

121. 250-S-IYT-6x15 Key

83. 250-S-IYT-2087 Dial

122. 250-S-IYT-2024 Washer

84. 250-S-IYT-1060 Dial positioning screw

123. 250-S-IYT-6Mx15-2008 Bolt

85. 250-S-IYT-2089 Hand wheel

124. 250-S-IYT-6Mx35 Bolt

86. 250-S-IYT-2091 Handle bar

125. 250-S-IYT-6004z-2084 Bearing

87. 250-S-IYT-2103 Long, travel adjusting

126. 250-S-IYT-S-18 Snap ring

screw

127. 250-S-IYT-2018 Oil cup

88. 250-S-IYT-2104 Adjusting screw sleeve

128. 250-S-IYT-5x5x20 Key

89. 250-S-IYT-2068 Table stopper

129. 250-S-IYT-M5x10 Bolt

90. 250-S-IYT-2060 Table locking screw

130. 250-S-IYT-6Mx45 Bolt

91. 250-S-IYT-2060 Handle bar

131. 250-S-IYT-6Mx15 Bolt

92. 250-S-IYT-2057 Saddle

132. 250-S-IYT-S-18 Snap ring

93. 250-S-IYT-2058 Saddle gib

133. 250-S-IYT-10M Bolt

94. 250-S-IYT-2069 Rubber sheet

134. 250-S-IYT Iron sheep

95. 250-S-IYT-2401 Cross lead screw

135. 250-S-IYT-M6x8 Bolt

96. 250-S-IYT-2037 Cross feed nut

136. 250-S-IYT-8Mx25 Bolt

97. 250-S-IYT-2042 Cross feed bearing bracket

137. 250-S-IYT-AW09 Washer

98. 250-S-IYT-2068 Stop block

138. 250-S-IYT-7x7x20 Key

99. 250-S-IYT-2102 Stop block fixture

139. 250-S-IYT Iron sheep soft pipe

100. 250-S-IYT-2103 Cross travel adjusting

screw

101. 250-S-IYT-2104 Adjusting screw sleeve

CAUTION:

102. 250-S-IYT-2015 Knee

103. 250-S-IYT-2016 Knee gib

Find the serial number from the

104. 250-S-IYT-2017 Knee locking screw

drawing, then use it to obtain

105. 250-S-IYT-2019 Gear shaft sleeve

the part number from this list.

106. 250-S-IYT-2020 Gear shaft

108. 250-S-IYT-2029 Elevating handle clutch

109. 250-S-IYT-2030 Handle arm

140. 250-S-IYT Cable

110. 250-S-IYT-2012 Elevating gear

141. 250-S-IYT Terminal contactor

111. 250-S-IYT-2009 Elevating lead screw

142. 250-S-IYT Pipe lead

112. 250-S-IYT-2007 Elevating lead screw set nut

113. 250-S-IYT-2059 Chip guard

114. 250-S-IYT-2001 Base

Page | 16

CONTACT DETAILS

Head Office & Showroom

Address: Hawarden Industrial Park,

Hawarden,

Chester,

CH5 3PZ

Tel national: 01244 531631

Tel International: +44 1244 531631

Fax National: 01244 531331

Fax International: +44 1244 531331

Midlands Factory & Showroom

Address: Unit 4 Plant Lane Business Park,

Plant Lane, Burntwood,

Staffs,

WS7 3GN

Tel National: 01543 448940

Tel International: +44 1543 448940

Fax National: 01543 448938

Fax International: +44 1543 448938

Email: sales@chestermachinetools.com

Website: www.chestermachinetools.com

This manual suits for next models

1

Table of contents

Other CHESTER Power Tools manuals