CHESTER 830VS User manual

Warning: Failure to follow these rules may result in serious injury.

1. For your own safety, carefully read this instruction manual before operating the

machine, learn the machines application and limitations as well as the specific

hazards associated with this type of machine.

2. Always keep the guards in place and in working order.

3. Always wear eye protection, normal glasses only have impact resistant lenses and

are not suitable as safety glasses, also use a face or dust mask if the cutting

operation is dusty.

4. Remove any adjusting keys and wrenches before operating the machine.

5. Keep the work area clean and clear of any obstacles.

6. Do not use the machine in a dangerous environment, do not expose the machine

to rain or use the machine in damp or wet conditions. Keep the work area well

lighted.

7. Keep children and other visitors away from the machine and the work area.

8. Make the workshop childproof by using padlocks, master switches or by removing

any starter keys.

9. Do not force a machine to do a job for which it was not designed and only use the

machine at a rate for which it was designed.

10.Only use an extension cord that is in good condition and that is suitable for the

current that this machine will draw. An undersized cord will cause a drop in the

line voltage which will result in a loss of power and overheating. If in doubt, use a

larger than necessary cable for this machine.

11.Wear the appropriate safety clothing and do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewellery that can get caught in the moving parts

of the machine. The use of non-slip footwear is recommended as is wearing a

protective hat or a hairnet to contain long hair.

12.Make sure that the workpiece is secured in a vice or with the appropriate clamps,

do not attempt to hold the workpiece by hand.

13.Do not overreach, maintain a proper footing at all times.

14.Keep the tooling sharp and clean for the best and safest performance, follow the

instructions for lubricating and changing accessories.

15.When performing any maintenance or changing accessories such as cutting tools

etc. make sure that the machine has been turned off.

16.Make sure that the switches are in the off position before starting the machine to

reduce the risk of accidents due to unintentional starting.

17.Only ever use the recommended accessories, the use of improper accessories

may cause injury or damage the machine.

18.Never stand on the machine, it could tip or the cutting tool could be unintentionally

caught causing injury to the user.

19.Before starting the machine, check for any damaged parts such as guards or

covers and that they can be safely operated and that they will perform their

intended function. Check the alignment of the moving parts, for any binding of the

moving parts, any broken parts and the mounting of any parts that may affect the

machines operation. A guard or other part that is damaged should be repaired

correctly or replaced.

20.Only feed work into the cutting tool against the direction of rotation of the spindle.

21.Never leave a machine running unattended, make sure that the machine is

disconnected from the power supply and has come to a complete stop before

leaving it.

22.Make sure that the machine is disconnected fromthe power supply while the motor

is mounted, connected or disconnected.

Grounding Instructions

In the event of a malfunction or a breakdown, grounding provides a path of least

resistance for the electrical current to reduce the risk of electric shock. This machine

has been equipped with an electric cable with an equipment-grounding conductor and

a grounding plug.

The plug must be plugged into a matching outlet that has been correctly installed and

grounded in accordance with the local laws and regulations.

Do not modify the plug provided, if it will not fit the outlet, have the correct outlet

installed by a qualified electrician.

Improper connection of the grounding conductor can result in a risk of electric shock.

The conductor has been insulated with a green and yellow stripe jacket, if repair or

replacement of the cable is required, do not connect the earthing cable to a live

terminal.

Only ever use 3 core cables and three prong grounding plugs when using this machine

and repair or replace the plug or cable if they are damaged immediately.

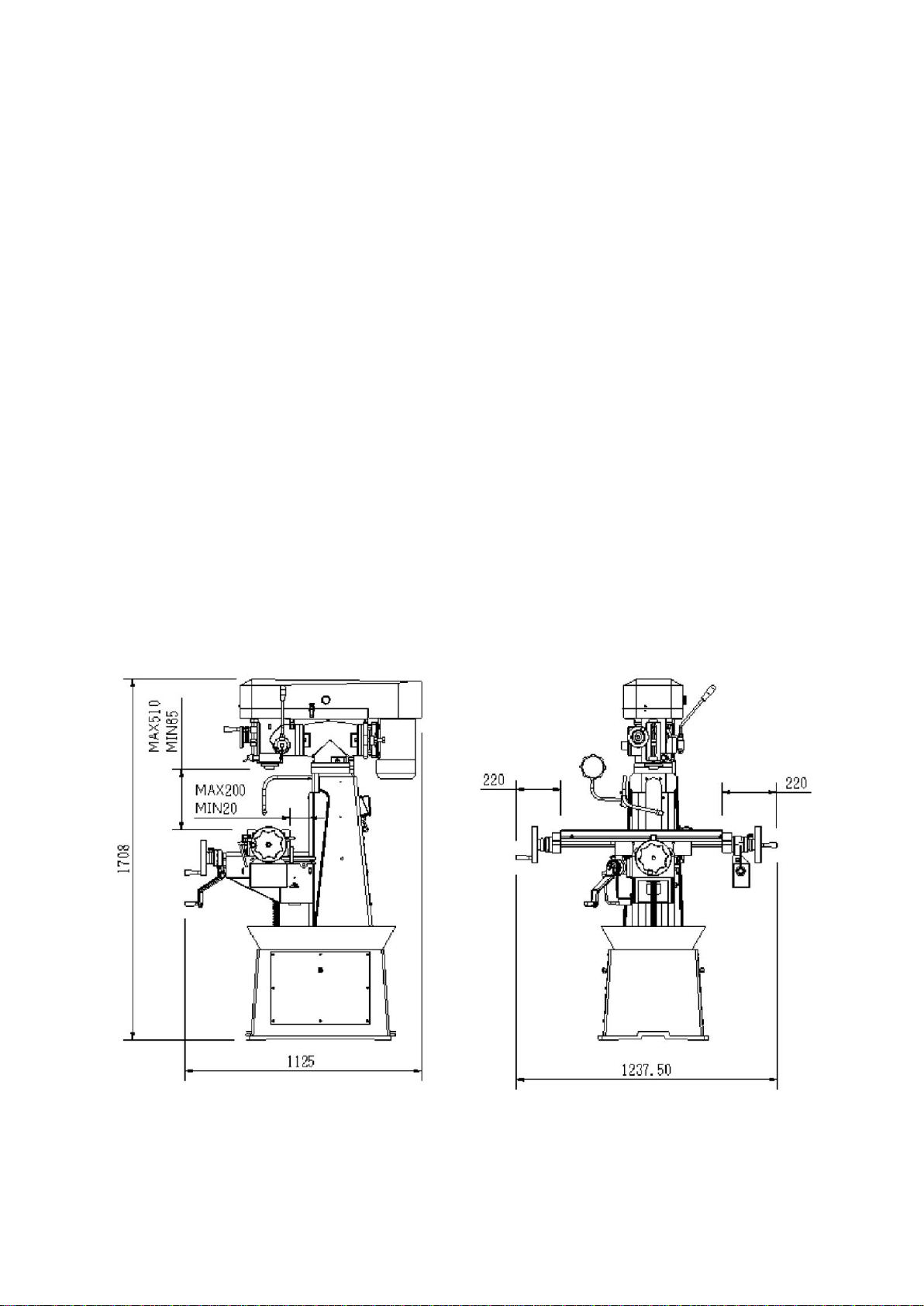

Machine Dimensions

Specifications

Spindle Taper

R8

Spindle Travel

88.9mm

Spindle Speed

200-2250rpm

Distance Spindle to Table Surface

57-510mm

Size of Worktable

205x760mm

Size of T-Slots

14mm

Number of T-Slots

3

Maximum Longitudinal Travel of Table

470mm

Maximum Cross Travel of Table

200mm

Vertical Travel of Table

455mm

Leadscrew for Drill Chuck

3mm Pitch

Vertical Head Tilt Angle

±90°

Head Swivelling Angle

360°

Motor

1.13kW (1.5Hp)

Net Weight

450Kg

Size

1100x1100x1900mm

Features

1. This machine is a vertical milling machine and has been designed to be easy to

use and to provide convenient operation with dual table handwheels.

2. This machine is practical for technical schools, small parts production, tool rooms,

R&D work and maintenance shops.

3. This machine is suitable for many operations including conventional milling,

compound angle milling, engraving, drilling and jig boring.

4. The castings are a high strength material that have been aged for several months

before normalizing and tempering to minimize deformation.

Note:

1. Remove the case carefully to prevent damaging the machines paintwork, in the

event that the machine is damaged in transit, contact the dealer immediately.

2. The machine has been carefully inspected and tested before it leaves our factory,

contact the dealer if any defects are found on delivery.

3. Read the manual carefully and become familiar with the location of all of the parts

to ensure the continued safe operation of this machine, it is important that the

location of the emergency stop button is noted before use in the event of an

emergency.

Installation

Install this machine on a solid, level foundation, ensure that space is provided around

the machine to allow for the movement of the head in the horizontal axis and to allow

for maintenance to the electrical system.

Cleaning and Lubricating the Machine

Once the machine is in position, thoroughly clean the machine with kerosene or other

non-flammable cleaning solutions. Once all of the anti-rust grease has been removed,

apply a thin layer of lubricating oil on the surface of the guideways, make sure that the

machine is correctly lubricated prior to operating.

Levelling the Machine

Set the machines level prior to operating by placing an engineers level on the

worktable in both the longitudinal and cross directions.

Isolation Switch

The isolation switch is located on the left side of the column and turns the machine on

and off.

Adjustment of the Table Feed Travel

The longitudinal and cross feed can be setfor any travel distance by adjusting the stop

set screws that are located in front of the table and at the right side of the knee.

Adjustment of the Gibs

The table is provided with a full length tapered gib in the saddle which has been fitted

with an adjustment screw on each end. To adjust the gib, tighten the two screws until

a slight drag is felt when moving the table. If the table is not tight enough, loosen the

adjusting screw on the small end and tighten the adjusting screw on the big end, if the

gib is too tight, reverse the procedure. The procedure is the same on the saddle and

knee gibs.

Clamping Table, Saddle and Knee

When milling with the longitudinal table feed only, it is advisable to clamp the knee

with the column and the saddle with the knee to add rigidity to these parts and be able

to make heavier cuts with the minimum amount of vibration. The saddle locking lever

is located on the left-hand side of the saddle, ensure that the clamping pressure is

adequate to hold the saddle securely.

The table clamping levers are located in front of the saddle and should always be

clamped when longitudinal movement is required.

The knee clamping lever is located on the left side of the knee, leave the knee clamped

at all times unless the knee is in operation.

Motor Mounting and Shifting Belts for Speed

The motor is mounted on a plate that is secured on the pulley housing. Release the

belt set unit by turning the handle at the side of the motor then shift the belts to the

desired speed before tightening the belt set unit. A speed chart is attached inside the

pulley cover.

Quill Lock and Vertical Feed

The handle at the right lower corner of the head is the quill lock, when the vertical feed

is not in use, set the handle to lock the quill and make the head more stable.

Open the pulley cover to locates a vertical oil cup in front of the pulley, open the cup

and fill with oil a couple of times a day, this will lubricate the whole vertical spindle

system from the top to the bottom.

The micrometer depth stop is graduated in millimeters, by using these graduations it

is possible to accurately work to different depths. A lock nut can be found under the

micrometer nut to ensure that the micrometer nut is secure.

Quill Clutch

The vertical feed is controlled by a handwheel at the front of the head and a handle at

the right-hand side of the head. When the handwheel is in use, tighten the clutch lock

nut by hand or loosen it for hand operation. Use the handwheel for fine feed and the

handle for higher feed rates.

Vertical Head and Tee Adaptor

The vertical milling head can be tilted 90° in either direction by loosening the four

locking bolts on the tee adaptor.

Loosen the two sets of bolts on the adaptor, the vertical milling head can then be

swiveled 120°, tighten the bolts after the movement is complete. The motor and milling

head must tilt together for the motor and head are suspended on the same pulley

housing.

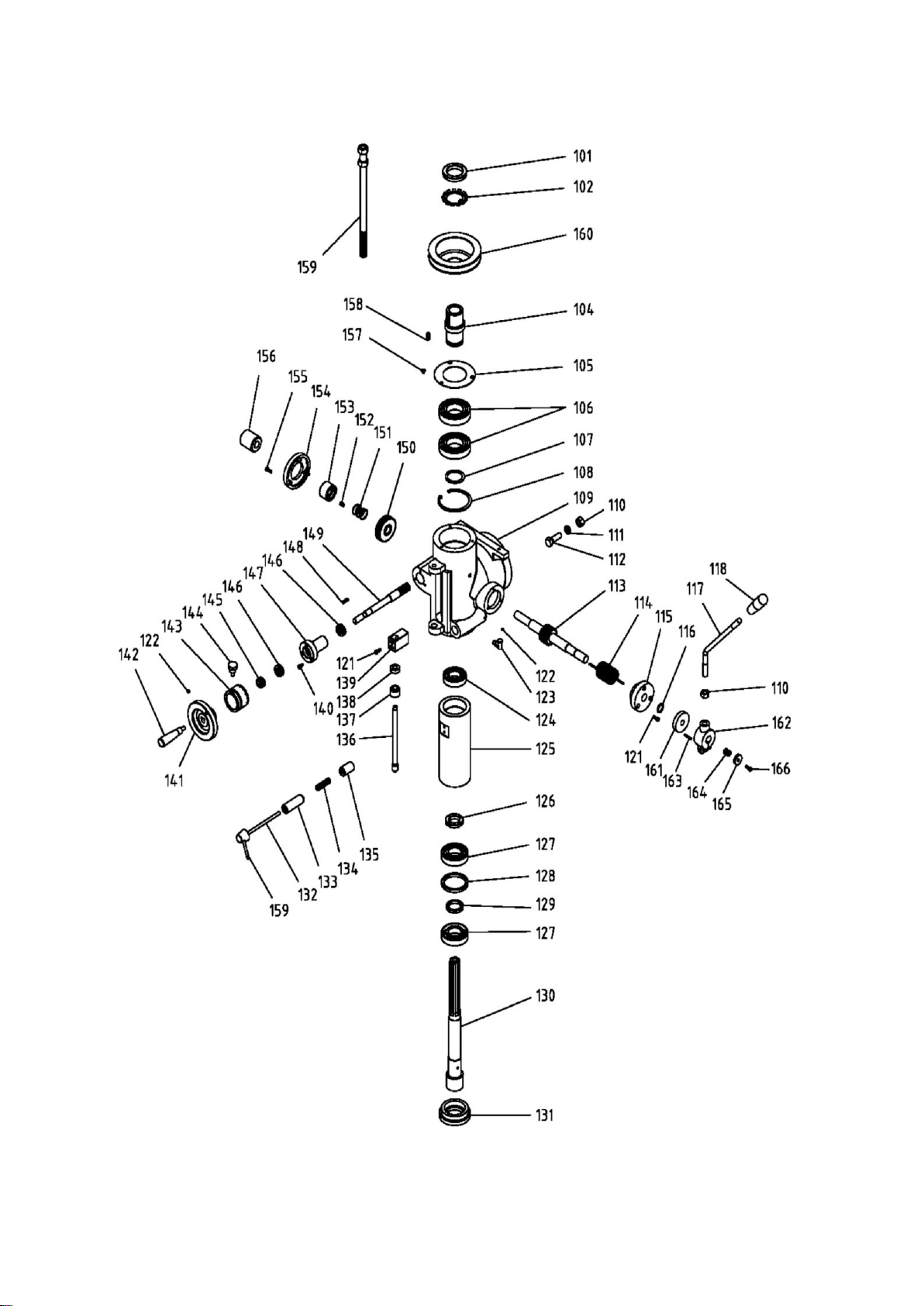

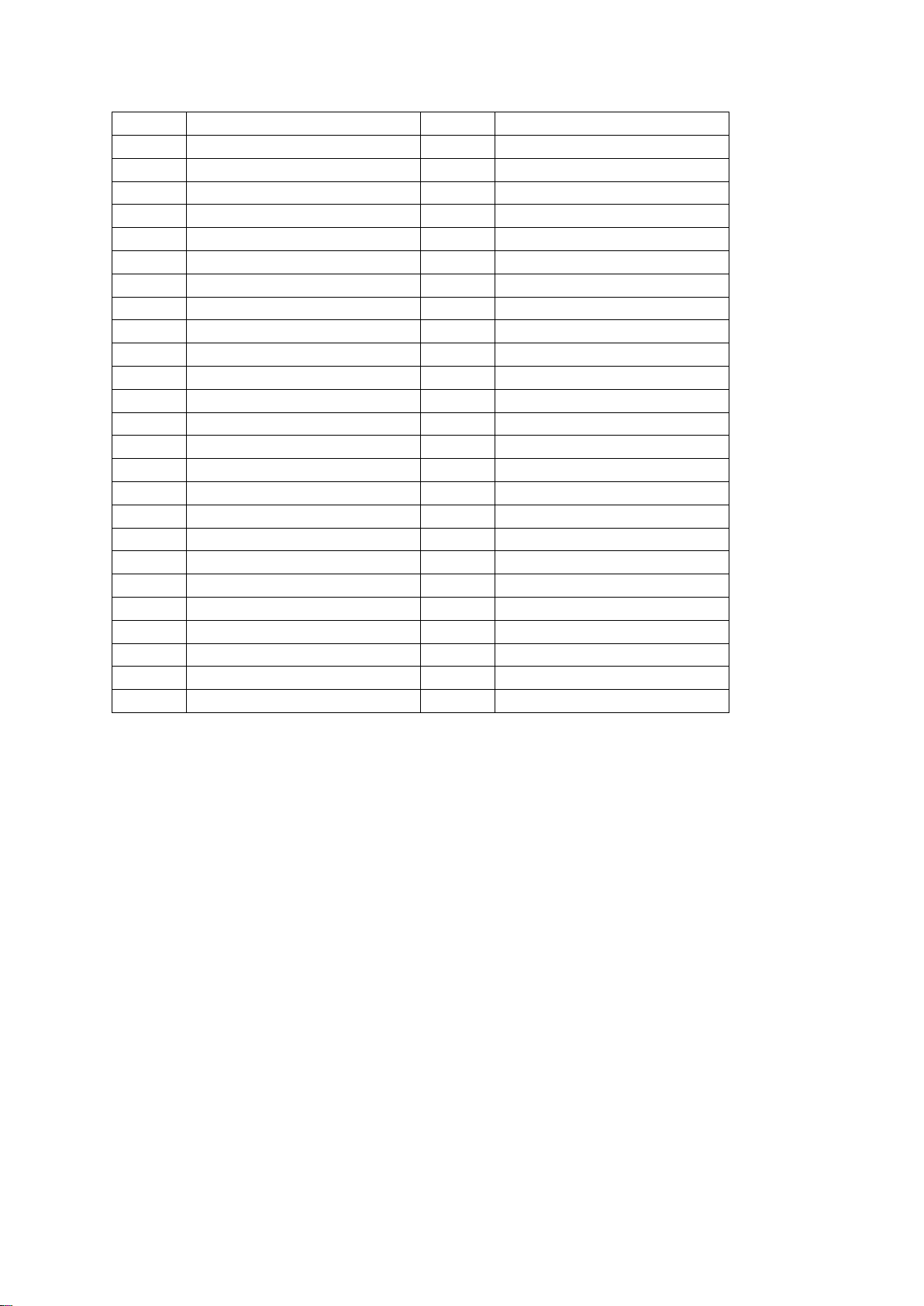

Part

Description

Part

Description

101

Nut

132

Lock Knob Shaft

102

Washer

133

Lock Block (L)

103

****

134

Spring

104

Spline Shaft

135

Lock Blocks (S)

105

Bearing Cover

136

Screw

106

Bearing 6209ZZ

137

Lock Nut

107

S-Ring 45

138

Height Nut

108

C-Ring 85

139

Block

109

Head Casting

140

M5-15 Pan Head Screw

110

1/2" Nut

141

Handwheel

111

1/2" Lock Washer

142

Handle

112

1/2" - 1½" Screw

143

Stepped Sleeve

113

Gear Shaft

144

Dial Positioning Screw

114

Spring

145

9/16" Nut

115

Flange Cover

146

Bearing 51102

116

S-Ring 19

147

Sleeve

117

Handle Lever

148

5x5x20 Key

118

Knob

149

Worm Shaft

119

M8-25 Cap Screw

150

Coupling Worm Gear

120

Handle Base

151

Spring

121

M5-16 Cap Screw

152

6x6x15 Key

122

M6-8 Set Screw

153

Coupling

123

Oil Cup

154

Plate

124

Bearing 6206ZZ

155

M5-10 Pan Head Screw

125

Spindle Quill

156

Knob

126

Nut

157

M5-8 Pan Head Screw

127

Bearing 7207

158

Key

128

Bearing Washer (B)

159

Lock Handle

129

Bearing Washer (S)

160

Spindle Pulley

130

Spindle

161

Space

131

Spindle Nut

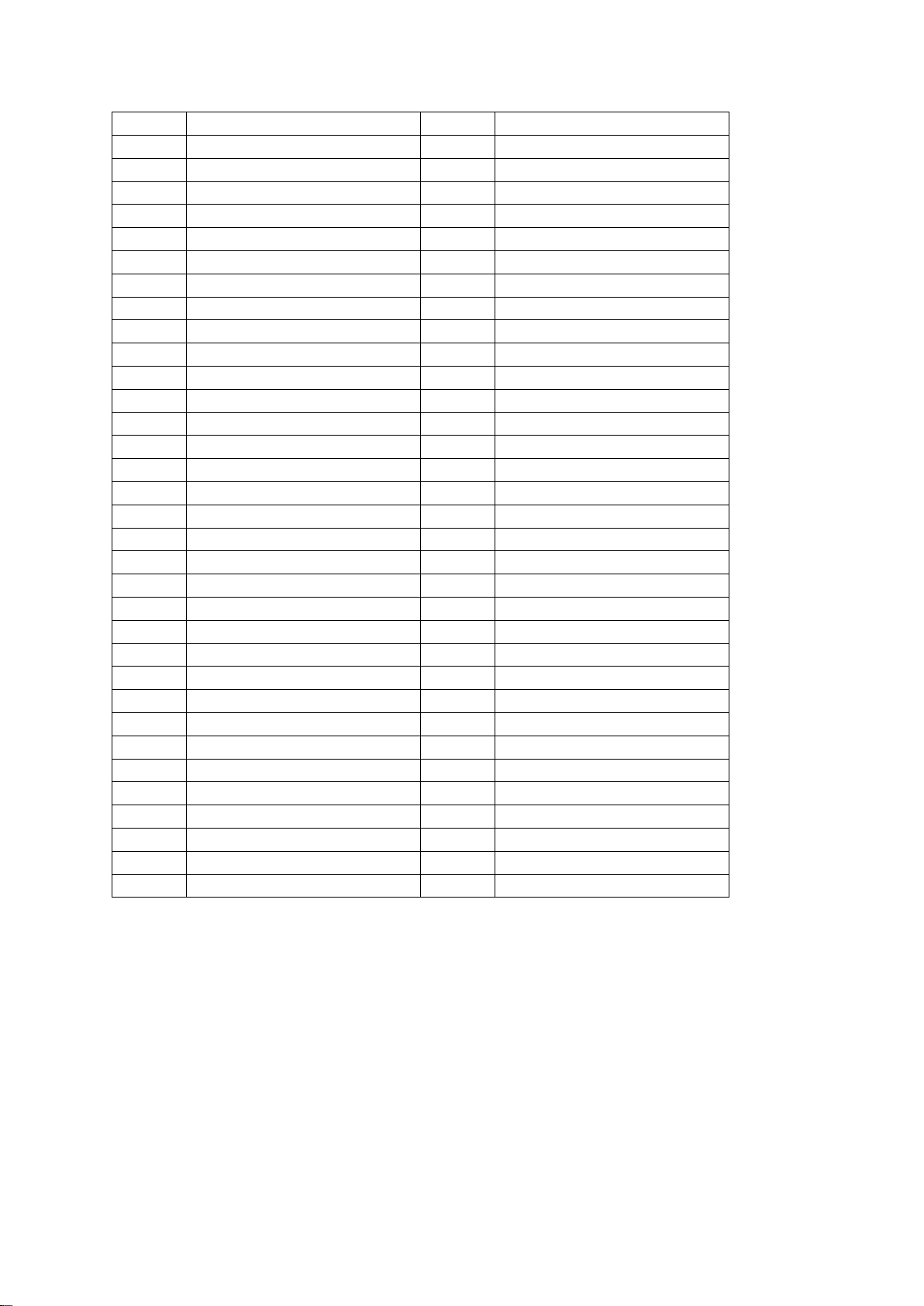

Part

Description

Part

Description

201

5x5x40 Key

221

****

202

****

222

****

203

M6-8 Set Screw

223

****

204

****

224

****

205

M8x-20 Cap Screw

225

Lower Belt Cover

206

M8 Washer

226

M6-35 Screw

207

Motor

227

M6 Washer

208

M16-75 Screw

228

Latch

209

M16 Nut

229

M3-8 Pan Head Screw

210

Bracket

230

M5-8 Pan Head Screw

211

1/2" - 1½" Screw

231

M5 Nut

212

1/2" Lock Washer

232

Cover Supporting Arm

213

1/2" Nut

233

M5-10 Pan Head Screw

214

1/2"- 1¾" Screw

234

Cover Hinge

215

Mounting Plate

235

****

216

Pivot

236

****

217

Vertical Head Adaptor

237

****

218

Upper Belt Cover

238

Belt B-59

219

Knob

239

Motor Pulley

220

****

240

M5 Washer

Part

Description

Part

Description

301

Handle

326

M5-30 Pan Head Screw

302

5/8" Nut

327

Adjsuting Screw

303

M6-8 Set Screw

328

Handle Bar

304

Handle

329

Table Locking Screw

305

Dial

330

M6-16 Cap Screw

306

Dial Positioning Screw

331

M5 Nut

307

M6-25 Cap Screw

332

M5-10 Ppan Head Screw

308

Spacer

333

Rubber Sheet

309

S-Ring 20

334

Gib

310

Bearing 6004ZZ

335

M5-25 Cap Screw

311

M6-45 Cap Screw

336

Limit Seat

312

Lead Screw Bracket (R)

337

Cross Nut

313

5x5x20 Key

338

M8-25 Cap Screw

314

Long Leadscrew

339

Saddle

315

M6-8 Pan Head Screw

340

Stop Block

316

Rubber Sheet

341

M5-20 Pan Head Screw

317

Rubber Sheet Holder

342

Longitudinal Nut

318

Table

343

M6 Washer

319

Star Washer

320

Bearing 6004ZZ

321

M10-30 Screw

322

Adjsuting Screw Sleeve

323

M10 Nut

324

Gib

325

Limit Block

Part

Description

Part

Description

401

****

434

Bearing Housing

402

****

435

Cross Leadscrew

403

Column

436

Bearing 6204zz

404

Lamp Assembly

437

Leadscrew

405

M6-8 Cap Screw

438

Pedestal

406

Gib

439

Cover

407

Lock Screw

440

Holder

408

Oil Joint

441

Machine Base

409

Knee

442

Cover

410

Knee Cover

443

Limit Block

411

M3-6 Pan Head Screw

444

Limit Track

412

Handle Bar

445

M10-30 Screw

413

Oil Pump

446

Sleeve

414

M5-15 Pan Head Screw

447

M10 Nut

415

Nut

448

M6-30 Screw

416

Tab Washer

449

1/2" - 2" Screw

417

Bevel Gear

450

1/2" Lock Washer

418

Bearing 6004ZZ

451

10x20 Pin

419

Gear Shaft Sleeve

452

****

420

M6-16 Cap Screw

453

3/16" - 1/2" Pan Head Screw

421

5x5x20 Key

454

Column Cover

422

Gear Shaft

455

M6-8 Pan Head Screw

423

S-Ring 20

456

Cable

424

Coupling

457

Strain Relief

425

M6-8 Set Screw

458

3/16" - 3/4" Pan Head Screw

426

Dial Positioning Screw

459

Cable (3)

427

Dial

460

3/16" Nut

428

Crank Arm

461

Contactor

429

S-Ring 18

462

Cable (4)

430

Handle Bar

463

Bus Bar

431

Handwheel

464

Mounting Track

432

Dial

465

AC Motor Controller

433

Bearing 51104

Part

Description

Part

Description

P01

Set Nut

501

M5-15 Pan Head Screw

P02

Dial

502

Nozzle Hose

P03

M6-25 Cap Screw

503

Pipe Union

P04

Power Feed

504

Hose

P05

3x3x30 Key

505

Splash pan

P06

Stop W/Plunger Assembly

506

M6-8 Pan Head Screw

P07

Auto Stop Switch

507

M6-15 Pan Head Screw

P08

M6-16 Pan Head Screw

508

M6 Washer

P09

M6 Washer

509

Pump Motor

P10

Transformer

510

Pump Cord

511

Kettle

512

Switch

Table of contents

Other CHESTER Power Tools manuals

Popular Power Tools manuals by other brands

TOOLCRAFT

TOOLCRAFT T-HLP 2000 W operating instructions

HIKOKI

HIKOKI CV 12DA Handling instructions

Black & Decker

Black & Decker SZ360T instruction manual

Bosch

Bosch GST 25 Metal Professional Original instructions

Electronica Technologies

Electronica Technologies EL700 manual

Mafell

Mafell DD40G Original operating instructions

Parkside

Parkside PDSP 1000 E6 Translation of the original instructions

Euro Shatal

Euro Shatal RP3014E-50 Operating instructions and spare parts list

Makita

Makita DSC163ZK instruction manual

Makita

Makita DJV140 instruction manual

Porter-Cable

Porter-Cable 7539 instruction manual

ABB

ABB ACS560 Hardware manual