Chesterton 442C Manual

442C™ Cartridge

Split Mechanical Seal

Installation, Operation and Maintenance Instructions

TABLE OF CONTENTS

INSTALLATION, OPERATION and

MAINTENANCE INSTRUCTIONS

Seal Data Reference

(Insert seal and equipment data here for future reference)

ITEM #

SEAL

(Example: 442C – 50 mm SSC/CB)

INSTALLATION DATE

1.0 Cautions.............................................................................2

2.0 Transport and Storage.................................................2

3.0 Description........................................................................2

3.1 Parts Identification .............................................................2 - 3

3.2 Operating Parameters.............................................................. 3

3.3 Intended Use........................................................................... 3

3.4 Dimensional Data...............................................................4 - 5

4.0 Preparation for Installation .................................6 - 8

4.1 Equipment............................................................................... 6

4.2 442C Cartridge Split Mechanical Seal.....................................7

5.0 Seal Installation..................................................... 9 - 11

5.1 442C Installation Video......................................................... 11

6.0 Commissioning/Equipment Start-up..................11

7.0 Decommissioning/Equipment Shut Down .......11

8.0 Spare Parts ....................................................................11

9.0 Seal Maintenance and Repair ......................12 - 16

9.1 442C Seal Repair Instruction Video.......................................16

9.2 Returning Seals for Repair;

Hazard Communication Requirements .................................. 16

2

These instructions are general in nature. It is assumed

that the installer is familiar with seals and certainly with

the requirements of their plant for the successful use of

mechanical seals. If in doubt, get assistance from someone

in the plant who is familiar with seals or delay the installation

until a seal representative is available. All necessary auxiliary

arrangements for successful operation (heating, cooling,

flushing) as well as safety devices must be employed. These

decisions are to be made by the user. The decision to use this

seal or any other Chesterton seal in a particular service is the

customer’s responsibility.

Transport and store seals in their original packaging.

Mechanical seals contain components that may be subject to

alteration and ageing. It is therefore important to observe the

following conditions for storage:

• Dust free environment

• Moderately ventilated at room temperature

• Avoid exposure to direct sunlight and heat

Do not touch the mechanical seal for any reason while it is

operating. Lockout or uncouple the driver prior to personal

contact with the seal. Do not touch the mechanical seal

while it is in contact with hot or cold fluids. Ensure that all the

mechanical seal materials are compatible with the process

fluid. This will prevent possible personal injury.

• For elastomers, storage conditions should conform to

ISO 2230; particularly storage temperatures between 15°C

(59°F) and 25°C (77°F). If stored outside these ranges, the

seal assembly or spare parts should be unboxed in a clean

environment, with ambient temperature within the previously

stated ranges, and allowed to recover for at least 1 hour

prior to installation. Failure to follow this step can impact the

performance of the seal.

1.0 CAUTIONS

2.0 TRANSPORT AND STORAGE

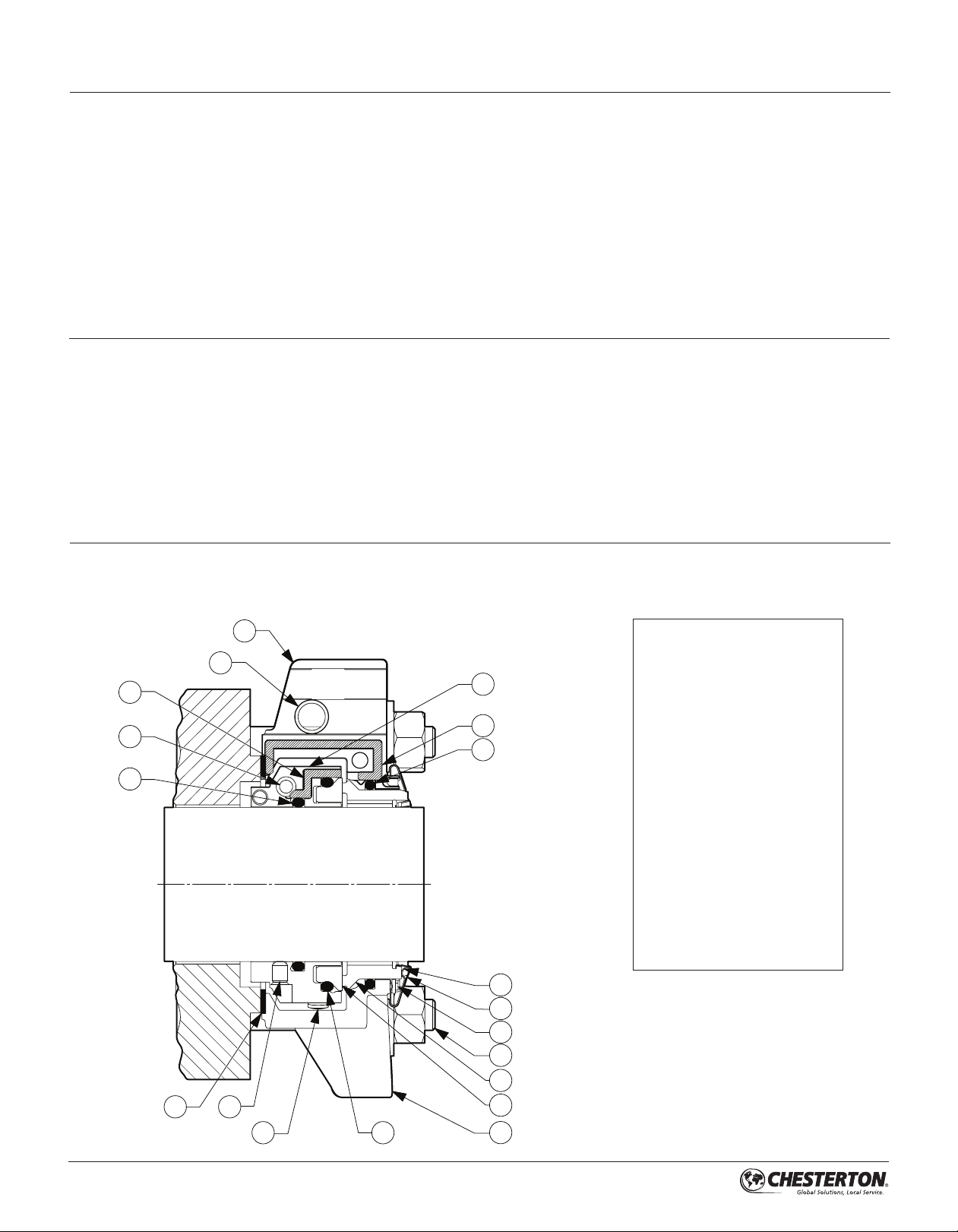

KEY

1 – Rotary Holder

2 – Holder Cap Screw (X)

3 – Holder Gasket

4 – Shaft O-Ring

5 – Rotary O-Ring

6 – Rotary Face

7 – Stationary Face

8 – Stationary O-Ring

9 – Gland Gasket

10 – Gland Cap Screw (Y)

11 – Stuffing Box Gasket

12 – Bolt Tab

13 – Spring

14 – Spring Retainer

15 – Centering Button

16 – Gland

17 – Stuffing Box Bolts (Z)

18 – Spring Lifter

19 – Holder Set Screw (W)

3.0 DESCRIPTION

3.1 Parts Identification

Figure 1

B

L

G

P NPT

P NPT

1

2

3

4

6

7

8

9

10

11

12

14

13

15

16

17

18

19

5

3

3.2 Operating Parameters*

Pressure Limits:

All 442 Seals can withstand operating pressures from full

vacuum (710 mm Hg /28") to the maximum pressures at the

conditions listed.

Small Sizes:

25 mm through 60 mm (1.000" through 2.500")

Reaction Bonded Silicon Carbide/Carbon – (3600 RPM)

up to 30 bar g/450 psig

Use 4 bolt mounting configuration for pressures above

20 bar g/300 psig

Large Sizes:

65 mm through 120 mm (2.625" through 4.750")

Reaction Bonded Silicon Carbide/Carbon – (1750 RPM)

up to 18 bar g/250 psig

Use 4 bolt mounting configuration for pressures above

14 bar g/200 psig

Speed Limits:

To 20 m/s (4000 fpm)

Temperature Limits:

To 120°C (250°F)

* Consult Chesterton Mechanical Seal Application Engineering for higher

operating conditions.

3.3 Intended Use

The mechanical seal is specifically designed for the intended

application and is to be operated within the operating

parameters as specified. For use beyond the intended

application and/or outside the operating parameters, consult

Chesterton to confirm the suitability of the mechanical seal

prior to putting the mechanical seal in operation.

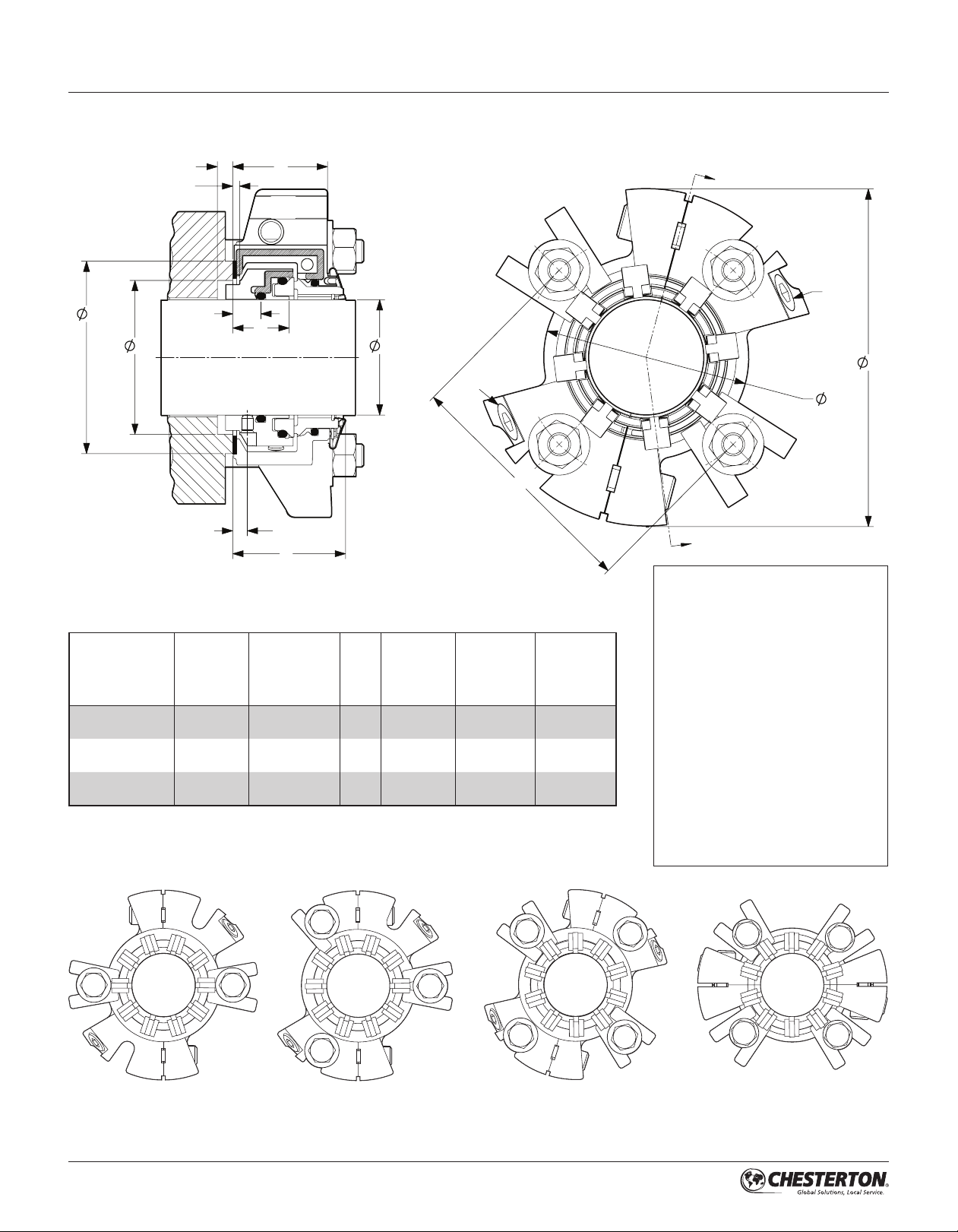

3.0 DESCRIPTION cont.

3.1 Parts Identification

Figure 2

KEY

NOT SHOWN AS PART OF INSTALLED SEAL

20 – Rotary Holder Installation Spacer

21 – Rotary Holder Shipping Spacer

22 – Gland Shipping Spacer

23 – Gland Installation Tool

23

20 21 22

44

KEY (chart)

A – Shaft Size

B – Max. Gland Dia.

C – Min./Max. Stuffing Box Dia.

D – Gland Length

E – Minimum Stuffing Box Depth

F – Outboard Seal Length

G – Min./Max. Bolt Circle by Bolt Size

H – Min. Stuffing Box Face

Outside Diameter

L – Gland Hub Outside Diameter

M – Holder End from Box

N – Installation Dimension

P – NPT Size

Q – Shaft O-Ring from Box

R – Set Screw from Box

S – Min. Sleeve Length from Box

E

N

D

G

H

C

B

L

P NPT

P NPT

M

A

F

Q

R

Table 1 – Dimensional Data (Metric and Inch)

SHAFT SIZE

M

HOLDER

INSIDE

DIAMETER

FROM BOX

N

INSTALLATION

DIM

P

NPT

SIZE

Q

SHAFT

O-Ring

FROM BOX

R

SET SCREW

FROM BOX

S

SLEEVE

LENGTH

FROM BOX

25 mm to 38 mm

(1.000" to 1.500")

24,4 mm

(0.96")

2,4 mm

(0.09") 1/4" 12,7 mm

(0.50")

5,8 mm

(0.23")

15,2 mm

(0.60")

40 mm to 60 mm

(1.625" to 2.500")

24,4 mm

(0.96")

2,4 mm

(0.09") 3/8" 12,7 mm

(0.50")

5,8 mm

(0.23")

15,2 mm

(0.60")

65 mm to 120 mm

(2.625" to 4.750")

27,1 mm

(1.07")

2,4 mm

(0.09") 3/8" 12,4 mm

(0.49")

5,8 mm

(0.23")

15,7 mm

(0.62")

2 BOLTS 3 BOLTS 4 BOLTS

Figure 4 – Mounting Configurations with Bolt Tabs

3.0 DESCRIPTION cont.

3.4 Dimensional Data (Drawings)

Figure 3

5

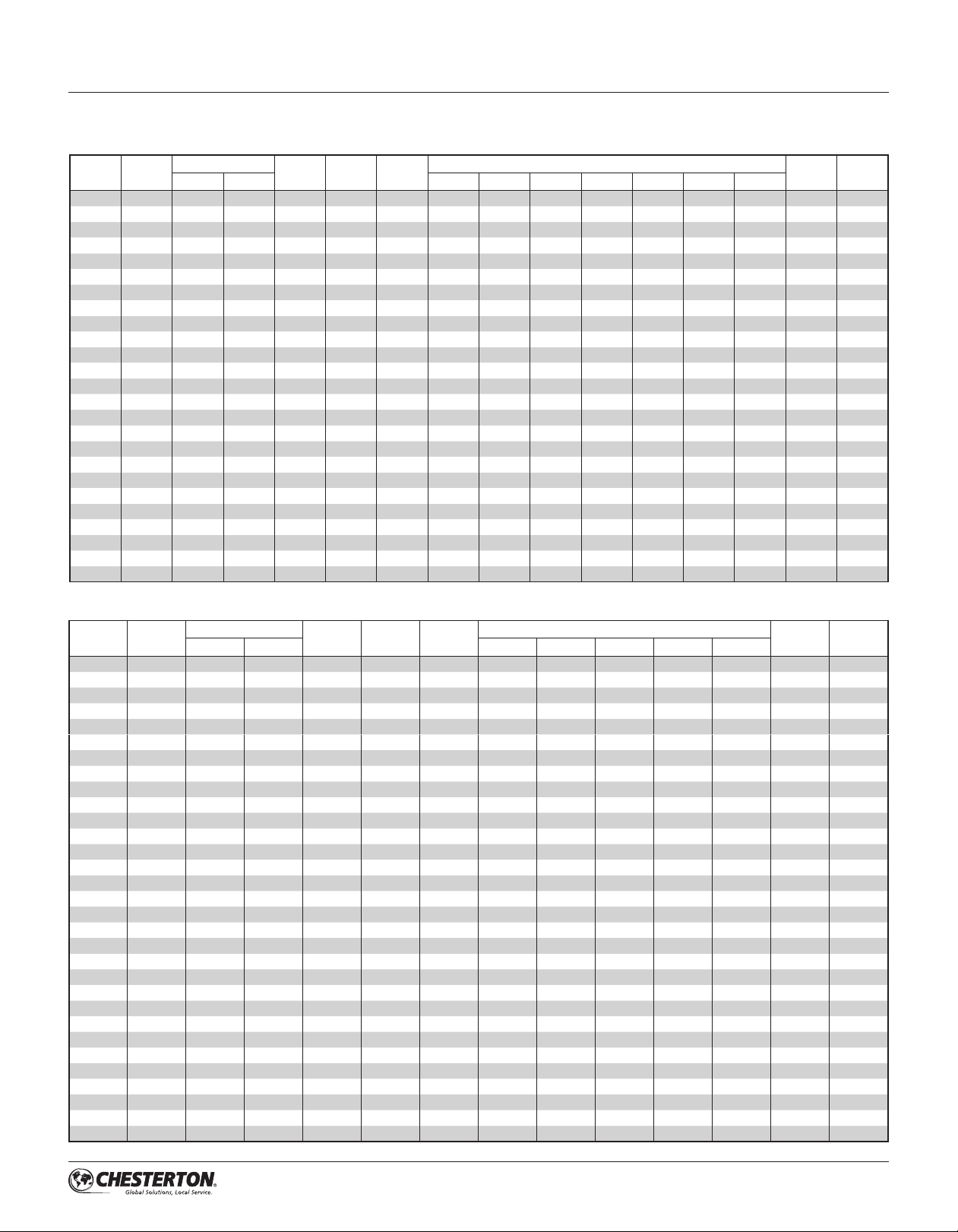

3.0 DESCRIPTION cont.

Table 2 – Dimensional Data

METRIC - Millimeters

AB

MAX

CDE

MIN FG MIN H

MIN

L

MAX

MIN MAX 8 mm 10 mm 12 mm 14 mm 16 mm 18 mm 20 mm

25,0 125,5 47,2 53,3 40,1 4,3 47,8 79,8 81,8 83,8 85,8 87,8 - - 59,9 70,9

30,0 125,5 47,2 53,3 40,1 4,3 47,8 79,8 81,8 83,8 85,8 87,8 - - 59,9 70,9

32,0 125,5 47,2 53,3 40,1 4,3 47,8 79,8 81,8 83,8 85,8 87,8 - - 59,9 70,9

33,0 125,5 47,2 53,3 40,1 4,3 47,8 79,8 81,8 83,8 85,8 87,8 - - 59,9 70,9

35,0 127,4 49,3 60,5 40,1 4,3 47,8 81,8 83,8 85,8 87,8 89,8 - - 66,8 72,8

38,0 130,5 52,3 63,5 40,1 4,3 47,8 85,0 87,0 89,0 91,0 93,0 - - 69,9 76,0

40,0 133,6 55,6 66,8 40,1 4,3 47,8 87,4 89,4 91,4 93,4 95,4* - - 73,2 79,0

43,0 136,8 58,7 70,0 40,1 4,3 47,8 90,5 92,5 94,5 96,5 98,5* - - 76,2 82,0

45,0 136,8 58,7 70,0 40,1 4,3 47,8 90,5 92,5 94,5 96,5 98,5* - - 76,2 82,0

48,0 140,0 62,0 73,2 40,1 4,3 47,8 97,7 95,7 97,7 99,7 101,7* - - 79,5 85,2

50,0 143,2 65,0 76,2 40,1 4,3 47,8 98,4 100,4 102,4 104,4 106,4* - - 82,6 88,4

55,0 146,3 68,3 79,2 40,1 4,3 47,8 101,6 103,6 105,6 107,6 109,6 - - 85,9 91,5

60,0 152,6 74,7 85,6 40,1 4,3 47,8 107,8 109,8 111,8 113,8 115,8 - - 92,2 97,9

65,0 196,1 85,1 108,0 48,0 8,1 57,7 - - 140,6 142,6 144,6 146,6* 148,6* 120,7 126,6

70,0 196,1 85,1 108,0 48,0 8,1 57,7 - - 140,6 142,6 144,6 146,6* 148,6* 120,7 126,6

75,0 202,5 91,4 114,3 48,0 8,1 57,7 - - 146,2 148,2 150,2 152,2 154,2* 127,0 133,0

80,0 208,8 97,8 120,7 48,0 8,1 57,7 - - 154,8 156,8 158,8 160,8 162,8 133,4 139,3

85,0 215,2 104,1 127,0 48,0 8,1 57,7 - - 158,9 160,9 162,9 164,9 166,9 139,7 145,7

90,0 215,2 104,1 127,0 48,0 8,1 57,7 - - 158,9 160,9 162,9 164,9 166,9 139,7 145,7

95,0 221,5 110,5 133,4 48,0 8,1 57,7 - - 165,2 167,2 169,2 171,2 173,2 146,1 152,0

100,0 227,9 116,8 139,7 48,0 8,1 57,7 - - 171,6 173,6 175,6 177,6 179,6 152,4 158,4

105,0 234,2 123,2 146,1 48,0 8,1 57,7 - - 177,7 179,7 181,7 183,7 185,7 160,3 164,7

110,0 240,6 129,5 152,4 48,0 8,1 57,7 - - 184,3 186,3 188,3 190,3 192,3 165,1 171,1

115,0 240,6 129,5 152,4 48,0 8,1 57,7 - - 184,3 186,3 188,3 190,3 192,3 165,1 171,1

120,0 246,9 135,9 158,8 48,0 8,1 57,7 - - 190,6 192,6 194,6 196,6 198,6 171,5 177,4

INCH

AB

MAX

CDE

MIN FG MIN H

MIN

L

MAX

MIN MAX 3/8" 1/2" 5/8" 3/4" 7/8"

1.000 4.94 1.86 2.10 1.58 0.17 1.88 3.20 3.33 3.45 3.58* - 2.35 2.79

1.125 4.94 1.86 2.10 1.58 0.17 1.88 3.20 3.33 3.45 3.58* - 2.35 2.79

1.250 4.94 1.86 2.10 1.58 0.17 1.88 3.20 3.33 3.45 3.58* - 2.35 2.79

1.375 5.02 1.94 2.38 1.58 0.17 1.88 3.28 3.40 3.53 3.66* - 2.63 2.87

1.500 5.14 2.06 2.50 1.58 0.17 1.88 3.40 3.53 3.65 3.78* - 2.75 2.99

1.625 5.26 2.19 2.63 1.58 0.17 1.88 3.50 3.63 3.81* 3.94* - 2.87 3.11

1.750 5.39 2.31 2.75 1.58 0.17 1.88 3.63 3.75 3.94* 4.06* - 3.00 3.23

1.875 5.51 2.44 2.88 1.58 0.17 1.88 3.75 3.88 4.06* 4.19* - 3.12 3.35

2.000 5.64 2.56 3.00 1.58 0.17 1.88 3.94 4.06 4.19* 4.31* - 3.25 3.48

2.125 5.76 2.69 3.12 1.58 0.17 1.88 4.06 4.19 4.31 4.44* - 3.37 3.60

2.250 5.88 2.81 3.25 1.58 0.17 1.88 4.19 4.31 4.44 4.56* - 3.50 3.73

2.375 6.01 2.94 3.37 1.58 0.17 1.88 4.31 4.43 4.56 4.69* - 3.62 3.85

2.500 6.13 3.06 3.75 1.58 0.17 1.88 4.57 4.70 4.82 4.95* - 4.00 4.23

2.625 7.72 3.35 4.25 1.89 0.32 2.27 5.44 5.56 5.69 5.81* 5.94* 4.75 4.99

2.750 7.72 3.35 4.25 1.89 0.32 2.27 5.44 5.56 5.69 5.81* 5.94* 4.75 4.99

2.875 7.97 3.60 4.50 1.89 0.32 2.27 5.66 5.78 5.91 6.03* 6.16* 5.00 5.24

3.000 7.97 3.60 4.50 1.89 0.32 2.27 5.66 5.78 5.91 6.03* 6.16* 5.00 5.24

3.125 8.22 3.85 4.75 1.89 0.32 2.27 6.00 6.12 6.25 6.37* 6.50* 5.25 5.48

3.250 8.22 3.85 4.75 1.89 0.32 2.27 6.00 6.12 6.25 6.37* 6.50* 5.25 5.48

3.375 8.47 4.10 5.00 1.89 0.32 2.27 6.16 6.28 6.41 6.53 6.66* 5.50 5.74

3.500 8.47 4.10 5.00 1.89 0.32 2.27 6.16 6.28 6.41 6.53 6.66* 5.50 5.74

3.625 8.72 4.35 5.25 1.89 0.32 2.27 6.41 6.53 6.66 6.78 6.91* 5.75 5.99

3.750 8.72 4.35 5.25 1.89 0.32 2.27 6.41 6.53 6.66 6.78 6.91* 5.75 5.99

3.875 8.97 4.60 5.50 1.89 0.32 2.27 6.66 6.78 6.91 7.03 7.16* 6.00 6.24

4.000 8.97 4.60 5.50 1.89 0.32 2.27 6.66 6.78 6.91 7.03 7.16* 6.00 6.24

4.125 9.22 4.85 5.75 1.89 0.32 2.27 6.90 7.02 7.15 7.27 7.40* 6.25 6.49

4.250 9.22 4.85 5.75 1.89 0.32 2.27 6.90 7.02 7.15 7.27 7.40* 6.25 6.49

4.375 9.47 5.10 6.00 1.89 0.32 2.27 7.16 7.28 7.41 7.53 7.66* 6.50 6.74

4.500 9.47 5.10 6.00 1.89 0.32 2.27 7.16 7.28 7.41 7.53 7.66* 6.50 6.74

4.625 9.72 5.35 6.25 1.89 0.32 2.27 7.41 7.53 7.66 7.78 7.91* 6.75 6.99

4.750 9.72 5.35 6.25 1.89 0.32 2.27 7.41 7.53 7.66 7.78 7.91* 6.75 6.99

* Two bolts only using bolt tabs

66

If practical, place the dial indicator tip on the end of the shaft

sleeve or on a step in the shaft to measure end play. Alternately

push and pull the shaft in the axial direction. If the bearings are

in good condition, end play should not exceed 0,13 mm (.005").

Remove all sharp corners, burrs, and scratches on the shaft,

especially in areas where the O-Ring will slide, and polish if

necessary to achieve a 0,8 micron (32 microinch) Ra finish.

Make sure the shaft or sleeve diameter is within 0,05 mm

(.002") of nominal.

Use a dial indicator to measure the shaft runout in the

area where the seal will be installed. Runout should not

exceed 0,001 mm TIR per millimeter (.001 inch TIR per inch)

of shaft diameter.

If possible, attach a base dial indicator to the shaft and rotate

both the indicator and shaft slowly while reading the runout

of the stuffing box face. Misalignment of the stuffing box face

relative to the shaft should not exceed 0,005 mm TIR per mm

(.005 in per inch) of shaft diameter.

The stuffing box face must be flat and smooth enough to

seal the gland. Surface roughness should be 3,2 microns

(125 microinch) Ra maximum for gaskets and 0,8 micron (32

microinch) Ra for O-Rings. Steps between halves of split case

pumps should be machined flat. Make sure the stuffing box is

clean and clear along it’s entire length.

4.0 PREPARATION FOR INSTALLATION

4.1 Equipment

2

1

34

.005"

0,13 mm

32 µ"

0,8 µm Ra

ø

ø

200

<

<

ø

<ø

1000

ø

<

.002"

0,05 mm

±

125 µ"

3,2 µm

7

4.2 442C Cartridge Split Mechanical Seal

Review seal packaging ensuring no damage or shortage has

occurred to the contents.

Review the seal fit dimensions in Tables 1 and 2 to ensure the

equipment to be sealed has the required dimensions.

Record the seal Item Number and Name found on the label

for referencing when contacting AW Chesterton Application

Engineering.

Installation is straightforward, provided the parts are handled

and installed carefully. Make sure your hands are clean.

Prepare a clean work surface on which to place parts.

NOTES:

• The gland and rotary holder halves are matched pairs by

the same number stamped on each half; face halves are

matched pairs; mixing components from different seals will

result in seal failure.

• Greasy fingerprints on seal faces, dirt particles on the

faces seal faces/splits or misaligned face splits may cause

leakage. Do not bring the assembly halves together before

actual installation. Damage to the seal ring splits may occur.

REQUIRED FOR INSTALLATION

(Items are provided with seal):

• Hex key wrenches

• Grease

• Cleaning wipes

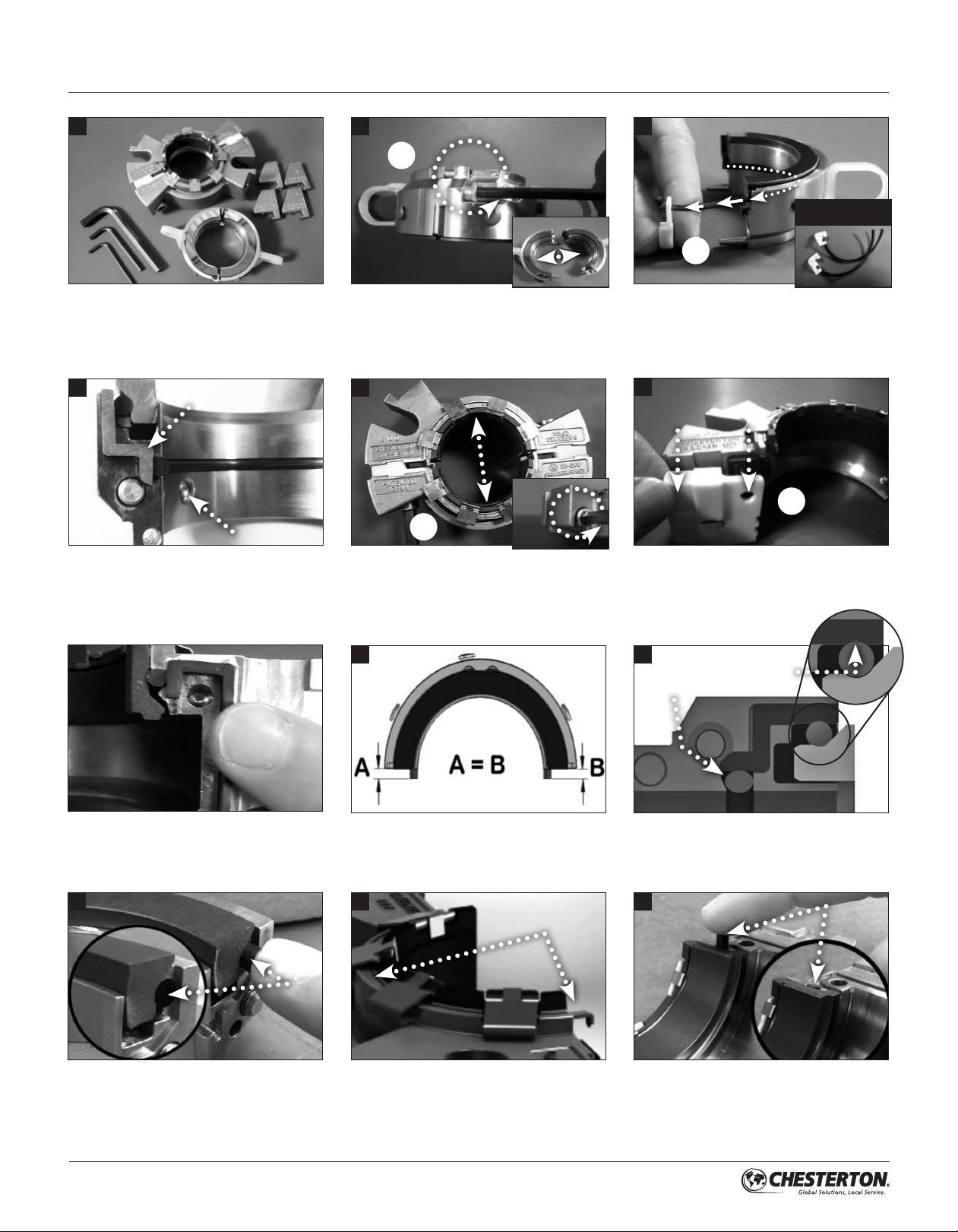

4.0 PREPARATION FOR INSTALLATION cont.

8

4.0 PREPARATION FOR INSTALLATION cont.

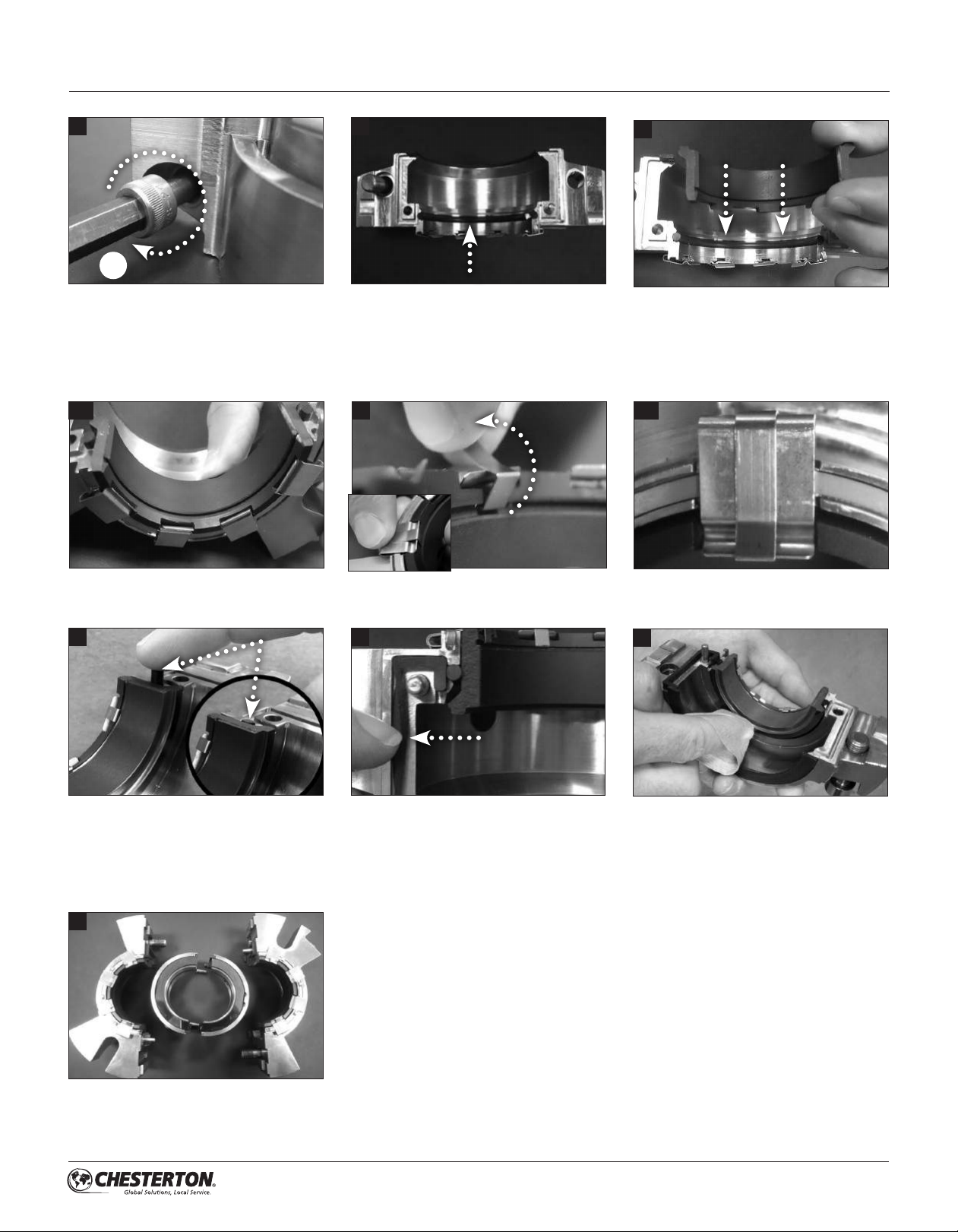

1

Remove seal from packaging and place on

clean work surface. Ensure installation spacers

are seated on outside diameter of rotary holder

halves. Important: DO NOT glue any O-Rings,

holder or gland half gaskets!

2 3

2X

2X

Disengage rotary holder screws and separate

rotary holder halves.

Important! Remove entire shipping spacer

assembly from each holder half by pulling on tab;

retain for future use. Caution: Do not push on

the rotary faces. Re-install shipping spacers if

this occurs.

Shipping Spacer

Assembly

Remove gland split shipping spacers from each

gland half.

6

2X

5

Disengage gland cap screws and separate gland

halves.

2X

7

Ensure that the gland gaskets are lubricated and

seated in their grooves.

Ensure that the rotary holder shaft O-Ring is

properly seated in its groove with both ends

protruding evenly. Apply grease to shaft O-Ring

only where it contacts the shaft.

8

11

Ensure that gland spring lifter is extended

prior to starting installation of gland assembly.

If spring lifter is not in its proper position, review

rebuild instructions.

Spring Lifter

To prevent seal leakage, ensure that the

stationary face O-Ring ends are flush with but

not below the stationary face splits. Carefully

push on O-Ring ends if they protrude past the

face splits. Preparation complete; go to Seal

Installation

12

To prevent seal leakage, ensure that the rotary

face O-Ring ends are flush with but not below

the face splits. Push on O-Ring ends if they

protrude past the face splits.

10

9

Ensure the rotary face O-Rings are positioned

in holder O-Ring detent. If rotary face O-Rings

are not in the holder detent, review rebuild

instructions.

Rotary holder

O-Ring detent

Shaft O-Ring

4

Ensure that the holder gaskets are lubricated and

seated in their grooves. Important: Set screws

protruding past the inside diameter may cause

the holder to deform resulting in shaft leakage

and/or damage to the rotary faces.

Holder Gasket

Set Screw

5.0 SEAL INSTALLATION

5

Gaps at holder splits should be equal on both

sides.

3

Use hex wrench and alternately tighten holder

cap screws to finger-tightness to allow holder

to slide along the shaft. Caution: Care should be

taken not to rotate the rotary holder on the shaft.

2X

Push holder assembly so that plastic installation

spacers contact the stuffing box. Face. Use hex

wrench and alternately tighten holder cap

screws (Refer to Table 3 - Holder Cap screw

Torque Values). Ensure gaps at holder splits are

equal on both sides (see Figure 5).

Caution: DO NOT push directly on seal face.

4

2X

7

Alternately tighten 2 holder set screws (1 per

holder half) (refer to Table 4 – Holder Set

Screw Torque Values).

2X

Table 3

Holder Cap Screw Torque Values

SEAL SIZE

HOLDER

CAP

SCREW* (X)

HEX

WRENCH

SIZE

25 mm to 60 mm

(1" to 2.5")

4,8 Nm

(43 in-lbf) 5/32

65 mm to 120 mm

(2.625" to 4.75")

12,4 Nm

(110 in-lbf) 3/16

* Recommended maximum

Table 4

Holder Set Screw Torque Values

SEAL SIZE

HOLDER

SET SCREW*

(W)

HEX

WRENCH

SIZE

25 mm to 120 mm

(1" to 4.75") 4,3 Nm

(38 in-lbf) 1/8

* Recommended maximum

6

Remove installation spacers; retain for future

use.

2X

8

Clean rotary face with supplied cleaning wipe,

ensuring there is no debris at splits. Caution: Do

not push on seal face - it may cause the seal face

to misalign resulting in seal leakage.

2

Bring rotary holder assembly halves together

over shaft, engaging the pins. Caution: DO NOT

use holder installation spacers as handles. Note:

If shaft cannot be rotated manually, the holder

split line should not align with the gland split line

(refer to steps 12 and 17).

1

Equipment shaft should be cleaned and greased

prior to rotary holder installation. Apply supplied

grease only to face splits. Do not apply grease

to o-ring ends. Caution: Dirt particles on seal

face splits may cause leakage. The rotary holder

should not be rotated on the shaft during Steps

2 through 4 as it may lead to shaft leakage and/

or face damage.

10

Apply supplied grease only to face splits. Do

not apply grease to O-Ring ends. Caution: Dirt

particles on seal face splits may cause leakage.

9

Install gland installation tool between holder

assembly and stuffing box face.

9

10

5.0 SEAL INSTALLATION cont.

Seal installation complete (refer to EQUIPMENT

STARTUP). Note: Four bolt configuration

is shown. (refer to Figure 4 - Mounting

Configurations for other bolt quantities).

1917

If possible rotate gland together with shaft when

aligning gland bolt slots with the stuffing box bolt

holes (refer to step 12 ).

Alternately tighten gland cap screws to specified

torque (refer to Table 5 – Gland Cap Screw and

Stuffing Box Bolt Torque Values). Note: The

spring lifter will automatically move into its final

position once the gland cap screws are tightened.

13

2X

15

2X

Carefully remove the gland installation tool,

taking care not to dislodge the gland stuffing

box gasket. Retain the gland installation tool for

future use.

1614

Bring the second gland half squarely into

position against the gland installation tool,

ensuring the pins and gland bolts are engaged.

11

Clean stationary face with cleaning wipe,

ensuring that there is no debris at splits.

Position the gland splits approximately 90

degrees from the rotary holder splits.

12

90°

Bring the first gland half squarely into position by

sliding the gland gasket face against the gland

installation tool, ensuring the stationary face

does not make contact with the rotary face.

13

18

Install and alternately tighten stuffing box

bolts to recommended torque (refer to

Table 5 – Gland Cap Screw and Stuffing Box

Bolt Torque Values).

2X or 4X

Table 5 – Gland Cap Screws and Stuffing Box Bolt Torque Values

SEAL SIZE GLAND

CAP SCREWS* (Y)

HEX WRENCH

SIZE

STUFFING BOX

BOLTS** (Z)

25 mm to 60 mm

(1" to 2.5")

14-20 Nm

(125 – 175 in-lbf) 5/16 13,5-27 Nm

(15 – 20 ft-lbf)

65 mm to 120 mm

(2.625" to 4.75")

17-23 Nm

(150 – 200 in-lbf) 3/8 27-34 Nm

(20 – 25 ft-lbf)

* Recommended maximum

** Typical Values: Torque necessary to seat stuffing box gasket varies with application.

Installation Tool

11

5.0 SEAL INSTALLATION cont.

6.0 COMMISSIONING / EQUIPMENT START-UP

7.0 DECOMMISSIONING / EQUIPMENT SHUT DOWN

8.0 SPARE PARTS

5.1 442C INSTALLATION VIDEO

To view an instructional installation video, please scan the

QR Code with your mobile device or go to our web page

at www.chesterton.com/442C_Videos and click on the

desired video.

1. Rotate the shaft by hand, if possible, to ensure no metal-to-

metal contact within the seal. A slight drag may be found

due to the seal faces and the centering buttons but the shaft

should rotate freely.

2. Attach appropriate plumbing/environmental controls to

the seal. Take all necessary precautions and follow normal

safety procedures before starting the equipment.

3. Depending on how carefully the seal components were

handled during installation, split seals may drip on startup.

For example, greasy fingerprints on the faces or misaligned

face splits may cause leakage. This type of leakage usually

decreases and stops over a period of time. If the leakage

remains steady, check O-Rings and gaskets for proper

installation and check the faces for chips, scratches and

proper alignment.

Please Contact Chesterton Mechanical Seal Application Engineering for

assistance regarding split seals.

Ensure that the equipment is electrically isolated. If the

equipment has been used on toxic or hazardous fluids, ensure

that the equipment is correctly decontaminated and made safe

prior to commencing work. Ensure that the pump is isolated

and check that the stuffing box is drained from any fluid and

pressure is fully released. Disassemble the 442C split seal and

remove from equipment in the reverse order from installation

instructions. Incase of disposal, ensure the local regulations

and requirements for disposal or recycling of the different

components in the seal are adhered to.

Use only Chesterton original spare parts. Use of non-original

spare parts represents risk of failure, danger to persons/

equipment and voids the product warranty.

Spare Parts Kit can be purchased from Chesterton,

referencing the recorded seal data from cover page.

12

9.0 SEAL MAINTENANCE AND REPAIR

4

7

1

5

8

2

Remove used rotary face halves by pushing on

end of face and sliding out of rotary holder half.

Remove used holder cap screws from holder

halves.

Prepare a clean work surface for seal

disassembly and rebuild.

Remove used rotary face O-Ring halves.

Remove used centering buttons from outside

diameter of rotary holder.

Remove used rotary holder gaskets.

Remove used holder set screws (2 places) from

rotary holder.

Remove used shaft O-Ring halves.

6

3

2X

2X

9

Remove used gland gaskets from gland grooves.

A correctly installed and operated mechanical seal requires little

maintenance. It is recommended to periodically check the seal for

leakage. Wearing components of a mechanical seal such as seal

faces, O-Ring, etc., require replacement over time. While a seal is

installed and operating, maintenance is not possible. Therefore it

is recommended that a spare seal unit or a spare parts kit be held

in stock to allow quick repair.

1. Only the gland and rotary holder are reused. Caution: The

gland, rotary holder, face halves and O-Rings are matched

pairs; do not mix halves from different seals since this will cause

seal failure.

2. The following items, in addition to wrenches, grease and

cleaning wipes, will be required for rebuild:

• Small pliers (remove centering buttons)

• Small, flat-head screwdriver (set spring lifter location)

• Plastic tipped mallet or hammer (replace

centering buttons)

• Cleaning solvent (clean elastomer/gasket surfaces)

3. Note the condition of the parts, including elastomer surfaces

and gland springs. Analyze the cause of failure and correct the

problem, if possible, before reinstalling the seal.

4. Clean all elastomer and gasket surfaces with

cleaning solvent.

16

Remove all spare parts kit components from

packaging and place on the clean work surface.

15

Remove used gland cap screws.

2X2X

9.0 SEAL MAINTENANCE AND REPAIR cont.

Remove used stationary face O-Ring.

11

18

Lubricate threads with a recommended anti-

seize compound and install new holder set

screws (2 places) in rotary holder. Important:

Prior to installing the rotary holder on the shaft/

sleeve, check to ensure the holder set screws are

not protruding beyond the inside diameter of the

rotary holder.

2X

19

Lubricate threads with a recommended anti

seize compound and install holder cap screws in

rotary holder half.

2X2X

Install new centering buttons on outside

diameter of rotary holder. Important: Make sure

buttons are fully seated without deforming the

exposed heads

17

2X6X

12

Remove used stuffing box gasket from gland

recess and all adhesive residue with cleaning

solvent.

13

Remove used springs from gland halves by

tapping them from the gland half inside diameter

with a small hammer

Remove spring lifter halves from gland halves.

14

Apply a thin film of grease and install shaft

O-Ring halves in rotary holder halves. O-Rings

must protrude evenly from both holder half ends.

(Refer to step 9 on page 8).

20

10

Remove used spring retainers from gland

halves. Note: When last retainer is removed the

stationary seal ring can be removed

21

Install rotary holder shipping spacers in rotary

holder halves to hold the rotary face O-Ring in

place.

13

14

Clean rotary face halves with cleaning wipe.

27

9.0 SEAL MAINTENANCE AND REPAIR cont.

26

Install installation spacers on outside diameter of

holder halves.

2X

25

Apply a thin film of grease and install holder half

gaskets (1 per holder half).

2X2X

Install spring lifter clips in gland halves.

30

22

Apply a thin film of grease and install rotary face

O-Ring halves in rotary holder halves.

28

Bring gland halves together. After peeling off

protective backing, seat one gasket half in the

gland recess ensuring that cut end aligns with

gasket guide. Seat second gasket half into gland

recess, ensuring that it butts up to cut ends of

first half.

Gasket Guide

Set spring lifter location using a flat head

screwdriver. Important: End of spring lifter must

be aligned with edge of the end spring. Remove

all clips and retain for re-setting lifter location.

32

31

Install spring lifter in gland halves such that

leading end is exposed beyond last spring.

Important: Bent TAB on spring lifter must be

installed on the recessed side of the gland.

2X

29

Install springs into spring slots on gland. Use a

plastic tipped mallet to ensure springs are seated

into place.

6X, 8X or 10X

Spring lifter clips installed in gland halves.

30a

24

Ensure that the rotary face O-Ring ends are

flush, not below, with the face splits. Push on

O-Ring ends if they protrude past the face splits.

Install rotary face halves in rotary holder halves.

Important: Manually press to seat the rotary

face in the holder halves while keeping pressure

on the plastic spacer and protruding O-ring to

ensure the O-ring position is maintained.

Align flat on outside diameter of rotary face with

flat on inside diameter surface of rotary holder.

23

15

39

Clean stationary face halves with cleaning wipe

to ensure there is no debris on face and at splits.

Stationary face half installed in gland half.

Important: Ensure that O-Ring splits are still

protruding evenly at both sides.

35a

Spring retainer installed.

36a

Seal components are ready for installation.

Proceed to Seal Installation Instructions.

40

9.0 SEAL MAINTENANCE AND REPAIR cont.

34

Apply a thin film of grease to the stationary face

O-Ring halves and install in gland halves; Ensure

that O-Ring splits are protruding evenly on both

sides.

Install stationary face halves into gland halves.

35

38

Apply a thin film of grease to gland gaskets and

install in grooves of gland halves. Note: Gland

gaskets must be installed on gland end where

stuffing box face gasket protrudes.

2X 2X2X

33

Install new gland cap screws in gland halves.

Note: Gland cap screws are installed in one end

of each gland half, in the ends away from the

mounting bolt slot.

2X

36

Install spring retainers in gland halves, holding

the stationary seal ring half in the gland.

Ensure that the stationary face O-Ring ends

are flush with and not below the stationary face

splits. Push on O-Ring ends if they protrude past

the stationary face splits.

37

FORM NO. EN14068 REV 8 01/19

860 Salem Street

Groveland, MA 01834 USA

Telephone: 781-438-7000 Fax: 978- 469- 6528

www.chesterton.com

© 2019 A.W. Chesterton Company.

® Registered trademark owned by A.W. Chesterton Company

in USA and other countries.

Chesterton ISO certificates available on www.chesterton.com/corporate/iso

DISTRIBUTED BY:

9.1 442C SEAL REPAIR INSTRUCTION VIDEO

To view an instructional video on how to repair the 442C,

please scan the QR Code with your mobile device or go to our

web page at www.chesterton.com/442C_Videos and click

on the desired video.

9.2 RETURNING SEALS FOR REPAIR AND

HAZARD COMMUNICATION REQUIREMENTS

Any mechanical seal returned to Chesterton that has

been in operation, must comply with our Hazard

Communication requirements. Please scan the QR

Code with your mobile device or go to our web page at

www.chesterton.com/Mechanical_Seal_Returns to

obtain information required for returning seals for repair

or seal analysis.

9.0 SEAL MAINTENANCE AND REPAIR cont.

Other manuals for 442C

1

Table of contents

Other Chesterton Industrial Equipment manuals