Chesterton CMS 2000 Manual instruction

CMS 2000

Pneumatic Injection System

Instructions

Setup and Operation

SAFETY INFORMATION

To avoid personal injury or property

damage during system operation, read

and follow all cautions, warnings, and

instructions, included with or attached

to each product. Chesterton cannot

be responsible for damage or injury

resulting from unsafe use of product,

lack of maintenance, or incorrect

product and system application.

Contact Chesterton Packing Application

Engineering when in doubt as to safety

precautions or applications.

3. Disconnect air supply when pump

is not in use. NEVER remove swivel air

connector while air line is pressurized.

4. The pump is equipped with an overload

valve, preset for maximum operating

pressure. DO NOT attempt to adjust the

overload valve. If adjustment is required,

contact the factory. Adjustment by other

than qualified personnel may cause

malfunction, damage to the system,

and/or personal injury.

Set Up:

1. Remove the CMS 2000 PNEUMATIC

INJECTION SYSTEM (004536) from

the Packing Box.

2. Take note that the CMS 2000

PNEUMATIC / HYD PUMP (004537)

is permanently fixed to a removable

plate attached to the bottom of the

Toolbox.

3. The pump can be removed from the

toolbox bracket along with mounting

plate, by unclipping the four swing

fasteners holding the plate in place.

4. Barrel (16) is pre-fitted permanently

to cylinder (11) with coupling (10).

Do not attempt to disassemble.

NOTE: The CMS 2000 PNEUMATIC / HYD PUMP comes from the factory pre-filled with the proper amount of

hydraulic oil. There should be no need to add hydraulic oil when the system is new.

WARNING

1. Always wear proper personal

protective gear when operating

hydraulic equipment (i.e. safety

glasses, gloves, etc.).

2. The system operating pressure

must not exceed the pressure rating

of the lowest rated component in the

system. Make sure that all system

components are protected from

external sources of damage, such

as excessive heat, flame, moving

machine parts, sharp edges, and

corrosive chemicals.

MECHANICAL PACKING

INSTALLATION INSTRUCTIONS

FORM NO. 071137 Rev. 1

PRINTED IN USA 01/06

860 Salem Street

Groveland, MA 01834 USA

Tel: 781- 438-7000 • Fax: 978-469-6528

www.chesterton.com

©A.W. Chesterton Company, 2006. All rights reserved.

®Registered trademark owned and licensed by the

A.W. Chesterton Company in USA and other countries.

PRIMING THE PUMP

If pump does not operate properly,

it may have lost its prime. Follow the

procedure below to prime your pump,

if necessary.

1. Fill pump with hydraulic oil (004211),

if necessary. See filling instructions.

2. Place pump on horizontal surface.

3. Set air supply pressure to 30-40 psi

(2,1 – 2,7 bar).

4. Move pump treadle to RELEASE

position.

5. Depress the button under the treadle

to activate pump. Operate pump

in RELEASE position momentarily

several times to allow oil to flow back

into pump and fill passage ways.

6. To verify that pump is primed, operate

as normal with cylinder attached.

If pump still does not deliver oil, contact

Chesterton Packing Application Engineering.

When the unit will be stored for 30 days or more:

1. Wipe the entire unit clean.

2. Disconnect all air pressure and hydraulic lines to prevent accidental operation.

3. Cover the unit.

4. Store in a clean, dry environment. DO NOT expose equipment to extreme temperatures.

3. Change hydraulic oil after every

100 hours of operation. In dusty

or dirty areas, it may be necessary

to change the oil more frequently.

To change the oil, drain used oil

through the fill opening and fill

reservoir to 1/2" (1 cm) below the

fill opening with clean hydraulic oil.

Dispose of used oil in accordance

with local regulations.

MAINTENANCE

1. Periodically check all hydraulic and air

connections to be sure they are tight.

Loose or leaking connections may

cause erratic and / or total loss of

operation. Replace or repair all

defective parts promptly.

2. Periodically check the hydraulic

oil level in your system. See filling

instructions on page 2.

5. Replace the fill plug making sure the

seal is centered properly on the plug.

If leakage still occurs, remove oil and

call your inside Chesterton Customer

Service Representative.

3. Replace the fill plug and finger tighten.

CAUTION: DO NOT use a wrench.

Over-tightening will tear the reservoir bladder.

4. Tip the pump for leakage. If leakage

occurs, remove the plug and check

the plug seal for cuts or nicks.

Replace the seal if necessary.

ISO Certifications available at www.chesterton.com/corporate/iso

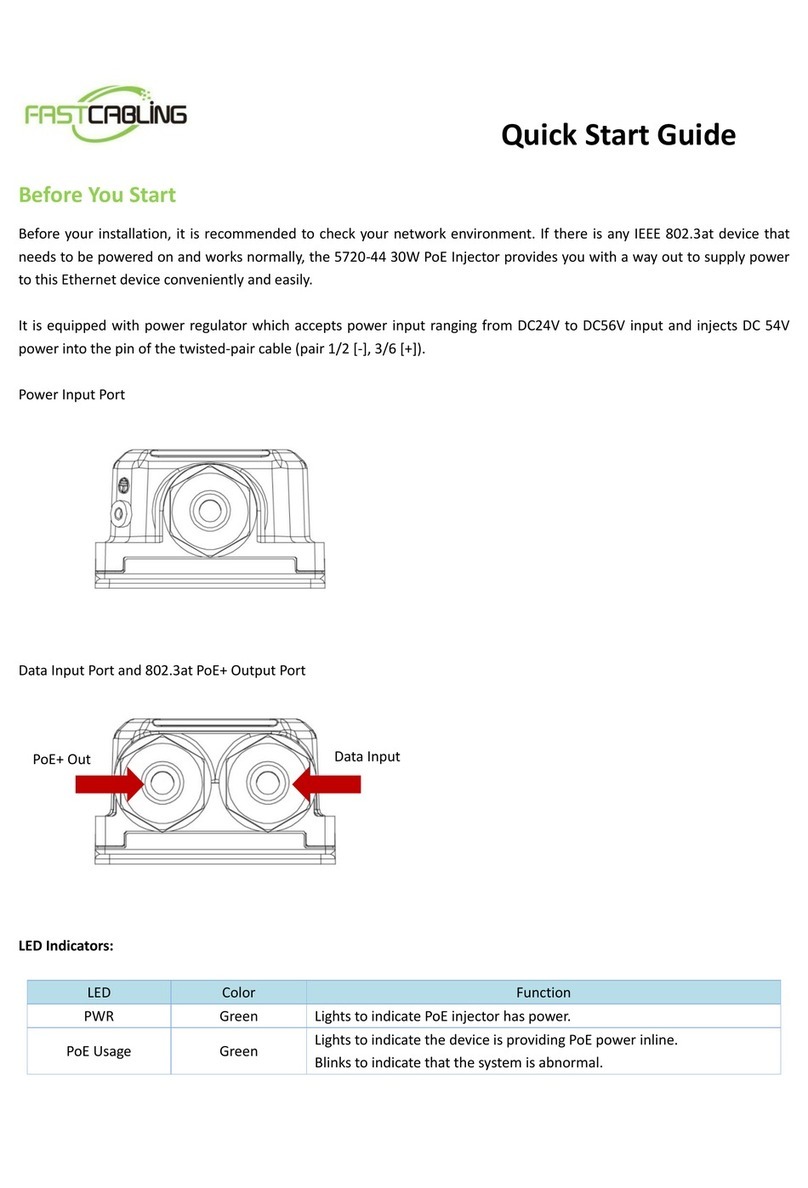

Connect the Air Supply

Recommended air inlet pressure

is 60 - 100 psi (4,1 - 6,9 bar).

Loading:

A. Unscrew barrel cap (15).

B. Load CMS-2000 injection compound.

Refer to Item #073738, CMS-2000 Automated

Installation Instructions for details.

C. Replace system barrel cap (15).

D. Tighten system cap (15) with the

spanner wrench (004220) included.

E. Be sure to have appropriate CMS-

2000 transmission hose (17) firmly

attached before system is operated.

Connect an air line to the 1/4" quick

disconnect (20) on the pump.

Make sure connection is tight.

Adjust Hydraulic Pressure

The hydraulic pressure output of your

air pump is controlled by the air pressure

into the pump. Increasing the air inlet

pressure will increase hydraulic output

pressure, and decreasing air inlet

pressure will decrease the hydraulic

output pressure.

Use the above illustrations for reference

Hydraulic Connections:

Connect Gauge / Tee assembly to swivel fitting Afirst.

Then connect hose (18) to the gage tee (12) and the hydraulic cylinder (13).

Assure all fittings are tight.

NOTE: Chesterton requires installing a gauge in line to monitor hydraulic system pressure.

Operation:

1. Check the oil level in the pump, and add oil if necessary.

2. Check to make sure all air and hydraulic connections

are secure before operating the pump.

To Activate the Pump

Depress the ADVANCE end (air input

end) of the treadle* as shown in Figure 6

and the air motor will be activated to

pump Hydraulic oil to the system.

Fig. 6

Fig. 6a

Fig. 6b

To Hold Load Pressure

The air motor will stop and hold

load pressure when the treadle

is in the free NEUTRAL position.

See Figure 6a.

To Release Load Pressure

To release load pressure or

retract a cylinder, depress

the RELEASE end of the

treadle as shown in Figure 6b.

ADVANCE

treadle*

NEUTRAL

2 3

RELEASE

The CMS-2000 Injection System will need re-loading if the pressure gauge reads

over 5000 psi. This is an indication that the piston has reached the barrel cap (15).

A. Release the hydraulic pressure by depressing the treadle as shown in Figure 6b.

B. Remove system barrel cap (15).

C. Using either bulk or cartridge, refill the CMS-2000 Injection System (16).

D. Replace the system barrel cap (15) and tighten with the spanner wrench.

E. The CMS-2000 Pneumatic Injection system is now ready for service.

* CAUTION: Gauge pressure greater than 5000 psi may result in rupturing safety disk.

Adding Oil to the Reservoir

1. Hold pump on end as shown in Figure 1 and remove fill plug.

2. Fill to 1/2" (1 cm) below the fill opening with supplied hydraulic

oil (004211). Use of fluids other than the supplied hydraulic oil

may cause damage and will void your warranty.

WARNING: Attempting to overfill the reservoir will cause the reservoir to

become pressurized. If the reservoir is subjected to high pressure, the

casing may rupture, causing personal injury and/or equipment damage. Fig. 1

Fill Plug

20

17 16 10 11 12

13

18

A

A

15

Other manuals for CMS 2000

1

Popular Laboratory Equipment manuals by other brands

CYTENA

CYTENA x.sight Software manual

Noztek

Noztek fusionX user manual

Arometrix

Arometrix FRACTION FINDER User manual with application notes

tecan

tecan infinite 200 Instructions for use

Lifeguard Aquatics

Lifeguard Aquatics AquaStep PRO R440515 instruction manual

Ovation

Ovation BioNatural 1160-0020 Operator's guide