CONTENTS

ENGLISH

Contents

CONTENTS .......................................................................................................................2

FOREWORD..........................................................................................................................4

SYMBOLS USED ..............................................................................................................4

SYMBOLS ON THE EQUIPMENT ....................................................................................4

RELEVANT EUROPEAN DIRECTIVES............................................................................4

TECHNICAL STANDARDS ...............................................................................................5

INTENDED USE ................................................................................................................5

PURPOSE OF THE MANUAL...........................................................................................5

GENERAL WARNINGS.....................................................................................................6

PACKAGE CONTENT ...........................................................................................................7

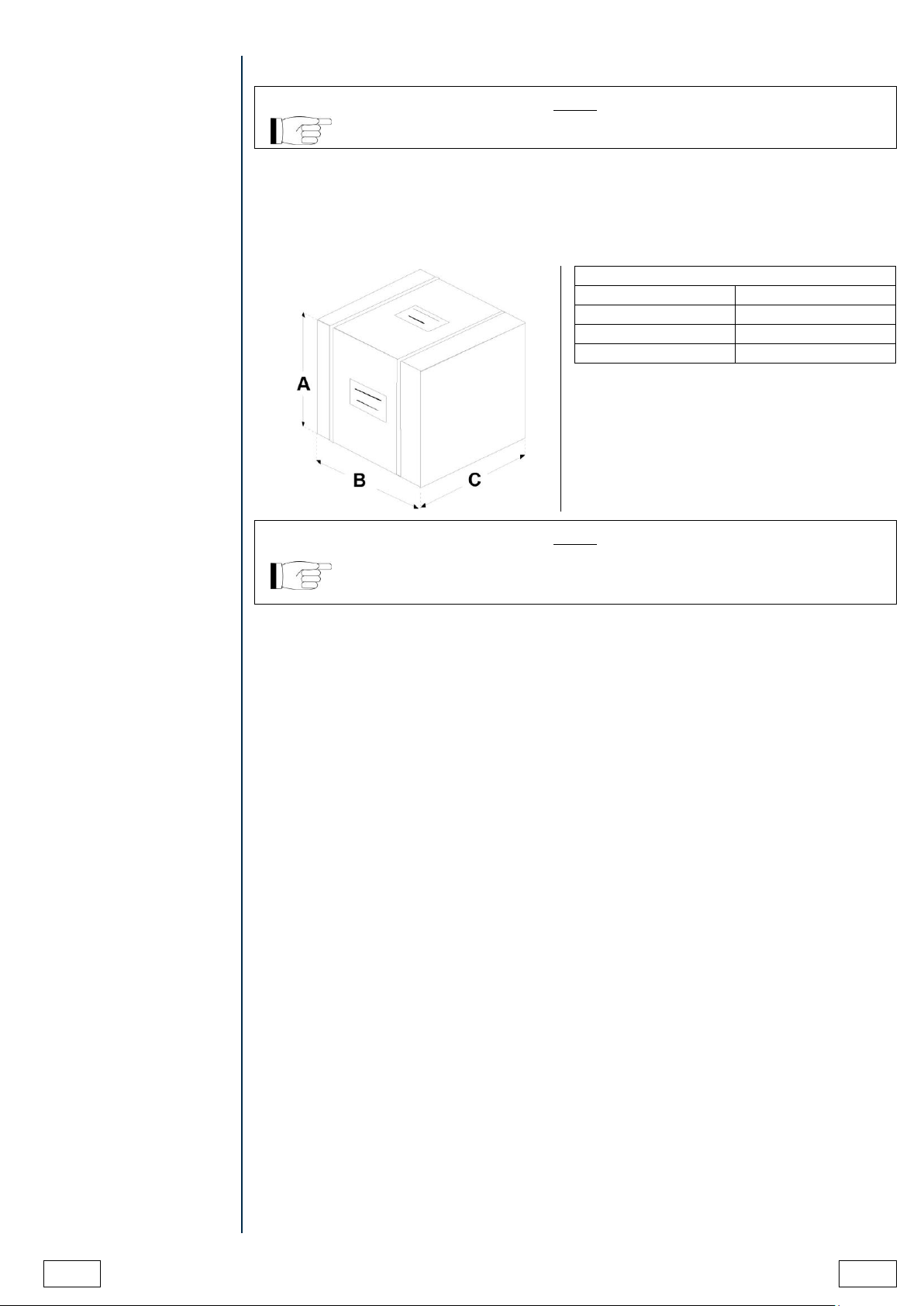

DIMENSION AND WEIGHT ..............................................................................................7

DESCRIPTION OF THE CONTENT .................................................................................7

PRODUCT HANDLING .....................................................................................................8

EMPTYING OF DETERGENT RESERVOIR AND WATER CIRCUIT..............................8

PRODUCT PRESENTATION ................................................................................................9

GENERAL CHARACTERISTICS ......................................................................................9

LCD ICONS .....................................................................................................................11

EXAMPLE OF WORKING CYCLE ..................................................................................11

SETTING UP THE DEVICE.................................................................................................12

FOREWORD ...................................................................................................................12

FOOT ADJUSTMENT......................................................................................................13

GENERAL PRECAUTIONS FOR INSTALLATION .........................................................13

ELECTRICAL CONNECTIONS.......................................................................................14

HYDRAULIC SET-UP......................................................................................................15

WATER FILLING .......................................................................................................15

HYDRAULIC SYSTEM REQUIREMENTS................................................................15

MAINS WATER .........................................................................................................16

WATER DRAINAGE..................................................................................................16

FIRST START-UP ...............................................................................................................18

DOOR OPENING ............................................................................................................18

BASKET EXTRACTION AND INSERTION .....................................................................19

FILLING OF SALT RESERVOIR.....................................................................................20

FILLING OF DETERGENT RESERVOIR........................................................................21

VALIDATED DETERGENTS ...........................................................................................21

DOOR CLOSING.............................................................................................................22

STARTING.......................................................................................................................23

MAIN MENU ....................................................................................................................23

CONFIGURATION...............................................................................................................24

SETTINGS.......................................................................................................................24

PREPARATION OF THE MATERIAL..............................................................................38

CYCLES...............................................................................................................................40

THERMAL DISINFECTION CYCLE (D90) ......................................................................40

WASHING CYCLE (W)....................................................................................................42

PRE-WASHING CYCLE ..................................................................................................43

CUSTOM CYCLES..............................................................................................................45

THERMAL DISINFECTION CYCLES SET BY THE USER (D1 CUSTOM, D2 CUSTOM)45

WASHING CYCLE DEFINED BY THE USER (W1 CUSTOM) .......................................47

DRYING FUNCTION ...........................................................................................................49