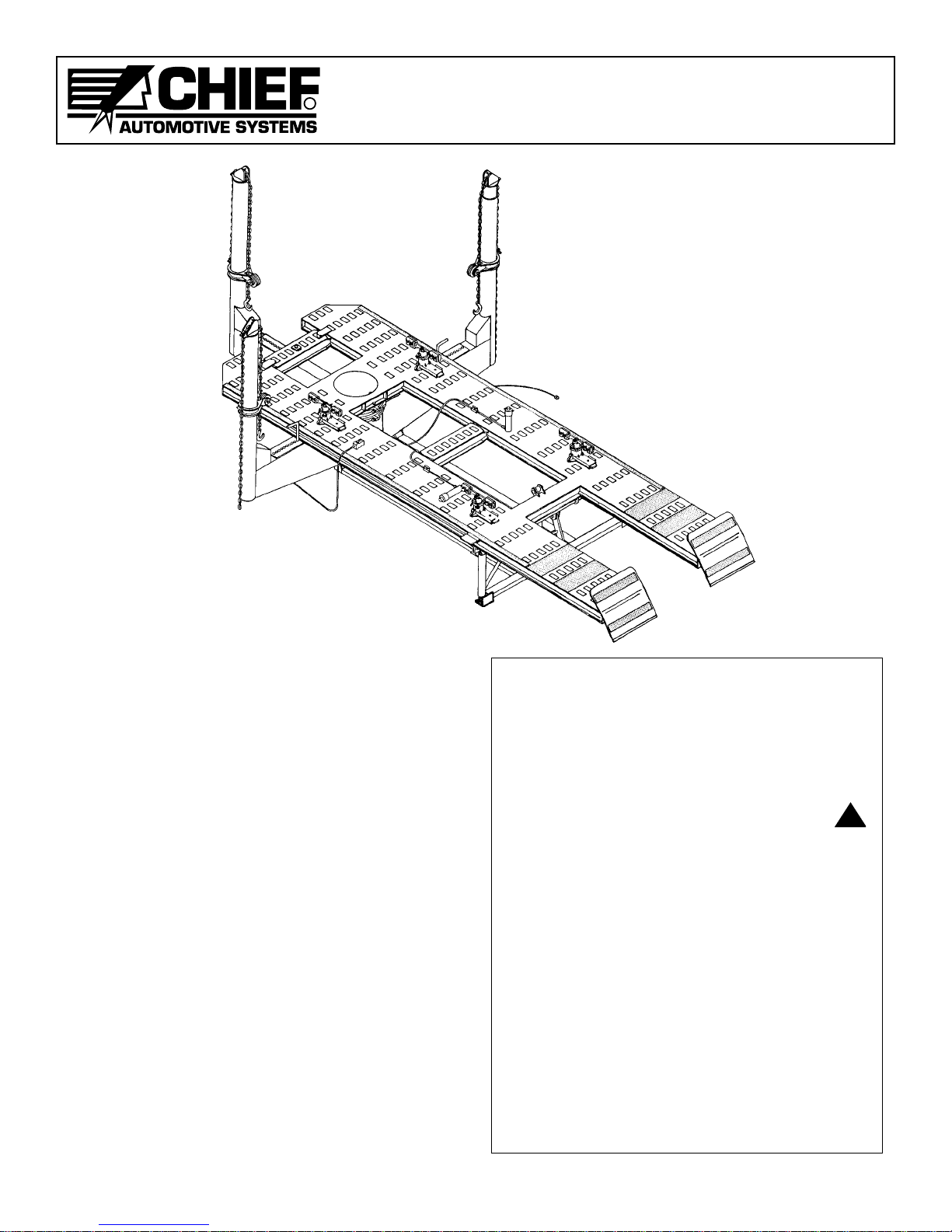

CHIEF EZ LINER S21M

USERS MANUAL

LOWERING/RAISING MACHINE

When lowering or raising a machine with a vehicle

aboard observe the following precautions.

CAUTION:

1. When driving or winching vehicle on or off machine,

use helper to guide you. If vehicle's brakes are inop-

erable, use a Chief Winch and refer to instructions

packaged with that accessory.

2. Immediately after positioning vehicle on main-

frame, put vehicle in park (if automatic transmis-

sion), apply vehicles emergency brake, and have

helper block vehicles wheels.

3. Prior to lowering machine, slowly roll vehicle to rear of

machine,put vehicle in park (if automatic transmission),

apply vehicles emergency brake, and block vehicles

wheels.Then install loading ramps at rear of machine.

4. Keep vehicles wheels blocked during raising and

lowering procedures and whenever vehicle is not

anchored to mainframe.

5. When raising or lowering machine with vehicle

aboard, DO NOT walk behind machine.

TO LOWER MACHINE

IMPORTANT: Observe preceding precautions when

lowering machine with vehicle

aboard.

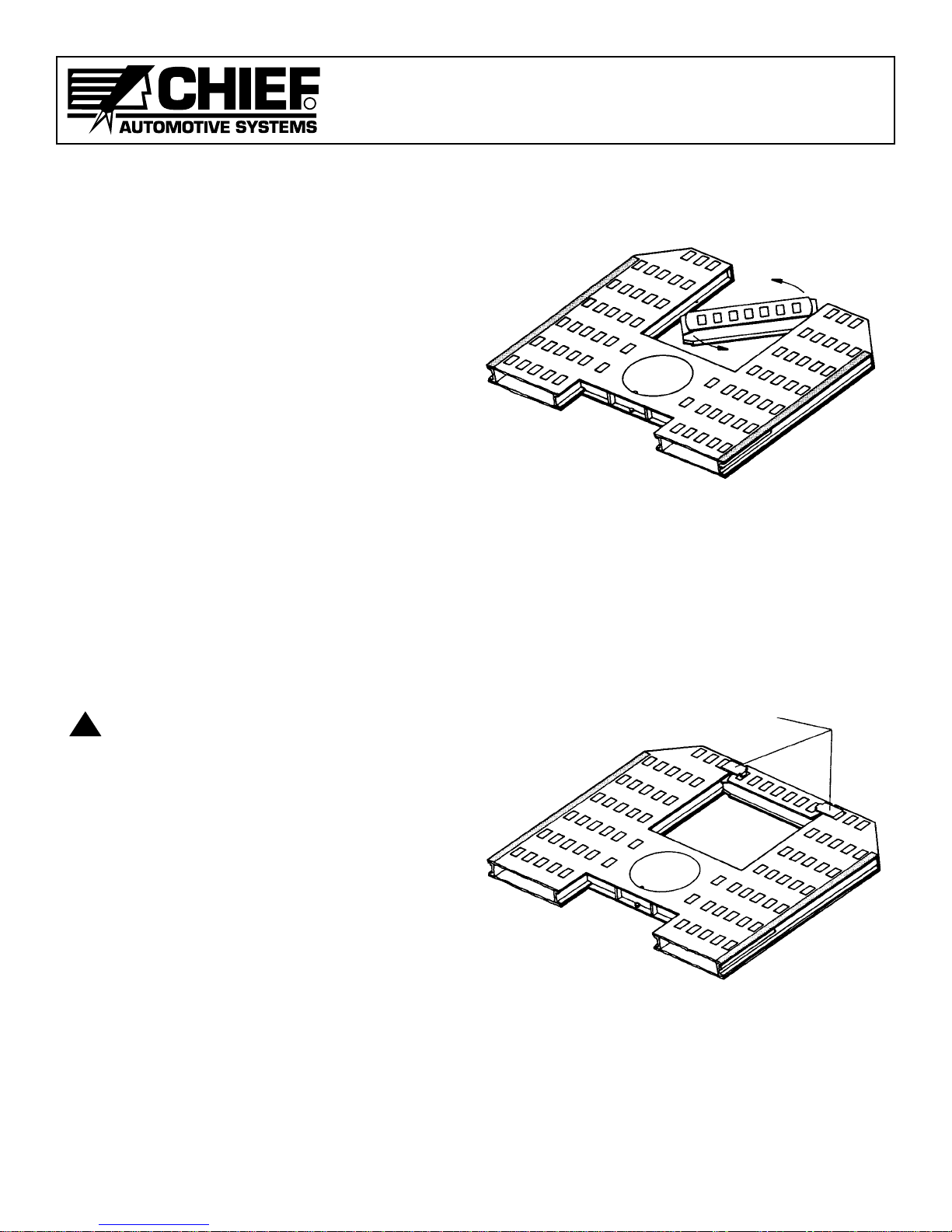

1. Position towers at front of machine and secure them

to front movable crossmember using tower pins.

NOTE: If EZ Liner is equipped with auxiliary tow-

ers, bolt these towers to sides of machine

using outermost tie down holes in fifth row

of tie down holes from rear of machine.(See

Auxiliary Tower Owners Manual.)

2. Install loading ramps at rear of machine.

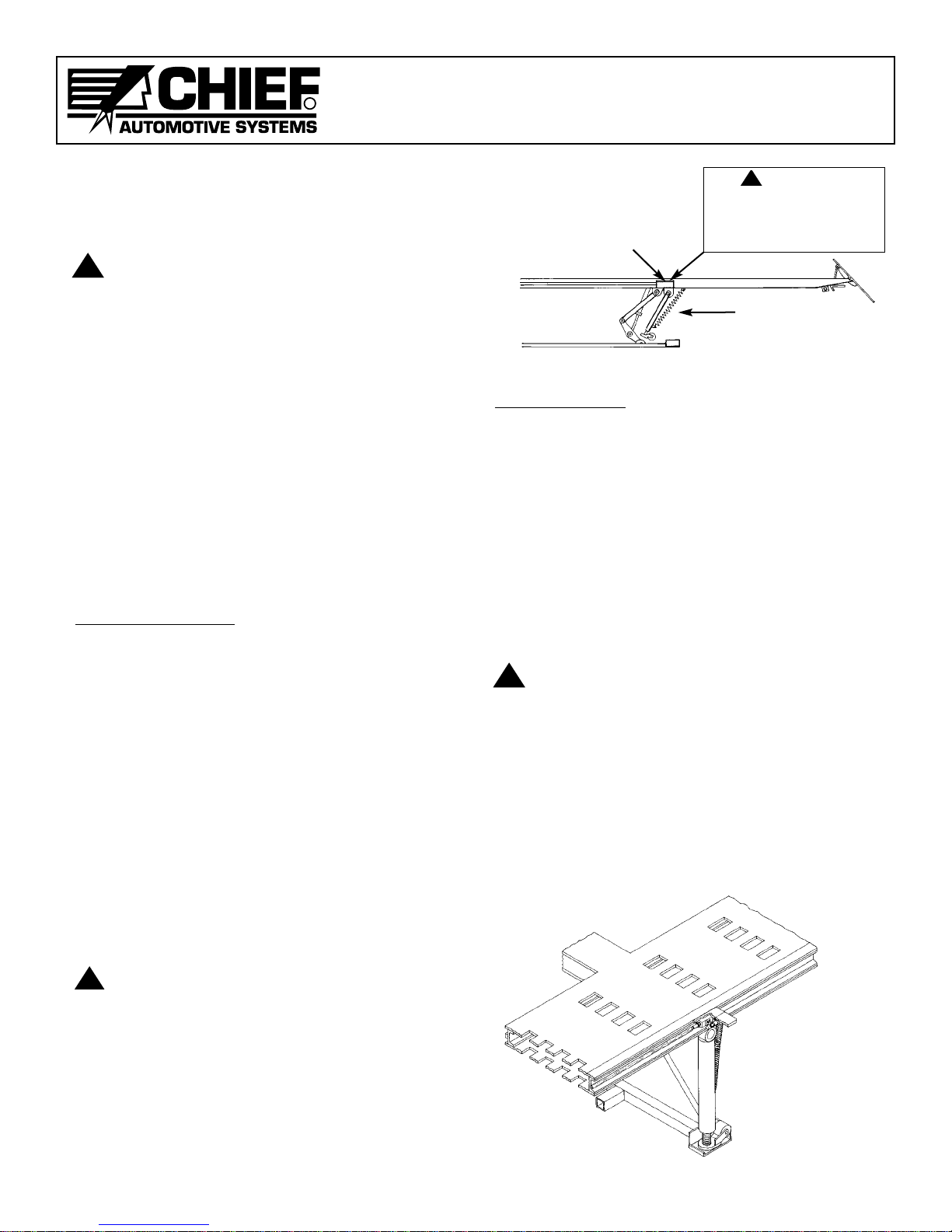

3. Raise lift valve cover and open lift valve half turn to

left. Then close all other ram valves.

4. Press 'up' button on remote control switch to lift

machine until there is no weight on stiff legs. Then

swing stiff legs forward until they are at 30 degree

angle from their vertical position. (See Figure 17.)

CAUTION:

1. Clear all obstacles from under and around

machine.

2. DO NOT allow anyone or anything to ride on

machine or be under machine during lowering

procedures.

5. Press 'down' button on remote control switch to

lower rear of machine to floor.

NOTE: DO NOT lay remote control switch on machine.

Figure 17

To Raise Machine

IMPORTANT: Observe preceding precautions when

raising machine with vehicle aboard.

1. Check location of towers making sure they are

secured to machine as noted in Step 1 —To Lower

Machine.

2. Raise lift valve cover and open lift valve half turn to

left. Then close all other ram valves.

3. Press ‘up’button on remote control switch to lift

machine until stiff legs are in upright position.Then

press ‘down’button to lower stiff legs into their

respective stiff leg catch. (See Figure 18.)

CAUTION:

1. Clear all obstacles from under and around

machine.

2. DO NOT allow anyone or anything to ride on

machine or be under machine during raising pro-

cedures.

NOTE: When mainframe lifts off floor, safety

ramps automatically pivot into position.

4. Close lift valve and lower lift valve cover.

IMPORTANT: Lift valve must be closed when

using auxiliary towers and rams.

Figure 18

8