Chopin RHEO F4 User manual

20, avenue Marcellin Berthelot - Z.I. du Val de Seine

92396 Villeneuve La Garenne cedex - France

Tél. : 33 (0)1 41 47 50 88 - Fax. : 33 (0)1 47 92 28 27

www.chopin.fr

RHEO F4

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

3

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

IMPORTANT

The technical elements that constitute this manual (text and illustrations) are not contractual,

their only target being to bring assistance for troubleshooting and repairing the Rheo F4.

Use, duplication or disclosure of subject data, for any purpose other than relating to the

servicing or repair of this equipment, is strictly prohibited without the written authorisation of

CHOPIN Technologies.

Rheo F4

5

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Table of contents

Chapter 1 Operation & Maintenance:

reminders & additional information . . . . . . . . . . . . 7

1. Operating conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Precautions linked to testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Control and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1. Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2. Failure modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3. Troubleshooting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4. Interconnection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Chapter 3 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2. Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Chapter 4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

1. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Rheo F4

6 Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

7

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

Chapter 1 OPERATION & MAINTENANCE:

REMINDERS & ADDITIONAL

INFORMATION

8Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

Chapter 1 Operation & Maintenance: reminders & additional information 9

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

Chapter 1. Operation & Maintenance: reminders &

additional information

This chapter summarizes the most important instructions relating to operation and maintenance of the RHEO

F4.

For detailed information, refer to Operating Manual.

In addition this chapter contains further information exclusively intended to staff authorised to manage

maintenance operations on devices.

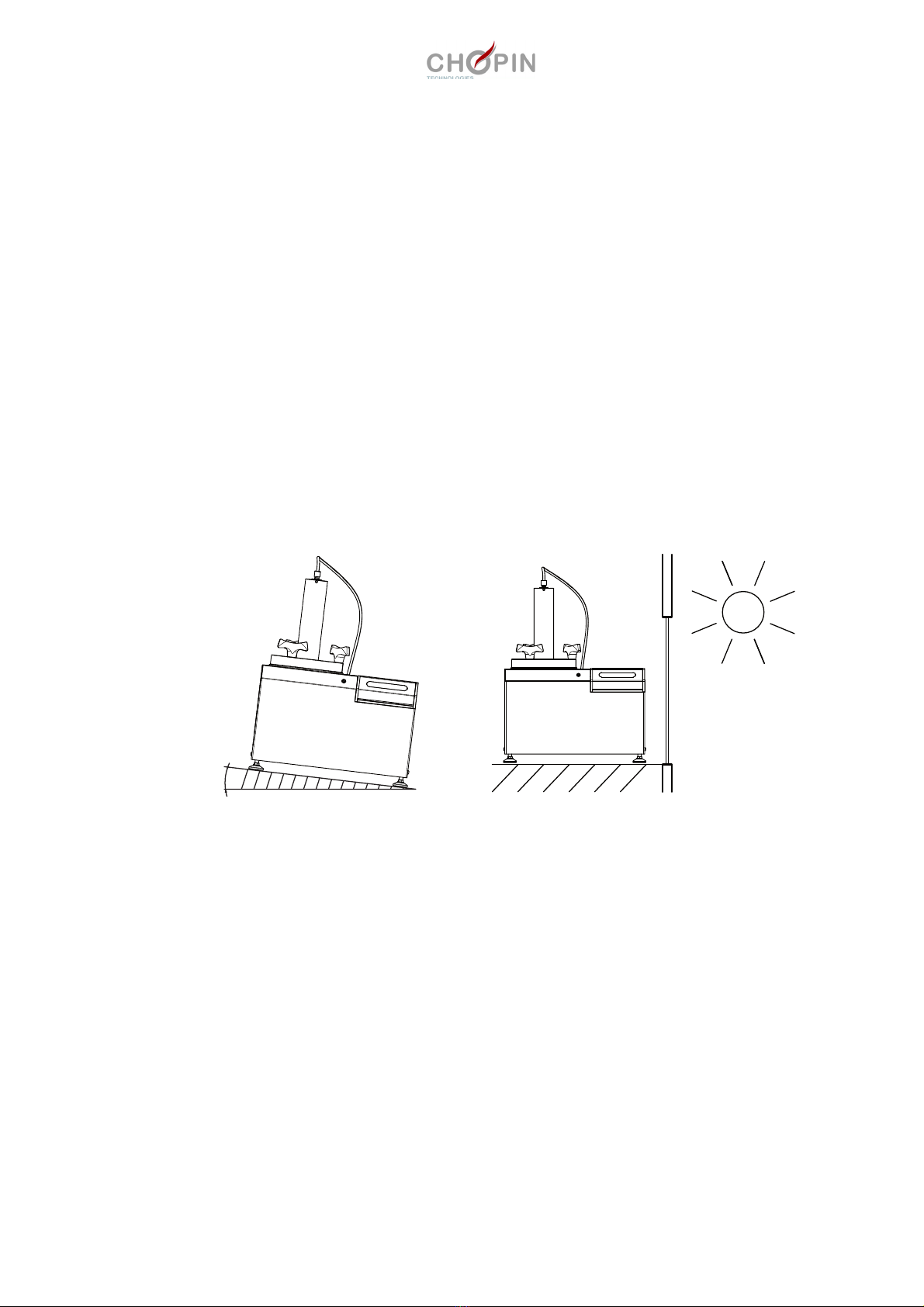

1. Operating conditions ■ Installation

The RHEO F4 must be installed on a flat, clean and tidy bench.

The device must not be installed close to a water source (taps).

The device must not be exposed to sunlight or heat sources.

■ Electrical connection

The electrical connection must have been carried out in conformity

with standard EN 61010 - installation class: II.

❏ Characteristics of the electric supply source:

• 220/240 V~ - 50/60 Hz - 150 W

• Connection with 2 Phase + Earth / 16 A plug

• The electrical network shall incorporate, upstream from the Rheo,

a differential circuit breaker with a sensitivity 30 mA - class AC.

❏ The 2 Phase + Earth supply plug can only be connected to a

socket equipped with a protective conductor.

This is a safety measure: if plugging-in cannot be achieved, do not

try to force, and call a specialist in order to install an adapted

socket.

< 3°

10 Chapter 1 Operation & Maintenance: reminders & additional information Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

■ Environment

❏ Temperatures:

Operation: 10 °C < T + 35°C

Use: inside laboratory ambient temperature 3 °C lower than the

temperature of the protocol used.

Storage: -25 °C < T + 55°C

❏ Hygrometry:

Use: HR 85 % to 20°C

Make sure the surroundings are dry, and that there is no risk of

water projection.

❏ Pollution:

The Rheo is designed so as to operate under conditions where

there is no pollution, only a dry and not conducting pollution.

2. Precautions linked to

testing

■ Cleaning

The cleaning instructions after each test are detailed in the

Operating Manual. They should be followed scrupulously, espe-

cially on points hereunder:

❏ After the test and before conducting a new test, clean the RHEO

F4.The bowl, the perforated basket and the weights must be kept

clean at all times. After each test, clean the basket and the weights

using a damp sponge. The bowl must be cleaned using a damp

cloth to prevent water entering the pressure tap at the bottom of the

bowl. In particular, thoroughly clean the bowl rubber seal and the lid

surface.

■ Between two tests

When the Rheo F4 is not being used, in order to avoid condensa-

tion and mould, do not tightly close the tank: leave the cover laid on

the studs.

■ Handling

Take special care when handling the displacement sensor: this is

an electronic device sensitive to shocks and humidity.

Chapter 1 Operation & Maintenance: reminders & additional information 11

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

3. Control and

maintenance

■ Additional menus

In addition to those described in the Operating Manual, the Rheo-

fermentometer incorporates other "screens" giving access to extra

information and adjustments which may be useful while isolating a

fault or performing particular controls.

These screens are accessible when the device is connected to

computer with an access to maintenance menu (restricted code:

3213).

It is possible from synoptic screen to enter the three sensors cali-

bration menus as well as air leakage test menu. It is also possible to

enter these different menus from [Tools] tab.

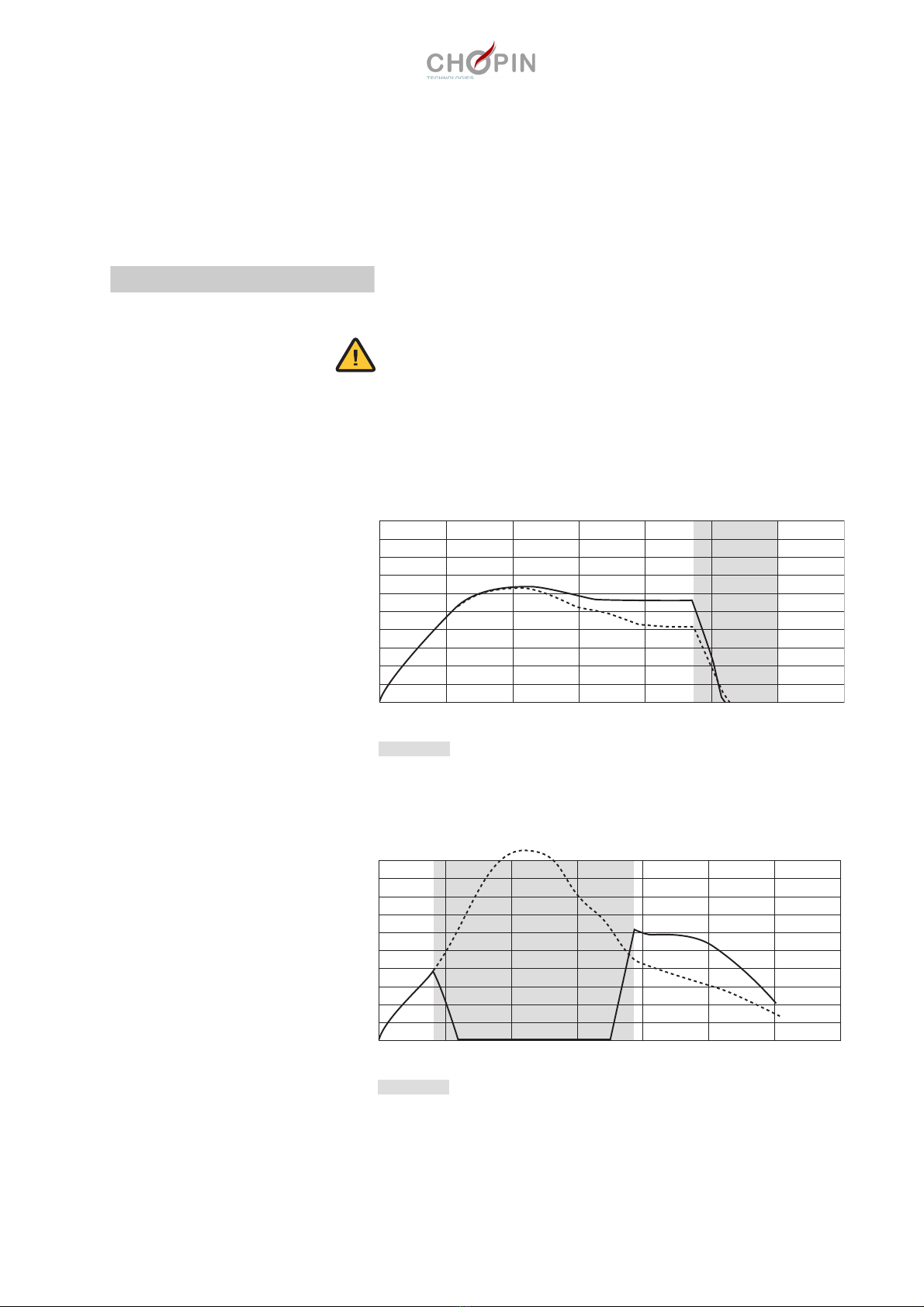

■ Calibration menus (A, B and C)

These three windows allow calibrating and checking sensors val-

ues.

Calibrations will be approached in chapter 3.

A

B

C

D

Item Description

A Height calibration

B Temperature calibration

C Air leakage test (Pressure)

D Pressure calibration

12 Chapter 1 Operation & Maintenance: reminders & additional information Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

■ Air leakage test menu

This window allows testing electrovalves and carrying out an air

leakage test.

■ General recommendations

For interventions on electronic circuits, take into account the risk of

electrostatic discharges: apply appropriate precautions (antistatic

floor, grounded wrist).

For maximum efficiency of maintenance activities on the Rheo F4,

especially when more than one device are run, it is recommended

to carefully record all pieces of information relating to the device

during its life time.

This of course applies to troubleshooting and repair activities, but

also to any particular event occurring while the Rheo works, such

as:

❏ suspicious curves,

❏ calibration tests carried out (height, temperature),

❏ ordinary service interventions (replacement of soda lime, air fil-

ter,…).

■ Preventive actions

It is reminded that, in addition to normal cleaning after each test, the

operator must proceed with a certain number of periodic operations:

Operation Periodicity

❏ Soda lime replacement 50 tests

❏ Air filter replacement1

1. Requires to open the Rheofermentometer: to be carried

out preferably by entitled repair personnel.

300 tests

❏ Air leakage test 3 months

or

after a long stop

(> 1 month)

❏ Control of height measurement

❏ Control of temperature measure-

ment

13

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

Chapter 2 TROUBLESHOOTING

14 Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

Chapter 2 Troubleshooting 15

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

Chapter 2. Troubleshooting

The aim of this chapter is, in case a fault appears, to discover the probable origin and to isolate the failed com-

ponent or sub-assembly, if any; recovery actions from this situation are then detailed.

For any inquiry to CHOPIN Technologies Service Department, please mention the serial no of the equipment.

1. Method ■ The possible failures are listed in paragraph 2. "Failure

modes".

These failures are classified as follows:

- A. Declared faults,

- B. Abnormal test results,

- C. Other faults.

❏ Other abnormal events may occur: the solution should then be

found by proceeding with analyses and comparisons. Simplified

interconnecting schematics are provided in §4. of this chapter, that

may help when doing troubleshooting.

Of course, in case of difficulty or doubt, CHOPIN Technologies

remains at disposal to try to solve the problem, by phone, fax or e-

mail.

Otherwise, the Rheo would have to be sent back to CHOPIN tech-

nologies for in-workshop troubleshooting and repair.

■ Before starting troubleshooting, it can be interesting to consult

the intervention logbook. Written remarks can also be useful, pro-

vided it has been recorded at the end of the last intervention.

❏ Regardless of the failure, it is recommended to carefully record

the conditions under which the failure occurred.

In case a failure occurred during test, it would be wiser, when possi-

ble, to keep track of the test results.

■ For each failure mode, the table in §3. "Troubleshooting instruc-

tions" indicates the isolation process that must be followed chrono-

logically.

16 Chapter 2 Troubleshooting Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

2. Failure modes A Declared faults

If the measurement seems abnormal, check on the synoptic screen

that read values are not aberrant.

A-1 HEIGHT FAULT Read height value is aberrant.

A-2 TEMPERATURE FAULT Read temperature value is aberrant.

A-3 PRESSURE FAULT Read pressure value is aberrant.

A-4 COMMUNICATION FAILURE

RHEO F4

Application communication light remains shaded.

Item

Description

A Height sensor value

B Temperature sensor value

C Pressure sensor value

A

B

C

Chapter 2 Troubleshooting 17

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

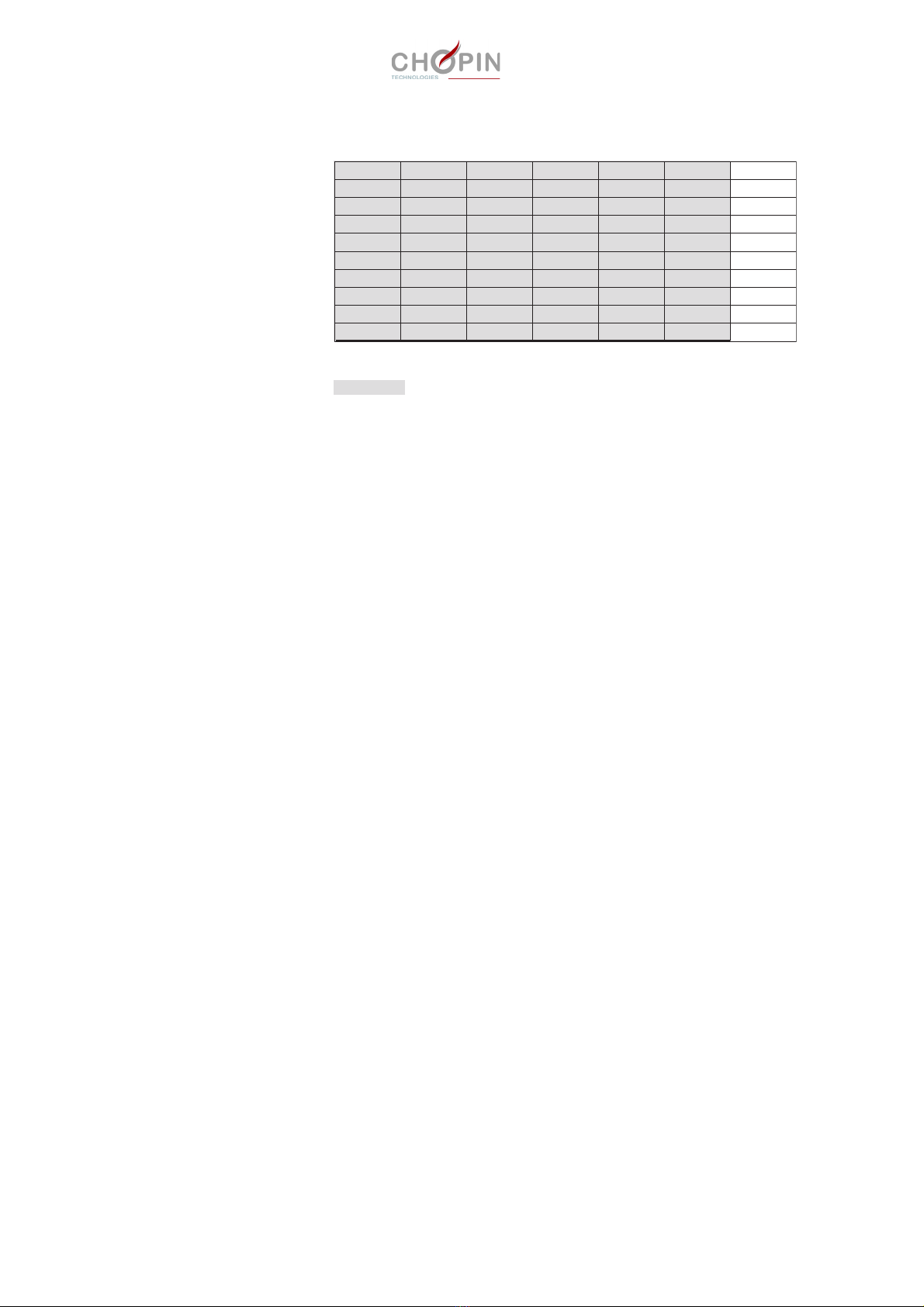

B Abnormal test results

The recording curves hereunder show the typical effects of some

internal failures occurring in the Rheo F4.

For analysis of "normal" results, i.e on a Rheo in good working

order, refer to the Operating Manual Rhéo F4.

Some internal failures may lead to apparently plausible test results.

This is the case when, for example, a very slight leak exists in the

pneumatic circuit, or when a sensor has slightly drifted.

The operator shall therefore proceed with periodic controls of some

"sensitive" functions, with the help of dedicated built-in functionali-

ties, in particular.

❏ "Air leakage test" (see in Chapter 3 instruction Operation 6-4),

❏ control of the displacement sensor (see instruction Operation 6-1)

B-1 CURVE TYPE 1

Pressure values recorded in direct and indirect cycles fall to zero.

B-2 CURVE TYPE 2

Pressure values recorded in direct cycle fall to zero.

Importante note

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

18 Chapter 2 Troubleshooting Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

B-3 CURVE TYPE 3

Pressure values recorded in direct cycle are too low.

B-4 CURVE TYPE 4

Early curve separation.

B-5 CURVE TYPE 5

Pressure values recorded in indirect cycle fall to zero, while those in

direct cycle are too high.

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

Chapter 2 Troubleshooting 19

Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

B-6 CURVE TYPE 6

Pressure values recorded in direct and indirect cycles remain to

zero.

B-7 CURVE TYPE 7

Pressure values recorded in indirect cycle remain to zero.

B-8 CURVE TYPE 8

Excessive pressure values.

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

STOP

0

50

100

0 1h2h3h

GAS RELEASE

Presence of a fault

20 Chapter 2 Troubleshooting Maintenance manual

MM-RHEOF4-EN ind. 1 - 09/2014

Rheo F4

B-9 CURVE TYPE 9

No height measurement recorded.

(Note: there is no fault message as for A-2, considering the meas-

urement value not being "out of range")

C Other faults

C-1 INSUFFICIENT HEATING The heating is insufficient if the set temperature of the protocol is

never met, or if the time to reach it is abnormally long.

Note: This time depends of course on the difference between

the targeted and ambient temperatures: it should normally not

exceed 1 hour.

3. Troubleshooting

instructions

Warnings:

• Any opening of the Rheo requires first the disconnec-

tion of the power cable.

• When conducting checks on an opened Rheo with the

need of the electrical power supply, apply adequate

safety measures.

0

50

100

0 1h2h3h

DOUGH DEVELOPMENT

Presence of a fault

Other manuals for RHEO F4

2

Table of contents

Other Chopin Measuring Instrument manuals