Chopin RHEO F4 User manual

20, avenue Marcellin Berthelot - Z.I. du Val de Seine

92396 Villeneuve La Garenne cedex - France

www.chopin.fr

Rheo F4

User’s manual

07/2015

Table of contents

1 Introduction.................................................................................................................................................7

2 Installation and start-up............................................................................................................................10

3 Use.............................................................................................................................................................18

4 Maintenance..............................................................................................................................................32

Appendix 1: Standard curves.............................................................................................................................36

Appendix 2: Improving flour quality..................................................................................................................39

Appendix 3: CHOPIN protocol...........................................................................................................................41

Rheo F4

User’s manual 3

07/2015

WARNING

The technical elements that constitute this manual (text and illustrations) are not contractual,

their only target being to bring assistance for using the Rheo F4.

Use, duplication or disclosure of subject data, for any purpose other than relating to the use or

servicing of the equipment, is strictly prohibited without the written authorisation of CHOPIN

Technologies.

Rheo F4

4 User’s manual

07/2015

Rheo F4

User’s manual 5

07/2015

Rheo F4

6 User’s manual

07/2015

Rheo F4

User’s manual 7

07/2015

1 Introduction

1.1 Measurement principle

Development of wheat and rye products during baking depends

both on the quantity of CO2in the dough aqueous phase and on

the rheological properties of the actual dough.

This development depends both on the capacity of the protein

network to be deformed under gas pressure and on the capacity of

the dough to retain this internal pressure until thermal denaturation

of the proteins and starch gelling. Measurement of flour proofing

ability is thus linked to the quality of the dough protein network

during its development.

1.2 Operating principle

The Rheo F4 analyses the development of a dough sample placed

in a test bowl and that will ferment under the conditions imposed by

the protocol used (temperature, weights placed on it, etc.).

Place the piston on the dough, which will

rise progressively as it ferments.

According to the test type conducted, the

piston is loaded by weights.

1

2

3

4

1 Proofing basket 2 Weight

3 Dough 4 Piston

The piston is directly connected to a height sensor that will

measure dough development. Moreover, the device bowl is

connected to a pressure sensor by means of a pneumatic circuit

that measures the pressure increase of the fermenting dough. The

result of a test is thus made up of two plots: the dough

development curve and the gas release curve.

The dough development curve is obtained by measurements taken

at regular intervals by the dough development sensor.

To plot the gas release curve, the pneumatic circuit runs pressure

measurement cycles. These pressure measurements are

converted into flow rates by the microprocessor.

Rheo F4

8 User’s manual

07/2015

The cycle principle consists in measuring total gas release and gas

release less its carbon dioxide trapped in the soda lime cartridge.

The difference between the two gas release curves gives the

quantity of carbon dioxide given off by the dough during the test.

zCycle description:

1. Direct cycle

Electrovalves B and B’ isolating the absorbent (soda lime

cartridge) in the direct circuit are closed, as well as circuit

bleed electrovalve C. Direct circuit isolation electrovalve A is

open. Pressure increase due to swelling of the fermenting

dough is measured by the electronic sensor.

2. Bleed cycle

Once the pressure measurement has been recorded,

electrovalves A,B,B’ are closed and electrovalve C opens to

bleed the circuit and set it to atmospheric pressure.

Electrovalve C then closes.

3. Indirect cycle

Direct circuit isolation electrovalve A and bleed electrovalve C

are closed. Electrovalves B and B’ isolating the soda lime

cartridge and the indirect circuit are open. The increase in

pressure due to dough swelling is measured without the

carbon dioxide that has been trapped by the soda lime.

4. Bleed cycle

A new bleed cycle is run just as described in point 2.

5. A direct cycle is then activated and so on until completion of the

time programmed in the protocol.

Cuve

Absorbant

Volume tampon

Pressure

sensor

Rheo F4

User’s manual 9

07/2015

1.3 Device characteristics

zGeneral characteristics

Power supply: 220/240 Vac - 50 /60 Hz - 150 W

Noise level: < 70 dB

Dimensions: Width x Depth x Height: 415 x 265 x 545 mm

Net weight: 12 kg

Gross weight: 20 kg

zFuse

Fuse 5x20 T 1.6A 250 V

zEnvironment

Indoor use

Storage temperature: – 25 to + 55° C

Device usage temperature: 10 to 35° C

Use: laboratory ambient temperature 3°C less than that of the

protocol used.

Hygrometry: RH<85% at 20° C

Fluctuation in supply voltage: < ± 10%

Degree of pollution as per EN 61010: 2

Installation category as per EN 61010: II

(overvoltage category)

Supply source characteristics:

Connection by 2P + earth / 16A power socket

The electrical network must comprise, upstream from the Rheo,

an RCD with a sensitivity 30mA, class AC.

Rheo F4

10 User’s manual

07/2015

2 Installation and start-up

2.1 Unpacking

The device is protected by a specific packaging. We strongly

recommend that you keep this packaging for transfers from

workstation to workstation or for return for service (re-dispatching

to CHOPIN Technologies or your distributor).

This packaging contains the Rheo F4 with its accessories.

1 2

3 4

5

Rheo F4

User’s manual 11

07/2015

2.2 Part lists

The Rheo F4 package contains the following parts in addition to

the device:

Soda lime cartridge

500 gr weights and standard support

piston assembly

Proofing basket

Power cable

Dough development sensor cable

Cable to computer

Bowl tightening nut

Temperature control support

Dough development

sensor

Pump

USB memory stick (user's

manual and software)

Rheo F4

12 User’s manual

07/2015

2.3 Connections

The Rheo F4 has the following connections.

1

5

4

3

2

1 Dough development sensor port 2 Computer port

3 I/O switch 4 Pneumatic circuit bleed

5 Power supply port

Connect the power cable to the supply port (5)

Connect the dough development sensor cable to the

Rheo F4 using port RJ (1), then connect the other side of

the cable to the dough development sensor.

Rheo F4

User’s manual 13

07/2015

The device must also be connected (2) to a computer.

Once all the connections have been made, press the I/O

switch.

Please wait for the Rheo F4 peripheral to be fully installed, this can

take a few minutes.

If the installation is incomplete, double click the executable on

the CDROM of the instrument.

Rheo F4

14 User’s manual

07/2015

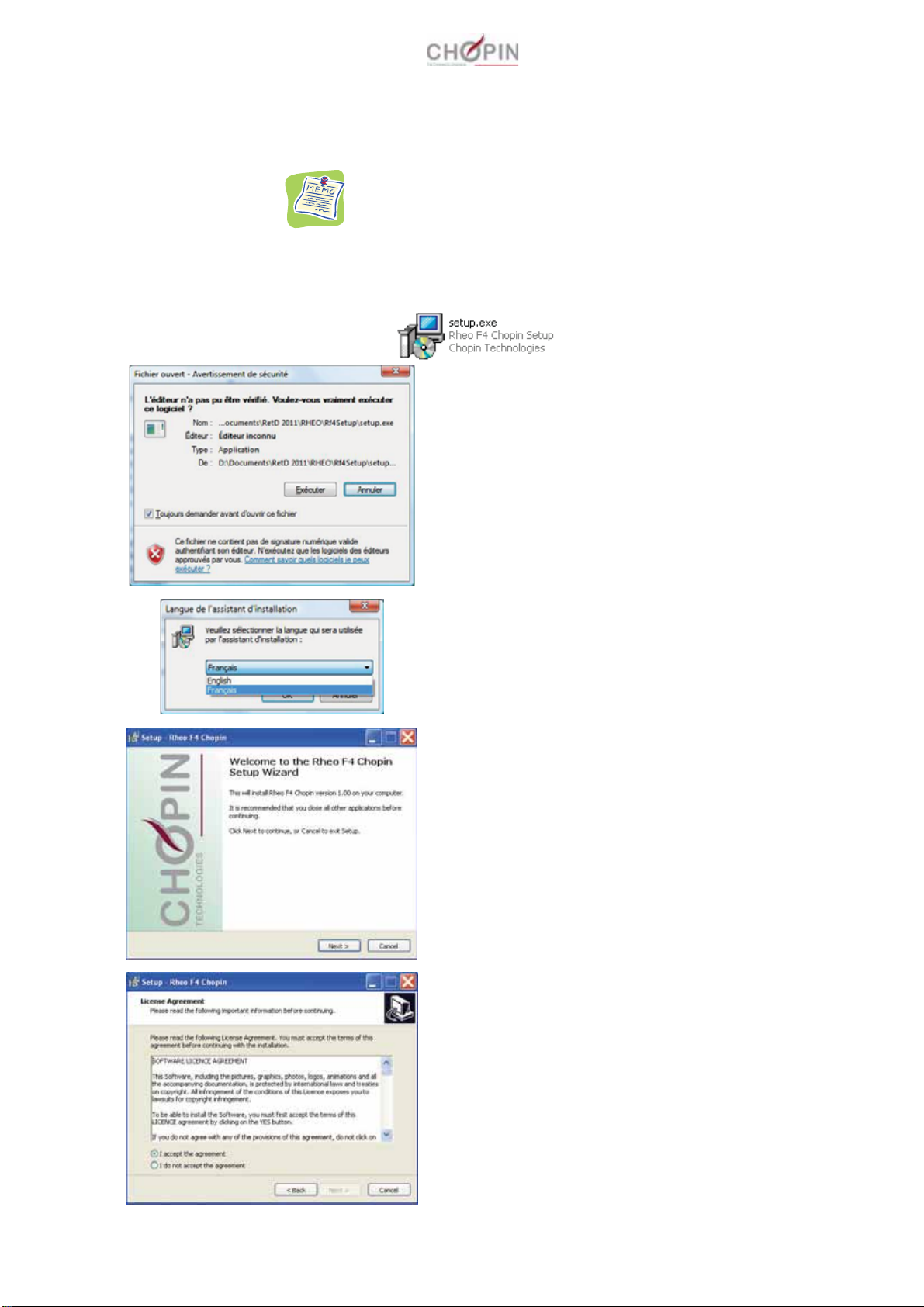

2.4 Installing the software

Before installing the software, please refer to the file "Read me

first" available on the USB stick provided.

Plug the USB stick supplied with the Rheo F4 on your computer.

Click on the software icon and then on setup.exe.

Click on [Exécuter].

Choose the installation wizard language and click

on [OK].

Installation starts, click on [Next].

Accept the license agreement and click on [Next].

Rheo F4

User’s manual 15

07/2015

Choose the installation folder and click on [Next].

Choose the folder where the icon will appear in the

start menu and click on [Next].

You can choose to create an icon on the desktop by

ticking the box. Click on [Next] to validate

installation.

Rheo F4

16 User’s manual

07/2015

2.5 Conditions of use

The Rheo F4 must be installed on a flat, clean and tidy bench.

The device must not be installed close to a water source (taps).

The device must not be exposed to sunlight or heat sources.

Ambient temperature must be at least three degrees below the

temperature of the protocol used.

2.6 Start-up of the Rheo F4

The Rheo F4 is a measurement device.

To display and interpret results, it must be connected to a

computer.

Switch on the computer to which the Rheo F4 is connected. Once

the operating system has been launched, start the software by

clicking on the icon:

The software opens:

Check that the device is connected to the computer.

Rheo F4

User’s manual 17

07/2015

To access the connection configuration menu, click on the icon:

[Connection]

The following window is displayed:

Select the COM port corresponding to the connection of your

device.

If you do not know your connection port, you can try them one

by one until the device is connected.

Once connected to the device, the software displays the message

at the bottom of the screen and enables the machine status LEDs.

The device is now ready to perform the tests.

Rheo F4

18 User’s manual

07/2015

3 Use

3.1 Preliminary parameter settings for running a test

When using the software for the first time, we recommend you

check the following parameters: customers, protocols and

configuration.

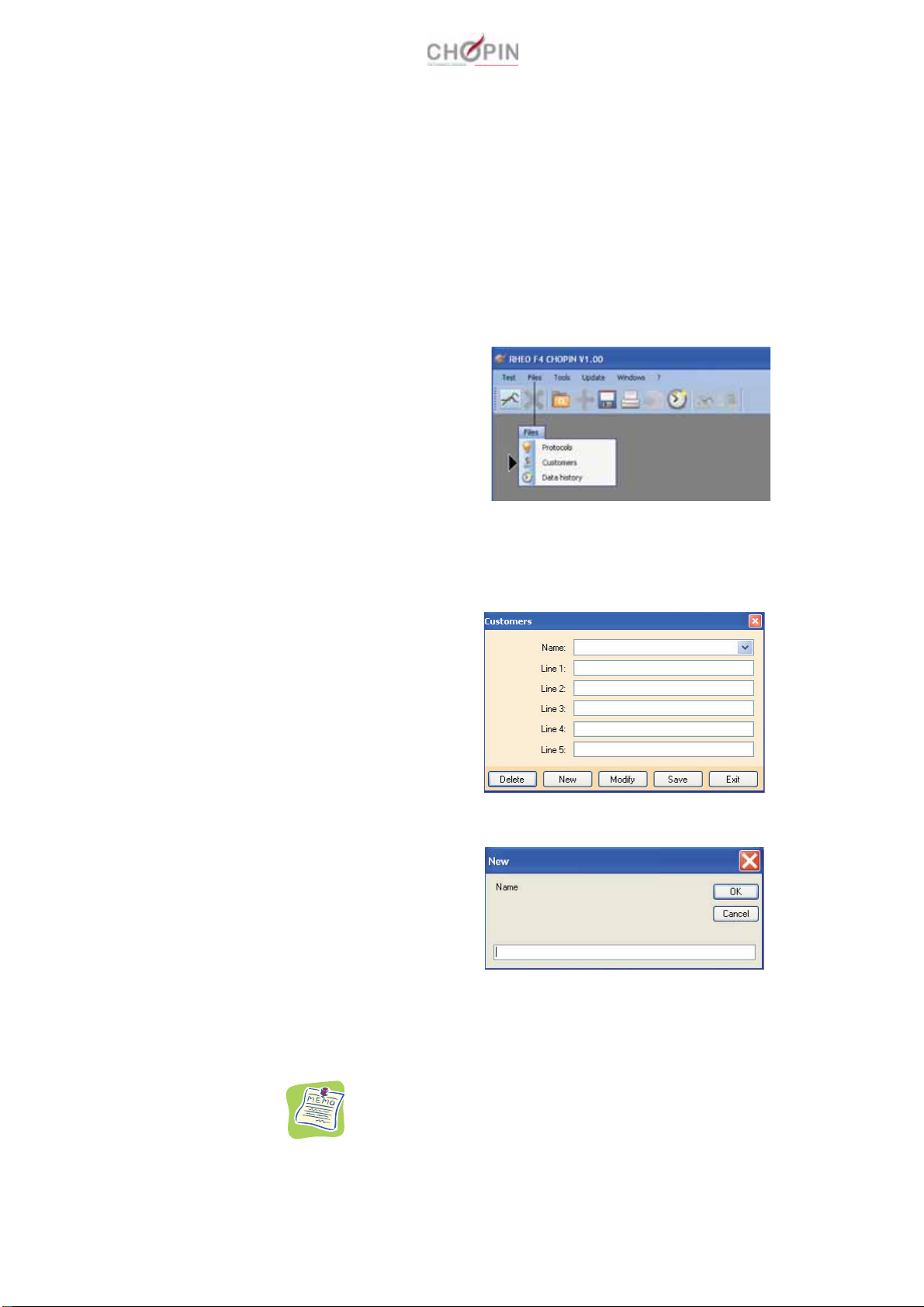

zCustomer parameters

To access customer parameters, click on the tab [Files] followed by

[Customers].

The following window is displayed:

You can thus define your various customers by clicking on [New].

Enter the customer name and click on [OK]. You can now enter

customer data using the 5 lines.

Click on [Save] then [Exit] once data entry is complete.

Existing customer file can be deleted or modified using this

window.

Rheo F4

User’s manual 19

07/2015

zProtocol parameters

To access protocol parameters, click on the tab [Files] followed by

[Protocols].

The following window is displayed:

You can thus define your own protocols by clicking on [New].

Enter the protocol name and click on [OK]. You can now enter the

protocol values. These values are (in order):

Test bowl temperature,

test duration in minutes,

weight of the dough sample used for the test in grams,

load weight placed on the sample in grams,

type of mixer used for dough kneading,

type of yeast used,

quantity of yeast in %.

Once the protocol values have been entered, press [Save] to save

the protocol. Once the protocols have been entered, you can click

on [Exit].

Rheo F4

20 User’s manual

07/2015

Existing protocols file can be deleted or modified using this

window.

You cannot edit the CHOPIN protocol. When this protocol is

selected in the drop-down menu, you cannot click on

[Delete] or [Modify]

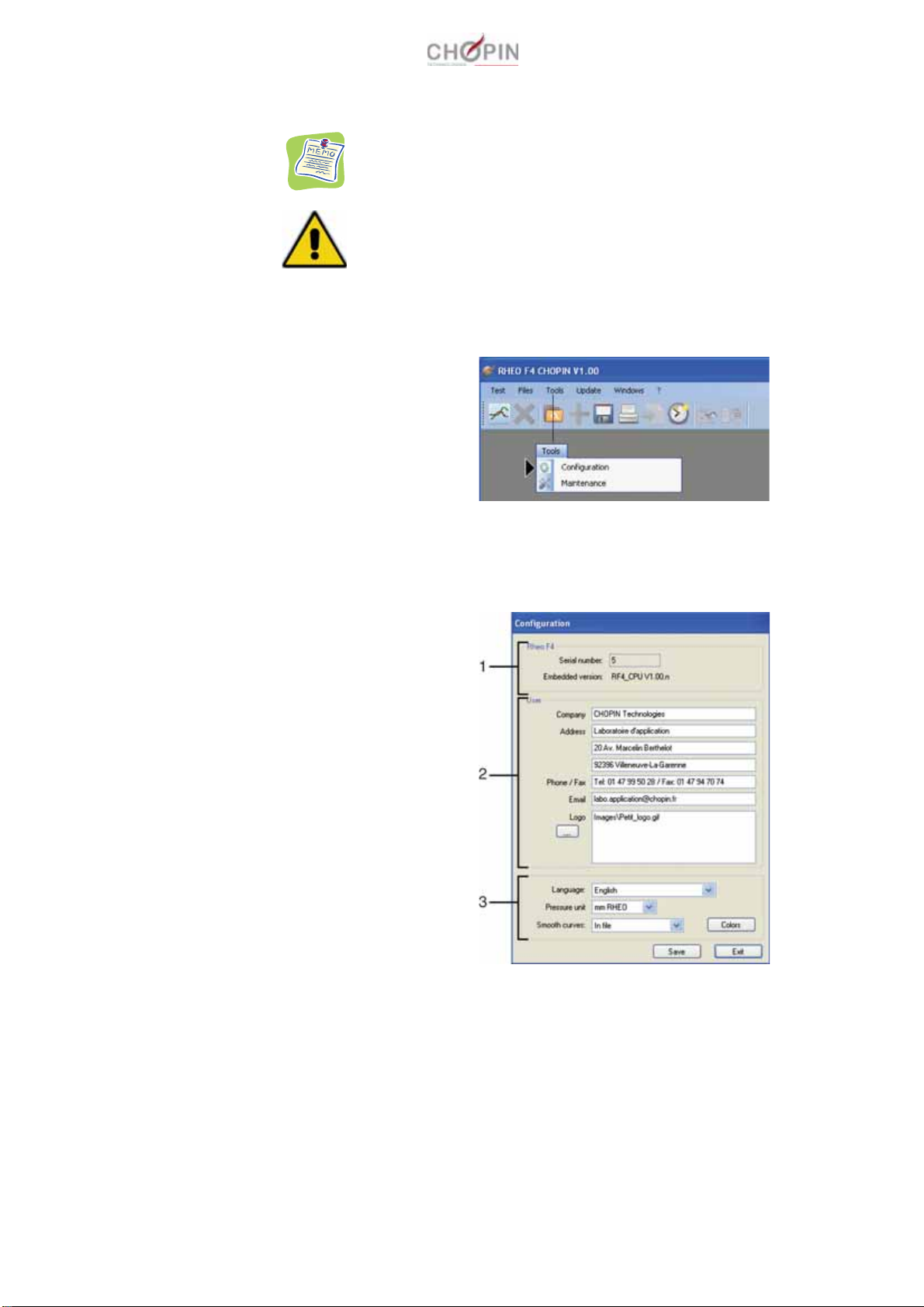

zConfiguration parameters

To access the configuration parameters, click on the tab [Tools]

followed by [Configuration].

The following window is displayed:

The Rheo F4 section (1) gives the device serial number and the

version of the embedded software.

The User section (2) lets you enter your personal information such

as your address, phone and fax numbers, and lets you choose a

picture for the logo.

Section (3) lets you choose the software language, the pressure

unit, and the curve smoothing process.

Other manuals for RHEO F4

2

Table of contents

Other Chopin Measuring Instrument manuals