Christini AWD User manual

Service Manual

Page 1

Service Manual

Christini Technologies, Inc.

421 N. 7th Street Suite 200

Philadelphia, PA 19123

215.351.9895

215.351.9896 fax

info@christini.com

Version 1.3

Service Manual

Page 2

Service Manual

Page 3

Table of Contents

Introduction; Tools you’ll need 4

AWD Bike Detail Illustration 5

Bike Disassembly Flowchart 6

White Brothers AWD Fork Removal 7

White Brothers AWD Fork Drive Shaft Maintenance 8

AWD Drive Shaft Removal and Installation 10

AWD Engagement Clutch Detail 13

AWD Engagement Switch Detail 16

AWD Engagement Cam Detail 17

Rear Suspension Detail 18

AWD Bearing Maintenance 19

Routine Maintenance Schedule 20

General Notes 21

AWD Lubrication Guide 22

AWD Troubleshooting 23

Appendix:

Christini AWD Limited Warranty 24

Christini Owner’s Registration Card 25

Front Hub Maintenance 15

Service Manual

Page 4

The CHRISTINI AWD consists of a patented lightweight, inter-

nalized, shaft-driven system that allows the rider to engage

both wheels for additional power when there is "wheel slip".

With the simple flip of a handlebar-mounted switch, the AWD

system provides increased control, traction and stability on

slippery or loose surfaces and unmatched power to climb

steep hills.

Simply stated, when the rear wheel slips — the front wheel

grips.

Congratulations! You own an All Wheel Drive Bicycle

• Allen Wrench Set

• 2, 2.5, 3, 4 with short end (supplied), 5, 6 millimeter

wrenches

• Plastic faced hammer or a rubber mallet

• Large flat bladed screwdriver & small flat bladed screwdriver

• Torx style wrench - included with disk brake set

• 10 millimeter box wrench

• Pair of needle-nose pliers

• Thread Retaining Compound:

• “Blue” Loc-tite 242 Removable Strength

• “Red” Loc-tite 262 Permanent Strength

The Tools You Will Need for Maintenance

Service Manual

Page 5

Page 5

AWD Detail Illustration

Service Manual

Page 6

Page 6

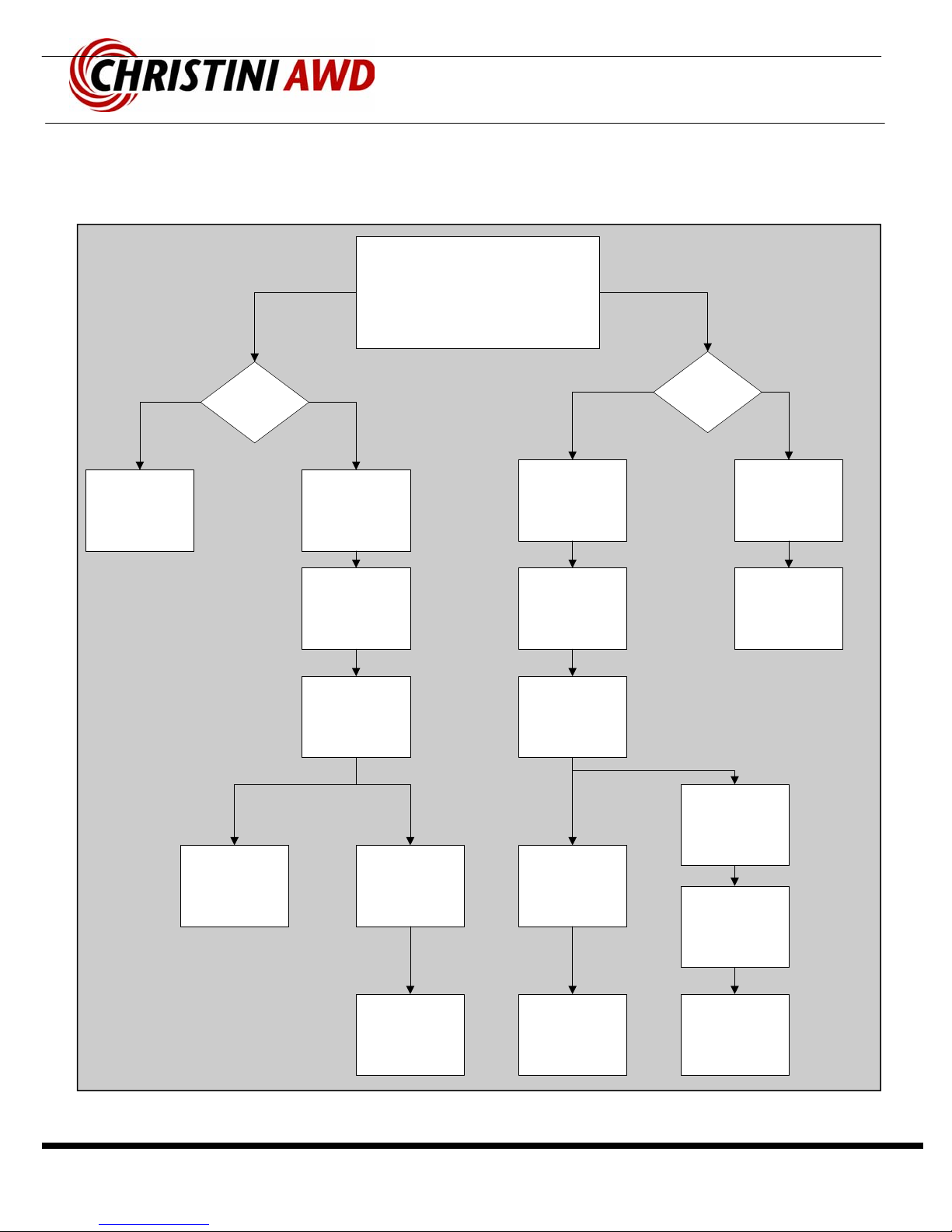

Bike Disassembly Flowchart

Remove Fork

Remove

Front Wheel

Remove Front

Bevel Gear

Remove Chain

Crown Cover

Remove Front

Pinion

Remove

Rear Wheel

Remove

Clutch

Remove Rear

Bevel Gear

Remove Shock

Remove

Suspension

Link

Remove Front

Drive Shaft

Remove Rear

Pinion

Remove Rear

Drive Shaft

Remove Pivot

Bolts

Remove Rear

Triangle

All Wheel Drive Bike

Disassembly Process

Separate the

Front and Rear

Driveshafts

Remove

Headtube

Gear and

Sprocket Shaft

Remove

Power

Transfer Chain

Remove Front

Driveshaft

Service Manual

Page 7

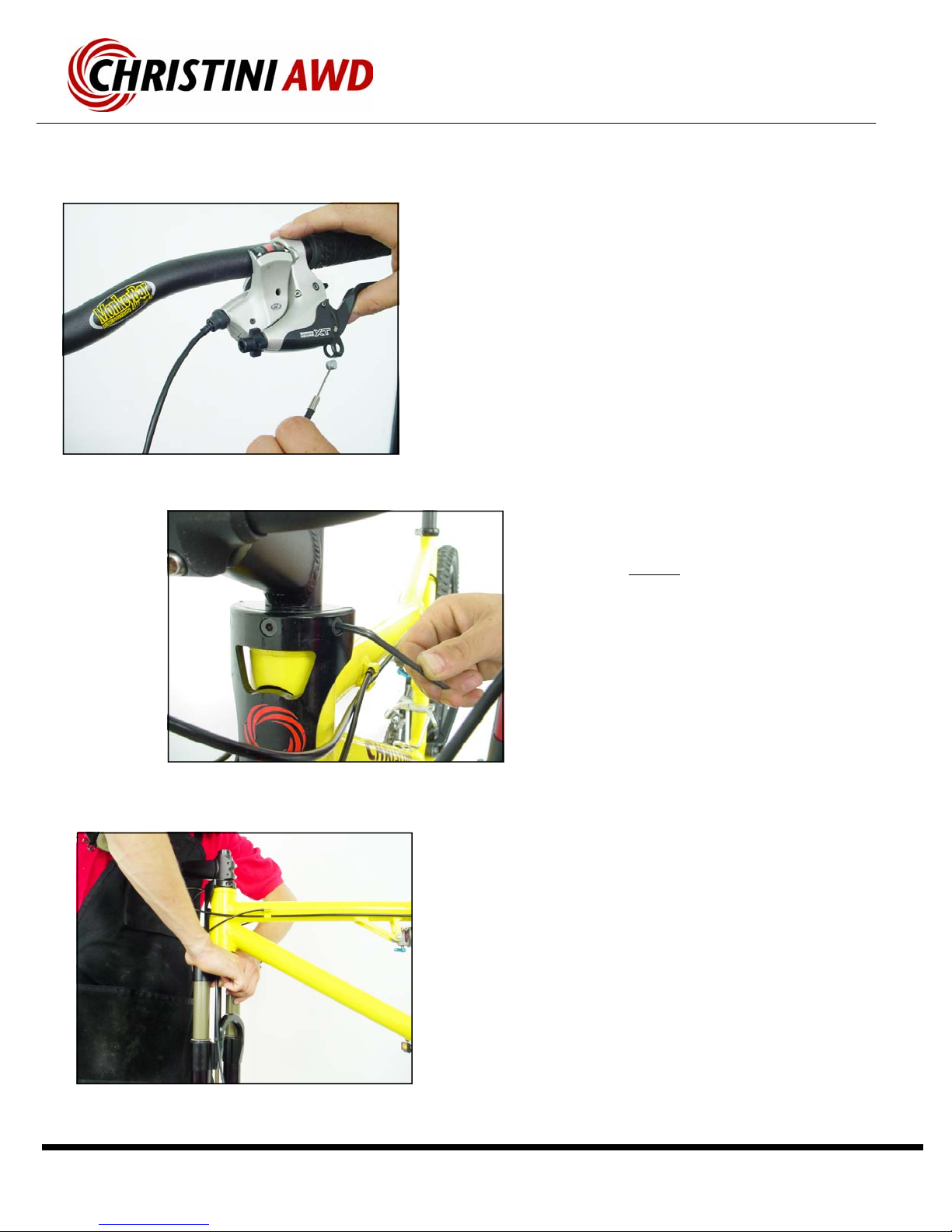

• Remove the front wheel. The fork legs may

need to be pulled apart slightly, since there is

a 1 mm indent on the non-disc brake side of

the front hub axle. This indent locates the

front bevel gear and provides support during

heavy AWD loading.

• Remove the front disk brake cable at the

lever—or remove the front disk brake caliper.

• Remove the three M6 bolts, located just

above the headtube on the front plate, that

attach the steering link to the upper steering

clamp.

• Warning—DO NOT use the rounded Bohndus

end of the Allen wrench when first loosening

the bolts. You will strip the hex head of these

bolts.

• After these three bolts have been removed,

the fork can be pushed down out of the head-

tube of the bicycle. If necessary, use a plastic

hammer to tap the fork out. Hit the hammer

on the top of the brake arch to avoid damag-

ing the forks valves.

• Please refer to the White Brother’s AWD Fork

Owner’s Manual to service or adjust the front

suspension. (If lost see www.WhiteBros.com

for details)

Installation:

• Slide Lower steering tube into the support bear-

ings in the headtube.

• Tap the fork into place with a plastic hammer.

Do not tap the crown cover.

Custom White Brothers AWD Fork Removal

Service Manual

Page 8

Fork Driveshaft Maintenance

Removal

• Remove the four countersunk M4 screws under the

crown of fork which hold the crown cover plate in

place.

• Remove the Crown-Cover plate. Slide the Upper

Front driveshaft and the crown cover plate down, as

shown, towards the dropouts. The Upper Front

Driveshaft will compress and slide on the splined

portion of the drive shaft.

▪Remove the fork drive shaft capture bolt. It is an M6 bolt

on the end of the fork drive shaft located under the pinion gear.

▪To loosen the bolt, use the supplied short-end 4mm Allen

wrench to hold the bolt in position while turning the hex piece

of the driveshaft counterclockwise (from the top of the fork

looking down), with a 10mm box wrench.

▪TIP: If the driveshaft is stuck in the gear, loosen the bolt

halfway and then gently tap the blot head with a hammer to

free the driveshaft.

Service Manual

Page 9

Fork Driveshaft Maintenance

Installation:

▪Insert the drive shaft into the steering tube, sprocket first,

until the miter gear is fully seated on its sealed bearing

support.

▪Loop the chain around the shaft sprocket and the floating

cog. Press the cog into the bearing.

▪Press the upper hex portion of the driveshaft into the cog

and slide the chain crown up into place.

▪Use removable threadlocker when re-installing the crown

cover screws.

▪Use removable threadlocker on the pinion bolt.

Removal:

▪Slide the two sections of the front drive shaft together.

▪The chain crown cover can slide off at this point.

▪The pinion gear can also be removed at this point.

▪Remove the floating cog and power transfer chain from

the internal section of the chain crown.

▪Use your thumbs to press the center sprocket up through

the lower steering tube.

▪Carefully pull the drive shaft out of the steering tube.

Service Manual

Page 10

AWD Frame Drive-system Maintenance

Re-assembly:

▪Slide the rear pinion into the slot and then drop the rear

drive shaft down into the female spline on the pinion.

▪Apply removable threadlocker to the M6 bolt and tighten

by holding the bolt with a wrench and then spin the drive

system clockwise to tighten.

▪Install the rear shock mount bolt and the rear shock.

Removal:

▪Remove the M6 capture bolt from the rear pinion assembly on

the rear bevel dropout. Use the supplied short-end Allen Wrench to

hold the bolt while spinning the drive system by hand to remove the

bolt.

▪If necessary, use a 10mm wrench to spin the square spline

section of the drive system to help loosen the bolt.

▪Remove the rear shock mount bolt, and then slide the shock

out from between the Top Yoke, as shown.

▪TIP: Be careful not to chip the frame paint with the suspension

link when the rear triangle swings backward.

Service Manual

Page 11

AWD Frame Drive-system Maintenance

• Gently tap the round female slider section with a flat head

screwdriver and push the front drive shaft, which is attached

to the driving miter gear, out through the access hole in the

headtube.

Removal:

▪Remove the pivot bolt in the lower portion of the

suspension link. If necessary, use an Allen wrench smaller

than the internal threads to punch the female portion out.

▪Carefully lower the rear linkage until the bottom yoke is

resting on the bottom bracket pivot casing.

▪The main drive-shaft will separate at the square splined

universal joint section.

▪Remove the plastic dirt cover from the front of the

headtube access hole.

Service Manual

Page 12

• The entire driveshaft will push through the

support bearings located in the headtube.

• To remove the rear driveshaft, pull it forward

through the support bearings by gripping the

universal joint section.

• The rear drive pinion will slide out from the

dropout slot.

Installation:

• Slide the rear and front drive-shafts into their

respective frame tubes. The front shaft will

slide through the headtube support bearings

and then firmly seat on the edge of the miter

gear. The rear shaft will slide through the sup-

port bearings but may not seat completely on

the u-joint section. There may be a small gap

between the u-joint and the bearing the top

yoke.

• If necessary, replace the rubber u-joint boots.

• Slide the square spline section into the round

female section before you begin to re-attach

the suspension link and the shock.

AWD Frame Drive-System Maintenance

Service Manual

Page 13

AWD Clutch Maintenance

Removal:

▪Remove the rear wheel and quick release skewer.

▪Push down of the top clutch plate and rotate the bevel

gear until the clutch plate does not spring back up.

▪Remove the clutch snap ring from the groove in the top

of the rear bevel gear.

▪Slide the top “sliding jaw” of the clutch up and out of the

guides in the gear assembly.

Installation:

▪Attach the clutch and gear assembly to the rear wheel

(see page 14).

▪Make sure that the engagement cams are in the off

position, they should be flush with the surface of the dropout.

▪Re-install the rear wheel, making sure to seat the axle

completely into the rear dropouts.

▪Test the engagement and disengagement of the clutch.

Service Manual

Page 14

AWD Clutch Maintenance

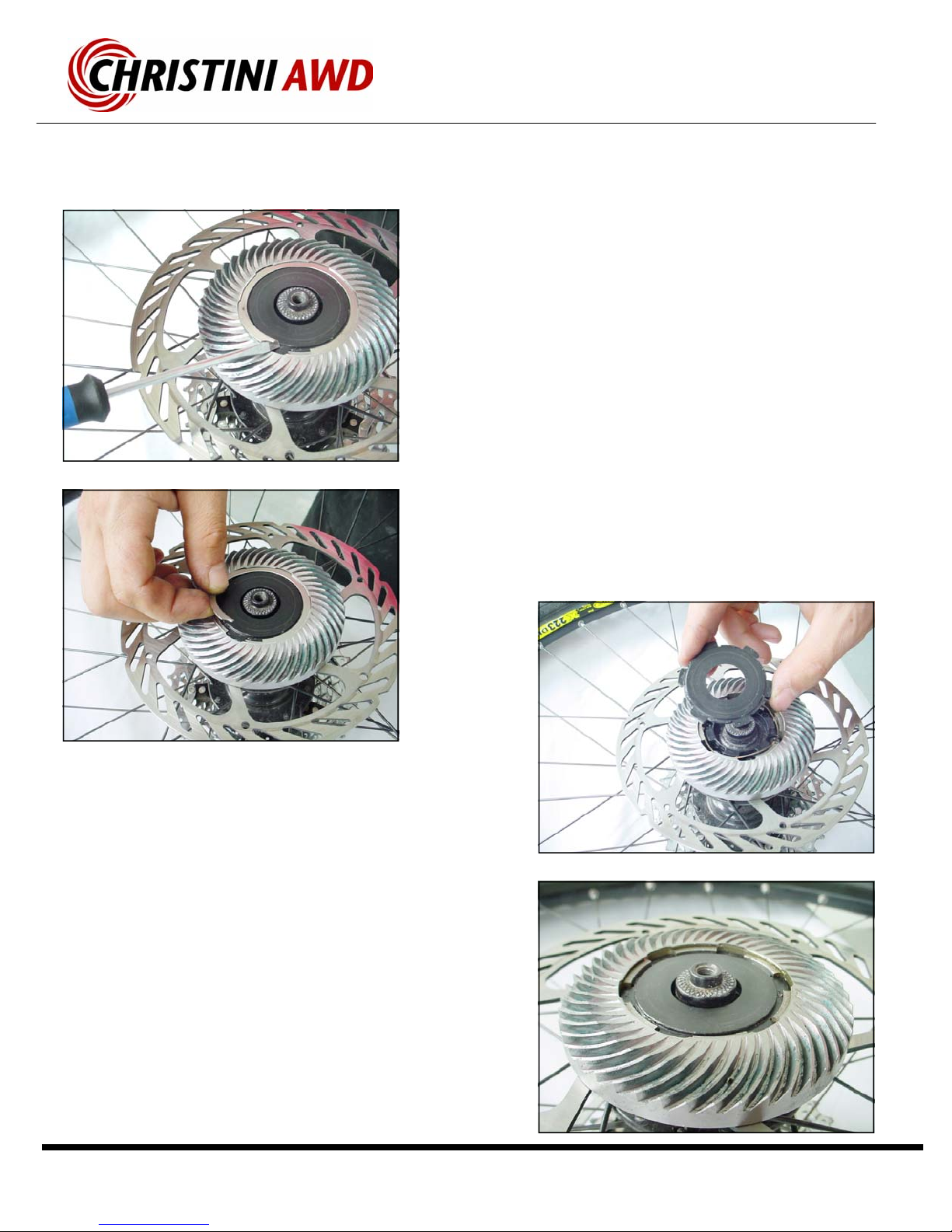

Re-assembly:

▪Press the clutch bearing and locked jaw into the gear.

▪Install the circular wave spring into the locked jaw section

making sure that the broken “tabs” are facing away from

the hub are lined up with a sliding jaw guide slot (top left

picture).

▪Install the sliding clutch plate by lining up the 6 guides

into the appropriate slots, then press down on the plate 4-

5mm and slightly rotate the plate until it does not spring

back up.

▪Install the snap ring and make sure that the clutch is free

to rotate when the sliding jaw is pressed in completely.

Removal:

▪Remove the circular wave spring.

▪Use a Torx wrench to remove the 6 disk brake bolts that

attach the gear assembly to the disk brake hub.

▪Remove the gear assembly from the hub.

▪To remove the “locked jaw” turn over the gear assembly,

and remove the 4 M3 countersunk bolts that attach the large

diameter clutch bearing to the gear.

▪Press or tap out the locked jaw section from the bearing.

Service Manual

Page 15

Front Hub Maintenance

Re-assembly:

▪Press the axle and freewheel insert back into the hub

shell until the insert is flush with the hubshell bearing. A

plastic hammer may be needed to tap the insert back into

place.

▪Insert the end caps onto the axle and tighten the set

screws.

▪Note: The flat face of the gear side end cap should face

outward.

Removal:

▪Loosen the set screws on the end caps and remove them

from the axle.

▪With a plastic hammer, tap the disc side axle to loosen

the freewheel insert. A punch may be needed to

completely free the insert from the hubshell.

▪Remove the freewheel insert and axle from the hub.

▪Apply a light oil or grease to the roller bearings inside the

hubshell.

Note: It is not necessary to remove the bevel gear or the

brake rotor to service the freewheel.

Service Manual

Page 16

• Install the switch on the handlebar before the shifter

pods and grips. Make sure that the cable adjuster

faces forward.

• Use 2mm Allen wrench to tighten the clamp bolt which

secures the switch to the handlebars.

• Apply grease through the holes in the side of the switch

body directly to the ball bearings if the engagement

switch becomes hard to move.

AWD Engagement Switch Detail

Service Manual

Page 17

Cable Adjustment:

• To attach the cable from the switch to the en-

gagement cams, loosen the set screw located

in the top of the long cam and slide the cable

through.

• Install the rear wheel and clutch assembly in

the dropouts.

• To adjust the cams, press the engagement

switch down. Pull the cable taunt and tighten

the set screw.

• Adjust the actuation of the system using the

cable adjuster on the AWD switch. Press the

engagement switch up and turn the cable ad-

juster counterclockwise until the lever begins

to pull away from the switch body (second pic-

ture from the top).

• Turn the cable adjuster back 3/4 of a turn and

make sure the ball bearings seat completely in

the switch body holes.

AWD Engagement Cams

Cam Removal:

• To remove the cam system from the

dropouts, loosen the hex set screw on

the long cam.

• Slide the short cam and hex shaft out

from the dropout.

• Remove the long cam, torsion spring

and Teflon washers.

Service Manual

Page 18

• Disassemble the shock by removing the upper

shock bolt using a 5mm Allen wrench and an

10mm box wrench.

• Remove the large bolts where the rear triangle

and the front triangle connect at the suspen-

sion pivot.

• Remove the M8 bolts from the remaining con-

nection between the suspension link and the

rear triangle.

• There is a washer on either side of the

suspension link that needs to be installed

between the link and the rear triangle.

This washer fits through the threaded sec-

tion of upper suspension link bolts.

• During re-assembly—use removable

threadlocker on all pivot bolts.

Rear Triangle Detail

Service Manual

Page 19

• All bearings should rotate smoothly.

• Bearings should be replaced if they begin to

make excessive noise or they feel “notchy”.

• Bearings are sealed and do not require lubri-

cation.

• Please contact Christini if you think a bearing

needs to be replaced.

AWD Bearing Maintenance

Service Manual

Page 20

As Needed

• Wash exposed drive system parts with

soap and water or a bike cleaner.

• Replace bearings if excessive noise or

friction develops.

• Lubricate all spline shafts if suspen-

sion performance is effected.

• Replace worn or damaged mud

guards.

Monthly

• Tighten frame linkage bolts.

• Check disk brake bolts.

• Lubricate headtube gearset with

grease.

• Lubricate the front and rear bevel

gears with chain lube.

Yearly

• Disassemble, clean and inspect the

rear bevel clutch assembly.

• Apply lightweight oil lube to the front

“silent freewheel” hub.

Routine Maintenance Schedule

AVOID:

• Water in the headtube.

• Water inside the frame.

• Mud, dirt, or sand in the u-joints or

gear sets for extended periods.

Table of contents