Chrosziel MagNum MN-100 User manual

Quic

k R

eference

Guide

V2.6

Relates To Firmware Version 00.06.xx

MN

-

00

Chrosziel GmbH, Klausnerring 6, 8555 Heimstetten, Germany, Phone +49 89 90 09 0, Fax +49 89 447 086 , [email protected]; http://www.chrosziel.de

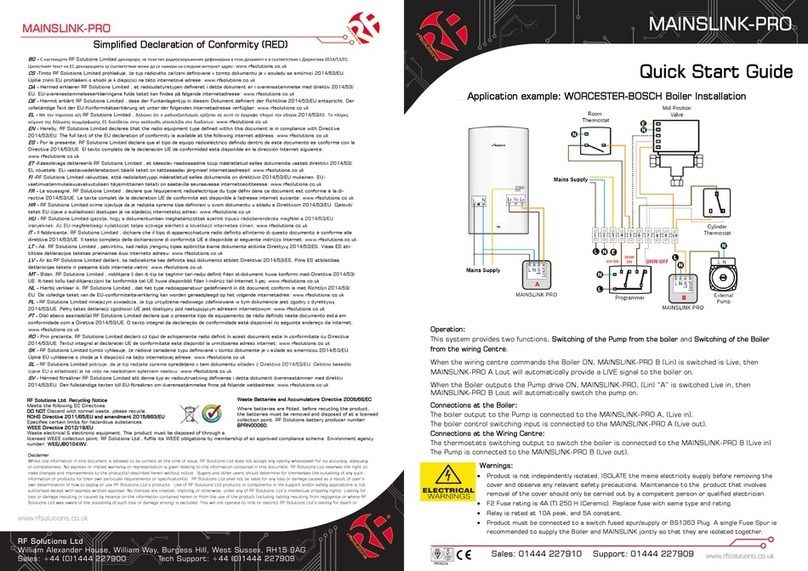

Motor Control Unit

Hand Control Unit

Light socket

Only for o

riginal scale

illumination LED light!

Battery

7.2V SONY FM-50/55

Type

Power Button (On/Off) & LED

Green = Battery Good

Flashing = Battery Low - change batt

ery

Unit switches off automatically,

when

battery power becomes too low

Area of built-in GHz Antenna

Do not cover- keep clear!

Camera Record

Start/Stop

LED flashes = Record is on

Automatic adjustment of lens-

scale

limits and motor-test of

connected

digital motor:

This adjustment has to be made whenever

motor and/or lens are changed.

Do not blo

ck or stop the lens while end stops

are checked, all parameters will then be

stored incorrectly!

Procedure:

• engage motor onto lens (not at an

end stop)

• Push "Motor Cal." button, red LEDs flash

• Motor starts turning slowly

The lens-scale limit

will be checked and

stored automatically.

Motor Socket

Type: Lemo EGG. B. 307

Pin : Motor –

Pin 2: Motor +

Pin 3: Encoder channel A

Pin 4: +5V

Pin 5: earth/ground

Pin 6: Encoder channel B

Pin 7: Sense

Power LED

Green = Power Good (> 2V)

Red = Input voltage low

Flashing = voltage drop occurred

Power In ( 0V -30V;

with

electronic Fuse & reverse

protection) & Cam Start/Stop

Type: Lemo 0B.305

Pin : Battery plus

Pin 2: CAM Relay contact

Pin 3: CAM Relay contact 2

Pin 4: Battery minus / GND

Hand wheel with fixed Fluid

Drag

Accepts 2 different types of scales:

Big Ring

Small Ring

(as shown in photo)

Menu Navigation

Press Center button to

enter the Setup Menu

Battery Release

Slide to the right to change battery

USB Socket for Software Updates and USB Status LED

(always update both MCU and hand unit)

Software updates are provided by Chrosziel, when available .

Update Procedure:

Copy the two software files into the root

of an USB stick (FAT/FAT32

formatted)

Plug USB stick into socket.

Power down the unit

Press and hold down “Motor Cal” button and repower the receiver.

Unit will perform the update indicating the progress by different LED flashing

patterns on the front. After update the Unit restarts automatically

USB Socket for Software

Updates (always update both

MCU

and hand unit)

Software

updates are provided by

Chrosziel, when available.

Update Procedure:

Copy the two provided

software

files into the root of an USB stick

(FAT/FAT32 formatted)

Power down the handset

Plug USB stick into socket.

Press

and hold down “REC”

button and power on the handset.

Unit will perform the update

indicating the progress by

different LED flashing patterns on

the front. After update the Unit

restarts automatically

Area of Built-in GHz Antenna

Do not cover- keep clear!

Cam Start/Stop indicator

LED

blue =

relay switches

active/connected

off =

relay switches

inactive/disconnected

Radio Channel Selector + Rf Error LED

Select radio channel within the 2.4 GHz

Band

(select 5 .. F)

. Red LED goes on if connection

error occurs.

Channels 0..4 not valid! If chosen,

LED is flashing.

Cam Start/Stop

Type: Lemo ECB.0B.309

Pin 8: CAM Relay

Pin 9: CAM Relay 2

Rf Error LED

Rf Error LED goes on if no

connection to at least one

hand unit could be

established.

Choose same channel in the

Set Up menu of the ha

nd

unit.

Motor Status Red LEDs

Signaling

Slow flashing =

m

otor limits

need to be calibrated

Fast flashing =

motor

calibration in progress

Off with motor c

onnected =

motor l

imits are calibrated,

ready to shoot

4 User assignable Keys

(U .. U4)

Currently fixed to spread

the

wheel scale

Recommendation:

Use a 24V-30V power supply

for

best motor performance!

Cal. Focus

Motor Calibration

< Done

Cal.

Iris

(Zoom)

Select a

m

otor with

u

p/

d

own

b

uttons and

then press center button of the k

eypad,

automatic or manual end stop c

alibration is

initiated.

Start Motor Calibration remo

tely

Spreading of the Wheel

Spreading is done by pressing one of the user keys .. 4. Spreading function needs to be assigned to the desired user keys*. Default

mode

is*: U -4 spread the wheel scale. So there are four different spreading setups available.

To set a spreading:

a) Move wheel to the desired first starting point, press a user key for more than second and keep pressing during the procedure

b) Respective yellow LED starts flashing

c) Move wheel to the desired second point, release the user key

d) Spreading is applied between the two points, respective yellow LED lights up continuously

To switch off a spreading: Press the user keys for which a spreading is activated less than second, respective yellow LED goes off.

To recall a formerly programmed spreading: Press the same user key again for less than second.

*Currently the assignment of spreading function is fixed to the default set up. Later software versions will allow to assign

different functions

to the 4 user keys.

Calibrating motors in

manual

"Photo Lens" mode

Unlike commonly used lenses in the film industry the lenses for still cameras do not feature physical end stops on their

gears. Therefore it is

not possible to calibrate so-called photo lenses by the motor controller automatically.

The MagNum motor controller addresses this issue by

allowing a desired motor socket to be configured as "Lens Type = photo". The manual procedure is as follows:

mount motor as normal on the support rod and engage it to the lens in a middle position of the available range of movement

press calibration button once; motor LEDs start flashing fast but motor will not start moving on its own as it would in "Cine" mode

move motor by hand by manually turning lens to both of the limits (infinite & near) of the lens gear

turn motor back to a middle position after

press calibration button a second time , motors will now start moving measuring automatically lens parameters between the two

chosen

end points

after this calibration is finished

Hints:

As most motors show a certain amount of play/backlash, turn the motor a little further than normally necessary in order to compensate

this

play regarding the correct end stops on both limits.

Some motors do not allow turning manually in both directions – in this case engage the motor on one limit and turn

the motor just in the

direction to the opposite limit.

If switched to "On",

w

heel or

s

lider

operate reversed. Operation d

irection

depends on how motors are mounted

and on the preferences of the user

*Setting is stored in the hand u

nit and

is independent from settin

g in second

hand unit.

Reverse Wheel

off

Reverse Slider

Save Exit Cancel

off

Setup Scales

-

R

ever

se Scale Direction

*

Ctrl. ID

:

Switch the hand unit ID to 2 if

two controllers shall be used (s

plit

functions F & I to two controllers). ID

controls F & I by default. If a second

unit is set to ID 2, this unit wi

ll take

over con

trol of motor I by its hand

wheel if MN-

200R motor controller is

used.

You must not have more than

one

hand unit set to the same ID!

Left-Handed: If "yes",

the Display is

rotated by 80° in order to make left-

handed operation more easy

Setup

Hand Unit

Display Options

Ctrl. ID < >

1

Serial Socket

Wheel/Slider Cal.

Set Up Hand Unit

Left

-

Handed

< Back

Load Defaults

no

Serial Socket:

No support!

Display Options:

Select, whether several displays shall appear on

the main screens info area (i.e. Cam.-Power)

Wheel/Slider Cal.: Basic calibration of the hand wheel to its

respective mechanical operating range

Set Up

Motor Output*

Link

to

:

Assigned

f

unction

(Focus / or

Iris)

Mode: Switch to dimmer m

ode here.

Dimmer cable can be controlled.

Range: Switch to 3D Rig mode

if

required

Direction : Reverse motor direction

Play/Safety: Modify play (b

acklash)

compensation for heavily used m

otors

with a large amount of p

lay in the

gearbox.

Modify the sa

fety distance, the motor stays away from the

mechanical Lens End Stops (S3D Rigs). Torque:

Reduce torque of

the motor to mid (50%) or low (25%).

Lens Type:

Cine = End stops will be calibrated automatically; Photo

= End stops are calibrated manually.

*Setting is stored in the motor box in the non-

volatile memory and is

editable on hand unit 2 as well

M1 Set Up

Link to

motor

F

Mode

Lens

norm

0 / 0

Full

Save Exit Cancel

Direction

Range

Play/ Safety

Torque

Photo

Lens Type

Frequency Table:

Channel

Center Frequency

0

n.a.

n.a.

2

n.a.

3

n.a.

4

n.a.

5

2.400.75 GHz

6

2.40375 GHz

7

2.40975 GHz

8

2.42275 GHz

9

2.44075 GHz

A

2.44375 GHz

B

2.44975 GHz

C

2.46275 GHz

D

2.47075 GHz

E

2.47375 GHz

F

2.48 75 GHz

Select whether

h

and

u

nit with ID or

2 can trigger the record signal

Select mode entry and modify t

rigger

mode with -/+ buttons

*Setting is stored in the motor b

ox in

the non volatile memory and

is

editable on hand unit 2 as well

Set Up the Record Start/Stop Trigger*

Record Trigger

Enabled ID:

Ma

tching

:

1

Start Stop

Mode: < Pulse >

Save Exit Cancel

Calibrate Motors

Light ON/OFF

Radio Channel

Record Trigger

Scales

Set Up Hand Unit

Motor Setup

Switch

LED

swan

-

neck

l

ight on

/off

Setup Screen

(press Center Button from Main Screen)

Select radio channel and range

(MHz or GHz)

Sel

ect camera record start/stop mode

Reverse wheel &/or slider operating

direction

Start motor calibration remotely

Motor setup (torque ; direction;

play

correction ...)

Select hand Unit ID, serial socket

mode, calibrate the hand wheel &

slider, assign user keys

Menu Navigation

Power

b

utton

, press for more than 2

seconds to switch hand unit off;

can

be used to exit a sub menu as well

Select menu item (up)

Press center button to enter set up

menus

Edit values (left = -; right = +)

Select

m

enu

i

tem (

d

own)

Main Screen

Data al

ways visible

,

from left to right:

Battery indicator

Hand unit ID (can be or 2)

RF signal strength indicator

Bidirec

tional link indicator:

Green = connection OK –

may go

red intermittently

Display of power supply voltage on

receiver side*

ID 1

Cam. Pow.: 13.5V

*Display can be disabled/enabled on menu entry "Display Options"

Set Up

Motors &

Servo Lens Control

Motor

:

Enter

c

onfiguration

menu

of

the motor output

Motor 2: No support

in combination

with MN- 00 motor controller!

Servo Lens Setup*: No Support

on

MN- 00 motor controller!

*Setting is sto

red in the motor box in the non

-

volatile memory

Motor Setup

Motor 2 (I/Z)

Servo Lens Setup

F:

Motor 1 (F)

I:

Z:

< Back

on

on

off

Please no

te: When this screen is visible

the MagNum wireless

connection is temporarily disconnected as the hand unit scans

through all available RF channels at this time searching for

possible frequencies. For GHz range (Channels 5 - F) internal

antennas are used.

Set the Frequency Range and the Radio Channel

Set Radio

Chan.: 8

Freq. :

Spectrum

2422

.

75

Table of contents

Popular Control System manuals by other brands

D&R ELECTRONICS

D&R ELECTRONICS RDS17S manual

Mircom

Mircom PRO-2000 Series Operation manual

GRASS VALLEY

GRASS VALLEY JUPITER CONTROL SYSTEM - S V7.9.0 release note

Emerson

Emerson ECB-D20 technical information

Ormazabal

Ormazabal cgmcosmos-l General instructions

Springtree

Springtree DMX600 User manual and installation guide