Circuit-test DMR-2400 User manual

USER'S MANUAL

DIGITAL MULTIMETER

DMR-2400

CIRCUIT-TEST ELECTRONICS

www.circuittest.com

– 1 –

TABLE OF CONTENTS

SAFETY

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION

Front Panel Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIFICATIONS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ranges and Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATING INSTRUCTIONS

1. DC Voltage Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. AC Voltage Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

3. DC Current Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

a) less than 200mA DC current

b) 200mA or more DC current

4. Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Continuity Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

6. Diode Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Signal Injection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. Battery Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

– 2 –

SAFETY INFORMATION

This meter is CUL and UL approved. This meter is designed to be safe un-

der the following conditions: indoor use, altitude up to 2000m, temperature

5°C to 40°C, maximum relative humidity 80% for temperatures up to 31°C

decreasing linearly to 50% relative humidity at 40°C and rated pollution

degree 2. Caution and proper guidelines must be followed for personal

and product safety. Read this instruction manual carefully and completely

before using the meter. Lack of caution or poor safety practices can result

in serious injury or death.

• This meter is not recommended for high voltage industrial use; for

example, do not use for measurement on 440VAC or 600VAC industrial

power mains. The unit is intended for use with low energy circuits up to

600VDC / 600VAC or high energy circuits up to 250VAC / 250VDC only.

• Use caution when working above 60VDC or 30VAC RMS as these volt-

ages pose a shock hazard.

• Always consider circuits to be energized. Never assume any equipment

to be de-energized.

• Always start with power off. Set the function switch to the correct setting

before making any measurements and do not change position of the

function switch during measurements.

• Never connect unit to AC or DC powered circuits when the function

switch is set to resistance, diode check or continuity ranges.

• Always disconnect the power when performing resistance, diode or

capacitance tests. Discharge capacitor before testing.

• Disconnect the live/positive test lead (red) prior to disconnecting the

common/negative test lead (black).

• When ʻLO BATʼ appears on the display, change both batteries to

achieve more accurate readings.

• Disconnect test leads from the meter before removing the batteries or

the fuse.

• Do not operate the unit unless the case is completely closed.

• When using the test probes always keep fingers behind the finger

guards. Never touch the exposed probe tip.

• Always inspect the instrument, test leads and other accessories for

damage prior to use.

• Use only UL recognized test leads (included with this meter).

– 3 –

SAFETY SYMBOLS

Safety symbols and special annunciators on the meter and in this manual

indicate cautions and warnings of important operational procedures that must

be followed to ensure personal and product safety.

This symbol indicates a General Warning. When adjacent to a termi-

nal or operating device indicates that the operator must refer to an

explanation in the Operating Instructions.

500V

MAX

This symbol indicates that the terminal(s) so marked must not be con-

nected to a circuit point at which the voltage with respect to ground

exceeds 500V AC/DC.

This symbol adjacent to one or more terminals indicates them as

being associated with ranges that may in normal use, be subjected

to particularly hazardous voltages. For maximum safety, the meter

and its test leads should not be handled when these terminals are

energized.

INTRODUCTION

DMR-2400 is a manual ranging compact digital multimeter with a 2000 count

LCD display. This meter can measure/test the following:

– Voltage – DC Current

– Resistance – Continuity

– Diode – Audio Devices (Signal Injection)

FRONT PANEL DESCRIPTION

NO. ITEM DESCRIPTION

1LCD Display 3-1/2 digit 2000 count LCD Display

2Function Switch Function switch to select measurement mode

310A Jack Positive input jack to plug in red test lead for 10A measurement

only

4V/ /mA/ Jack Positive input jack to plug in red test lead for voltage, resistor,

current up to 200mA and signal injection

5 Jack Plug in black test lead in all measurement modes, common ground

– 4 –

SPECIFICATIONS

GENERAL

Display: 3 1/2 digit 2000 count LCD

Maximum Display: 1999

Ranging: Manual

Polarity: Automatic, minus (-) sign indicates negative polar-

ity, no sign for positive polarity

Input impedance: 1M DCV / 452K ACV

Diode Test: Test current of 1.5mA maximum

Signal Injection: 2VAC Peak Approx., 30 to 40Hz Square Wave

Over range indication: ʻIʼ is displayed

Operating Temp: 0 to 50°C (32 to 122°F)

Power Source: 2 x AA 1.5V Batteries

Fuse: 0.8A/250V (5x20mm Fast Acting),

10A/250V (6.3x32mm Fast Acting)

Dimensions: 145(H) x 70(W) x 32(D) mm

(511/16 x 23/4 x 11/4")

Weight: 216g (7.6oz)

Accessories included: One pair of test leads, 2 x AA batteries,

Userʼs manual

– 5 –

RANGES AND ACCURACY

FUNCTION RANGE RESOLUTION ACCURACY

DC VOLTAGE

(DC V)

200mV

2000mV

20V

200V

1000V

100µV

1mV

10mV

100mV

1V

±(1% reading + 6 digits)

±(1.5% reading + 8 digits)

AC VOLTAGE

(AC V)

200V

750V

100mV

1V

±(1.2% reading + 20 digits)

DC CURRENT

(DC A)

200µA

2000µA

20mA

200mA

10A

100nA

1µA

10µA

100µA

10mA

±(1.2% reading + 8 digits)

±(1.2% reading + 10 digits)

RESISTANCE 200

2000

20k

200k

2000k

20M

100m

1

10

100

1k

10k

±(1.2% reading + 8 digits)

±(2% reading + 10 digits)

NOTE: Accuracy consists of: (% reading i.e. accuracy of the measurement circuit +

digits i.e. accuracy of the analog to digital converter)

– 6 –

OPERATING INSTRUCTIONS

1. DC VOLTAGE MEASUREMENT

WARNING: MAXIMUM INPUT IS 1000V DC. USE EXTREME CAUTION WHEN WORKING

WITH HIGH VOLTAGES. NEVER APPLY THE TEST LEAD TO THE MEASURING CIRCUIT WHEN

CHANGING THE POSITION OF THE FUNCTION SWITCH. IF YOU ARE UNSURE OF THE VOLTAGE

BEING MEASURED, SELECT THE HIGHEST RANGE AND REDUCE UNTIL A SATISFACTORY

READING IS OBTAINED.

➔ Set the function switch to 1000 on the DC VOLTS scale.

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

➔ Apply the test leads to the circuit to be measured. Ensure that the black

lead is connected to the negative side of the circuit and red lead to the

positive.

➔ Read the displayed voltage.

➔ If the reading displayed does not have a sufficient number of digits i.e.

00.2 Instead of 1.786, set the function switch to the next lower range.

Repeat until you have maximum digits possible without displaying ʻIʼ.

➔ If the minus (-) sign appears it means the voltage is negative at the

point being measured.

➔ If ʻIʼ appears on the display, it indicates over-range. Immediately remove

test leads from the measuring circuit to avoid any damage to the meter.

The input voltage should not exceed the measurement capability of this

meter.

2. AC VOLTAGE MEASUREMENT

WARNING: MAXIMUM INPUT IS 750V AC. USE EXTREME CAUTION WHEN WORKING

WITH HIGH VOLTAGES. NEVER APPLY TEST LEADS TO THE MEASURING CIRCUIT WHEN

CHANGING THE POSITION OF THE FUNCTION SWITCH. IF YOU ARE UNSURE OF THE VOLTAGE

BEING MEASURED, SELECT THE HIGHEST RANGE AND REDUCE UNTIL A SATISFACTORY

READING IS OBTAINED.

➔ Set the function switch to 750 on the AC VOLTS scale.

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

➔ Apply the test leads to the circuit to be measured.

➔ Read the displayed voltage.

– 7 –

➔ If the reading displayed does not have a sufficient number of digits, i.e.

115 instead of 115.4, set the function switch to the lower range.

➔ If ʻIʼ appears on the display, it indicates over-range. Immediately remove

test leads from the measuring circuit to avoid any damage to the meter.

The input voltage should not exceed the measurement capability of this

meter.

3. DC CURRENT MEASUREMENT

WARNING: WHEN MEASURING CURRENT REMOVE ALL POWER FROM THE CIRCUIT

BEING TESTED. NEVER APPLY THE TEST LEAD TO THE MEASURING CIRCUIT WHEN CHANG-

ING THE POSITION OF THE FUNCTION SWITCH. IF YOU ARE UNSURE OF THE CURRENT

BEING MEASURED, SELECT THE HIGHEST RANGE AND REDUCE UNTIL A SATISFACTORY

READING IS OBTAINED.

a) Less than 200mA DC Current Measurement

➔ Set the function switch to 200m on the DC AMPS scale.

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

➔ Remove power from the circuit that is to be measured. Open up the

circuit and connect the black lead to the negative side and the red lead

to the positive side of the circuit so that the test leads are in series with

the load to be measured.

➔ Apply power to the circuit.

➔ Read the displayed current.

➔ If the numeric value in the display is too small, change the function

switch to next lower range. Repeat until you have maximum digits pos-

sible without displaying ʻIʼ.

➔ If ʻIʼ appears on the display, it indicates over-range. Immediately remove

test leads from the measuring circuit to avoid any damage to the meter.

b) 200mA or more DC Current Measurement

CAUTION! Do not exceed 10 seconds when measuring the 10A range and

wait for 30 minutes between each measurement.

➔ Set the function switch to 10A on the DC AMPS scale.

➔ Plug the red test lead in 10A jack and the black test lead in jack.

– 8 –

➔ Remove power from the circuit that is to be measured. Open up the

circuit and connect the black lead to the negative side and the red lead

to the positive side of the circuit so that the test leads are in series with

the load to be measured.

➔ Apply power to the circuit.

➔ Read the displayed current.

➔ If ʻIʼ appears on the display, it indicates over-range. Immediately remove

test leads from the measuring circuit to avoid any damage to the meter.

4. RESISTANCE MEASUREMENT

WARNING: NEVER CONNECT THE TEST LEAD TO ANY VOLTAGE WHEN THE FUNC-

TION SWITCH IS SET TO . REMOVE ALL POWER FROM THE CIRCUIT BEING TESTED WHEN

CHECKING RESISTANCE. DISCHARGE ANY CHARGED CAPACITORS. NEVER APPLY THE TEST

LEAD TO THE MEASURING CIRCUIT WHEN CHANGING THE POSITION OF THE FUNCTION

SWITCH. IF YOU ARE UNSURE OF THE RESISTANCE BEING MEASURED, SELECT THE HIGH-

EST RANGE AND REDUCE UNTIL A SATISFACTORY READING IS OBTAINED.

➔ Set the function switch to the desired OHMS scale.

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

➔ Apply the test leads to the resistor being measured. If the resistor is part

of a circuit, it is necessary to disconnect one end of the resistor to avoid

any unwanted interference from the rest of the circuit.

➔ Read the displayed resistance.

NOTE:

• ‘I’ is also displayed when the inputs are not connected.

• When measuring resistance above 1M , the meter may take a few seconds to get

a stable reading.

• Never measure a resistor that has voltage on it.

5. CONTINUITY TEST

WARNING: NEVER CONNECT THE TEST LEADS TO ANY VOLTAGE WHEN THE FUNC-

TION SWITCH IS SET TO 200 . REMOVE ALL POWER FROM THE CIRCUIT BEING TESTED

WHEN CHECKING RESISTANCE. DISCHARGE ANY CHARGED CAPACITORS.

➔ Set the function switch to 200 on the OHMS scale.

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

– 9 –

➔ Apply the test leads to the circuit.

➔ If there is continuity, the display will read about 0.5 Ohms. If there is an

open circuit, the display will read ʻIʼ.

6. DIODE TEST

WARNING: NEVER CONNECT THE TEST LEAD TO ANY VOLTAGE WHEN THE FUNC-

TION SWITCH IS SET TO . REMOVE ALL POWER FROM THE CIRCUIT BEING TESTED WHEN

PERFORMING THE DIODE TEST. DISCHARGE ANY CHARGED CAPACITORS.

Note: If the diode is part of a circuit, it is necessary to disconnect one end of the diode

to avoid any unwanted interference from the rest of the circuit. The value indicated in

the display during the diode check is the forward bias voltage.

➔ Set the function switch to 2000 on the OHMS scale.

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

➔ Apply the test leads across the diode terminals and note the

meter reading.

➔ Reverse the diode and note this reading. Based on the readings the

result can be evaluated as follows:

– If one reading is around 0.5 and the other reading is ʻIʼ, the

diode is good

– If both readings are ʻIʼ, the diode is open (defective)

– If both readings are very small or 0 (zero), the diode is shorted

(defective)

7. SIGNAL INJECTION FUNCTION

This function allows the injection of square wave of about 2V peak at a

frequency of 30 to 40 Hz into an audio device.

➔ Set the function switch to .

➔ Plug the red test lead in V/ /mA/ jack and the black test lead in

jack.

➔ Apply the black test probe tip to the circuit ground and the red test probe

tip to the point in the circuit where you wish to inject the test signal.

– 10 –

8. BATTERY REPLACEMENT

WARNING: DISCONNECT BOTH TEST LEADS FROM ANY SOURCE OF VOLTAGE

BEFORE REMOVING THE BACK COVER. DO NOT OPERATE THE METER UNTIL THE BACK

COVER IS IN PLACE AND FASTENED SECURELY.

ʻLO BATʼ will appear in the display when the battery drops below the operating

voltage and requires replacing.

➔ Turn off the meter and disconnect both test leads.

➔ Remove the single screw securing the battery/fuse cover and lift to

open.

➔ Replace both AA batteries observing the correct polarity.

➔ Replace the cover and tighten the screw.

9. FUSE REPLACEMENT

WARNING: DISCONNECT BOTH TEST LEADS FROM ANY SOURCE OF VOLTAGE

BEFORE REMOVING THE BACK COVER. DO NOT OPERATE THE METER UNTIL THE BACK

COVER IS IN PLACE AND FASTENED SECURELY.

a) 0.8 Amp Fast acting 5x20mm Fuse

➔ Turn off the meter and disconnect both test leads.

➔ Remove the single screw securing the battery/fuse cover and lift to

open.

➔ Remove the batteries.

➔ Gently pull the fuse from its holder by pulling gently on the ribbon.

➔ Replace the blown fuse with a CSA/UL listed fast acting fuse rated at

0.8A/250V only (GMA-0.8A, with the same ribbon ring around the fuse).

Do not use a fuse which has higher rated value than specified or try to

bypass the fuse.

➔ Replace the batteries and cover and tighten the screw.

– 11 –

b) 10 Amp Fast acting 6.3x32mm Fuse (by a professional person

only)

➔ Turn off the meter and disconnect both test leads.

➔ Remove the two screws at the back of the case.

➔ Remove the single screw securing the battery/fuse cover and lift to

open.

➔ Remove the batteries.

➔ Carefully lift the top of the case away from the bottom.

➔ The 10 amp fuse is the larger fuse on the bottom of the PC board,

which should now be in full view. Carefully remove the old fuse and

replace it with a new CSA/UL listed fast acting 10A/250V fuse only

(AGC-10A).

MAINTENANCE

a) Always keep the meter dry.

b) Keep the meter clean. Wipe the case occasionally with a damp cloth.

Do not use chemicals, cleaning solvents or detergents.

c) Use and store the meter in recommended normal environmental

conditions. Extreme temperatures can shorten the life of the electronic

components.

d) Use only fresh batteries.

e) Remove the batteries when the meter is not being used for a long

period of time.

– 12 –

ACCESSORIES

Test Leads (TL-107)

Fuses: 5x20mm Fast 0.8A/250V, 6.3x32mm Fast 10A/250V

Batteries: 2 x AA

OPTIONAL:

Test Leads with Screw-on Alligator Clips (TL-222)

LIMITED WARRANTY

Circuit-Test Electronics warrants to the original purchaser that this product

be free of defect in material or workmanship for a period of 2 years from the

date of purchase. Visit our website (www.circuittest.com) for information on

warranty service.

Any product which has been subjected to misuse or accidental damage is

excluded from the warranty. Except as stated above, Circuit-Test Electronics

makes no promises or warranties either expressed or implied including war-

ranties of merchantability or the fitness for any particular purpose.

Register your product online at www.circuittest.com

CIRCUIT-TEST

ELECTRONICS

A division of R.P. Electronic Components Ltd.

www.circuittest.com

Table of contents

Other Circuit-test Multimeter manuals

Circuit-test

Circuit-test DMR-1500 User manual

Circuit-test

Circuit-test DMR-1100A User manual

Circuit-test

Circuit-test DMR-6700 User manual

Circuit-test

Circuit-test DMR-3600 User manual

Circuit-test

Circuit-test DCL-420 User manual

Circuit-test

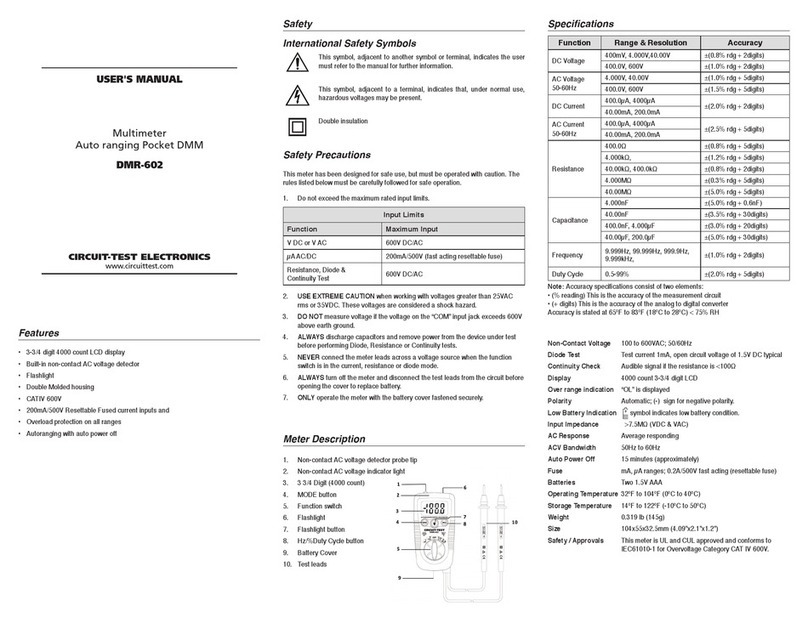

Circuit-test DMR-602 User manual

Circuit-test

Circuit-test DMR-4200 User manual

Circuit-test

Circuit-test DMR-6550 User manual

Circuit-test

Circuit-test DCL-280 User manual

Circuit-test

Circuit-test DMR-6500 User manual