CITC STARHazer II User manual

STARHazer IITM

Operating Instructions

P/N 100033/100038

(120 VAC/230v)

1

Thank you for purchasing this StarHazer IITM

As you will notice from the table of contents, the manual for your new

product is quite extensive.

To guarantee perfect and successful work with this machine, please

take some time to read the manual carefully.

And finally, we believe you will enjoy years of great haze effects if you

care for and maintain your StarHazerTM.

CITC

2100 196th St. S.W., St e. 138

Lynnw ood, WA 98036

(888) 786- CIT C

www.cit cfx.com

2

Contents

1. Set of Equipment Supplied 3

2. Accessories 3

3. Description 4

4. Safety Instructions 5

5. Operating the StarHazerTM 5

5.1 Selecting the Location

5.2 Electrical Power Requirements

5.3 Hooking things up

5.4 Operating the machine

5.5 Troubleshooting

5.6 Notes on Optional DMX Control

6. Service and Maintenance 8

7. Technical Data 9

8. Limited Warranty Conditions 10

1. Set of Equipment Supplied

StarHazer IITM

3

Remote Cycle-Timer Controller w/XLR 3 pin 25’ (7.6m)

DMX Control on-board with in/out

Power Cord

Instruction booklet

Extra fuse in fuse release holder

2. Accessories

CITC’s High Performance Fluid (oil-based) (formerly Diffusion Fluid)

P/N 150660 (available in gallon (3.8 liter) and 5-gal. (19 liter) cubitainer)

Wireless Remote Control to 100’ (30m) Receiver & Sender (P/N 250010)

StarHazer IITM roadcase

Please check whether all the products you ordered are supplied.

3. Description of the StarHazer IITM

oThe StarHazer II TM has new DMX control with 5 pin in/out panel mounts that are protected

by the protruding sidewalls. The unit now has 3 pin XLR remote with locking connector. The

improved, higher pressure compressor provides finer haze using less fluid while making haze.

It is by far a much longer-lasting haze effect than conventional water-based hazers or foggers,

which is completely safe for people, children, and animals to breathe. There is no odor with

toxin-free High Performance Fluid haze. One tiny half ounce of fluid per hour of constant

operation testifies to the tiny amount of particles being used to create such long lasting effects

(3-4 hours), compared to hazers using a quart per half hour or more.

oCalifornia Occupational Safety and Health Association tested this haze fluid to determine that

"people working for 40 hours a week for 50 years would not suffer any adverse health

effects". This is due to: A) the very low amount of fog fluid being used, B) the highest grade

medicinal mineral oil being used, C) absolutely no heating element to create the irritation

usually associated with hazing machines.

oHaze from the StarHazer IITM Haze Machine is completely different from any other hazer on

the market. It operates without the use of a heating element (heating elements that create a

heated chemical reaction for haze). The fire departments have been extremely happy to hear

that this machine won’t catch on fire if allowed to run empty, because it is made to operate

without any type of heater or other fire causing generation.

4

oInternally, the atomizer breaks up a high grade medicinal mineral proprietary formula into

such tiny particles, that it produces an opaque haze that is filtered several times to remove

larger size particles (over 20 microns) before it is mixed with the ambient air thrown 25’ from

the machine.

oBecause lights and lasers look best when fog is evenly distributed throughout the room, the

hazer has two built in circulation fans that circulate the air from the room with the haze. This

atmospheric effect lasts over 2-3 hours and is evenly dispersed from floor to ceiling, wall to

wall.

oIn just 3 months, a StarHazer IITM Haze Machine owner, using High Performance Fluid

(formerly called Diffusion Fluid) can regain the cost of this machine through lower costs of

operation…1/16 electricity, 1/30 fluid, and no breakdowns compared to hazers half the price

when used daily, year after year.

oWhen the StarHazer II™ Haze Machine timer on the remote control (included) is used, you

have 100% less chance of ever having residue from over-hazing (turn it on and leave). Now

you can just set the timer and the unit will automatically, constantly turn on/off your unit

when the timer comes on.

1. Safety instructions

WARNING: R ead and u nderstand all labels and o perating

instructions before attempting installation.

oRisk of electrical shock- Never open the machine without disconnecting power lead first!

This device is supplied with a grounding conductor. To reduce risk of electrical shock,

connect only to properly grounded, grounding type receptacles. Never remove the third prong

from the plug.

oThis machine requires a 120VAC/10 A circuit for operation. During operation a circuit

should be dedicated to the StarHazer IITM Haze Machine. If you have any doubts about the

capacity or grounding of your existing circuits, consult a qualified electrician.

oNever use water-based fluids. This would cause irreversible damage to the tank. Operating

the pump with other than CITC Oil-based hazing fluid is not covered under warranty.

oBe sure area around hazer is dry before applying electrical power.

oMake sure that your unit is pointed in a direction that leaves a 12ft (4m) open area out in

front. Place the front of the machine away from direct contact with electrical instruments and

people. There is no heat in this unit.

oFluid is very slippery when spilled. Care in keeping any drips or spills cleaned up is

necessary.

oDo not store StarHazer II TM Haze Machine in freezing conditions. Below 50o F it will not

start.

5. Operating the STARHAZER IITM Haze Machine

5.1 Selecting the Location

Secure a good location for the machine to rest solidly on the floor so that the output of the

machine will not be restricted. Make sure that your unit is pointed in a direction that leaves an

5

open area out in front and can travel 12ft (4m) without restriction. Place the front of the machine

away from direct contact with electrical instruments and people. Always allow plenty of air

circulation to allow the haze to expand, separate and enlarge. Proper circulation of the haze is

important. Place the hazer at the opposite side of the room from the return air-conditioning duct to

help cause the haze to circulate evenly, without curls of haze or hot spots. For large rooms, use a

long-distance fan like the Director FanTM or Director Jr. FanTM. This evens the haze for quicker

balance. You will quickly see the double fans are filtered, and spread haze more rapidly.

5.2 Electrical Power R equirements

This machine requires a separate circuit for operation. The StarHazer IITM Haze Machine

During operation this circuit should be dedicated to the Haze Machine. If you have any

doubts about the capacity or grounding of your existing circuits, consult a qualified

electrician. Do not add other equipment on this circuit.

5.3 Hooking things up

1. Pour ½- 1½quarts High Performance™hazing fluid into top fill spout. Use of any other fluids

will void your warranty. Do not overfill! Check fill window to see that the fluid does not go past

fill arrow. Never use water based fluids. This will clog the tubing, causing irreversible damage

to the tank and possibly damaging the compressor or hoses.

2. Check for proper matching voltage outlet. Plug in cord provided.

5.4 Operating the machine

1. Allow a 12’ open area around machine for circulation of haze (do

not enclose).

2. The upper switch located next to the power switch says “Direct”

and “Controls”. Place the switch in upper position for operation of

the machine without the use of any controls – controls that are

plugged in will not work when the switch is “up” on “Direct”.

When wanting any of the controls like the remote or DMX to

operate, place the switch “down” to use.

3. When the power switch is turned on, the light on the switch will

illuminate. Remote, DMX or 100vac control plug must be

plugged in to operate machine.

4. For cycle-timing of the haze, you must use the remote control.

The red “on/off” button must be depressed for “Timer” or “Haze”

functions to work. The fan comes on when the timer cycle begins

and goes off when the cycle ends. The fan goes on or off each

time you press haze. Haze will fill a 300-500 seat auditorium

within 15-30 minutes. The absolute cleanest haze is when you

keep a light haze by using the cycle-timer. The haze from the

StarHazer IITM Haze Machine is recommended to be used for 10-20 minutes initially (depending

on the size of the auditorium), and then “on” for up to 2 minutes every 1 – 4 minutes “off”

TIMER

REMOTE

TIMER

ON/OFF

CONTROL

ON/OFF HAZE

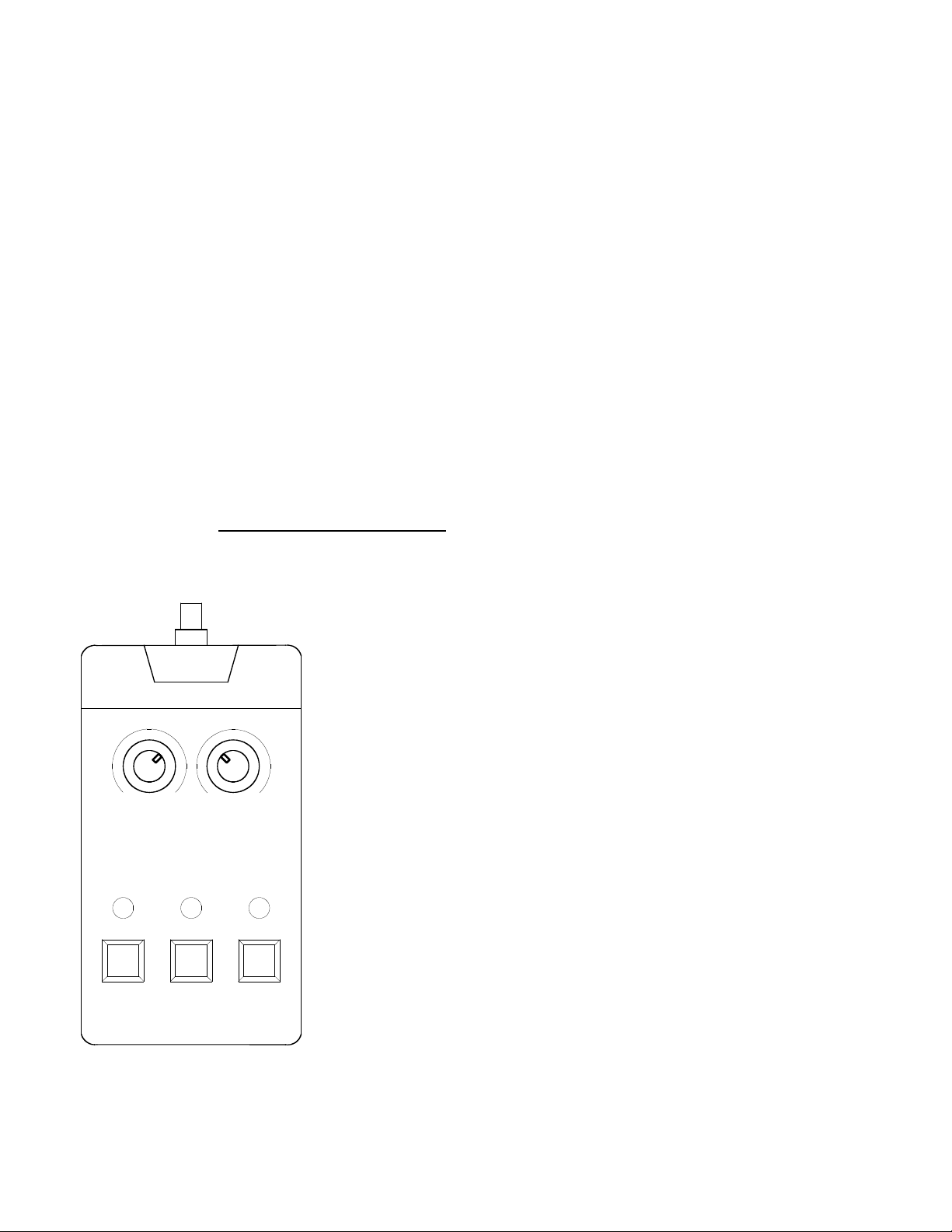

HC-1 REMOTE CONTROL

DURATION INTERVAL

00 2 MIN 4 MIN

(Time OFF)

(Time ON)

YELLOW RED GREEN

6

thereafter, so as not to set off smoke alarms in laser games, night clubs, or equally sized

entertainment facilities. Adjust as desired. Haze lasts 3-4 hours.

5. Operate for 15-30 minutes for 3-4 hours of haze. If continually left on, check fluid level every 8

hours. Caution: Over haze of facility is difficult to clear. Wait 20 minutes after each application at

first to be sure of density.

6. The built-in filter continually works to provide only the smallest droplets of haze, reducing the

possibility of residue. Overall use of fluid is reduced dramatically because of this feature. One

half ounce of fluid in haze lasts 45-60 minutes. Approximately 1/2 oz.(15 ml) used per hour of

operation.

7. When finished, wipe machine with a clean cloth and store covered to prevent dust and dirt from

accumulating on the machine. Vacuum or clean filter on fans by removing plastic housing and

rinsing or washing filter with soapy water. Dry. Replace.

8. If shipping by a common carrier, you must empty all fluid from the unit by opening top cap,

tipping upside down and moving with a slight rocking motion clockwise over a drain basin or

funnel into a bottle. Reusing this fluid requires filtering through a nylon. Always check used fluid

for clarity. If separation is seen, discard and fill with fresh fluid.

5.5 Troubleshooting

1. If the fuse blows

•If hazer stops working, first check fuse located under the plug. Remove the plug.

With a screwdriver, slide drawer straight out (completely removing drawer), the fuse is

located on the end. If blown, a replacement fuse is located inside the box next to it.

Use old fuse to push out new fuse and snap into the position .

•Inadequate extension cords can result in low line voltage, which causes the fuse to

blow. Check cords for proper size and condition (14 gauge AWG or larger for 120v).

Machine should be level to operate properly.

2. If the compressor starts to work, then stops and pops the fuse

You may have a cold unit. Below 55oF is too cold and will not start. Replace the fuse,

warm the unit with a hair dryer, light bulb, or just let it sit in a warmer environment. Once

it is warmed up to 65°F (18.3 C), try again.

3. If there is no haze

•If compressor is running, but no haze is coming out, be sure you have used the

correct hazing fluid. Water-based haze fluid causes clogging of the tiny arteries

and will cause the unit to stop working. Replacement of tank may be necessary if

this occurs.

•Check haze fluid level. (it should be no higher than “Full” line indicated). Overfilling

causes reduced haze and high amounts of residue. Be certain of fluid level. Empty

completely if overfilled and run empty to clear head.

7

5.6 Notes on DMX operation

Each DMXed unit will occupy a unique DMX address on the DMX chain. By adjusting the

dip switches on the side of the DMX control box, the user may assign one address to the

machine, giving you on/off control with one DMX channel (there is no timer on this DMX).

Step 1). Attach the DMX 5 pin plug to the upper remote female connector located on

the back of the hazer.

Step 2). The DMX address is configured by adding the dip switch numbers together

to total the number required. For example, DipSwitch 1 + 6 = 33. Your DMX channel

would be 33.

Dip Switch 1 2 3 4 5 6 7 8 9

Channel # 1 2 4 8 16 32 64 128 256

When you move the slide control or digital control, the unit will turn on at approximately

the 50% setting.

“Input” and “Output” designations on the DMX 5-pin XLR connectors are arbitrary (i.e.,

you can use the input plug for output and visa-versa). It is not necessary to attempt

converting your DMX line’s connector to female/male to match the appropriate socket on

the plug. As long as it is looped in/out, it will work.

6. Service and Maintenance

Care of your S tarHazer IIT M will give you years of service.

Note: cleaning your unit is going to pay off in constant

good performance.

1. When finished, wipe machine with a clean cloth and store covered to prevent dust and

dirt from accumulating on the machine. Clean any spilled fluid from spout area.

2. Reusing this fluid requires filtering through a nylon. Always check used fluid for clarity.

3. Periodically vacuum dust from fan filter. If filter becomes clogged, change or wash in

soapy water by popping off filter cover, removing filter foam, and then replacing.

4. Observe the filter foam on the front of the machine. If it appears that it is clogged or dirty,

it must be cleaned with soapy water. Remove first by sliding it out from under the hold-

down screws. Wash. Dry. Replace.

5. Do not transport or ship with fog fluid inside the machine. If shipping by a common

carrier, you must empty all fluid from the unit by tipping upside down and moving

clockwise over a drain basin. Put unit in a plastic bag to prevent dripping in box. Most

carriers will return leaking units.

7. Technical Data

STARHAZER IITM Technical Data P/N 100033 (230V P/N 100038)

Type of Haze

Odorless, even, transparent, long-lasting

High Performance Fluid P/N 150660

8

Weight

44 lb (19.95 kg)

Size

24½” x 12” x 12½”

(62.2 cm x 30.5 cm x 31.8 cm)

Shipping Weight

52 lb (23.6 kg)

Shipping Box Size

31” X 16” X 16”

(78.74 cm x 40.6 cm x 40.6 cm)

DMX

DMX on board 5 pin XLR in/out

Fluid

CITC’s High-Performance Fluid (oil-

based) P/N 150660, gallons (3.8 liter), 5-

gal. cubitainer (19 liter) & 55-gal. (208

liter) drum)

Fluid Consumption

1 oz (15 ml) per hour or 1 qt (0.95 liter)

per 32 hours

Output

70,000 cubic feet/hour

(21,336 meters/hour)

Warm Up Time

None, instant on—no warm-up

Continuous haze

Yes-best with cycle-timing

Duration

20 minutes of haze lasts 3-4 hours

Electrical Supply

120 VAC, 60 Hz, 5a

or 230 VAC, 50 Hz, 3a

Fuse

120VAC: 8A – 250 V, 5x20 mm

230VAC: 5A – 250V, 5x20 mm

Limited Warranty

Five year limited warranty on tank and

compressor, 90 days on electrical

components

Remote Control

On/off, cycle timer 25’ cord, 3 pin XLR

in/out connectors, 0-60 s “On”, 0-4 m “Off”

Added Features

*Direct/Manual operation switch

*Operate without remote or DMX

*Dual vane higher distance output

*protected control panel

*Dual fans 2 x output

*Dual easy clean filters

*Quiet operation insulation

*Added relays for higher performance

*Shock absorbing stand-off’s

*Baffled air circulation

*Up angled vane output-quick haze

Rev. 7/23/05

8. Limited Warranty Conditions

This limited warranty guarantees to the original purchaser that this product shall be free of defects in

material and workmanship, under normal use, for a period of one year from the date of purchase shown on

the sales receipt. This warranty covers parts and labor providing the product is returned to CITC in the

9

original shipping carton and packaging. The warranty for electrical is a (90) NINETY DAY limited

warranty.

Damage resulting from shipping, accidents, misuse, negligence, unauthorized repairs or modification is

not covered by this warranty. Using any fluid other than what is recommended for this machine will void

warranty. No liability is accepted for injury or for loss, damage or expense resulting from any interruption

whatsoever in the operation of the product or from any consequential loss arising there from. No liability

is accepted for normal wear and tear.

We wish to satisfy YOU, our customer, and have implemented many measures to prevent problems and

assure customer satisfaction. However, should you need a missing part or have a functional problem with

your product, please call (888) 786-CITC from 7:30 am – 4:00 pm (Pacific Time) Monday – Friday,

except for holidays. Our customer service department will respond to your problems immediately.

Please have the following information available when you call:

Model and Serial Number

Where and when the product was purchased

Nature of the problem

Subject to the following conditions, CITC will repair any defect or fault in the unit if it is caused

by a proven factory defect within one year of delivery to the end user. Insignificant deviations of

the regular product quality does not guarantee replacement rights, nor do faults or defects caused

by water, by generally abnormal environment conditions or Force Majeure:

1. Faulty parts will be repaired or replaced (manufacturer’s choice) with correct parts. Faulty

units must be shipped to CITC at customer’s expense. An RMA# must come with the unit.

2. The customer loses all rights for limited warranty services, if any repairs or adjustments are

done to the units by unauthorized persons and/or if spare parts are used, which are not

approved by CITC. The right of limited warranty service is also lost if a fluid other than

appropriate CITC fluid has been used or if units are sent to in with full fluid bottles.

3. Freight costs to and from CITC when under the limited warranty services are the

responsibility of the customer. Customer must place appropriate insurance on return of

product. However, if product is returned due to factory defect within the first 30 days of

receipt, CITC will cover the cost of returning the repaired unit to the customer.

4. Limited warranty services do not cause an extension of the limited warranty time or the start

of a new limited warranty time. The warranty of replaced parts ends with the limited

warranty time of the whole unit.

5. If a defect/fault can not be repaired by us in a satisfactory time, we will, within 30 days after

sale of the unit, either:

Replace the whole unit for free or take back the whole unit and refund the purchase price.

6. Further claims, especially for damages, losses etc. outside the unit are excluded.

10

7. Your limited warranty coverage is based on completion of the warranty card and returning it

with your proof of purchase within 30 days of purchase.

Your limited warranty coverage is based on completion of the warranty card and

returning it with your proof of purchase within 30 days of purchase. If you should

send the unit for service, do not forget to remove any liquid from the fluid bottle,

and place unit in original box. Obtain your RMA# by calling CITC. Payment

arrangements for repair must be made before receiving RMA # in case unit is not

covered under Limited Warranty.

Send unit to:

CITC

RMA # XXXXXXX

2100 196th Street SW Suite #138

Lynnwood, WA 98036

Tel: (888) 786-CITC or (425) 776-4950

Fax: (425) 776-5129

Website: www.citcfx.com

E-mail: info@citcfx.com

2100 196th St. SW, #138, Lynnwood, WA 98036-7083

425-776-4950 FAX: 425-776-5129

www.citcfx.com info@citcfx.com

June 17, 2005

Table of contents

Other CITC Fog Machine manuals