3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

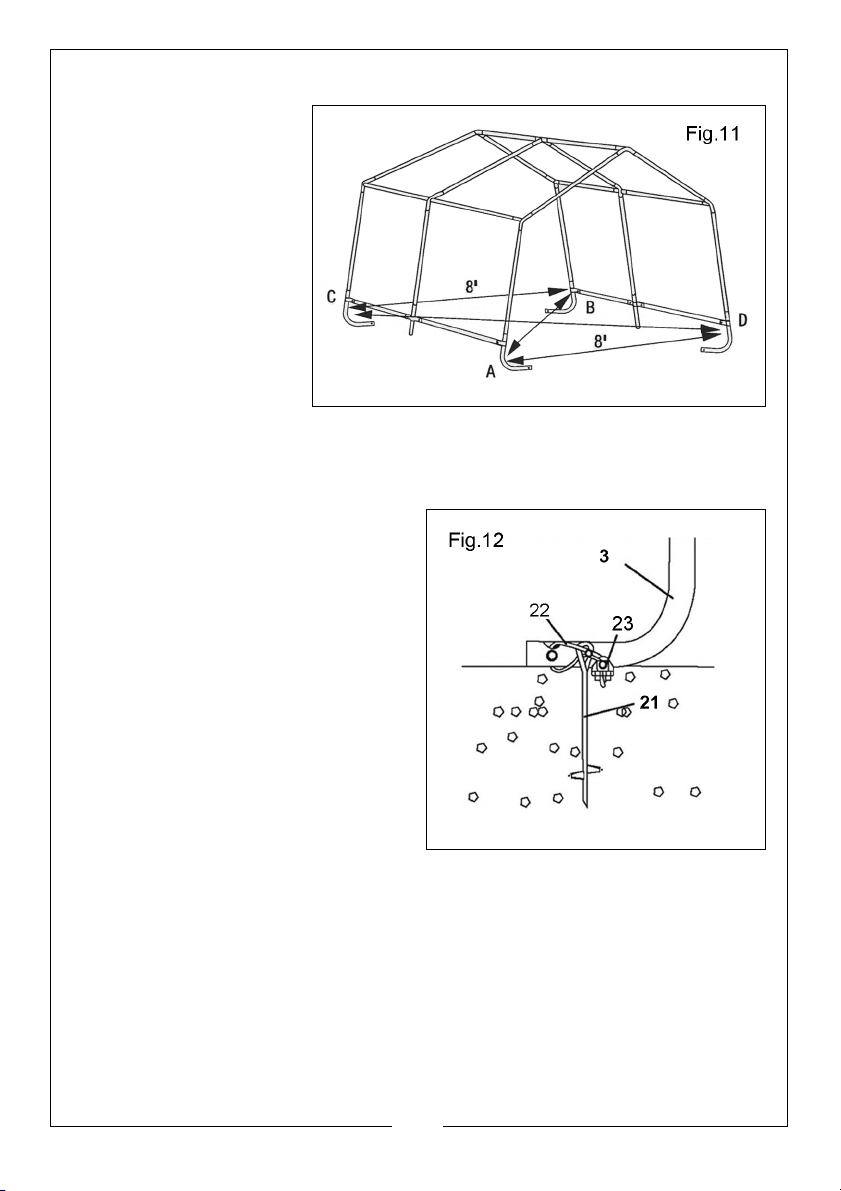

the ground area is of tarmac or concrete, the use of ground anchor holding-

down bolts will be required to anchor the shed to the floor.

A masonry floor such as block paving or concrete is ideal, but if this is not

being supplied, a timber or shuttering plywood floor, protected by a suitable

groundsheet should be used. This will help to create a dry storage environment

by insulating the storage space from ground moisture.

Proper anchoring and keeping the cover tight and free of snow and debris is

the responsibility of the user. Damage caused by improper anchoring is not

covered under warranty.

CARE OF THE SHED STRUCTURE

This shed is NOT designed to support heavy snow. Snow or ice accumulation

may cause your shed to collapse. To avoid overload, use a ladder to brush

snow and ice off the roof top with a broom or mop to prevent collapse with

the resultant damage to property or personal injury.

NEVER clear the roof of snow or debris from inside the shed.

DO NOT use hard-edged tools or instruments, such as rakes or shovels to

remove snow. These can cause punctures to the cover.

DO NOT use bleach, alkaline or harsh detergents for cleaning. Doing so will

damage the material. Soap and warm water are recommended.

In order to reduce risk of burning and avoid damage, DO NOT- cook, smoke,

refuel or use any open flame devices in or around the garage.

USING THE STORAGE SPACE

NEVER run the engine of any vehicle or machine inside a closed shed. Ensure

that there is adequate ventilation for engines or for any work with paints,

cleaners. etc. by opening the door panel and keeping it raised.

Take steps to avoid the buildup of condensation inside the shed. Cool, damp

winter days and moisture from the breath and body heat of personnel may

cause condensation on the inside of the top cover of the shed.

For long term storage of moisture sensitive belongings in all weathers, the use

of a dehumidifier may be required, such as those in the CLARKE range. A

suitable extension lead to a locally available power supply will be required.

Condensation will be much less of an issue during the summer months.

A supply of fresh air through the doorway will at least partly remove this issue.

If storing a motorcycle in your shed over the winter months we recommend

the use of a secondary lightweight cover over your motorcycle.