OOMB 1227 Iss 02

Consort Equipment Products Ltd

Registered Office: Thornton Industrial Estate

Milford Haven, Pembrokeshire, SA73 2RT

Tel: 01646 692172 Fax: 01646 695195

BS EN ISO 9001 Registered Company No FM12671

INSTALLATION, OPERATION and MAINTENANCE INSTRUCTIONS FOR

Sanfire 40 Sanitary Incinerator

Catalogue Number: HE6820

PLEASE RETAIN THIS LEAFLET FOR FUTURE MAINTENANCE

INSTALLATION

Unpack and dismantle the unit as follows:-

a) Remove the ash drawer

b) Remove the two fixing screws on the

inner top edge of the charging door (C

Fig 4)

c) Slide the charging door outer plate

upwards and remove.

d) Remove the 4 cover fixing screws. The

cover will then be released and can be

detached by sliding forward.

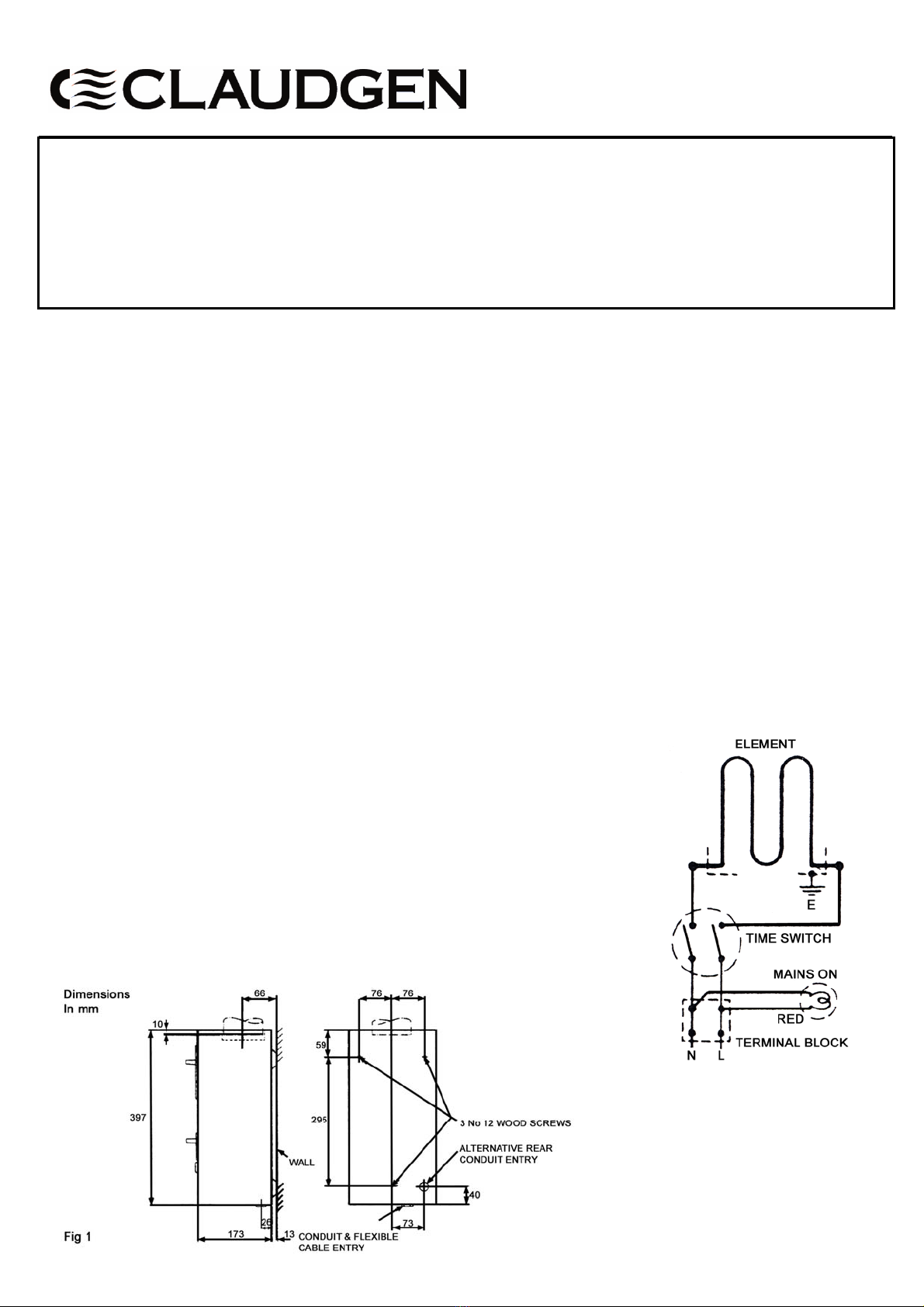

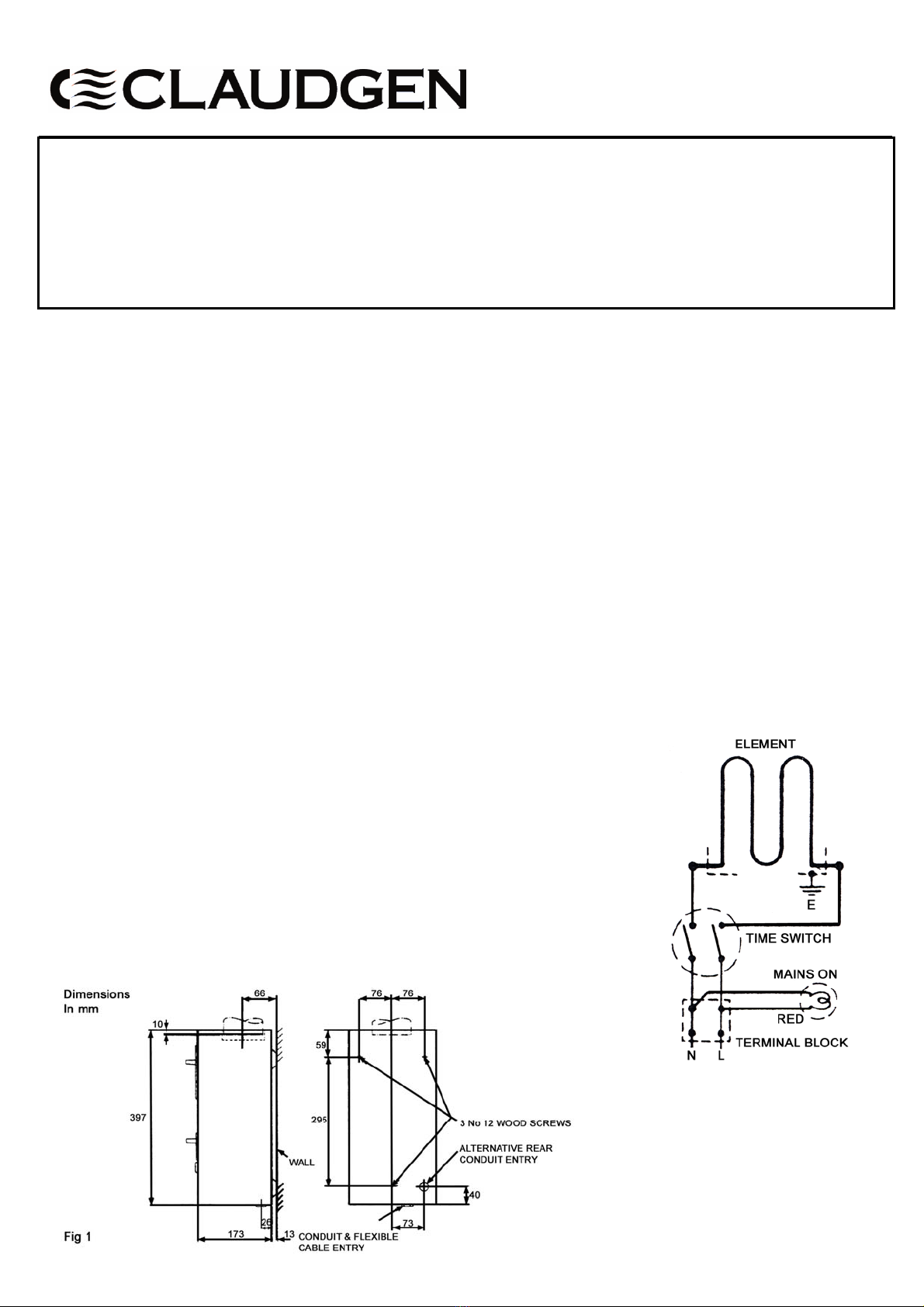

The incinerator should be positioned with the

top of the unit 1.22 mm from floor level and

secured by three No 12 wood screws.

Keyhole slots are provided in the fixing lugs.

Dimensions of the fixing points are given in

Fig 1.

To allow the unit to be removed or to be

installed when the flue is already in position,

a clearance of 9.5 mm must be left between

the lower end of the flue and the top of the

incinerator so that the unit can be raised

sufficiently above its normal position to

allow the fixing screw heads to come out of

the keyhole slots in the fixing lugs.

Dimensions given in Fig 1 allow an

appropriate clearance between the bottom of

the flue and the top of the unit. To fix the

unit, insert the screws so that the heads are

about 6 mm from the wall. Suspend the unit

by means of lugs provided on the three wall

fixing screws. During this operation the flue

should be inserted into the socket of the

incinerator. When in position tighten the

screws firmly. When installed, the

incinerator will stand away from the wall

leaving a 13 mm gap. This gap must not be

obstructed as it is for ventilation purposes.

Single Flues

a) The incinerator should be sited in a

position which eliminates inclined flue

runs as far as possible.

b) The Sanfire 40 accepts 76.2 mm i.d. flue

piping, the first 600 mm of which we

recommend you use our HE6767

600 mm flue. From this, our flue

adaptor HE6768 should be used to

enable connection to a 3” (76 mm) flue.

The remaining lengths and accessories

should be in a light gauge aluminium or

fibre cement.

c) In changing direction use bends with a

minimum angle of 1200fitted with

cleaning doors. In straight runs, pipes

fitted with cleaning doors should be

provided as necessary for maintenance

purposes. Regular cleaning of flues is

essential.

d) To minimise the possibility of down

draughts, a vertical flue length of 2.7 m

or more is recommended.

e) The flue should be taken above the eaves

of the building or surrounding structures.

Externally the flue should be stood off

the wall to clear eaves or coping and, if

necessary, should be taken through such

a projection to avoid bends near the flue

termination. The installation should be

completed with a suitable cowl.

f) All flue connections should be carefully

sealed including the joint on the socket

of the incinerator.

g) Where a long inclined or any horizontal

flue run is unavoidable ask for details of

a suitable fan to assist ventilation.

Common Flues

Sanfire incinerators can be easily connected

to common flues and used in mechanically

ventilated toilets provided that forced

extraction is incorporated in the main stack.

For guidance on design, details of fittings

and fan requirements for common flues, ask

for Advisory Leaflet HLT/1041.

NB

When designing flue systems attention

should always be given to the relevant

British Standards and BS Codes of Practice

for Building and Flues, also to the Building

Regulations.

Electrical Connections

a) The Sanfire 40 is suitable for connecting

to a 220/240 volts single phase AC

supply (for other voltages, ask for

technical information).

b) The unit is rated 550 watts at 230 volts.

c) A separate 5 amp fuse must be provided

in the supply wiring to the unit.

d) An entry is provided at the rear of the

unit for connection of 20 mm conduit or

a small BESA box mounted in the wall

behind the unit. An alternative 20 mm

conduit entry and a cable clamp for

connection by flexible cable are also

provided in the base of the unit. These

positions are shown in Fig 1.

e) Connect the mains leads to the terminals

as shown in Fig 2.