5

•

Installing the projector

The projector can be mounted in any position without its operating characteristics

being affected.

IMPORTANT: fix the projector in the desired position utilizing the holes in the

bracket (2).

Secure preferably using a ø10 bolt with nut and lock washer (version HMI 575) -

two ø12 bolts with nuts and lock washers (version HMI 1200).

Make certain that the anchorage is stable before positioning the projector.

IMPORTANT: the safety wire must be secured to the projector and to the support-

ing structure in such a way that if the bracket should fail, the projector will fall as short

a distance as possible.Following any such failure, the safety wire must be replaced

with a genuine Clay Paky spare.

•

Minimum distance from target objects

The projector must be positioned in such a way that

objects struck by the beam are separated from the

lens at least by the distance indicated on the lamp

change label against the symbol shown alongside.

•

Minimum distance of inflammable materials from any part of the equip-

ment: 0.1 m (4”) for HMI 1200, 0.07 m (3”) for HMI 575.

The appliance may be mounted on surfaces rated normally inflam-

mable.

IMPORTANT: For better and more reliable operation of the projector, the ambient

temperature must not exceed 35° C (95° F). Protection factor IP 20:the appliance is

protected against penetration of solid bodies more than 12mm (0.5”) in diameter

(first digit 2), but can be damaged by spray, jet, drip or rain water (second digit 0).

TIGER C.C.

ENGLISH

HMI 575

HMI 1200

2

4

8

765

1

3

3

1

POWER SUPPLY AND INTERFACE

2

•

Connecting to the electrical power supply

The operations described in this heading must be carried out by a licensed

electrician.

It is good policy to connect projectors to the power supply by way of dedicated switch-

es, so that each can be turned on and off individually from a remote station.

The projector is designed to operate at the voltage and frequency indicated on the

electrical data plate (14) affixed to the rear end.

Check that these two values correspond to the mains voltage and frequency.

IMPORTANT: the projector must be connected to a power supply circuit having

a proper earth system (Class I appliance).

•

Connecting the control signals

0-10V CONNECTION

- Independent operation

INSTALLING THE PROJECTOR

1

•

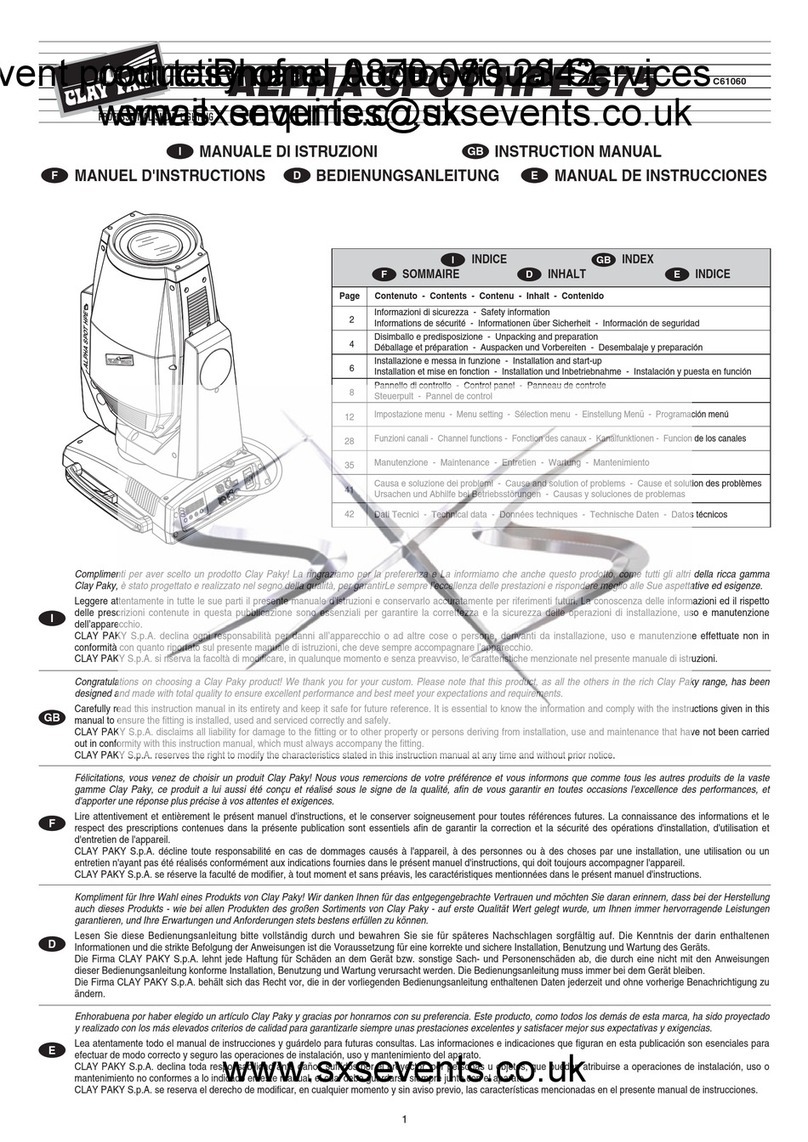

Unpacking

Open the box, remove the projector from the packing and place it on a flat, hori-

zontal surface.

Unpack the standard accessories supplied with the equipment. Inspect the lamp

change label (1) and replace it with one of the optional language versions if nec-

essary.

Make certain that the label is never removed, as it displays important safety infor-

mation.

•

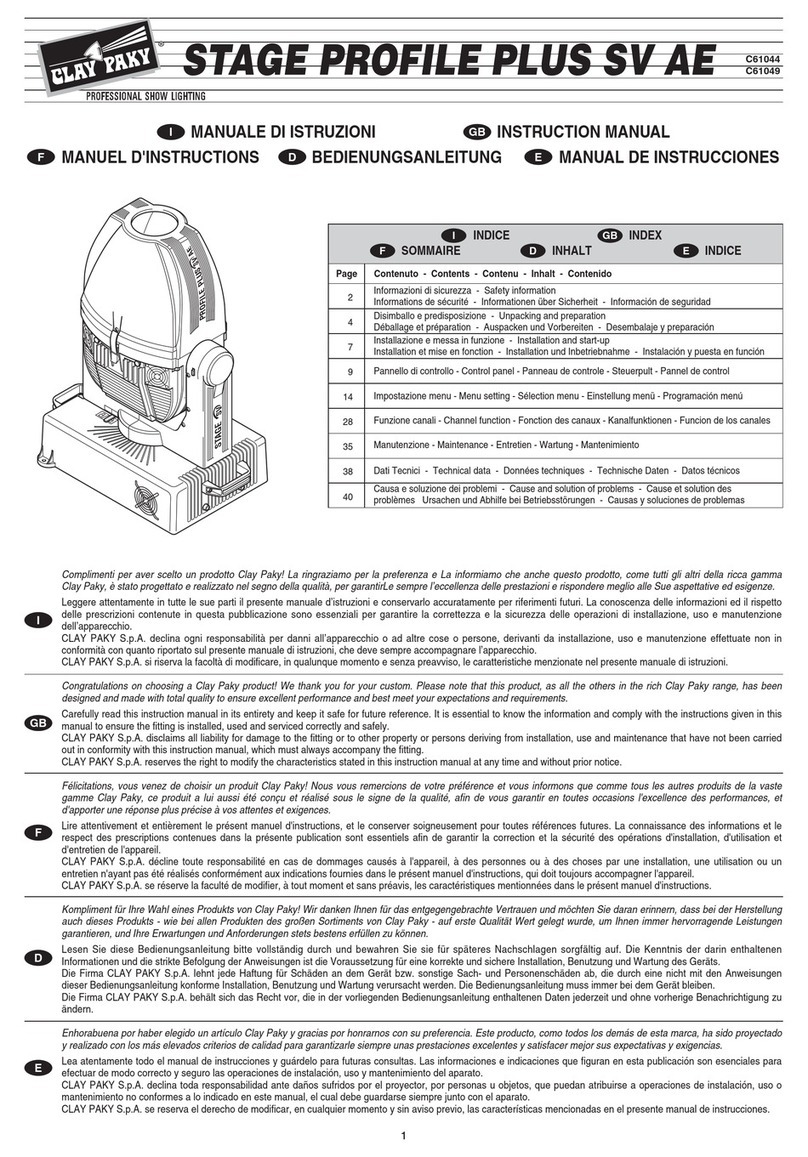

Initial assembly operations (HMI

575 version)

Position the bracket (2) as required and

secure by tightening the knobs (3). The

bracket can also be fitted on the under-

side of the projector by removing screws

(4) and knobs (3).

•

Initial assembly operations (HMI

1200 version)

Position block (5) on the projector

body so that it is aligned with the

threaded holes; secure graduated

plate (6) with eyebolt (7) and then fit

knob (3) and washer (8).

Position bracket (2) on graduated plate

(6) at the desired height; insert bushing

(9), chamfered washer (10) and screw

(11) in the selected hole and tighten

using the supplied Allen key.

The bracket can also be fitted on the

underside of the projector by inverting

the position of graduated plate (6).

If the projector has been shipped with

plate (6) already fitted, before remov-

ing the plate (if necessary) remove the

safety bolt located inside the fixture in

correspondence with eyebolt (7).

Set the projector support in the

desired position and secure by tight-

ening knobs (3).

Fasten the safety wire (12) of lamp

change cover (13) to graduated plate (6).

•

Fitting the lamp

Refer to directions for replacement of

the lamp given under heading 6 MAIN-

TENANCE.

9213

12 6 3 10 11

14

•

Fitting the safety wire

A safety wire (25) is supplied for use with

version HMI 1200.The wire must be secured

to the gantry or other structure and then

anchored to the eyebolts (7) on the projector

itself.

25

7