2

ALPHA WASH 1500 LT

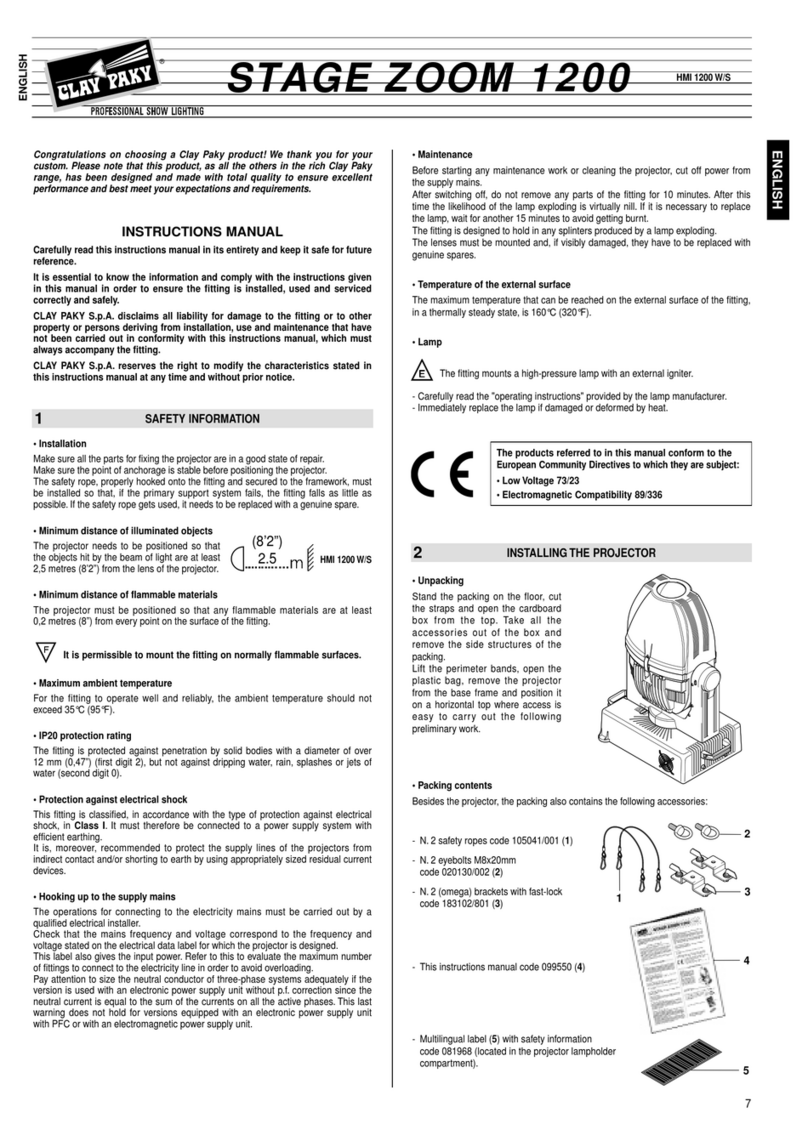

• Installation

Make sure all parts for fixing the projector are in a good state of repair.

Make sure the point of anchorage is stable before positioning the projector.

The safety chain must be properly hooked onto the fitting and secured to the framework, so that, if

the primary support system fails, the fitting falls as little as possible.

If the safety chain gets used, it needs to be replaced with a genuine spare.

• Minimum distance of illuminated objects

The projector needs to be positioned so that the objects hit by the beam of light are at least 5 metres

(16’ 5”) from the lens of the projector.

• Minimum distance from flammable materials

The projector must be positioned so that any flammable materials are at least 0.20 metres (8") from

every point on the surface of the fitting.

• Mounting surfaces

It is permissible to mount the fitting on normally flammable surfaces.

• Maximum ambient temperature

Do not operate the fixture if the ambient temperature (Ta) exceeds 40° C (104° F).

• IP20 protection rating

The fitting is protected against penetration by solid bodies of over 12mm (0.47”) in diameter (first

digit 2), but not against dripping water, rain, splashes or jets of water (second digit 0).

• Protection against electrical shock

Connection must be made to a power supply system fitted with efficient earthing (Class I appliance

according to standard EN 60598-1).

It is, moreover, recommended to protect the supply lines of the projectors from indirect contact

and/or shorting to earth by using appropriately sized residual current devices.

• Connection to mains supply

Connection to the electricity mains must be carried out by a qualified electrical installer.

Check that the mains frequency and voltage correspond to those for which the projector is designed

as given on the electrical data label.

This label also gives the input power to which you need to refer to evaluate the maximum number

of fittings to connect to the electricity line, in order to avoid overloading.

• Temperature of the external surface

The maximum temperature that can be reached on the external surface of the fitting, in a thermally

steady state, is 150°C (302°F).

• Maintenance

Before starting any maintenance work or cleaning the projector, cut off power from the mains

supply.

After switching off, do not remove any parts of the fitting for at least 10 minutes. After this time the

likelihood of the lamp exploding is virtually nill. If it is necessary to replace the lamp, wait for another

20 minutes to avoid getting burnt.

The fitting is designed to hold in any splinters produced by a lamp exploding. The lenses must be

mounted and, if visibly damaged, they have to be replaced with genuine spares.

• Lamp

The fitting mounts a high-pressure lamp that needs an external igniter. This igniter is fitted onto the

apparatus.

- Carefully read the "operating instructions" provided by the lamp manufacturer.

- Immediately replace the lamp if damaged or deformed by heat.

• Battery

This product contains a rechargeable lead-acid battery. To preserve the environment, please

dispose the battery at the end of its life according to the regulation in force. Instructions on how to

remove the battery from the product are available on www.claypaky.it

AFETY INFORMATION

The products referred to in this manual conform to the European Community Directives to which

they are subject:

•Low Voltage 2006/95/CE

•Electromagnetic Compatibility 2004/108/CE

5

1500W

IP20

Pb