cleanAIR AtmosAir FC-400 Series Technical Document

OUR MISSION

To improve health and wellness by actively restoring indoor air

to its pure, natural state where no pollution or contaminants

exist, while reducing energy use and emissions in the process.

AtmosAir.com

CAG-06-21-003

IMPORTANT

Save this Document

for Future Reference &

Warranty Information

FC-400 Series

Installation, Operation

and Maintenance Guide

Installation, Operation & Maintenance Guide FC-400 Series 2

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

! I M P O RTANT!

READ THIS BEFORE STARTING INSTALLATION.

DO NOT THROW AWAY THIS GUIDE.

How to Contact Us: If you need help, please contact an

AtmosAir Representative for technical assistance.

For safe installation you MUST:

■Always disconnect power to the unit before handling any of the

components.

■DO NOT connect to the power before the installation is complete and

personnel are aware of the imminent operation. Secondary voltage to the

ionization tube can be as high as 3000 Volts AC.

■Carefully read this instruction booklet before beginning the installation.

■Follow each installation or repair step exactly as shown and explained in

this guide.

■Observe all local, state, national and international electrical codes.

■Pay close attention to all warnings and caution notices given in this guide.

!CAUTION!

Do not touch while in operation shut off electricity before servicing!

This equipment should be inspected frequently and collected dirt removed from it regularly to prevent excessive

accumulation that may result in ashover or risk of re.

!MISE EN GARDE!

Ne touchez pas pendant le fonctionnement couper l’électricité avant l’entretien

Cet équipement doit être inspecté fréquemment et la saleté collectée doit être retirée régulièrement pour éviter

toute accumulation excessive pouvant entraîner un contournement ou un risque d’incendie.

Installation, Operation & Maintenance Guide FC-400 Series 3

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

Table of Contents

01 PRODUCT OVERVIEW 4

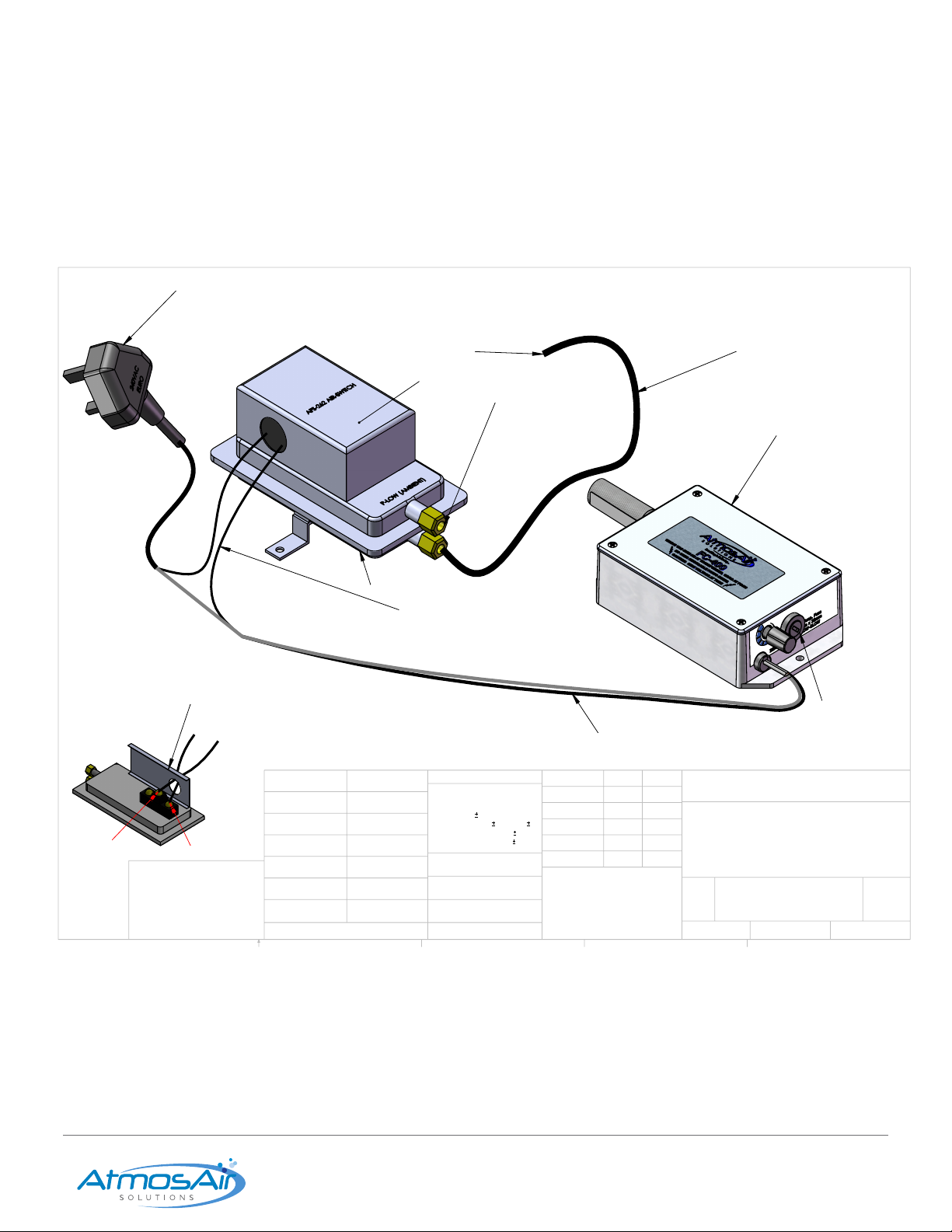

FC-400 Diagram 4

02 INSTALLATION 5

Mechanical Installation 5

Electrical Installation 6

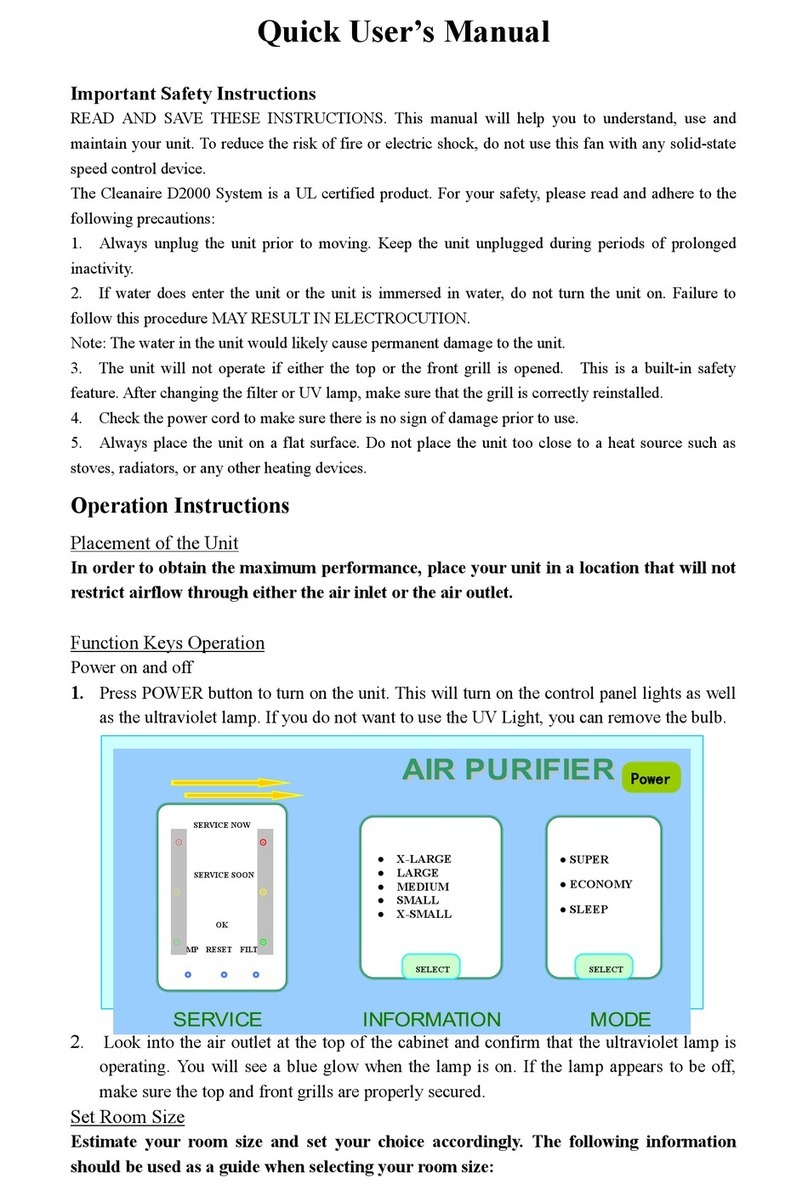

03 FIELD WIRING DIAGRAMS 7

Diagram 1 8

Diagram 2 9

Diagram 3 10

Diagram 4 11

Diagram 5 12

04 OPERATION 13

05 MAINTENANCE RECOMMENDATIONS 13

06 TROUBLESHOOTING 14

07 EXPLANATION OF TECHNOLOGY 15

08 PRODUCT WARRANTY 16

79.38mm

(3.125")

Installation, Operation & Maintenance Guide FC-400 Series 4

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

01 PRODUCT OVERVIEW

The AtmosAir FC-400 series ionization generators are designed for installation in air conditioning systems or in custom-designed

air distribution systems. AtmosAir equipment is effective in reducing odors and harmful pollutants through the introduction of

positive and negative ions into the airstream to be treated. The number and size of the ionization units used is dependent upon the

airow, size of the space, and severity of the pollution and odors. The AtmosAir FC-400 series equipment is designed for minimal

maintenance. The FC-400 series has two components that require inspection and maintenance:

1. AtmosAir FC-400 series base unit components + fuse

2. Ionization tube

There are no user-serviceable components inside.

Because there are no moving parts, little maintenance is required, and the systems have very low failure rates. For more

information, read the AtmosAir FC-400 series submittal document.

FC-400 Diagram

AtmosAir FC-400 Layout:

A. Power Input

B. Ionization Tube

C. Blue LED Power Light

D. Mounting Holes

E. Fuse Holder

F. 24 VAC to 12 VAC Mini Transformer

Overall Mounting Plate Dimensions:

152.40mm (6”) L x 88.90mm (3.5”) W x 40.64mm (1.6”) H

Installation, Operation & Maintenance Guide FC-400 Series 5

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

02 INSTALLATION

AtmosAir FC-400 series equipment are mounted using the baseplate mounting ange. The units operate best when located after

all lters, coils, and fans. Various mounting arrangements are possible; however, the available options may be limited due to size

and conguration restrictions. When mounted, the FC-400 ionization system should not be exposed to condensing moisture or

excessive heat (refer to the Product Submittal for maximum environmental temperature specications). The AtmosAir FC-400

operates on 100-250 VAC, 50/60 Hz. The tube and electrode contacts should not come into contact with any conductive surface. A

minimum 38.1mm (1.5”) clearance around the tube is recommended.

Mechanical Installation

1. Carefully remove the equipment from its shipping container.

Inspect the box, components, and tubes for damage. Verify

that the unit’s voltage rating is the same as the available

voltage, 100-250 VAC 50/60 Hz.

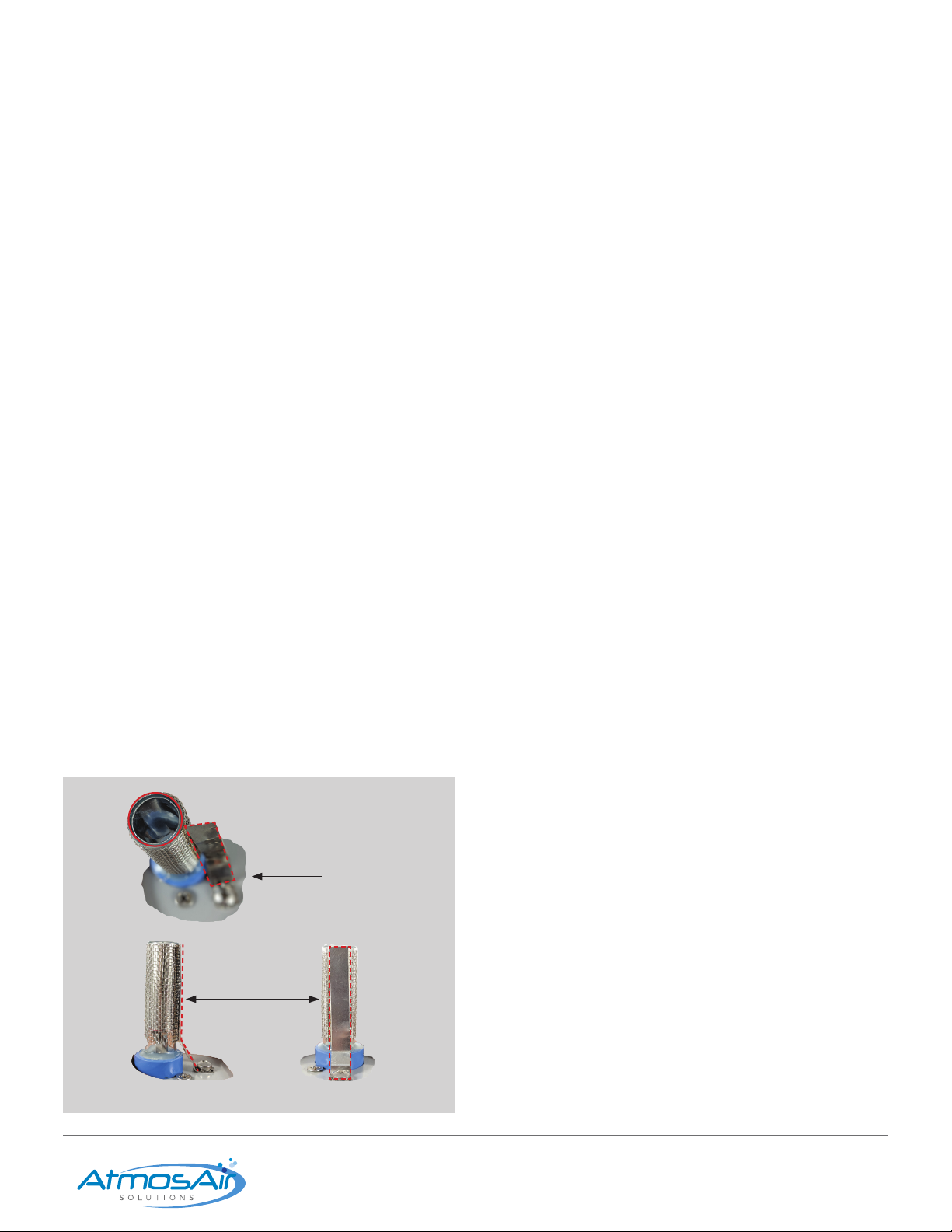

2. Install the ionization tube: Gently pull the conductor strap

back to allow the tube to turn freely; screw the end screw of

the tube into the tube-holder hand-tight. Ensure that the tube

is FULLY SEATED.

3. Once the tube is secure, return the conductor strap to

its normal position and ensure solid, at, and continuous

contact is made with the tube’s outer mesh.

(See page 8.)

!!!WARNING!!!

The secondary voltage to the ionization tubes can be as high as 3000 volts AC. Do NOT connect to power before the installation is complete and all

personnel are aware of imminent operation. Always disconnect power to the unit before handling any of the components.

Electrical

Connection Nut

B-Tube Screw SEATEDNOT FULLY

SEATED Tube Holder

Fig. 2.1a Fig. 2.1b

4. Location and Orientation: Install the unit downstream of

lters, coils, and fans with tubes perpendicular to airow

whenever possible. Contact AtmosAir Engineering for

Installations outside this scope.

5. Mark the drill holes for the self-tapping screws to mount the

FC-400.

6. Afx the unit securely using self-tapping screws. Do not over-

tighten, this may strip the screw-hole.

7. Units should be installed to allow easy access for

maintenance. Install units so that the power adjustment

knob, fuse, and status light are easily accessible, variable, and

visible.

Installation, Operation & Maintenance Guide FC-400 Series 6

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

Electrical Installation

■AtmosAir FC-400 series systems require an average of 4.5 watts per unit.

■Follow proper electrical procedures, guidelines, and codes for providing power supplies to the systems. Including

requirements for conduit, sufcient ampacity, phase balancing, etc. Electrical installation should be performed by a qualied

electrician.

■Field-install a power plug outlet or power receptacle within 1.83 meters (6’) of the unit(s).

■Each FC-400 series unit is shipped with an 2.44 meters (8’) power cord with a eld install pair of wire hot/neutral connector on

one end and a quick-disconnect plug on the other end. The FC-400FM has a polarized quick-disconnect on the unit. Each unit is

shipped with two wiring options per country-specic requirements:

1. Two-conductor, eld wire connection (No Ground)

2. NEMA 5-15 two-prong plug adapter

Caution!

A non-functioning LED light may improperly indicate that the system is not functioning. Be sure to disconnect from the main power before performing

maintenance or troubleshooting the system.

!!!WARNING!!!

THE SECONDARY VOLTAGE TO THE IONIZATION TUBE CAN BE AS HIGH AS

3000 VOLTS AC. DO NOT CONNECT TO POWER BEFORE THE INSTALLATION IS COMPLETE

AND ALL PERSONNEL ARE AWARE OF IMMINENT OPERATION. ALWAYS DISCONNECT

POWER TO THE UNIT BEFORE HANDLING ANY OF THE COMPONENTS.

Installation, Operation & Maintenance Guide FC-400 Series 7

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

BLACK (HOT) WIRE TO N/O

NORMALLY OPEN AND

COM

AIRFLOW SAMPLING TUBE

INSERT 6" INTO AHU OR DUCT AFTER

FAN, AIRFLOW INTO TUBE END.

SILICONE IN PLACE

LEAVE OPEN TO

AMBIENT AIR

LID IS REMOVABLE

1/4" POLYETHYLENE

TUBING

MOUNT ON DUCT OR AHU

JUNCTION BOX

120 VAC

LO

HI

COMMON

NORM

OPEN

AFS 262

WIRING

GREEN SHRINK

TUBES

FEMALE SPADE TERMINALS

FOR FIELD CONNECTION

USA NEMA 5 PLUG

120VAC 60Hz IN,

12VDC OUT

12VDC

.500mA FUSE

5mm x20mm glass

ATMOSAIR FC-400

OR FC-400FM

FC-400/AFS262

DO NOT SCALE DRAWING

FIELD

WIRING DIAGRAM

FC-400 SERIES TO AFS-262

AIRSWITCH

SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:3

REV.

C

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

COMMENTS: FIELD WIRING DIAGRAM

FOR CONNECTING FC-400 SERIES TO

AFS-262 AIR SWITCH TO LINE VOLTAGE

Q.A.

Rev C SB 3-12-21

ENG APPR. TA 2-21-19

2/21/19

DRAWN HRG 2-21-19

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

.010

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ATMOSAIR SOLUTIONS. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ATMOSAIR SOLUTIONS IS PROHIBITED.

5

4

3

2

1

ATMOSAIR SOLUTIONS

FC-400 SERIES

SERIES TO

AFS-262

CONNECTIONS

03 FIELD WIRING DIAGRAMS

Installation, Operation & Maintenance Guide FC-400 Series 8

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

BLACK (HOT) WIRE TO N/O

NORMALLY OPEN AND

COM

AIRFLOW SAMPLING TUBE

INSERT 6" INTO AHU OR DUCT AFTER

FAN, AIRFLOW INTO TUBE END.

SILICONE IN PLACE

LEAVE OPEN TO

AMBIENT AIR

LID IS REMOVABLE

1/4" POLYETHYLENE

TUBING

MOUNT ON DUCT OR AHU

COMMON

NORM

OPEN

AFS 262

WIRING

ATMOSAIR FC-400

OR FC-400FM

12VDC

1Amp FUSE

5mm x20mm

glass

240 VAC

50/60HZ

'EURO' PLUG

WITH 13 AMP

INTEGRAL FUSE

FC-400/AFS262

DO NOT SCALE DRAWING

FIELD

WIRING DIAGRAM

FC-400 SERIES TO AFS-262

AIRSWITCH (PLUG)

SHEET 1 OF 1

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:3

REV.

A

DWG. NO.

A

SIZE

TITLE:

NAME

DATE

COMMENTS: FIELD WIRING DIAGRAM

FOR CONNECTING FC-400 SERIES TO

AFS-262 AIR SWITCH TO PLUG

Q.A.

ENG APPR. HG 3-12-21

DRAWN SB 3-12-21

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

.010

ANGULAR: MACH

BEND

TWO PLACE DECIMAL

.010

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ATMOSAIR SOLUTIONS. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ATMOSAIR SOLUTIONS IS PROHIBITED.

5

4

3

2

1

ATMOSAIR SOLUTIONS

FC-400 SERIES

SERIES TO

AFS-262

CONNECTIONS

03 FIELD WIRING DIAGRAMS CONTINUED

Installation, Operation & Maintenance Guide FC-400 Series 9

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

4"-6"

21 GAUGE

48"

18 GAUGE

24VAC

(NO POLARITY)

12VDC

(POLARIZED)

BLACK -

WHITE

WHITE

RED +

BLACK -

RED +

MOUNT INTO 2.5"

HOLE IN DUCT

ATMOSAIR FC-400

OR FC-400FM

DO NOT SCALE DRAWING

FC-400 SERIES

24VAC INPUT

SHEET 1 OF 1

3/19/21

3/19/21

HG

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:4

WEIGHT:

REV.

A

Created: 3/19/2021

A

SIZE

TITLE:

ATMOSAIR SOLUTIONS

NAME

DATE

PRODUCTION APPR.

ENG APPR.

CHECKED

DRAWN SB

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

.xxx

ANGULAR: MACH

.xxx BEND

TWO PLACE DECIMAL

.xxx

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ATMOSAIR SOLUTIONS. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ATMOSAIR SOLUTIONS IS PROHIBITED.

5

4

3

2

1

Last Saved: 3/22/2021

XXX

XXX

COMMENTS:

XXX

XXX

XXX

JS

03 FIELD WIRING DIAGRAMS CONTINUED

Installation, Operation & Maintenance Guide FC-400 Series 10

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

2.5"

POSSIBLE

POSSIBLE

POSSIBLE

ATMOSAIR

FC-400 FM

12VDC

5' CABLE

120VAC TO 240VAC

AUTO SWITCHING

TRANSFORMER

GREEN SHRINK

TUBES

FEMALE SPADE

TERMINALS

FIELD WIRING

CONNECTION

(SUPPLIED)

5' CABLE

120/240 VAC

JCT. BOX

DO NOT SCALE DRAWING

TYPICAL AIR DUCT

FC-400 FM

MOUNTING

SHEET 1 OF 1

3/25/21

3/25/21

HG

SB

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:4

WEIGHT:

REV.

A

Created: 3/26/2021

A

SIZE

TITLE:

ATMOSAIR SOLUTIONS

NAME

DATE

PRODUCTION APPR.

ENG APPR.

CHECKED

DRAWN

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

.xxx

ANGULAR: MACH

.xxx BEND

TWO PLACE DECIMAL

.xxx

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ATMOSAIR SOLUTIONS. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ATMOSAIR SOLUTIONS IS PROHIBITED.

5

4

3

2

1

Last Saved: 3/26/2021

XXX

XXX

COMMENTS:

XXX

XXX

XXX

JS

03 FIELD WIRING DIAGRAMS CONTINUED

Installation, Operation & Maintenance Guide FC-400 Series 11

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

RETURN

SUPPLY

FAN

POSSIBLE

POSSIBLE TO INSTALL

IN RETURN

POSSIBLE

FILTER

B

12VDC

A

DETAIL B

UNIVERSAL SS304

MOUNTING BRACKET

PROVIDED

STANDARD

CAN BE BENT

PER APPLICATION

DETAIL A

FEMALE SPADE

TERMINALS

GREEN SHRINK

TUBES

120VAC TO 240VAC

AUTO SWITCHING

TRANSFORMER

FC-400 UNIT TYPICALLY INSTALLED

IN SUPPLY, HOWEVER UNDER

SPECIAL CIRCUMSTANCES

CAN BE INSTALLED IN RETURN

120/240VAC

SOURCE

AIRFLOW

DO NOT SCALE DRAWING

TYPICAL VERTICAL

FAN COIL FC-400

MOUNTING

SHEET 1 OF 1

3/25/21

3/25/21

HG

UNLESS OTHERWISE SPECIFIED:

SCALE: 1:4

WEIGHT:

REV.

A

Created: 3/25/2021

A

SIZE

TITLE:

ATMOSAIR SOLUTIONS

NAME

DATE

PRODUCTION APPR.

ENG APPR.

CHECKED

DRAWN SB

FINISH

MATERIAL

INTERPRET GEOMETRIC

TOLERANCING PER:

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL

.xxx

ANGULAR: MACH

.xxx BEND

TWO PLACE DECIMAL

.xxx

THREE PLACE DECIMAL

APPLICATION

USED ON

NEXT ASSY

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

ATMOSAIR SOLUTIONS. ANY

REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF

ATMOSAIR SOLUTIONS IS PROHIBITED.

5

4

3

2

1

Last Saved: 3/26/2021

XXX

XXX

COMMENTS:

XXX

XXX

XXX

JS

03 FIELD WIRING DIAGRAMS CONTINUED

Installation, Operation & Maintenance Guide FC-400 Series 12

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

Recommended Maintenance Procedures:

■Visually check the performance of the system by

checking the blue light on the unit. If not, proceed to the

troubleshooting section for repair. Maintain a physical

distance between all personnel and the tubes while

system is operating or turned on.

■Optional: Check performance using a high voltage

probe paired with a multimeter (minimum of 5000 V

probe). Contact AtmosAir for additional minimum probe

specications. Follow proper safety procedures for

dealing with high voltages. If you are uncertain, do NOT

perform any maintenance with the power on and proceed

to the next step.

■Disconnect the system from the main power before

performing any maintenance steps.

■Inspect the unit box, plastic tube caps, and tube-

mounting area. Remove particles from mounting area,

and thoroughly wipe clean any tracks or grooves that may

have developed in the plate or caps.

■Inspect connections: tightness of all nuts and screws;

remove deposits on the connections using wire brush or

similar tool - it may be necessary to remove the tubes for

this step.

■It may be benecial to clean the tubes to improve

performance. The tubes can be cleaned using an air

compressor for a quick clean, or more thoroughly with

cleaning solutions. Do not immerse the tubes in water.

Ensure that the tubes and mesh are completely dry

before re-installing.

04 OPERATION

Once the system is properly installed and all personnel are

clear of the high voltage tubes, the system can be turned on:

1. Ensure the ionization power knob is turned to the

appropriate quadrant: from low to high clockwise.

Typically, it is suggested to start at a baseline of 50%

ionization. Twenty-four hours later, re-evaluate your air

quality and adjust accordingly.

2. Plug the power cord on the FC-400 ionization system into

the plug receptacle.

3. Once the FC-400 system is plugged in the system will be

on. Check that the blue embedded LED light is lit. The LED

is programmed to indicate that the system is on, ionization

has been activated, and high voltage is being sent to the

tube.

4. Settings are determined upon commissioning and

installation with the Criteria below:

5. The system is intended to deliver ions into the treated area

such that the ion levels should be between 350 and 1500

negative ions/cm3. The desired ion increase is dependent

on many factors, including space, use, contaminant level,

humidity RH, and distribution effectiveness. An authorized

AtmosAir design consultant should recommend the

desired ion increase and appropriate system layout.

05 MAINTENANCE

REQUIREMENTS

Caution!

A non-functioning LED light may improperly indicate that the system

is not functioning. Be sure to disconnect from the main power before

performing maintenance or troubleshooting the system.

The maintenance requirements on an AtmosAir system are

mainly site-dependent; a heavily contaminated environment

may require more frequent inspection and maintenance.

Annual system maintenance is recommended. A bi annual

tube replacement is required. Your local AtmosAir dealer can

provide you with an annual service contract.

Tube Replacements:

Bi-annual tube inspections are recommended, in addition to

tube replacements once every two years as the production

efciency slowly declines over time due to the stress caused

by plasma and (lack of) cleanliness of the electrodes. Old

or excessively dirty tubes can also put undue stress on the

transformer causing premature failure.

Installation, Operation & Maintenance Guide FC-400 Series 13

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

06 TROUBLESHOOTING

In the event that the system is not functioning, follow these

steps IN ORDER:

1. Check the fuse. If it is blown, replace it with the appropriately

sized slow-blow 500 mA (0.5 Amps) glass 5 mm × 20 mm

fuse rated at 250 V and continue to the next step.

2. Check that the main power supply is sending the correct

power to the unit (100-250 VAC).

3. If the main power is controlled or any other power limiting

device is installed, check that these are not preventing power

from being sent to the system.

4. If power is reaching the unit and it was necessary to replace

the fuse, the next step is to determine whether there is a

fault in the system or a tube. First, to check that the system’s

power is functioning, set the ionization power knob and

the power switch both to the ‘off’ position. Make sure all

personnel are clear of the high voltage tubes, then re-

connect the power supply. Flip the power switch to ‘on’ and

observe the green light. If the light does not turn on, there

is still a problem with delivering power to the system. If all

external sources of failure are eliminated, the system should

be serviced by a qualied AtmosAir technician. Refer to the

contact information at the bottom of this page.

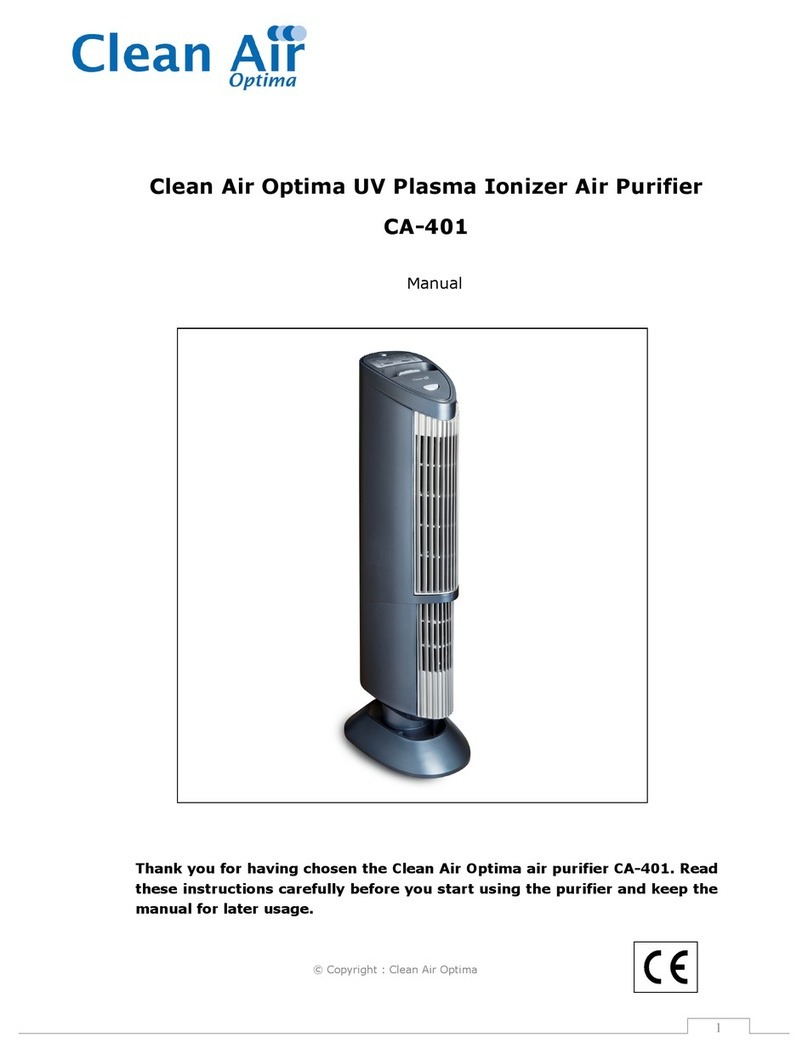

5. Check that the spring tang is making CLEAN, FLAT-TO-

TUBE contact with the tube as shown below:

The next step is to determine the cause of the failure, or

blown fuse. Typically, failures are caused by arcing between

the inner and outer electrodes, or between one electrode

and ground. Often, this occurs either because the tube

isn’t properly seated, or because of damaged tubes or dirty

and/or wet conditions that have allowed carbon tracking

to temporarily connect two electrodes and/or a grounding

point electrically.

6. Inspect the mounting plate for tracking evidence.

7. Inspect the tubes for cracks, pitting, or other degeneration

of the dielectric material that causes the dielectric to fail

and arcing to occur.

8. If physical inspection has not revealed the cause of failure,

one may carefully observe the tubes as the ionization

system is turned on to determine whether arcing is

occurring at a particular tube. The fuse will usually blow,

again, but for a short time, one may observe the cause

of the power surge in the form of a visual or audio cue.

Usually, a failing tube can be determined in a darkened

room by looking for a ash or arc from the failing tube.

9. If the fuse blows, then the system should be serviced by

a qualied AtmosAir Technician. You can contact repair

services at RMA@atmosair.com or by contacting us at

1-888-MY-AIR11.

10. If the fuse continuously blows, then the system should be

serviced by a qualied AtmosAir technician. DISCONTINUE

USE IMMEDIATELY!

11. Otherwise, replace the damaged tube(s), clean and

smooth any mounting plate or end cap carbon tracking,

and return the system to service.

Not Acceptable

Acceptable

Fig. 5a

Fig. 5b Fig. 5c

Installation, Operation & Maintenance Guide FC-400 Series 14

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

07 EXPLANATION OF TECHNOLOGY

AtmosAir Solutions’ ™ mission is to bring and restore every indoor environment the same clean and pure quality air that is typically

found at higher mountain elevations.

AtmosAir’s unique and proven air purication process signicantly reduces mold, controls the spread of bacteria and airborne

viruses, and reduces airborne particles that evade normal ltration solutions.

AtmosAir equipment uses non-thermal plasma technologies to generate bi-polar Ionization that attacks and breaks down odors

and contaminants.

Installation, Operation & Maintenance Guide FC-400 Series 15

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

y

y

CLEAN AIR GROUP, INC. – PRODUCT WARRANTY

Clean Air Group, Inc. d/b/a AtmosAir Solutions (“Clean Air Group”) warrants to the original purchaser of this product (“Customer”),

that should it prove to be defective by reason of improper materials or workmanship, for twenty-four (24) months from the date

of installation, or twenty-seven (27) months from the date of Clean Air Group’s delivery of the product, whichever occurs first,

Clean Air Group shall repair or replace the product without charge to the Customer. Proof of malfunction and return of the non-

working product must be presented by the Customer if submitting a warranty claim. This warranty is invalid if the factory applied

serial number has been altered or removed from the product. This warranty does not cover damage due to acts of God, misuse,

abuse, negligence, or modification of or to any part of the product. This warranty does not cover damage due to improper

installation, operation or maintenance, connection to improper voltage or electrical supply, or repair by anyone other than an

authorized Clean Air Group service provider. To obtain warranty service the Customer must: (1) provide proof of purchase in

the form of a Bill of Sale or receipted invoice, with evidence that the product is within the warranty period; (2) request a Return

Merchandise Authorization (“RMA”) from Clean Air Group prior to shipping; and (3) ship the product with the RMA to Clean Air

Group, freight prepaid, in either its original packaging or packaging affording an equal degree of protection. The product should

be delivered to AtmosAir, 2115 East Cedar Street, Suite 6, Tempe, AZ 85281. All transportation charges and shipping expenses

are the Customer’s responsibility. Clean Air Group will return the product by the same method it receives the product. A product

returned for repair after the warranty period, or that shows damage outside of the warranty coverage described herein, shall be

repaired for a reasonable charge as determined by Clean Air Group. The Customer will be advised of the cost of repair or

replacement before Clean Air Group proceeds.

THE OBLIGATIONS OF CLEAN AIR GROUP HERIN ARE EXPRESSLY GRANTED IN LIEU OF ALL WARRANTS, WHETHER

EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE. ALL IMPLIED WARRANTIES INCLUDING WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR PARTICULAR PURPOSE ARE LIMITED TO THE TERM OF THE EXPRESS WARRANTY GRANTED HEREIN.

Some states do not allow limitations on how long an implied warranty lasts, so the foregoing limitation or exclusion may not apply

to you.

With the exception of damages resulting from Clean Air Group’s failure to comply with any obligation under federal or state

warranty laws, Clean Air Group SHALL NOT BE LIABLE TO THE CUSTOMER OR ANY OTHER PERSON OR THIRD PARTY

FOR ANY DAMAGES, INCLUDING BUT NOT LIMITED TO CONSEQUENTIAL, SPECIAL, INDIRECT, INCIDENTAL AND

PUNITIVE DAMAGES AND/OR DAMAGES BY REASON OF INJURY TO ANY PERSON DUE TO ANY DEFECT OR

MALFUNCTION OF THE PRODUCT OR ANY PART OR PARTS THEREOF OR FOR ANY OTHER REASON. This warranty

gives you specific legal rights and you may have rights which vary from state to state. If your product is defective please contact

Clean Air Group or the dealer where you purchased the unit.

Disclaimer: The air purification technology provided by AtmosAir is intended to improve air quality. It is not intended to replace

reasonable precautions to prevent the transmission of airborne contaminants. Customer, its employees, invitees and all persons

having access to the serviced premises should comply with all applicable public health laws and guidelines issued by federal,

state and local governments and health authorities such as the Centers for Disease Control and Prevention (CDC). These

precautions include but are not limited to wearing face masks, social distancing, hand hygiene and appropriate sanitizing and

disinfecting. Clean Air Group does not assert that its products can protect people from viruses, bacteria or other airborne

contaminants, expressly excludes liability for loss or damage arising from any such claims, and does not assume any liability for

the consequences arising out of the application, use or misuse of its products, including any injury or damage to any person or

damage to any property as a matter of product liability, negligence, contract or otherwise.

Manufacturer,

Anthony M. Abate

Chief Technology Officer

Clean Air Group, Inc.

08 PRODUCT WARRANTY

Table of contents

Other cleanAIR Air Cleaner manuals

cleanAIR

cleanAIR Optima CA-803 User manual

cleanAIR

cleanAIR AtmosAir Everest User manual

cleanAIR

cleanAIR AerGO NA-041-R01 User manual

cleanAIR

cleanAIR Optima CA-267 User manual

cleanAIR

cleanAIR D2000 Owner's manual

cleanAIR

cleanAIR RESQUE 100 User manual

cleanAIR

cleanAIR AerGO A1 P R SL User manual

cleanAIR

cleanAIR AtmosAir 500 Series Technical Document

cleanAIR

cleanAIR Optima CA-401 User manual