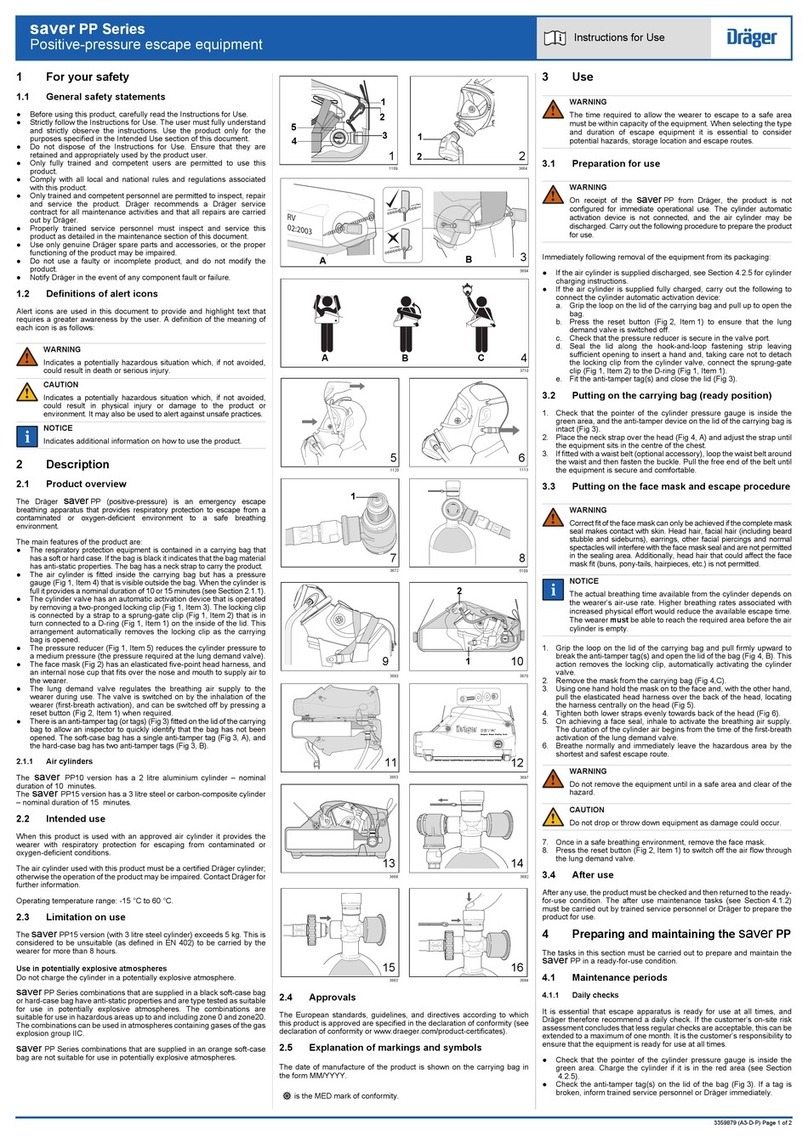

4 5

The complete system including accessories contains

the following components:

• Powered respiratory unit -1 pc

• Battery

• Belt

• Air supply hose

• Flow indicator

• Battery charger

• Manual for use

3.2. Assemblage

1. Connect the air supply hose to the powered respi-

ratory unit making sure the screw is tight enough so

the joint is leakproof.

2. Attach the lters to the unit - always all of the same

type!

3. Connect the hose to the headtop.

Basic description of usage and functions

CA Chemical 3F Plus

The unit can be switched on by pressing any of the

two controlling push-buttons shortly. Individual ow

levels can be changed by shortly pressing buttons

and . Instantly after switching the unit on you can

see information about the supplier of your powered

respiratory unit on the display; during the second vi-

sual display, you can go over to the MENU by pressing

both buttons at the sane time for 2 seconds; last the

information display will visualize giving you the fo-

llowing information: the actual ow level, the present

state of lter clogging and of baterry charging. For

better orientation, these specications are distingui-

shed by correspondent pictograms. The Flow Cont-

rol System keeps the air-ow steady irrespective of

the lter clogging or the degree of battery charging.

If it is impossible to keep the chosen air-ow, you will

hear an acoustic signal. If it is possible, the electro-

nics will automatically decrease the air-ow by one

level. If the unit is unable to keep the lowest practicable

air-ow, you will be warned by alarm and the reason for

this alarm as well as the instructons for needful inter-

vention into the unit will appear on the display. Next it

is urgent to stop work immediatelly and to replace the

lter or battery, eventually to charge the battery.

Detailed description of functions for unit 3F Plus

Monitoring panel – displays

selected standard, type of lter

in use, remaining and set alarm

time, present ow volume, the

present state of lter clogging and

battery charging.

Alarm – alarm informing the

user about unsatisfactory air-ow

through the unit due to lter clo-

gging. It is vital to leave the conta-

minated area and replace lters.

Alarm – alarm notifying the user

of the lter expiry which can be

pre-set. The alarm is also repre-

-sented by a red LED located

next to the display.

Alarm – alarm notifying the user

of battery discharge. It is vital to

leave the contaminated area and

replace or recharge the battery.

Alarm – alarm notifying the user

of time for service. It is necessary

to contact your supplier for regu-

lar service.

Standard selection for the unit.

EN 12 941 – is for hoods,shields

and helmets.

EN 12 942 – is for masks and

half-masks.

Filter type being used at present.

If the incorrect type of lter is set,

the lter clogging control does not

work correctly.

Setting the useful life of lters.

This function enables to watch

the life of the lters beginning at

the moment of setting the value.

This alarm is useful, for example,

if there is a time limit for using a

lter; e.g for mercury lters it is

only 50 hours.

Language setting- enables to set

the language of the MENU.

This function resets all speci-

cations of the unit to the initial

factory conguration.

Displays functional specications

of the unit, mainly for diagnos-

tics purposes of possible faults

during service.

Using the MENU for unit 3F Plus

MENU access– press both buttons at the same time for

2 seconds after switching the unit on.

• Movement to particular items of the MENU - button .

• Item selection from particular MENU oers - button .

• Conrmation of your selection from particular Menu

oers – long press on button .

• Leaving the MENU – long press of both buttons and .

• Turning the display orientation by 90° – short press

of buttons and .

4. Before usage

4.1. Control procedure before each usage

Make sure that:

• All components are all right without any visible vio-

lence or damage (above all there must not be any

cracks, holes, leakage).

• Replace any damaged and worn-down parts. Be

particular about the good state of the air supply hose

and of the sealing components

• The hose is connected correctly to the powered re-

spiratory unit as well as to the headtop; after swit-

ching the powered respiratory unit on, air is brought

into the headtop; the air-ow in the hose is sucient

(Point 4.2.)

• Charge the battery before using it for the rst time,

see Point 6.2.

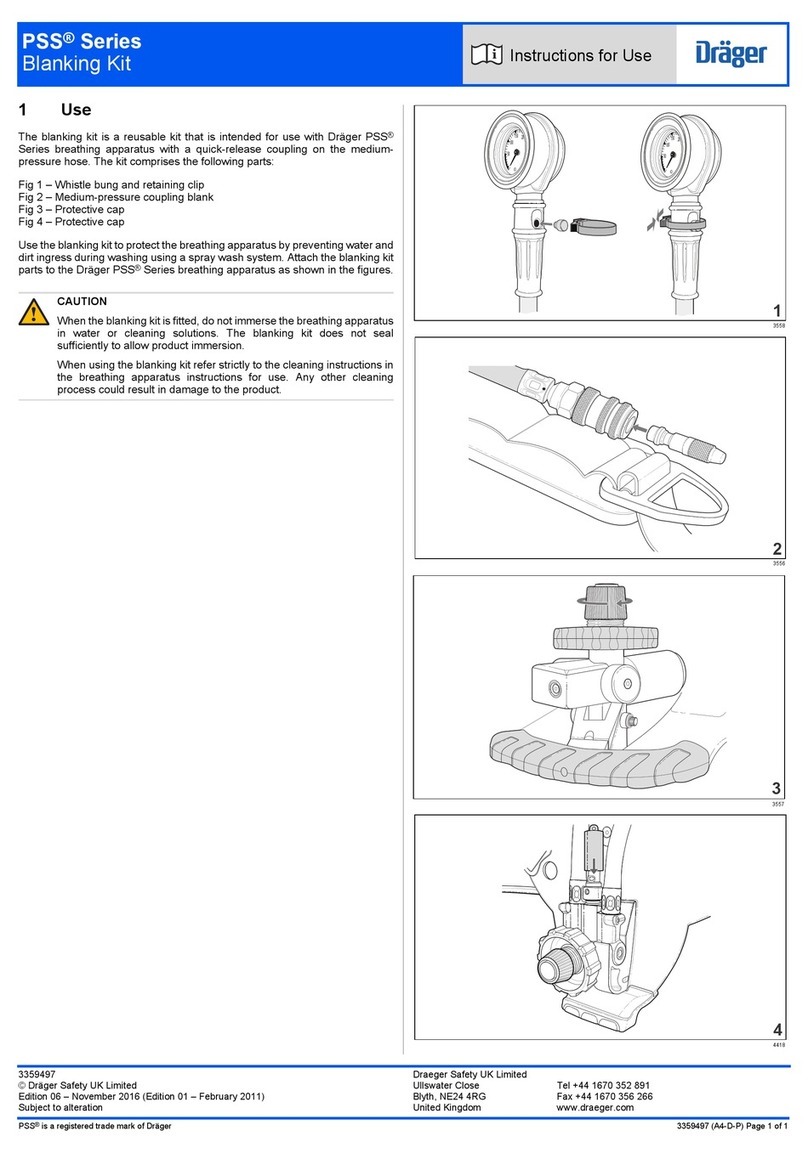

4.2. Air-owtest

Disconnect the air hose.

• Screw the air ow meter into the output thread of

the unit; then hold the unit in upright position at eye-

-level.

• Switch the lter unit on. The ow amount is satis-

factory if the ow meter oat is in the green eld. If

it is in the red eld (see picture attachment), the unit

must be inspected (see Chapter 7).

5. Maintainance and cleaning

• Always clean your CleanAIR® unit after nnishing

work. Check all parts by detail and replace damaged

parts.

• Cleaning must be done in a well ventilated room.

Beware of breathing in harmful dust settled on indi-

vidual parts of the lter unit and accessories!

• Do not use cleaning agents with solvents or abra-

sive cleaners in any case.

• The outer surface of the lter unit can be cleaned

with soft fabric moistened in solution of water and

usual washing-up liquid. After cleaning dry individual

parts properly.

• Do not allow water or other liquid to get into the lter

unit!

• The air hose can be washed out with clean water

after disconnection from the unit.

6. Spare parts replacement

CA Chemical 3F

There are three lters attached to the unit with thread

RD40x1/7“. The vital rule is to use a set of three lters

of the same type at a time!

Install only new lters without any damage.

It is forbidden to clean a lter or blow through it in

any way!

From the hygiene point of view it is recommended not

to leave a lter in the unit for more than 180 working

hours! It is also possible to use a pre-lter which holds

larger particles and especially aerosols which can stick

up the lter during paint-spraying and thus it prolongs

the life time of the lter.

Replacement of lters CA Chemical 3F

see Picture appendix no.2

Picture 2A :

Demounting is done by unscrewing each lter sepa-

-rately anticlockwise.

Caution! Before mounting new lters, make sure the

new lters are undamaged, in the original pac-king and

their service life is not expired (expiry is marked directly

on the body of the lter). Check also whether the seals

at the connecting points of the lters and the lter unit

are unfaulted and safe.

Picture 2B :

New lters are mounted one by one clockwise. It is ne-

cessary to be particular about screwing them tight to

ensure tightness of the joints.

6.2. Batteries

Important! Batteries are delivered uncharged. Each

time before using a battery for the rst time charge it.

The battery charger is not made for outdoor service. It

can be used only in premises protected against rain

and moisture. Never charge the battery in potentcially

explosive atmosphere. It is forbidden to use the batte-

ry charger for other purposes than those determined

by the producer. Charging starts after connecting the

charger to the power supply and the battery. As soon

as the battery is fully charged, the charger will switch

over to maintainance cycle and the battery stays fully

charged all the time. The charging time is 3-4 hours.

6.2.1. Battery charging

1. Check that the mains voltage is right for the

battery charger.

2. Connect the charger to the mains.

3. Connect the charger to the charging connector

located at the back of the battery. The charging