CleanCraft dryCAT 16 L - Class User manual

DRYCAT-SERIES

Dry Vacuum Cleaner

Instruction Manual

dryCAT 16 L - Class

dryCAT 16 L - Class

2 dryCAT-Series | Version 1.02

Imprint

Product identification

Dry Vacuum Cleaner Item number

dryCAT 16 L - Class 002116

Manufacturer

Stuermer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.cleancraft.de

Indications regarding the operating instructions

Original Instructions

Publication: 29.03.2021

Version: 1.02

Language: English

Author: RL

Indications regarding the copyright

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company Stürmer.Passing on as well as

copying of this document, the use and distribution of its

content are prohibited if not explicitly permitted. Contra-

ventions are liable to compensation.

Subject to technical modifications and error.

Contents

1 Introduction .............................................................3

1.1 Copyright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety........................................................................3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company ................ 4

2.3 Requirements to staff.......................................... 4

2.4 Personal protective equipment ........................... 5

2.5 General safety regulations.................................. 5

2.6 Safety labels ....................................................... 6

3 Intended use ............................................................7

3.1 Misuse ................................................................

4 Technical Data .........................................................7

4.1 Type plate ..........................................................

5 Transport, pac aging, storage...............................8

5.1 Transport ............................................................ 8

5.2 Packaging........................................................... 8

5.3 Storage ............................................................... 8

6 Description of the device........................................8

6.1 Scope of delivery ................................................ 9

6.2 Accessories ........................................................ 9

7 Assembly .................................................................9

8 Operation ...............................................................10

8.1 Start and Stop................................................... 11

8.2 Operating instructions....................................... 11

8.2.1 Suction and blowing function....................... 11

8.2.2 Air regulation ............................................. 11

8.2.3 Filter cleaning system................................ 11

8.3 Seal inspection ................................................. 11

9 Care, maintenance and repair ..............................12

9.1 Care by cleaning............................................... 12

9.2 Maintenance and repair.................................... 12

9.3 Replacing the filter............................................ 12

9.3.1 Cleaning the filter ........................................ 12

10 Disposal, recycling of used devices..................13

10.1 Decommission ................................................ 13

10.2 Disposal of electrical equipment.................... 13

10.3 Disposal of lubricants...................................... 13

10.4 Disposal via municipal collection

points ..................................................................... 13

11 Troubleshooting ..................................................14

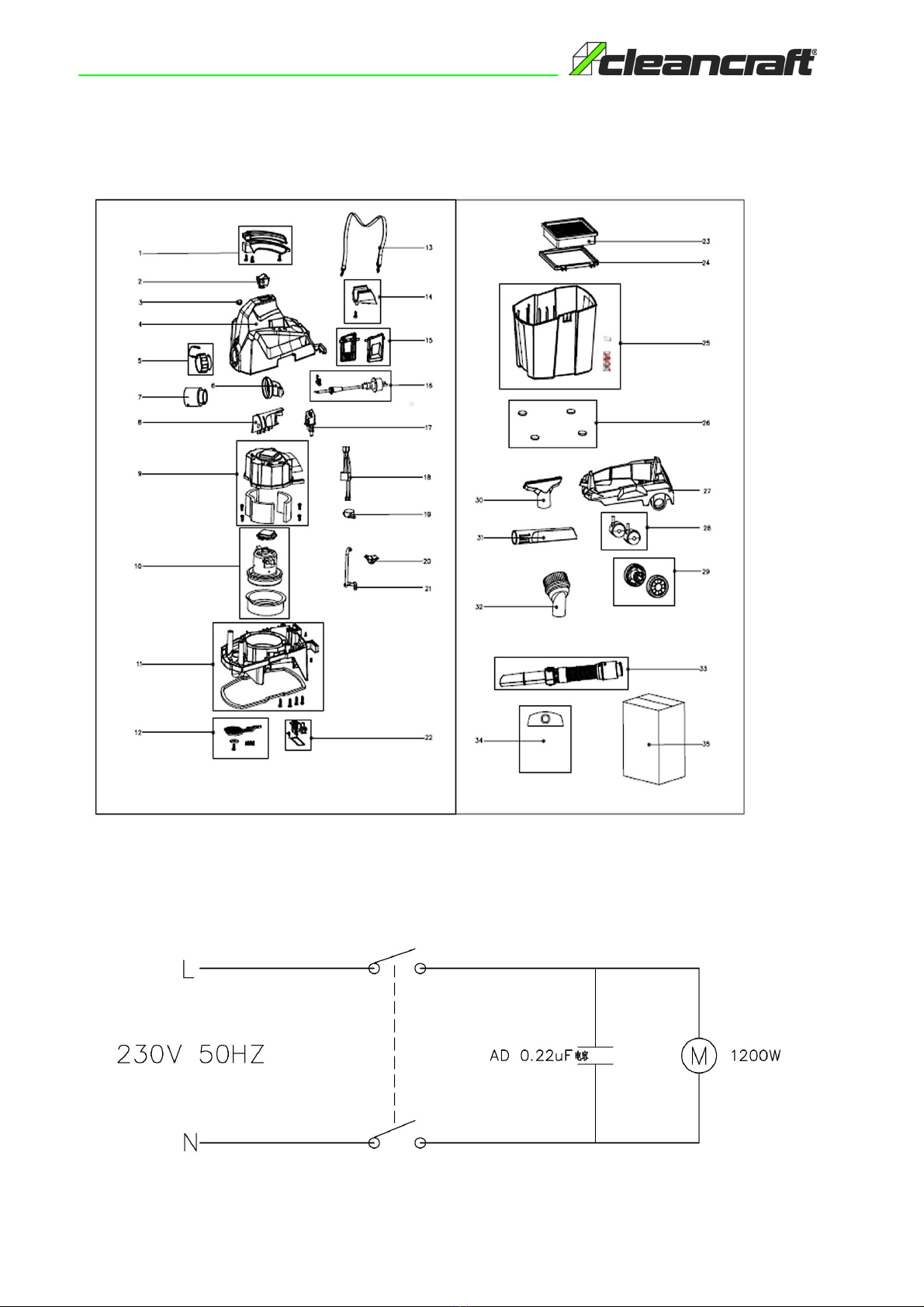

12 Spare parts drawing............................................15

12.1 Ordering spare parts...................................... 15

12.2 Spare parts drawing....................................... 16

13 Electrical circuit diagram....................................16

14 EC-Declaration of Conformity ............................17

Introduction

dryCAT-Series | Version 1.02 3

1 Introduction

You have made a good choice by purchasing the

CLEANCRAFT dry vacuum cleaner.

Read the operating manual thoroughly before com-

missioning the machine.

It gives you information about the proper commissio-

ning, intended use and safe and efficient operation and

maintenance of your dry vacuum cleaner.

The operating manual is part of the vacuum cleaner pac-

kage. Always keep this operating manual in the location

where your dry vacuum cleaner is being operated. All

local accident prevention regulations and general safety

instructions for the operating range of your va-cuum cle-

aner must also be complied with.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the va-

cuum cleaner. Any application beyond those described

is not permitted without the written approval of Stürmer

Maschinen GmbH.

For the protection of our products, we shall register tra-

demark, patent and design rights, as this is possible in

individual cases. We strongly oppose any infringement

of our intellectual property.

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your dry vacuum cleaner or if you need technical

advice. They will help you with specialist information and

expert advice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: [email protected]

Internet: www.cleancraft.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: ersatz[email protected]

We are always interested in valuable experience and

knowledge gained from using the application which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards and

rules, the state-of-the-art technology and our long-term

knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-ti-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task ba-

sed safety notes are included in the paragraphs of the in-

dividual phases of life.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are intro-duced by

signal words which express the concern of the risk.

D NGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

W RNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

4 dryCAT-Series | Version 1.02

Safety

Tips and recommendations

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and damages to property.

2.2 Obligations of the operating company

The operating company is the person who operates the

vacuum cleaner for business or commercial reasons by

herself, or leaves it to a third party for use or application,

and who bears the legal product responsibility for the

protection of the user, the staff or for third parties.

Obligations of the operating company:

If the vacuum cleaner is used for commercial purposes,

the operating company of the vacuum cleaner must com-

ply with the legal working safety regulations. There-fore,

the safety notes in this operating manual, as well as the

safety, accident prevention and environment protec-tion

regulations applying for the area of application of the va-

cuum cleaner must be met. The following applies in parti-

cular:

During the entire lifetime the vacuum cleaner, the opera-

ting company must verify whether the opera-ting ma-

nuals prepared by her correspond to the current status of

the regulations, and must adapt these if necessary.

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use of the vac-

uum cleaner. She must implement these in form of

operating manuals for the operation of the vacuum

cleaner.

- The operating company must unambiguously re-

gulate and determine the responsibilities for instal-

lation, operation, troubleshooting, maintenance

and cleaning.

- The operating company must ensure that all per-

sons who work with the vacuum cleaner, have read

and understood this manual. Furthermore she

must instruct the staff in regular intervals and in-

form them about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way.

Furthermore the operating company is responsible to

keep the vacuum cleaner always in a technically fla-

wless state. Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices chec-

ked regularly for their good working order and their

integrity.

2.3 Requirements to staff

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

C UTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

TTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may lead

to property and environmental damages if they are

not avoided.

NOTE!

This combination of symbol and signal words indi-cates

a potentially dangerous situation which may lead to

material or environmental damage if not avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

W RNING!

Danger in case of insufficient quali-

fication of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the vacuum cleaner and expose

themselves and others to the danger of severe or let-

hal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the wor-

king area.

Safety

dryCAT-Series | Version 1.02 5

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine. The qualifications of the personnel for the diffe-

rent tasks are mentioned below:

Operator:

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-for-

med beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company ex-pres-

sively commissioned the operator.

Electrically qualified person:

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

independently recognize and avoid possible dangers.

Qualified personnel:

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer:

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while wor-

king. The staff member has to wear personal protec-tive

equipment while performing different tasks on and with

the machine which are indicated in the individual para-

graphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 General safety regulations

Please note the following:

- Use the protective devices and fasten them se-

curely. Never work without the guards and keep

them in working order.

- Do not change the design of the dry vacuum cleaner

and do not use it for purposes other than the opera-

tions foreseen by the manufacturer.

- Ensure that there is sufficient lighting.

- Never work under the influence of diseases that im-

pair concentration, overtiredness, drugs, alcohol or

medication.

- Keep children and persons not familiar with the dry

vacuum cleaner away from their working environ-

ment.

- The dry vacuum cleaner must not be used by per-

sons with reduced physical, sensory or mental ca-

pacity.

- Do not pull on the power cord to unplug it from the

wall outlet. Protect the cord from heat, oil and sharp

edges.

- Immediately eliminate malfunctions that affect

safety.

- Protect the dry vacuum cleaner from moisture (risk

of short circuit).

- Before each use, make sure that no parts are dam-

aged on the dry vacuum cleaner.

- Damaged parts must be replaced immediately to

avoid sources of danger.

- Do not overload the dry vacuum cleaner! It works

better and safer in the specified power range.

- The unit must be used, assembled, repaired and

transported on a stable and safe surface.

- Do not use this unit outdoors, in high humidity envi-

ronments, or at low temperatures.

- Do not vacuum dust without a filter.

- Do not vacuum flammable materials.

- Do not vacuum explosive materials.

- Do not use the unit to vacuum explosive or flamma-

ble gases, liquids and dust particles, undiluted,

strong acids and alkalis, metal dust particles (such

as aluminum, magnesium, zinc) in combination with

strong alkaline or acid cleaning agents .

- Do not vacuum substances that can cause explo-

sions when in contact with air.

- Do not exceed the max. filling level of the container

- Do not use the vacuum cleaner in areas with tem-

peratures above 40 ° C.

- Do not vacuum glowing objects.

- Never open the tank during operation.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fal-

ling parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6 dryCAT-Series | Version 1.02

Safety

- Do not immerse the device in water and do not use

water jets to clean it.

- Never pull the power plug or the suction hose.

- Do not use compressed air to clean the dry vacuum

cleaner.

- Use only original spare parts and accessories to

avoid possible hazards and risks of accidents.

- Do not suck in any materials that could damage the

filter elements (e.g. glass).

- Make sure that the values indicated on the motor

block correspond to those of the mains voltage to

which you wish to connect the unit.

- When using extension cables, make sure that they

are compatible with the power cable (larger or equiv-

alent cross-section) and that they do not come into

contact with liquids or conductive surfaces.

2.6 Safety labels

The following safety labels and instructions are attached

to the vacuum cleaner (Fig. 1) and must be observed.

Fig. 1: Safety labels

If safety labels on the machine are damaged or missing,

this can cause errors, personal injury and material dam-

age. The safety symbols attached to the machine must

not be removed. Damaged safety symbols must be re-

placed immediately.

As soon as the signs are not clearly visible and compre-

hensible at first glance, the machine must be stopped

until new signs have been attached.

D NGER!

Check the power cord regularly for damage, cracks or

aging (hairline cracks). If necessary, replace the

cable before use.

D NGER!

Always unplug the appliance before performing any

work, especially when the appliance is unattended or

in the presence of children.

D NGER!

Never point the suction opening at sensitive body

parts - of humans as well as animals - such as eyes,

ears, mouth ect.

D NGER!

Store the device on a firm, level surface and only in a

closed room without humidity.

D NGER!

Only use the accessories supplied with the device or

accessories that are precisely specified in the

instructions. The use of other brushes may compro-

mise safety.

D NGER!

Never leave the running dry vacuum cleaner unatten-

ded. Always disconnect the mains plug from the soc-

ket when the dry vacuum cleaner is not in use and

keep it out of reach of children or unauthorized per-

sons.

D NGER!

In the event of the unit tipping over, it is recommen-

ded to upright again before switching off.

D NGER!

The device is not suitable for environments that are

are protected against electrostatic discharges.

D NGER!

This vacuum cleaner is equipped with built-in thermal

overload protection to protect the motor from high

temperatures. This may occur during heavy use. If

the motor shuts down during operation, turn off the

switch and allow the motor to cool for 15-30 minutes.

Turn on the dry vacuum and resume operation.

Intended use

dryCAT-Series | Version 1.02

3 Intended use

The dry vacuum cleaner is designed exclusively for vacuu-

ming dust and dirt, but not for wet vacuuming. The device is

suitable for use in public buildings such as hotels, schools,

factories, offices and stores.

The unit is suitable for the following applications:

Vacuuming dry, non-flammable dusts, wood chips and ha-

zardous dusts with exposure limits > 1 mg/m³ (dust class L).

The unit must be equipped with a suitable filter that corre-

sponds to the hazard classification of the dusts to be col-

lected.

Intended use also includes compliance with all the informa-

tion in these instructions. Stürmer Maschinen GmbH ac-

cepts no liability for design and technical modifications to

the dry vacuum cleaner. Claims of any kind for damage due

to improper use are excluded.

3.1 Misuse

4 Technical Data

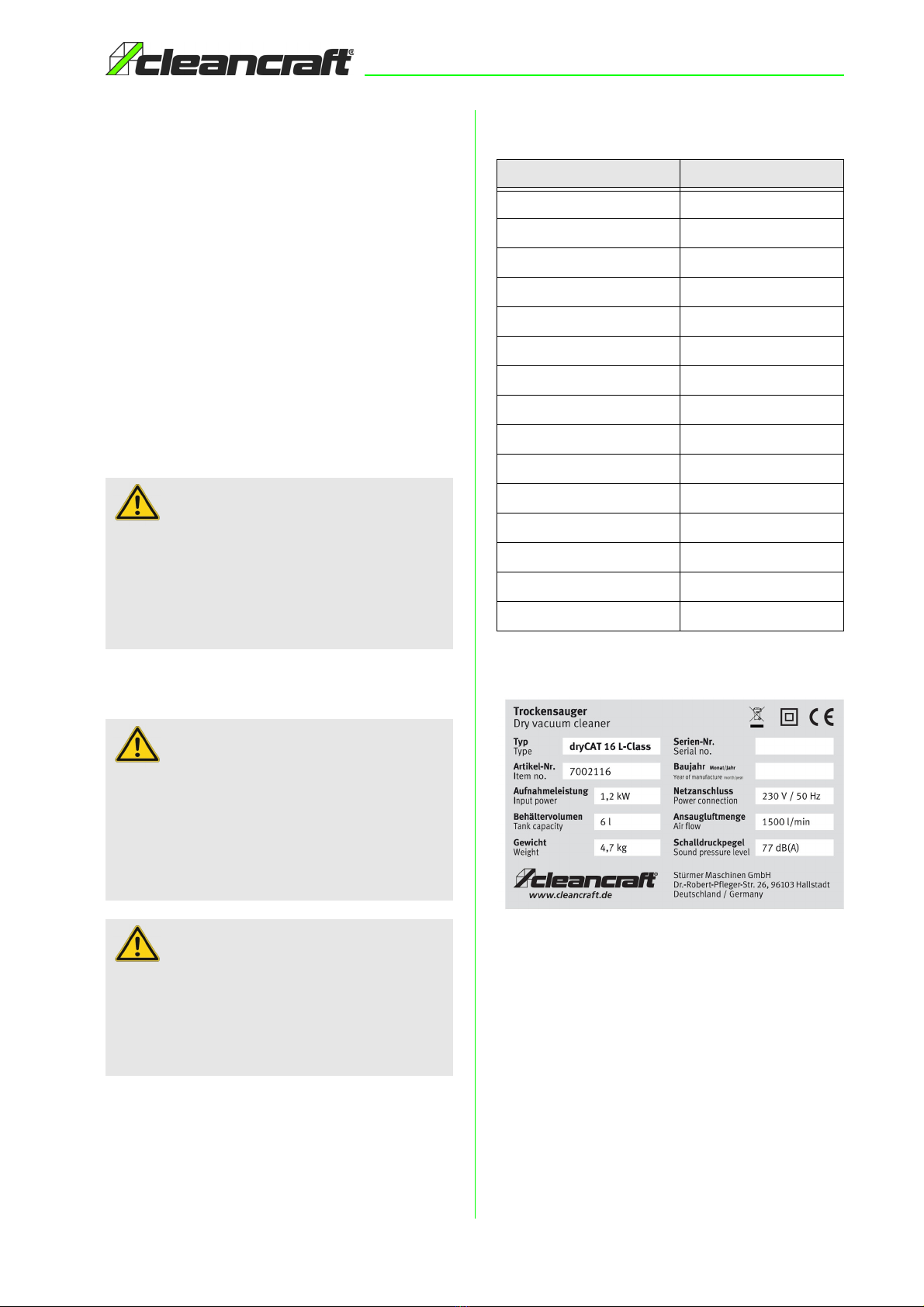

4.1 Type plate

Fig. 2: Type plate

D NGER!

Any modification of the device is prohibited. Modifica-

tion may result in fire and injury, including death, to

the user, in addition to voiding the warranty. The

manufacturer shall not be held liable for any damage

caused to objects or persons as a result of failure to

comply with these instructions or in the event of

misuse of the device.

W RNING!

Danger in case of misuse!

Misuse of the dry vacuum cleaner can lead to dange-

rous situations.

- Only operate the dry vacuum cleaner in the power

range listed in the technical data.

- Never bypass or disable the safety devices.

- Only operate the dry vacuum cleaner when it is in

perfect technical condition.

D NGER!

This dry vacuum cleaner is not suitable for sucking

up substances other than those specified in the

intended use . Never vacuum incandescent, flam-

mable, explosive or toxic substances.

- do not suck up materials that can damage the filter

elements (e.g. glass splinters, etc.).

Model dryC T 16 L - Class

Length 240 mm

Width/depth 200 mm

Height 400 mm

Weight 4, kg

Supply voltage 220- 240 V

Air flow 1500 l/min

Filter surface 3000 cm²

Dust class L-Class

Tank volume 6 Liter

Tank material Plastic

Hose diameter 30,5 mm

Sound pressure level 6,8 dB(A)

Cable length 6 m

Negative pressure 230 mbar

Absorbed power 1,2 kW

8 dryCAT-Series | Version 1.02

Transport, packaging, storage

5 Transport, pac aging, storage

5.1 Transport

Check the Dry Vacuum Cleaner for visible transport da-

mage after delivery. If you discover any damage to the

Dry Vacuum Cleaner, report this immediately to the

transport company or the dealer.

5.2 Pac aging

All packaging materials and packing aids used for the dry

aspirator are recyclable and must always be sent for ma-

terial recycling.

Shred cardboard packaging components and take them

to the waste paper collection.

The foils are made of polyethylene (PE) and the padding

parts of polystyrene (PS). These materials should be ta-

ken to a collection point for recyclable materials or to

your local waste disposal company.

5.3 Storage

Insert all accessories into the device according to Fig.3.

Store the Dry Vacuum Cleaner in a dry, clean and frost-

free environment.

Fig. 3: Storage

6 Description of the device

Illustrations in these operating instructions may dif-

fer from the original.

Fig. 4: Description of the device

1 ON/OFF switch

2 Unit head

3 Nozzle holder

4 Inlet opening

5 Tank

6 Chassis

Mounting clamps

8 Button for filter cleaning

9 Power cord

10 Suction tube

11 Suction tube holder

12 Carrying handle

13 Filter holder

14 Filter

15 Suction tube

16 Air regulation

1 Suction hose

18 Cuff

19 Upholstery nozzle

20 Brush nozzle

21 Dust bag

22 Crevice nozzle

23 Shoulder strap

ssembly

dryCAT-Series | Version 1.02 9

6.1

Scope of delivery

Fig. 4.1: Scope of delivery

The dry vacuum cleaner is supplied with:

- Suction hose with connector and handle

- Fleece filter bag

- Air filter

- Shoulder strap

- Crevice nozzle

- Upholstery nozzle

- Round nozzle

- Universal adapter

6.2

Accessories

7 Assembly

To make the dry vacuum cleaner ready for operation,

please proceed as follows:

Step 1: Remove the packaging of the dry vacuum cleaner

and check that there is no damage to the dry va-

cuum cleaner. Remove the scope of delivery (Fig.5,

Pos.C) from the container by opening the latch

(Fig.5, Pos.A) on the side of the upper part of the

housing (Fig.5, Pos.B).

Fig. 5: Assembly of the suction cup

Step 2: Insert the filter bag into the container.

Fig. 6: Insert filter bag

Step 3: Place the upper part of the housing back on the

container and close it.

Step 4: Insert the hose into the connection (Fig. , Pos.1)

and turn it to lock (Fig. , Pos.2). To remove the

hose again, turn it in the opposite direction and

pull it out.

Fig. : Connect suction hose

Description Item number

Chassis 013150

Hose with connector and

handle

013151

Fleece filter bag 013152

Air filter 013153

Shoulder strap 013154

Joint nozzle 013155

Upholstery nozzle 013156

Round nozzle with brush 01315

Universal adapter 013158

10 dryCAT-Series | Version 1.02

Operation

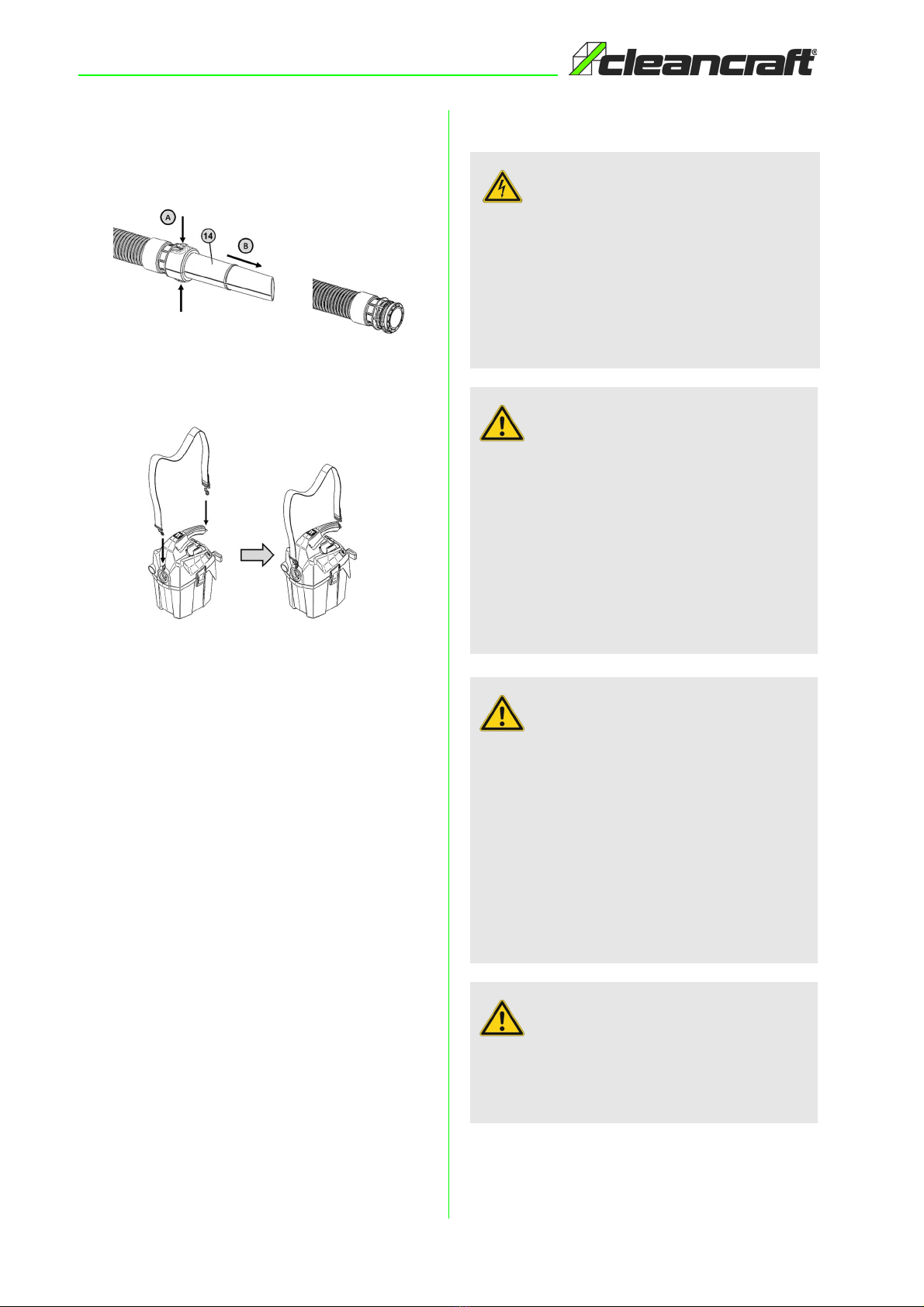

Step 5: Connect the suction tube to the extension or floor

nozzle (Fig.8) or other desired brush. The nozzle

tube (fig.8,pos.14) can be removed for suction by

pressing the button (fig.8,pos.A) and pulling out

the nozzle (fig.8,pos.B).

Fig. 8: Connect nozzle

Step 6: Insert the fasteners (Fig.9) of the carrying strap on

the left and right side of the dry vacuum cleaner.

Fig. 9: Using the shoulder strap

8 Operation

D NGER!

Danger to life from electric shock!

There is a danger to life in case of contact with live

components. Switched-on electrical components can

perform uncontrolled movements and lead to serious

injuries.

- Disconnect the mains plug or remove the battery be-

fore starting any settings on the dry vacuum cle-

aner.

D NGER!

The unit must be correctly mounted before use. It

must also be checked that the filter elements are cor-

rectly mounted and efficient.

The unit should only be operated, mounted, repaired

and transported on solid, level ground.

Make sure that the electrical data indicated on the

motor block correspond to those of the mains to

which the dry vacuum cleaner is to be connected and

that the mains plug of the dry vacuum cleaner

matches the socket outlet.

D NGER!

Always disconnect the power plug from the socket

before handling the switched-off vacuum cleaner.

Always check the supply cable for damage such as

cracks or signs of age. Replace the cord if neces-

sary before further use.

Replacement of a defective power cord must be per-

formed by technical service or qualified personnel.

When using an extension cable, make sure that it

has the same cable dimension as the power supply

cable of the vacuum cleaner and avoid contact of the

cables with liquids or conductive surfaces.

W RNING!

Before commissioning the device, make sure that the

voltage specified on the type plate corresponds to

the mains voltage.

Operation

dryCAT-Series | Version 1.02 11

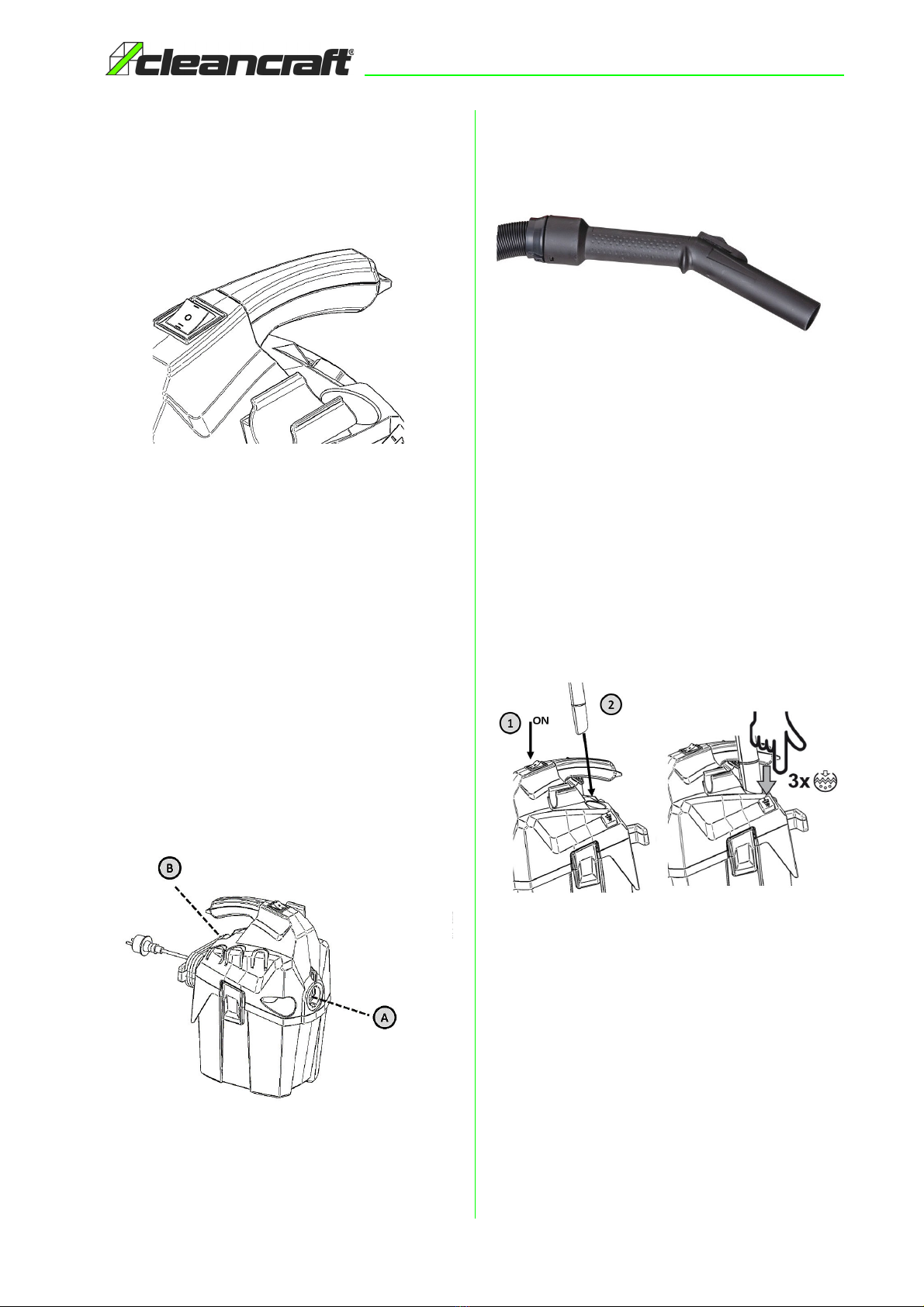

8.1 Start and Stop

Start

- Unwind the cable and insert the plug into a mains

socket.

- Press the on/off button.

Fig. 10: On - Off Switch

Stop

- Switch off the device and disconnect the plug.

- When pulling out the plug, always touch the plug,

not the cable.

8.2 Operating instructions

8.2.1 Suction and blowing function

The dry vacuum cleaner has 2 connections to which the

suction hose can be connected.

Suction function:

Insert the hose into the suction

connection (Fig.11, Pos A).

Blower function:

Insert the hose into the suction

connection (Fig.11, Pos.B).

Fig. 11: Suction and blowing function

8.2.2 Air regulation

The air flow can be adjusted or regulated at the end of

the hose by turning the air flow regulator.

Fig. 12: Air regulation

8.2.3 Filter cleaning system

The dry vacuum cleaner is equipped with a semi-auto-

matic filter cleaning system that can clean the filter from

dust and restore the suction power.

Step 1: Switch on the device.

Step 2: Insert the suction hose into the opening (Fig.13, Pos.

B).

Step 3: Press the filter cleaning button 3 times to clean the fil-

ter.

Fig. 13: Filter cleaning system

8.3 Seal inspection

Over time it is possible that the seals partially lose their

function. We recommend checking the locking hooks,

the flexible suction hoses and the seals for proper func-

tion at regular intervals.

Also check that the edges of the container are not dama-

ged.

B

12 dryCAT-Series | Version 1.02

Care, maintenance and repair

9 Care, maintenance and repair

9.1 Care by cleaning

The dry vacuum cleaner must always be kept in a clean

condition.

The motor ventilation slots must be kept clean to ensure

adequate cooling.

9.2 Maintenance and repair

Daily maintenance and control

- Make sure that the vacuum cleaner's power cord is

not damaged.

- Check that the filter unit is not damaged.

- Check the level of the container tank.

- Check that the suction hose and other accessories

are not damaged.

- Check the seal when you close the hooks on the

cover.

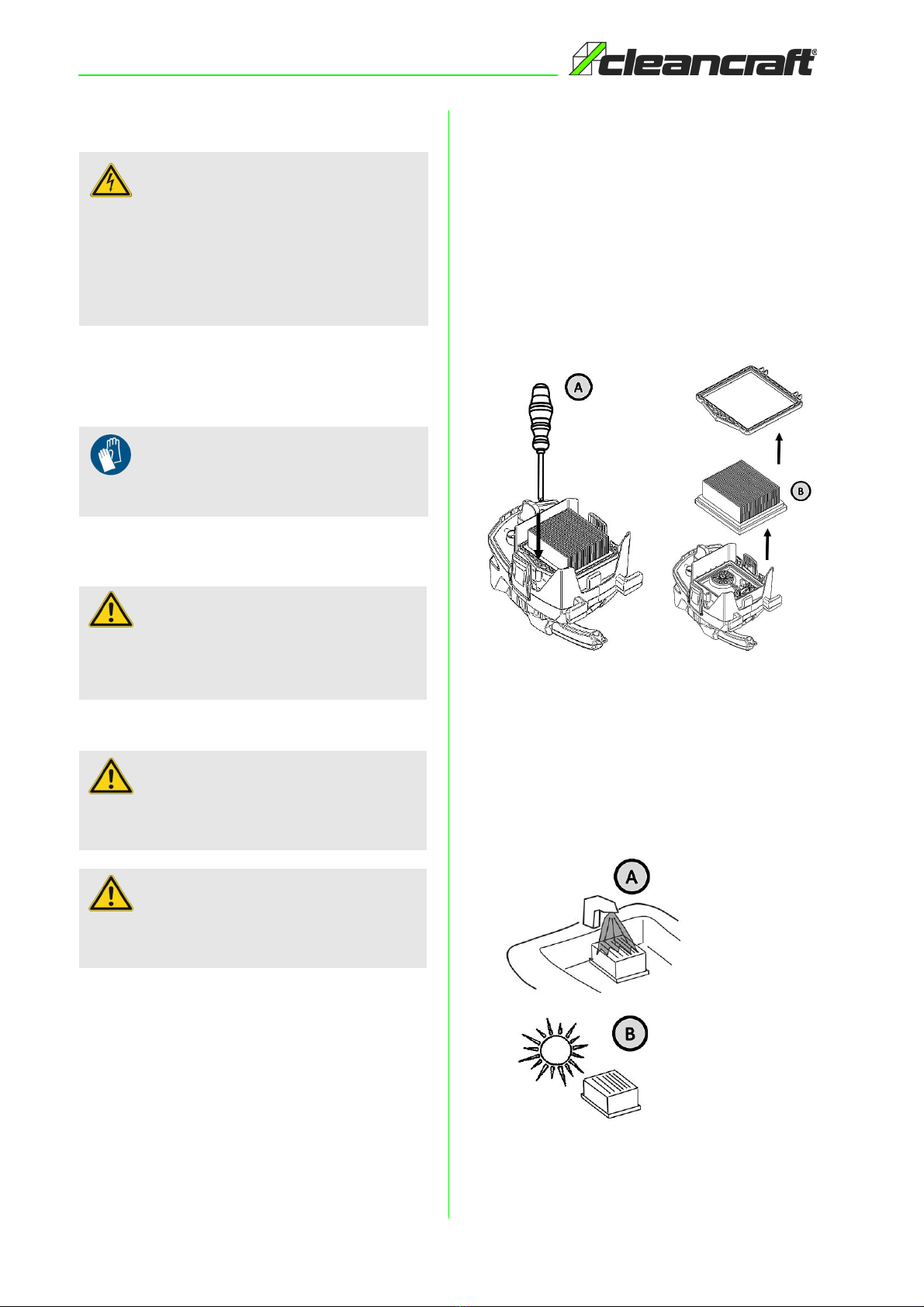

9.3 Replacing the filter

The filter will wear out over time and need to be replaced

with a new one, or it may become severely clogged/dirty

and need to be cleaned manually as the semi-automatic

filter cleaning is not sufficient to clean the filter.

Step 1: Switch off the device and disconnect the power plug.

Step 2: Open the locking hook and remove the upper part of

the housing.

Step 3: Loosen screw A (Fig.14) and remove filter B (Fig.14).

Fig. 14: Remove filter

Step 4: Assemble the new or cleaned filter in reverse order.

Be careful not to overtighten the screws.

9.3.1 Cleaning the filter

Once the filter is very dirty, clean it under cold water and

let it dry completely before reinserting it.

Fig. 15: Clean the filter

D NGER!

Danger of potentially fatal electric

shock!

There is a risk of fatal injury from contact with live

parts. Electrical components which are switched on

can carry out uncontrolled movements and cause

serious injuries.

- Disconnect the mains plug before starting cleaning

and maintenance work.

Protective gloves

For cleaning, wear suitable protective gloves to pro-

tect against injury.

D NGER!

The user must perform a technical check at least

once a year. This includes checking the filters for

insufficient airtightness and for the correct functioning

of the operating mechanism.

D NGER!

Maintenance and repairs must always be carried out

by qualified personnel; any damaged parts must only

be replaced with original spare parts.

D NGER!

During maintenance by the user, the device must be

disassembled, cleaned and checked without endan-

gering maintenance personnel or other people.

Disposal, recycling of used devices

dryCAT-Series | Version 1.02 13

10 Disposal, recycling of used devices

Please take care in your own interest and in the interest

of the environment that all component parts of the ma-

chine are only disposed of in the intended and permitted

way.

10.1 Decommission

Disused equipment must be taken out of service immedi-

ately in order to avoid later misuse and endangering the

environment or people.

- Remove all environmentally hazardous fluids from

the old unit.

- If necessary, dismantle the machine into manage-

able and usable assemblies and components.

- Guide the machine components and operating ma-

terials to the appropriate disposal routes.

10.2

Disposal of electrical equipment

Please note that electrical appliances contain a variety of

recyclable materials as well as environmentally harmful

components.

Make sure that these components are disposed of sepa-

rately and properly. In case of doubt, please contact your

municipal waste disposal.

If necessary, the help of a specialized waste disposal

company can be used for the treatment.

10.3 Disposal of lubricants

Please ensure that the coolants and lubricants used are

disposed of in an environmentally friendly manner. Ob-

serve the disposal instructions of your municipal waste

disposal companies. The disposal instructions for the lu-

bricants used are provided by the lubricant manufactu-

rer. If necessary, ask for the product-specific data

sheets.

10.4 Disposal via municipal collection

points

Disposal of used electrical and electronic equipment (to

be used in the countries of the European Union and

other European countries with a separate collection sy-

stem for this equipment).

The symbol on the product or its packaging in-

dicates that this product is not to be treated as

normal household waste and must be retur-

ned to a collection point for the recycling of

electrical and electronic equipment. By contri-

buting to the proper disposal of this product, you protect

the environment and the health of your fellow human

beings. Environment and health are endangered by in-

correct disposal. Material recycling helps to reduce the

consumption of raw materials. For more information

about recycling this product, contact your local commu-

nity, municipal waste management company or the store

where you purchased the product

.

14 dryCAT-Series | Version 1.02

Troubleshooting

11 Troubleshooting

D NGER!

If any of the following faults occur, immediately stop

working with the dry vacuum cleaner. Before you

start troubleshooting, switch off the dry vacuum cle-

aner and disconnect the power plug. Serious injury

could otherwise result. All repairs or replacement

work may only be carried out by qualified and trai-

ned personnel.

NOTE!

If you are unable to correct the problem with your va-

cuum yourself, please contact your nearest Clean-

craft dealer. Please write down the following informa-

tion from the vacuum or from the operating

instructions beforehand so that they can help you with

your problem in the best possible way.

- Model designation of the device

- Serial number of the device

- Year of manufacture

- Exact error description

Fault Possible cause Remedy

Device does not work 1. Mains plug is not plugged in.

2. Supply cables defective.

3. Switch defective

4. Motor defective.

5. Circuit breaker tripped

1. Plug in the power plug.

2. Call the service engineer.

3. Call service engineer.

4. Call service technician.

5. Check circuit breaker and allow unit to cool

down.

Suction power decrea-

ses

Blockages in the suction nozzle, suc-

tion pipe, suction hose or filter.

1. Remove blockages.

2. Clean or change the filter.

3. Engage the filter cover correctly.

4. Check the correct installation position of the fil-

ter.

Strong noise level while

the vacuum cleaner is in

operation

Filter or motor heavily contamina-

ted or clogged

Clean or replace filter. If the noise level remains

high, call a service technician.

Dry vacuum cleaner

switches off automati-

cally during operation

Thermal protection has tripped due

to a clogged filter or other overload.

1. Switch off the device and clean the filter or elimi-

nate the cause of the overload. Wait 15 to 30 mi-

nutes before operating the dry vacuum cleaner

into operation.

2. Check the power supply. The unit may not be

working due to a power surge.

Spare parts drawing

dryCAT-Series | Version 1.02 15

12 Spare parts drawing

12.1 Ordering spare parts

The spare parts can be obtained from the authorized de-

aler or directly from the manufacturer. The contact details

can be found in chapter 1.2 Customer service.

Specify the following key data when ordering spare parts:

- Device type

- Serial number

- Quantity

- Designation

- Desired shipping method (mail, freight, sea, air,

express)

- Shipping address

Spare parts orders without the above information cannot

be considered. In the absence of information on the ship-

ping method, shipping will be at the discretion of the sup-

plier.

Information on the device type, article number and year

of manufacture can be found on the type plate, which is

attached to the device.

Example

The engine for the Dry vacuum cleaner dryCAT 16 L -

Class must be ordered. The engine has the number 10 in

the spare parts drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (engine) and marked

positon number (10) to the dealer or spare parts depart-

ment and provide the following information:

- Type of device:

dryC T 16 L - Class

- Item number:

7002116

- Drawing number:

1

- Position number:

10

D NGER!

Risk of injury due to the use of

incorrect spare parts!

The use of incorrect or faulty spare parts can result in

danger to the operator and cause damage and mal-

functions.

- Only original spare parts from the manufacturer or

spare parts approved by the manufacturer are to be

used.

- In case of any uncertainties, always contact the ma-

nufacturer.

Garantieverlust

Bei Verwendung nicht zugelassener Ersatzteile

erlischt die Herstellergarantie.

16 dryCAT-Series | Version 1.02

Electrical circuit diagram

12.2 Spare parts drawing

The following drawing should help to identify necessary spare parts in case of service. To order, send a copy of the parts

drawing with the marked components to your authorized dealer.

Fig. 16: Spare parts drawing 1

13 Electrical circuit diagram

Fig. 1 : Electrical circuit diagram

EC-Declaration of Conformity

dryCAT-Series | Version 1.02 1

14 EC-Declaration of Conformity

Manufacturer/Carrier: Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

hereby declares that the following product

Product group : Cleancraft® Cleaning technology

Type of machine: Dry Vacuum Cleaner

Designation of the device: dryCAT 16 L - Class

Item number: 002116

Serial number *: ____________________

Year of manufacture *: 20_________

* fill in these fields according to the information on the type plate

due to its design and construction, as well as in the version placed on the market by us, complies with the relevant,

complies with the relevant essential health and safety requirements of the Low Voltage Directive 2014/35/EU.

pplicable EU directives: 2011/65/EU RoHS-Directive

2012/19/EU WEEE-Directive

2014/30/EU EMV-Directive

pplicable EU regulations: 190 /2006/EU REACH-Regulation

The following harmonized standards have been applied:

DIN EN 60335-1:2020-08 Household and similar electrical appliances - Safety - Part 1: General

requirements

DIN EN 60335-2-69:2015-0 Household and similar electrical appliances - Safety - Part 2-69: Particular

requirements for wet and dry vacuum cleaners, including power brush

for commercial use

DIN EN 62233:2008-11 Measurement methods for electromagnetic fields of household appliances

and similar apparatus with regard to human exposure

DIN EN 55014-1:2018-08 Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 1: Emission

DIN EN 55014-2:2016-01 Electromagnetic compatibility - Requirements for household appliances,

electric tools and similar apparatus - Part 2: Immunity - Product family

standard

DIN EN 61000-3-2:2015-03 Electromagnetic compatibility (EMC) - Part 3-2: Limits - Limits for harmonic

current emissions (equipment input current ≤ 16 A per phase)

DIN EN 61000-3-3:2014-03 Electromagnetic compatibility (EMC) - Part 3-3: Limits - Limitation of voltage

changes, voltage fluctuations and flicker in public low-voltage supply

systems, for equipment with rated current ≤ 16 A per phase and not

subject to conditional connection

Responsible for documentation: Kilian Stürmer, Stürmer Maschinen GmbH,

Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 09.12.2020

______________________

Kilian Stürmer

Managing Director

www.cleancraft.de

This manual suits for next models

1

Table of contents

Other CleanCraft Vacuum Cleaner manuals

CleanCraft

CleanCraft flexCAT 120 VCA User manual

CleanCraft

CleanCraft flexCAT 116 PD User manual

CleanCraft

CleanCraft dryCAT Series User manual

CleanCraft

CleanCraft flexCAT 120 VCA User manual

CleanCraft

CleanCraft flexCAT 290 EPT User manual

CleanCraft

CleanCraft VCA Series User manual

CleanCraft

CleanCraft flexCAT 262 IEPD User manual

CleanCraft

CleanCraft flexCAT 16 H User manual

CleanCraft

CleanCraft dryCAT 133 IC-HC Manual

CleanCraft

CleanCraft flexCAT Series User manual