CleanCraft flexCAT Series User manual

FLEXCAT-SERIES

Special Vacuum Cleaner

flexCAT 112 Q

Operating Instructions

flexCAT 116 Q

flexCAT 112 Q

flexCAT 116 Q

2flexCAT-Series | Version 1.04

Imprint

Product identification

Special Vacuum Cleaner Item number

flexCAT 112 Q 7003135

flexCAT 116 Q 7003140

Manufacturer

Stuermer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.cleancraft.de

Indications regarding the operating instructions

Original instructions

Edition: 09.01.2020

Version: 1.04

Language: English

Author: ES

Indications regarding the copyright

Copyright © 2020 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company Stürmer.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Content

1 Introduction .............................................................3

1.1 Copyright............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability ............................................ 3

2 Safety........................................................................3

2.1 Symbol explanation ............................................ 3

2.2 Obligations of the operating company............... 4

2.3 Requirements to staff.......................................... 5

2.4 Personal protective equipment........................... 5

2.5 General safety regulations.................................. 5

2.6 Safety labels on the vacuum cleaner ................. 6

3 Intended use ............................................................6

3.1 Unintended use .................................................. 7

3.2 Residual risks ..................................................... 7

4 Technical Data.........................................................7

4.1 Type plate........................................................... 8

5 Transport, packaging, storage...............................8

5.1 Transport ............................................................ 8

5.2 Packaging........................................................... 8

5.3 Storage ............................................................... 8

6 Description of the device........................................8

6.1 Assembly.......................................................... 10

7 Scope of delivery...................................................12

8 Operation ...............................................................13

8.1 Start and stopping............................................ 14

8.2 Controlling of the seal....................................... 14

9 Care, maintenance and repair..............................14

9.1 Care by cleaning .............................................. 14

9.2 Maintenance and repair ................................... 14

10 Disposal, recycling of used devices..................15

10.1 Decommissioning.......................................... 15

10.2 Waste disposal of electric equipment ............ 15

10.3 Disposal of lubricants..................................... 15

10.4 Disposal of the filter........................................ 15

11 Malfunctions ........................................................15

12 Spare parts...........................................................16

12.1 Ordering spare parts ...................................... 16

12.2 Spare parts drawings ..................................... 17

13 EU-Declaration of Conformity ............................21

Introduction

flexCAT-Series | Version 1.04 3

1Introduction

You have made a good choice by purchasing the

CLEANCRAFT vacuum cleaner

Read the operating manual thoroughly before commissioning

the machine.

It gives you information about the proper commission-

ing, intended use and safe and efficient operation and

maintenance of your vacuum cleaner.

The operating manual is part of the vacuum cleaner

package. Always keep this operating manual in the lo-

cation where your vacuum cleaner is being operated. All

local accident prevention regulations and general safety

instructions for the operating range of your vacuum

cleaner must also be complied with.

1.1 Copyright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the

vacuum cleaner. Any application beyond those de-

scribed is not permitted without the written approval of

Stürmer GmbH.

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your vacuum cleaner or if you need technical

advice. They will help you with specialist information

and expert advice.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

Email: service@stuermer-maschinen.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

Email: ersatzteile@stuermer-maschinen.de

We are always interested in valuable experience and

knowledge gained from using the application-which

then could be shared and be valuable to develop our

products even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards

and rules, the state-of-the-art technology and our long-

term knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- unauthorised modifications

- technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the ex-

planations and presentations described here in case of

special models, when using additional ordering options

or due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-

tions of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all important safety

packages for the protection of operating personnel as

well as for safe and fault-free operation. Other task-

based safety notes are included in the paragraphs of

the individual phases of life.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are

highlighted by symbols. The safety notes are introduced

by signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

WARNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

4flexCAT-Series | Version 1.04

Safety

Tips and recommendations

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and damages to property.

2.2 Obligations of the operating company

of the operator

The operating company is the person who operates the

vacuum cleaner for business or commercial reasons by

herself, or leaves it to a third party for use or application,

and who bears the legal product responsibility for the

protection of the user, the staff or for third parties.

Obligations of the operating company

If the vacuum cleaner is used for commercial purposes,

the operating company of the vacuum cleaner must

comply with the legal working safety regulations. There-

fore, the safety notes in this operating manual, as well as

the safety, accident prevention and environment protec-

tion regulations applying for the area of application of

the vacuum cleaner must be met. The following applies

in particular:

- The operating company must be informed about

the applying industrial safety regulations and fur-

ther analyse hazards resulting from the special

working conditions at the place of use of the vac-

uum cleaner. She must implement these in form of

operating manuals for the operation of the vacuum

cleaner.

- During the entire lifetime the vacuum cleaner, the

operating company must verify whether the oper-

ating manuals prepared by her correspond to the

current status of the regulations, and must adapt

these if necessary.

- The operating company must unambiguously reg-

ulate and determine the responsibilities for instal-

lation, operation, troubleshooting, maintenance

and cleaning.

- The operating company must ensure that all per-

sons who work with the vacuum cleaner, have

read and understood this manual. Furthermore

she must instruct the staff in regular intervals and

inform them about the hazards.

- The operator must provide the necessary protec-

tive equipment to the staff and order the use of the

necessary protective equipment in a binding way.

Furthermore the operating company is responsible to

keep the vacuum cleaner always in a technically flaw-

less state. Thus, the following applies:

- The operator must ensure that the maintenance in-

tervals described in this manual are kept.

- The operator must have all safety devices

checked regularly for their good working order

and their integrity.

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

ATTENTION!

This combination of symbol and signal words indi-

cates a possibly dangerous situation which may

lead to property and environmental damages if they

are not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not

avoided.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

Safety

flexCAT-Series | Version 1.04 5

2.3 Requirements to staff

Qualifications

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-

formed beyond the operation in the standard mode

must only be performed by the operator if it is indicated

in these instructions and if the operating company ex-

pressively commissioned the operator.

Electrically qualified person

Electrically qualified person is due to their professional

training, knowledge and experience as well as knowl-

edge of the relevant standards and regulations, in a po-

sition to carry out work on the electrical systems and to

independently recognize and avoid possible dangers.

Qualified personnel

Due to their professional training, knowledge and expe-

rience as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect

persons against impairments of safety and health while

working. The staff member has to wear personal protec-

tive equipment while performing different tasks on and

with the machine which are indicated in the individual

paragraphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 General safety regulations

Please note the following:

Use the safety devices and fasten them securely. Never

work without safety equipment and keep it in good

working order.

- Keep the machine and your work environment

clean at all times. Ensure sufficient illumination.

- The vacuum cleaner 's design must not be

changed; the machine must not be used for work

not intended by the manufacturer.

- Never work under the influence of illnesses that im-

pair concentration, drugs, alcohol or medication.

- Do not use the mains cable to pull the plug out of

the socket. Protect the cable against heat, oil and

sharp edges.

- Malfunctions impair the safety, please this rectify

immediately.

- Protect the vacuum cleaner against humidity (risk

of short circuit!).

- Before using the vacuum cleaner make sure that

no parts are damaged. Replace damaged parts

immediately to avoid sources of danger!

-

Never overload the vacuum cleaner! Working within

the stated performance limits is better and safer.

- Use only genuine spare parts and accessories to

avoid potential risks and risk of accident.

WARNING!

Danger in case of insufficient qualification

of the staff!

Insufficiently qualified persons cannot estimate the

risks while using the vacuum cleaner and expose

themselves and others to the danger of severe or

lethal injuries.

- Have all works only performed by qualified per-

sons.

- Keep insufficiently qualified persons out of the

working area.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fall-

ing parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

6flexCAT-Series | Version 1.04

Intended use

- The vacuum cleaner must not be used for the suc-

tion of water, oil or other liquids.

- Do not use the device at an altitude of 2000 m

above sea level.

- Never use the vacuum cleaner without a filter or

dirt container.

- Do not operate the vacuum cleaner with the wet

hands.

- This device is not suitable for picking up dust in

an environment where electrostatic discharges or

sparks occur. This can the cause of the damage to

the electrical components and people.

2.6 Safety labels on the vacuum cleaner

The following safety labels and instructions are attached

to the vacuum cleaner (Fig. 1) and must be observed.

Fig. 1: 1-2 Mandatory sign | 3 Warning symbol: Warning of electrical

voltage

If safety labels on the machine are damaged or missing,

this can cause errors, personal injury and material dam-

age. The safety symbols attached to the machine must

not be removed. Damaged safety symbols must be re-

placed immediately.

As soon as the signs are not clearly visible and compre-

hensible at first glance, the machine must be stopped

until new signs have been attached.

3 Intended use

The vacuum cleaner is exclusively intended for the suc-

tion of the dust and light dirt, but not for wet suction. The

vacuum cleaner must not be operated in the potentially

explosive environments.

The proper use also includes observing all indications in

these operating instructions. Any use beyond the proper

WARNING!

Do not vacuum with the vacuum cleaner hot objects

such as ashes or cigarettes!

There is a risk of fire!

WARNING!

Don't ever point the suction towards delicate parts of

the body – of people or animals - such as eyes, ears,

mouth, etc.

WARNING!

This device is not suitable for picking up health

endangering dust, unless special authorised

precautions are complied with

WARNING!

The vacuum cleaner shall not be used outdoors in

wet conditions.

WARNING!

If the device is equipped with the additional plug,

the power stated on the plug must not be excee-

ded. Failure to comply with this requirement may

result to a fire, the personal injury or even death to

the user.n.

Only use the parts supplied with the device or than,

that are specified in the instructions. The use of

other parts can impair the safety.

WARNING!

Never leave the running device unattended. Always

disconnect the power plug from the power socket

when not in use. Keep the device out of the reach of

children or unauthorized persons.

ATTENTION!

When the device fall over,it is then recommended

set the device up again before switching it off.

WARNING!

The power indicated on the additional plug must not

be exceeded. Make sure that the operating voltage

of the electrical device is the same as the supply

voltage of the vacuum cleaner

The connection for the additional accessories may

only be used for the extraction of dust.

Failure to comply with this requirement may result to

a fire, the personal injury or even death to the user.

WARNING!

The device is not suitable for environments that are

protected against electrostatic discharges

123

Technical Data

flexCAT-Series | Version 1.04 7

use or any other use is regarded as misuse. Under no

circumstances may personnel be lifted.

Stürmer Maschinen GmbH accepts no liability for any

constructional or technical modifications carried out on

the electric vacuum cleaner.

Any claims due to damages because of not intended

use are excluded.

3.1 Unintended use

3.2 Residual risks

Even if all safety instructions are observed, and the ma-

chine is put to its intended use, there are still residual

risks, which are listed below:

Risk of injury of upper and lower limbs while equipment

is operating.

4 Technical Data

Hand-arm vibrations on the suction hose are less than

2,5 m/s² as recommended by ISO 5349-1

WARNING!

Any change on the vacuum cleaner is prohibited.

The change may void the warranty, cause burns and

personal injury, even fatal for the user.

The manufacturer will not be liable for any damage

that the results from failure to follow these instructi-

ons or from the misuse of the equipment to objects

or persons.

WARNING!

Dangers in case of unintended use!

Unintended use of the vacuum cleaner can cause

hazardous situations.

- Only operate the vacuum cleaner within the perfor-

mance limits stated in the technical data.

- Do not bypass or disarm safety equipment.

- Only use the vacuum cleaner in technically perfect

condition.

- Use only for the vacuuming of the dust or dry mate-

rial.

- Never pick up the liquids!

- Only use the vacuum cleaner in the specified tem-

perature range

ATTENTION!

The vacuum cleaner is not suitable to absorb dan-

gerous dust. Do not vacuum any soot, flammable,

explosive or poisonous substances and liquids. The

maximum permissible temperature for absorbing

substances is 40 ° C / 104 ° F.

- do not vacuum the aggressive cleaning agents, as

they could damage the device.

- do not vacuum the materials, which can damage or

clog the filter elements (e.g., powder, toner,

gypsum, and other very small particle size sub-

stances).

- do not vacuum the water or other liquids!

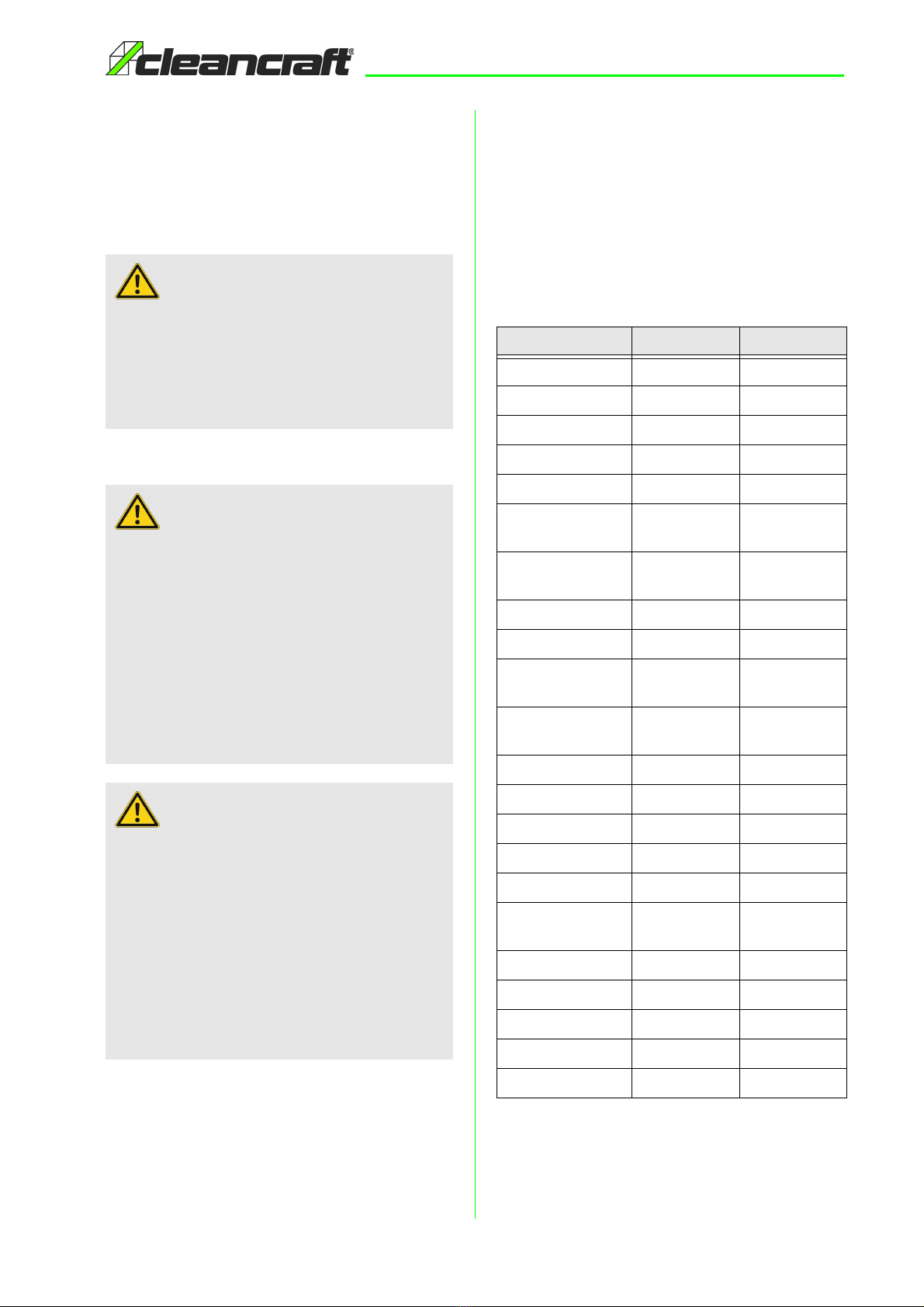

Model flexCAT 112 Q flexCAT 116 Q

Length 400 mm 400 mm

Width/Depth 400 mm 400 mm

Hight 330 mm 330 mm

Weight (Netto) 5,8 kg 5,8 kg

Max. output 840 W 700 W

Max. input rating

main motor

900 W 870 W

Electrical connec-

tion

230 V 230 V

Phase 1 1

Mains frequency 50 Hz 50 Hz

Energy efficiency

category

BA

Vacuum cleaner

type

dry dry

Airflow 2633 l/min 3050 l/min

Tank volume 12 l 16 l

Tank material Plastic Plastic

Hose diameter 36 mm 36 mm

Hose length 2 m 2 m

Sound pressure

level [dB(A)]

63 62

Cable length [m] 8,5 10

Filter surface 850 cm² 850 cm²

Number of motors 1 1

Output stages 1 1

Motor cooling Bypass Bypass

8flexCAT-Series | Version 1.04

Transport, packaging, storage

4.1 Type plate

Fig. 2: Type plate flexCAT 112 Q

5 Transport, packaging, storage

5.1 Transport

Check the vacuum cleaner on delivery for any visible

transportation damage. If you notice any damage to the

device please report this immediately to the carrier or

dealer.

5.2 Packaging

All used packaging materials and packaging aids are

recyclable and should be taken to a materials recycling

depot to be disposed of.

The delivery packaging is made of cardboard, so

please dispose carefully by having it chopped up and

given to the recycling collection

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). Deliver these substances to a

collection point for recyclable materials or to the waste

disposal company which looks after your region.

5.3 Storage

The vacuum cleaner should be stored in a dry, frost-free

environment.

6 Description of the device

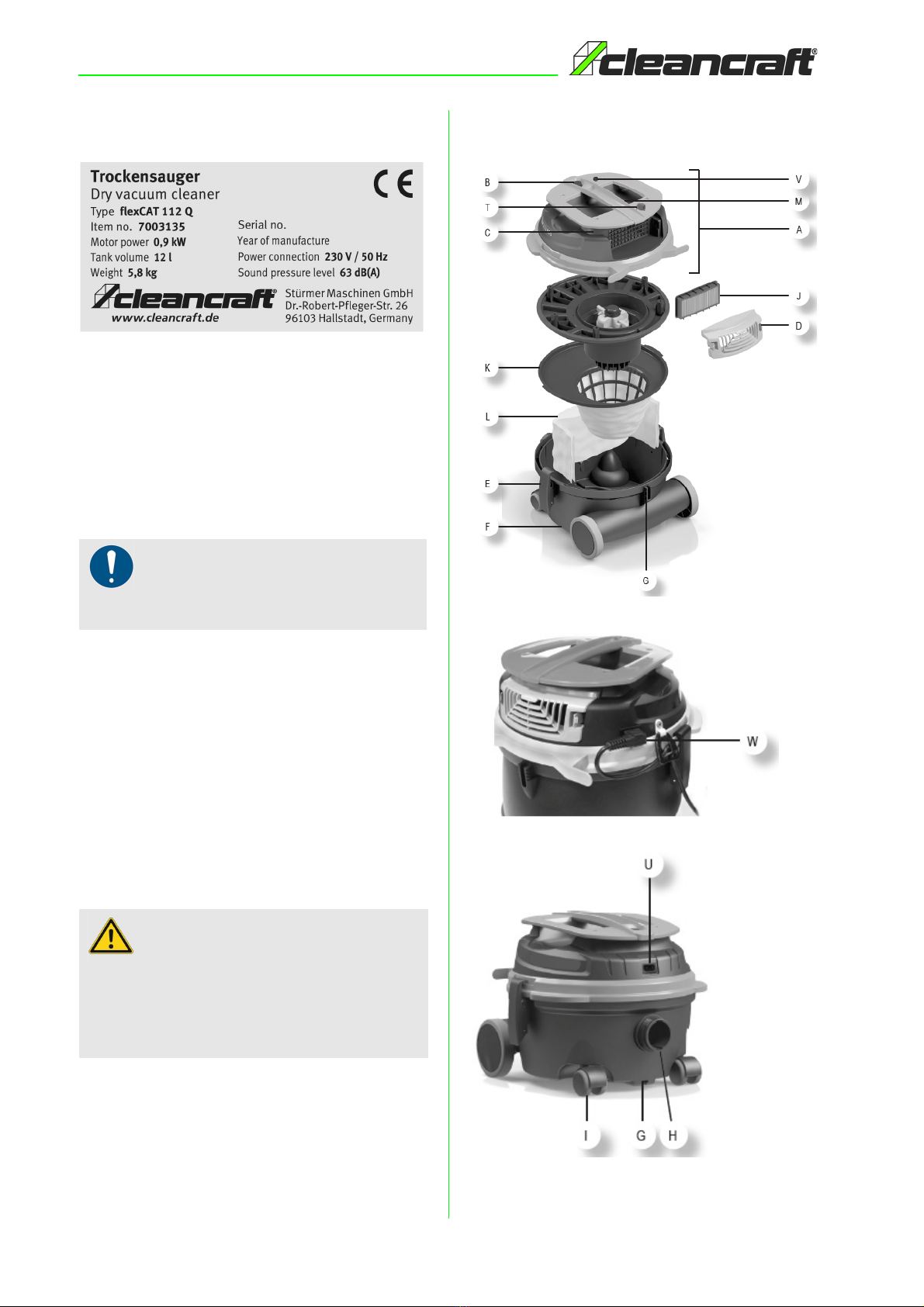

Fig. 3: Description of the device

NOTE!

The vacuum cleaner should be protected from hu-

midity.

WARNING!

Danger to life!

The packaging elements may pose potential hazards

(e.g., plastic bags):

- Packaging material for children and persons

who are unaware of their actions or keep ani-

mals inaccessible.

Description of the device

flexCAT-Series | Version 1.04 9

Fig. 3: Description of the device

A - Motor head

B - Switch

C - Cable holder

D - Exhaust air grid

E - Hooks

F - Tank

G - “T” slot

H - Inlet

I - Castor wheels

J - Exhaust air filter

K - Main filter to insert into the tank (filtering cartridge as

alternative)

L - Filter bag to apply on top of deflector.

This filter does not exclude the use of polyester filter,

that still has to be used.

M - Handle with incorrect air regulation

N - Flexible hose

O - Hose

P - Double use brush

Q - Crevice nozzle

R - Upholstery nozzle

S - Round brush

T - Speed regulator (optional)

U - Electric floor brush additional socket (optional)

V - Warning light

W - Detachable power cord

Z - Tool holder (optional)

Warning light

The vacuum cleaner flexCAT 116 Q is equipped with

the warning light (Fig. 4).

When the warning light activates means that the filtering

bag (Pos. L, Fig. 3) is full.

Fig. 4: Warning light

While vacuuming soft surfaces like carpets, couches

etc. the warning led can light even if the filter bag is not

full. If you move the tool away from the surface and the

light turns off, you can keep working.

Speed regulator

The vacuum cleaner flexCAT 116 Q is equipped with

speed regulator. The vacuum suction power can in-

crease or lower with the speed regulatorr (Fig. 5).

Fig. 5: Speed regulator

NOTE!

When the warning light activates, change the filter

bag (Pos. L, Fig. 3) and clean the main filter (Pos. K,

Fig. 3)

ATTENTION!

Stop using your vacuum cleaner if the warning light

is on. Overheating can take place, causing perma-

nent damages to the engine.

10 flexCAT-Series | Version 1.04

Description of the device

Detachable cable

The vacuum cleaner flexCAT 116 Q is equipped with a

detachable cable. With the help of this function can de-

tach the power cord (Fig. 6).

Fig. 6: Detachable cable

6.1 Assembly

Assembly of the filter bag

To make the dry vacuum cleaner ready, please proceed

as follows (Fig. 7):

Step 1: Insert filter bag L (Fig. 3) on top of the deflector

(Fig. 7 left).

Step 2: Check that the appliance is equipped with main

filter K (Fig. 3) and exhaust air filter J (Fig. 3) and

that they are correctly assembled.

Step 3: Insert the hose connector into the inlet H

(Fig. 3 and fig.7 middle).

Step 4: Insert the other side of the flexible hose into the

wand M (Fig.7 right) and twist it to tighten the

connection.

Fig. 7: Assembly of the filter bag

Step 5: Attach the wand to the hoses O (Fig. 3) and the

double use brush P (Fig. 3) or the desired tool.

Step 6: Turn the vacuum cleaner on through the switch

B (Fig. 3).

Assembly of the main filter

Step 1: Loosen the side hooks and remove the upper part

of the container.

Step2: Place the mail filter in the lower container part

(Fig. 8 left).

Step 3: Adjustment the main filter correctly (Fig. 8 right).

Fig. 8: Assembly of the main filter

Step 4: Reinstall the upper part of the container

Make sure that the main filter is properly seated on the

support grid (Fig. 9).

Fig. 9: Assembly of the main filter

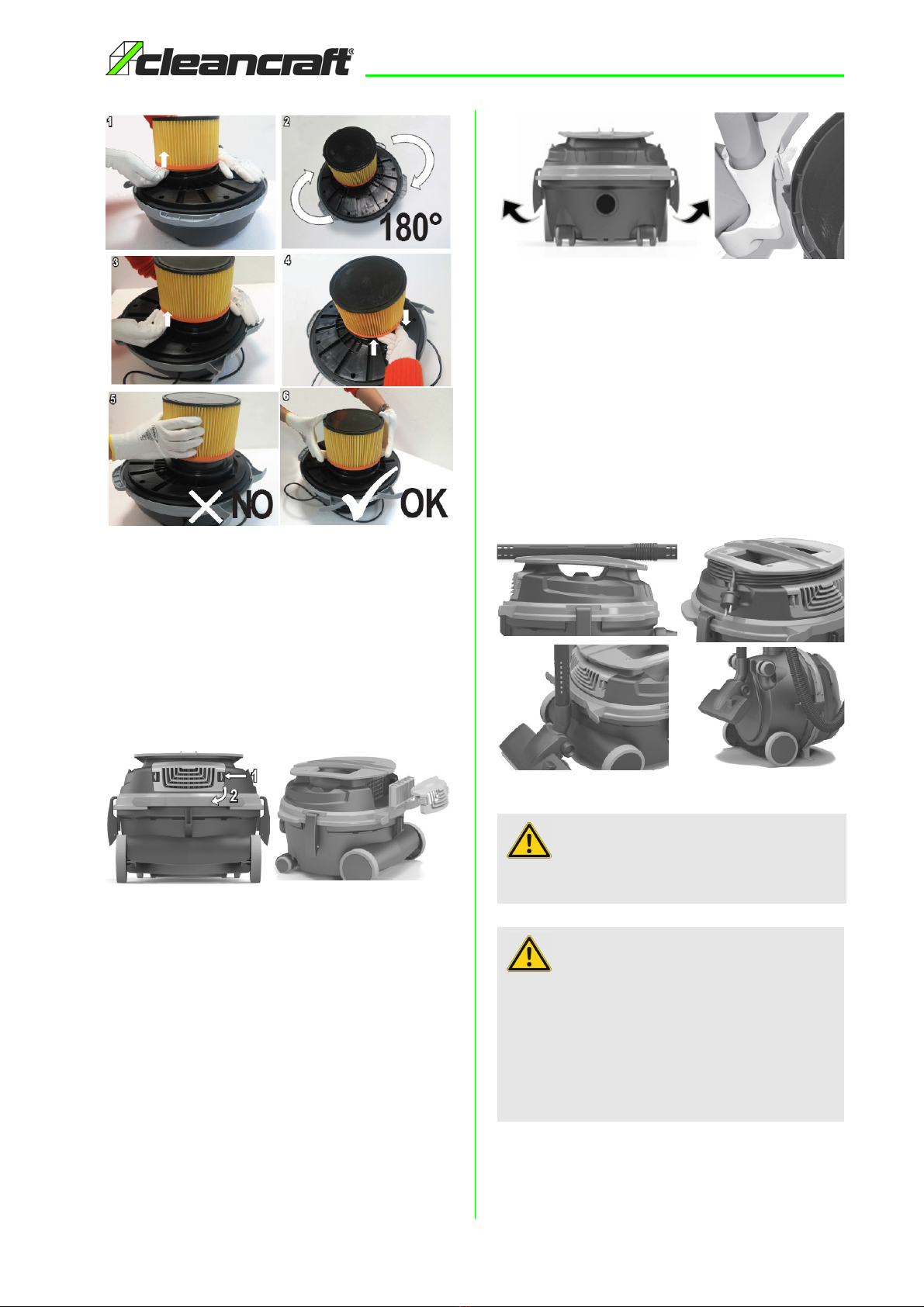

Replacing filtering cartridge

Step1: Loosen the side hooks. Remove the upper part of

the container and put as shown in the Figure 10.

Lift the filter a bit wide on a side (Fig. 10).

Step 2: Turn the complete upper part with the filter th-

rough180° (

Fig

. 10).

Step 3:

Lift the filter a bit on the other side (Fig.10).

Step 4: Check that the filter

is a finger's breadth from the

support surface (

Fig

. 10).

Step 5: If the filter is lifted around a finger's width, you

can pull it off as shown in the Figure 10, pos. 6.

NO

Description of the device

flexCAT-Series | Version 1.04 11

Fig. 10: Replacing filtering cartridge

Replacement of exhaust air filtering cartridge

Step 1: Loosen the clamping of the filter cartridge holder

by pressing the two levers for the spring locks 1

(Fig. 11).

Step 2: With the levers pressed, pull out the filter car-

tridge holder to the rear (Fig.11 right).

Fig. 11: Replacement of exhaust air filtering cartridge

Step 3: Replace the filter cartridge and slide the holder

back into the container until the spring locks en-

gage.

Assembly of the tool holder (optional)

Step 1: Open the container by loosening the two hooks

(Fig.12 left).

Step 2: Lift off the cap of the container (Fig. 12 center)

and push the tool holder into the groove provi-

ded on the lower container part (Fig. 5 right).

Fig. 12: Assembly of the tool holder (optional)

Storage options on the Special Vacuum Cleaner

The vacuum cleaner offers the possibility of placing the

tube on top of the container (Fig. 13 top left). The correct

storage of the power cable is the wound state at the top

of the container (Fig. 13, top right).

The double use brush can be clicked into the groove on

the front of the container (Fig. 13 bottom left) or on the

bottom of the container (Fig. 13 bottom right) for sto-

rage.

Fig. 13: Storage options

WARNING!

Danger when opening the tank!!

Never open the container while the vacuum cleaner

is in the operation!

ATTENTION!

Check the vacuum cleaner before use for the follo-

wing:

- Check the condition of the filters, replace the filter if

necessary.

- Check the fill level of the dry vacuum. When the dry

vacuum is completely full, empty it.

- Check the filter bag and replace if necessary.

12 flexCAT-Series | Version 1.04

Scope of delivery

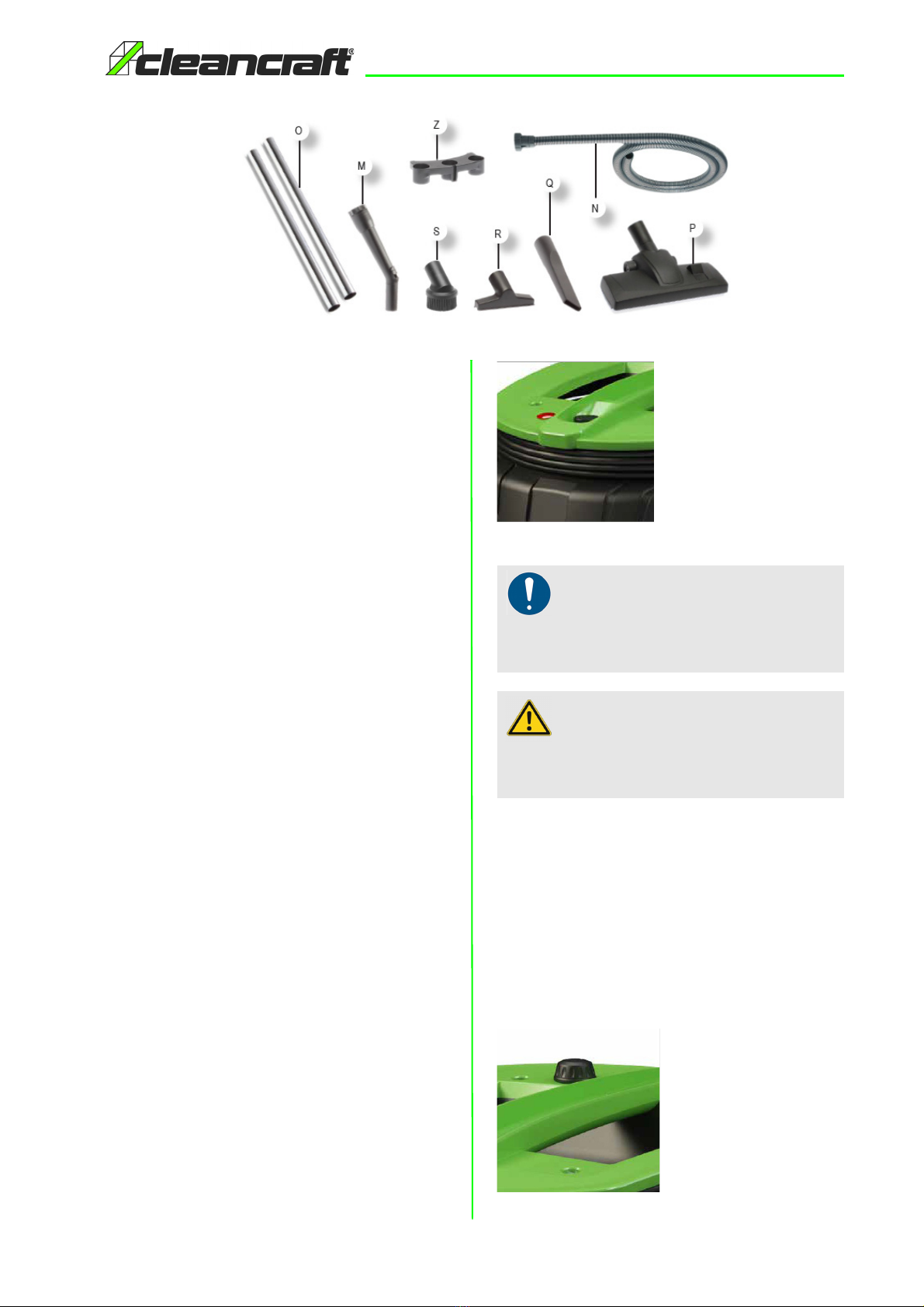

7 Scope of delivery

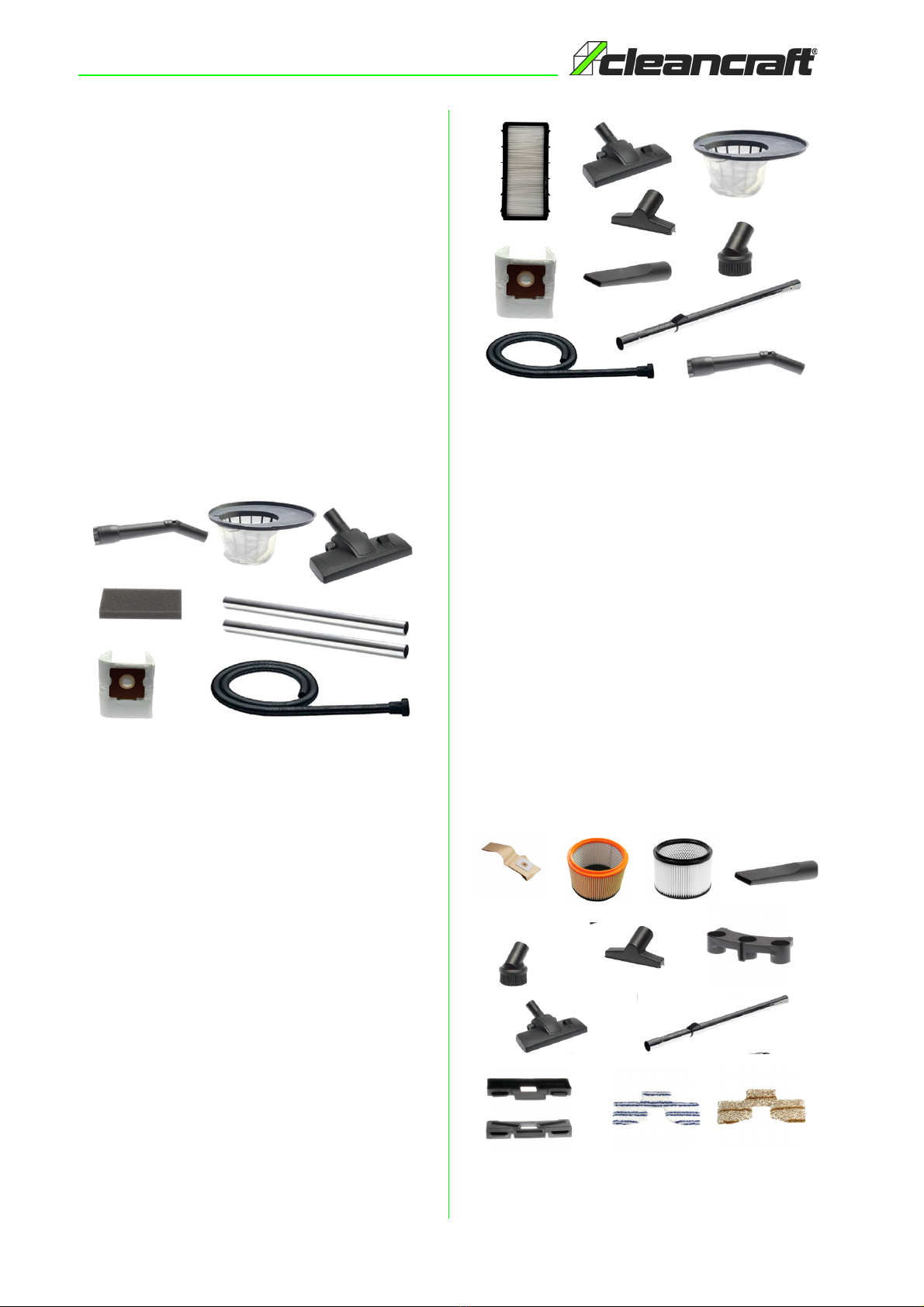

The Special Vacuum Cleaner flexCAT 112 Q will be deli-

vered with (Fig.14):

Item number: Designation:

7010360 Polyester filter 850 cm² (Pos. 2)

7010361 Filter bag 11 l (Pos. 6)

7010362 Exhaust air filter (Pos. 4)

7010363 Hose 2 m Ø 36 mm with connections

(Pos. 7)

7010364 Handle with incorrect air regulation

Ø 36/32 mm (Pos. 1)

7010365 Suction tube 47 cm Ø 32 mm (Pos. 5)

7010366 Double use brush (Pos. 3)

Fig. 14: Scope of delivery flexCAT 112 Q

The Special Vacuum Cleaner flexCAT 116 Q will be deli-

vered with (Fig. 15):

Item number: Designation:

7010360 Fabric filter 850 cm² (3)

7010361 Filter bag11 l (6)

7010380 Exhaust air filter (Poly M43 1 Micron) (1)

7010363 Hose 2 m Ø 36 mm with connections (9)

7010364 Handle with incorrect air regulation

Ø 36/32 mm (10)

7010372 Chrome suction tube Ø 32 mm (8)

7010366 Double use brush (2)

7010374 Crevice nozzle Ø 32 mm (7)

7010375 Roud brush Ø 32 mm (5)

7010376 Upholstery nozzle Ø 32 mm (4)

Fig. 15: Scope of delivery flexCAT 116 Q

Accessories for the flexCAT 112 Q (Fig.16):

Item number: Designation:

7010300 Paper filter bag (1)

7010303 HEPA-Cartridge filter (2)

7010302 Poly-cartridge filter (3)

7010374 Crevice nozzle Ø 32 mm (4)

7010375 Round brush Ø 32 mm (5)

7010376 Upholstery nozzle Ø 32 mm (6)

7010381 Holder for the nozzles and

suction tube (7)

7010372 Chrome suction tube Ø 32 mm (8)

7010382 Double use brush (9)

7010383 Pad holder for the double use brush (10)

7010384 Universal pad for the double use

brush (11)

7010385 Parquet pad for the double use brush (12)

Fig. 16: Accessories flexCAT 112 Q

4

23

1

5

67

4

23

1

5

6

7

8

9

10

4

23

1

5

67

9

10 11 12

8

Operation

flexCAT-Series | Version 1.04 13

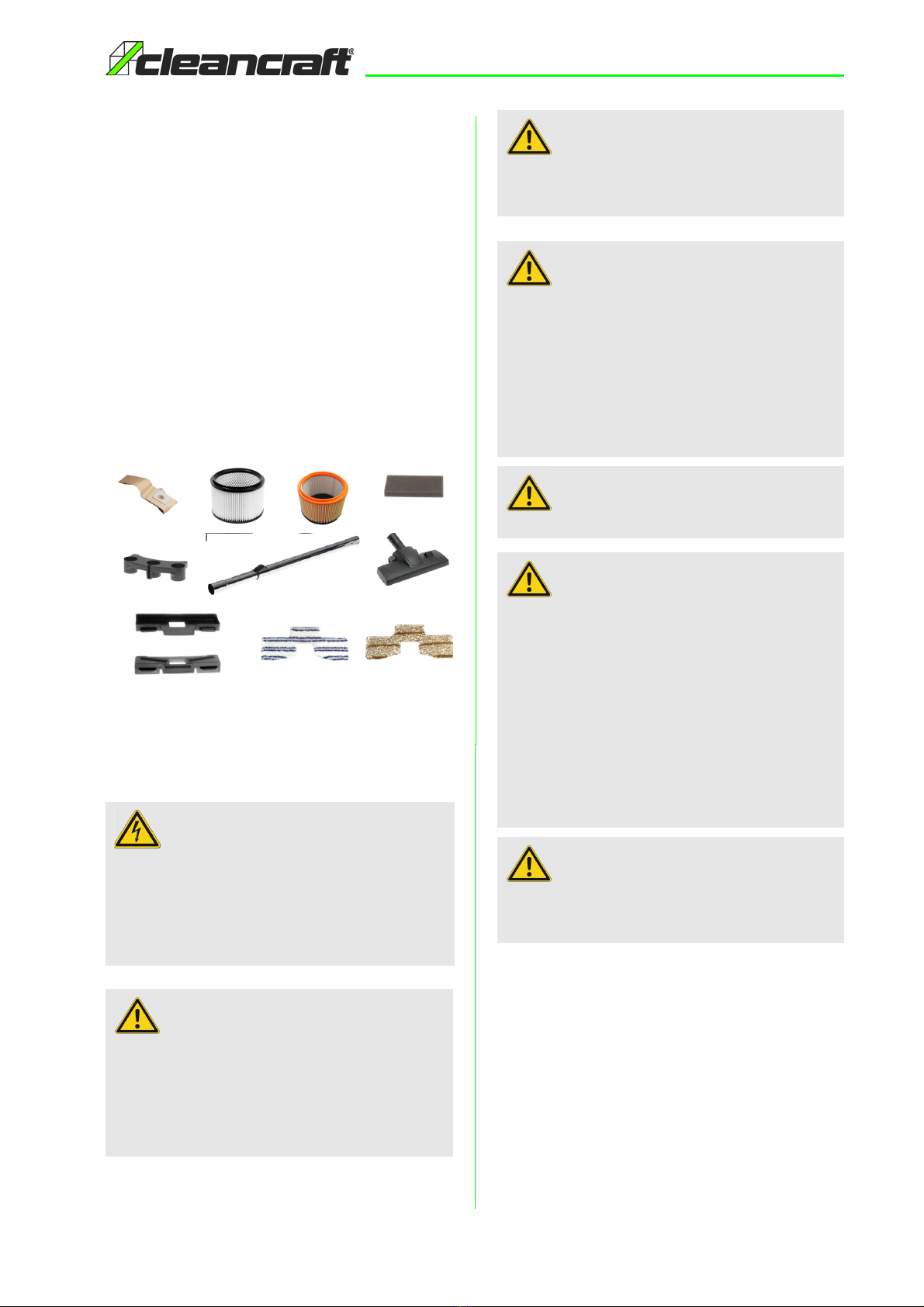

Accessories for the flexCAT 116 Q (Fig. 17):

Item number: Designation:

7010386 Paper filter bag (1)

7010302 Poly-cartridge filter (2)

7010303 HEPA-cartridge filter (3)

7010362 Exhaust air filter (4)

7010381 Holder for the nozzles and

suction tube (5)

7010372 Chrome suction tube 47 cmØ 32 mm (6)

7010373 Double use brush (7)

7010383 Pad holder for the double use brush (8)

7010384 Universal pad for the double

use brush (9)

7010385 Parquet pad for the double use brush(10)

Fig. 17: Accessories flexCAT 116 Q

8 Operation

DANGER!

Danger of potentially fatal electric shock.

There is a risk of fatal injury from contact with live

parts. Electrical components which are switched on

can carry out uncontrolled movements and cause

serious injuries.

- Disconnect the plug before starting adjustments to

the vacuum cleaner.

WARNING!

The power cable must be completely full free rolled

before using the device.

Do not use the device with the rolled cable!

Do not use the plug or the device with wet hands!

Do not vacuum the objects that could damage the

filter elements (for example a glass, metal, etc.)!

4

231

56

8910

7

ATTENTION!

To maintain the performance of the system, it is

recommended clean the filter after each use and

clean or replace the filter bag.

WARNING

The device must be correctly installed before use. It

must be checked that the filter elements are mounted

correctly and that they function correctly.

The device should only be operated, mounted,

repaired and transported on a stable, flat surface.

Before the unit is put into operation, make sure that

the operating voltage indicated on the type plate is

the same as the supply voltage avaible and that the

power plug of the vacuum cleaner suits on the socket.

CAUTION!

The device is only suitable for the use in the indoor!

WARNING!

Before you handle the switched-off vacuum cleaner

unplug the mains plug.

Regularly check the power cable and plug for

damage (insulation, etc.). A damaged cable must be

replaced before further use of the vacuum cleaner.

The replacement of a defective power cable must be

carried out by the technical service or by qualified

personnel.

When using the extension cord, make sure that it

has the same cable dimension as the power cord of

the device. Avoid getting the cable in contact with

the liquids or conductive surfaces.

ATTENTION!

Before the unit is put into operation, make sure that

the operating voltage indicated on the type plate is

the same as the supply voltage avaible.

14 flexCAT-Series | Version 1.04

Care, maintenance and repair

8.1 Start and stopping

Start

- Insert the power plug into a suitable power socket

- Press the ON/OFF switch.

Stopping

- Turn off the device and disconnect the power cord

- By disconnecting always pull on the plug, never on

the power cable.

8.2 Controlling of the seal

Over time, the quality of the seal may deteriorate as a re-

sult of the aging or damage. This leads to a decrease in

the suction power. We recommend regularly checking

the clamping hooks, flexible suction hoses and seals for

a perfect function.

Clean all seals after completing work. The fouling can

prevent a correct function and cause the damage.

Check that the edgings of the tank are not damaged.

9 Care, maintenance and repair

9.1 Care by cleaning

The vacuum cleaner must always be kept in a clean

condition.

Keep the ventilation slots of the engine clean to ensure

adequate cooling.

9.2 Maintenance and repair

General maintenance information

- Check regular the seals, plastic units, filter and the

switch for the damage. Replace this if necessary.

If the vacuum cleaner is not functioning properly, con-

tact a specialised dealer or our customer service.

Please find the contact data on chapter 1.2 Customer

service.

DANGER!

Danger of potentially fatal electric shock.

There is a risk of fatal injury from contact with live

parts. Electrical components which are switched on

can carry out uncontrolled movements and cause

serious injuries.

- Disconnect the plug before starting cleaning and

maintenance.

Use protective gloves!

Wear the suitable protective gloves by the cleaning

to protect against injury from chips.

ATTENTION!

Always empty the tank and clean all parts of the

vacuum cleaner after the vacuuming.

Clean all plastics and paint surfaces on the vacuum

cleaner with a lightly moistened cloth.

The cleaning must not be done by children, if they

are not controlled by adults.

Maintenance and repair works must only be perfor-

med by specialists.

Use only original spare parts in case of a repair.

WARNING!

Maintenance and repair works must only be perfor-

med by specialists.

Use only original spare parts in case of a repair.

Disposal, recycling of used devices

flexCAT-Series | Version 1.04 15

10 Disposal, recycling of used devices

Please take care in your own interest and in the interest of

the environment that all component parts of the machine

are only disposed of in the intended and permitted way.

10.1

Decommissioning

Immediately decommission disused machines in order

to avoid later misuse and endangering of the environ-

ment or personal safety.

Step 1: Eliminate all environmentally hazardous operat-

ing materials from the used device.

Step 2: If required, disassemble the machine into easy-

to-handle and usable components and parts.

Step 3: Dispose of machine components and operating

materials by the disposal channels provided.

10.2 Waste disposal of electric equipment

Please note that electrical devices contain a variety of

recyclable materials as well as environmentally harmful

components.

You contributes to that these components are disposed

of separately and properly. In case of doubt, please

contact your municipal waste disposal.

As necessary, a specialized waste disposal company can

help be used for the treatment.

10.3 Disposal of lubricants

Remove any leaking, used or excessive grease at the lu-

bricating points.

Disposal notes for used lubricants are available from the

manufacturer of the lubricants. If necessary, request the

product-specific data sheets.

10.4 Disposal of the filter

The filters are made of the environmentally friendly ma-

terials. You can dispose the filter in the normal house-

hold waste, as long as it contains no dirt prohibited in

the household waste.

11 Malfunctions, their potential causes

and remedies

IMPORTANT!

If one of the following malfunctions occurs, immedi-

ately stop working with the device. Before you start

troubleshooting, turn off the device and unplug the

power plug. Failure to do so can lead to serious

injury.

All repairs or replacement work may be performed

by qualified and trained expert staff only.

NOTE!

If you can not eliminate the problems with your va-

cuum cleaner yourself, then please contact your

CLEANCRAFT dealer. Please mark down the follo-

wing information from the vacuum cleaner or instruc-

tion manual, this will help you best with your problem.

- designation of the device

- serial number

- year of manufacture

- detailed fault description

Malfunc-

tion

Possible cause Remedy

Machine not working.

1. Power plug is not

plugged in.

2. Power supply ca-

bles defective.

3. Switch defective

4. Motor defective

1. Plug in the

power plug.

2. Call a service

technician

3. Call a service

technician

4. Call a service

technician

Suction decreases.

1. Blockages in the

suction nozzle,

suction hose or

filter.

2. Seals are not

tight.

1. Remove the

blockages,

clean the filter

2. Clean the seals

or replace the

seals.

3. Check the fit of

the filters and

the tank cap.

4. Check the hose

and connecti-

ons for the tight-

ness.

16 flexCAT-Series | Version 1.04

Spare parts

12 Spare parts

12.1 Ordering spare parts

The spare parts may be purchased with the authorised

dealer or directly with the manufacturer. Please find the

corresponding contact data in Chapter 1.2 Customer

service.

Indicate the following basic information for requests or

orders of spare parts:

- Type of device

- Item No.

- Position No.

- Year of construction:

- Quantity

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare part orders which do not include the above indi-

cations may not be taken into consideration. If the indi-

cations regarding the mode of dispatch are missing, the

product is dispatched at the discretion of the supplier.

You will find information regarding the device type, item

No. and year of manufacture on the type plate fixed to

the vacuum cleaner.

Example

A covering for the vacuum cleaner flexCAT 112 Q must

be ordered. The covering ist identifies in the spare parts

drawing with the position number 2.

When ordering spare parts, send a copy of the spare

parts drawing with marked component (covering) and

marked position number (2) to the authorized dealer or

to the spare parts department and provide the following

information:

Type of device: Special Vacuum Cleaner

flexCAT 112 Q

Item number: 7003135

Position No.: 2

The item number of your machine:

Special Vacuum Cleaner flexCAT 112 Q: 7003135

Special Vacuum Cleaner flexCAT 116 Q: 7003140

DANGER!

Danger of injury by the use of wrong spare

parts!

Dangers may result for the user and damages as

well as malfunctions may be caused by using wrong

or damaged spare parts.

- Only use original spare parts of the manufacturer or

spare parts admitted by the manufacturer.

- Always contact the manufacturer in case of uncer-

tainties.

Tips and recommendations

The manufacturer's warranty will become null and

void if non-permissible spare parts are used

Spare parts

flexCAT-Series | Version 1.04 17

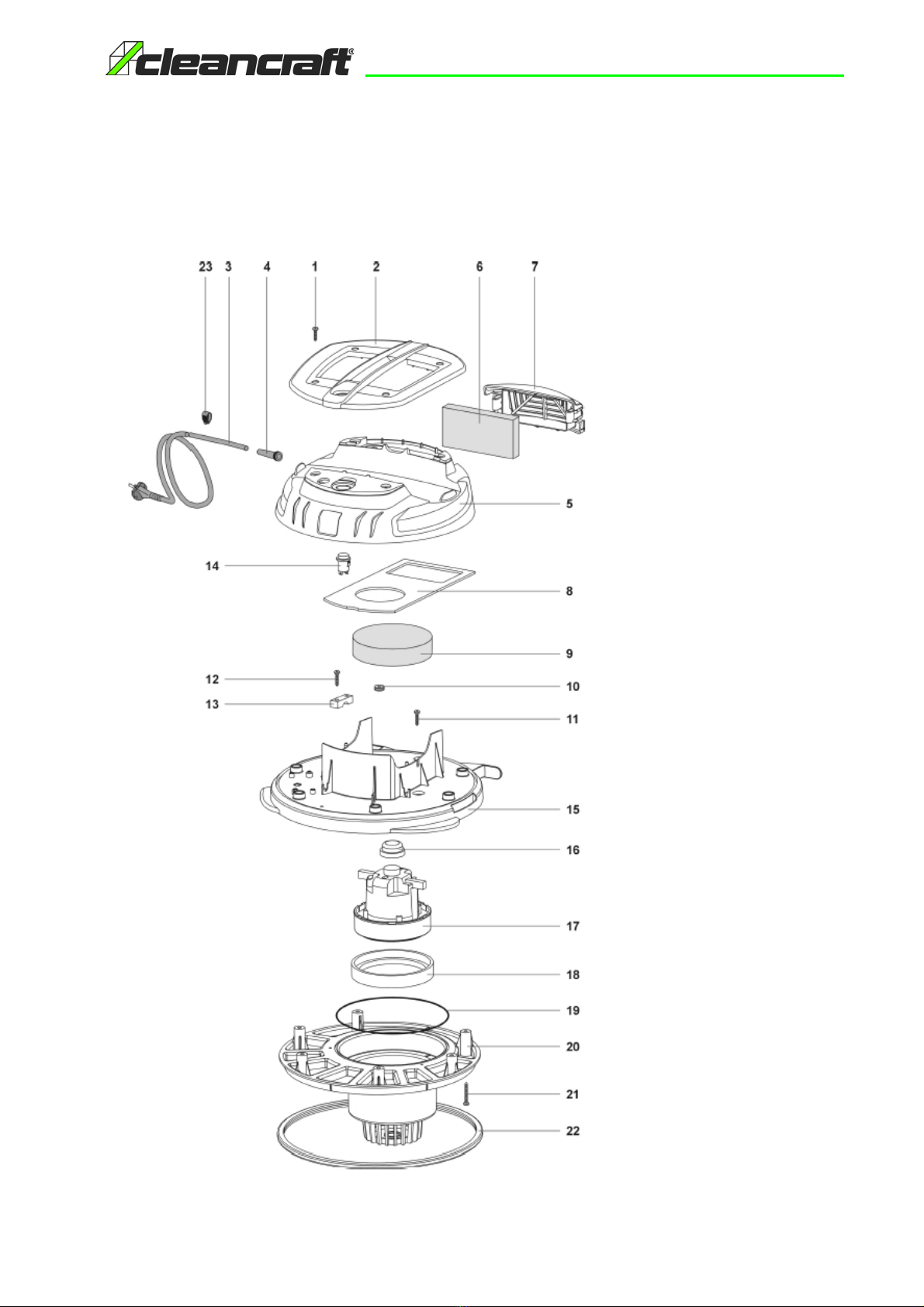

12.2 Spare parts drawings

In case of service, the following drawing shall help to identify the necessary spare parts. If necessary, send a copy of

the parts drawing with the marked components to your authorised dealer.

Spare parts drawings flexCAT 112 Q

Fig. 18: Spare parts drawing 1, head, flexCAT 112 Q

18 flexCAT-Series | Version 1.04

Spare parts

Fig. 19: Spare parts drawing 2, main filter flexCAT 112 Q

Fig. 20: Spare parts drawing 3, base frame, flexCAT 112 Q

Spare parts

flexCAT-Series | Version 1.04 19

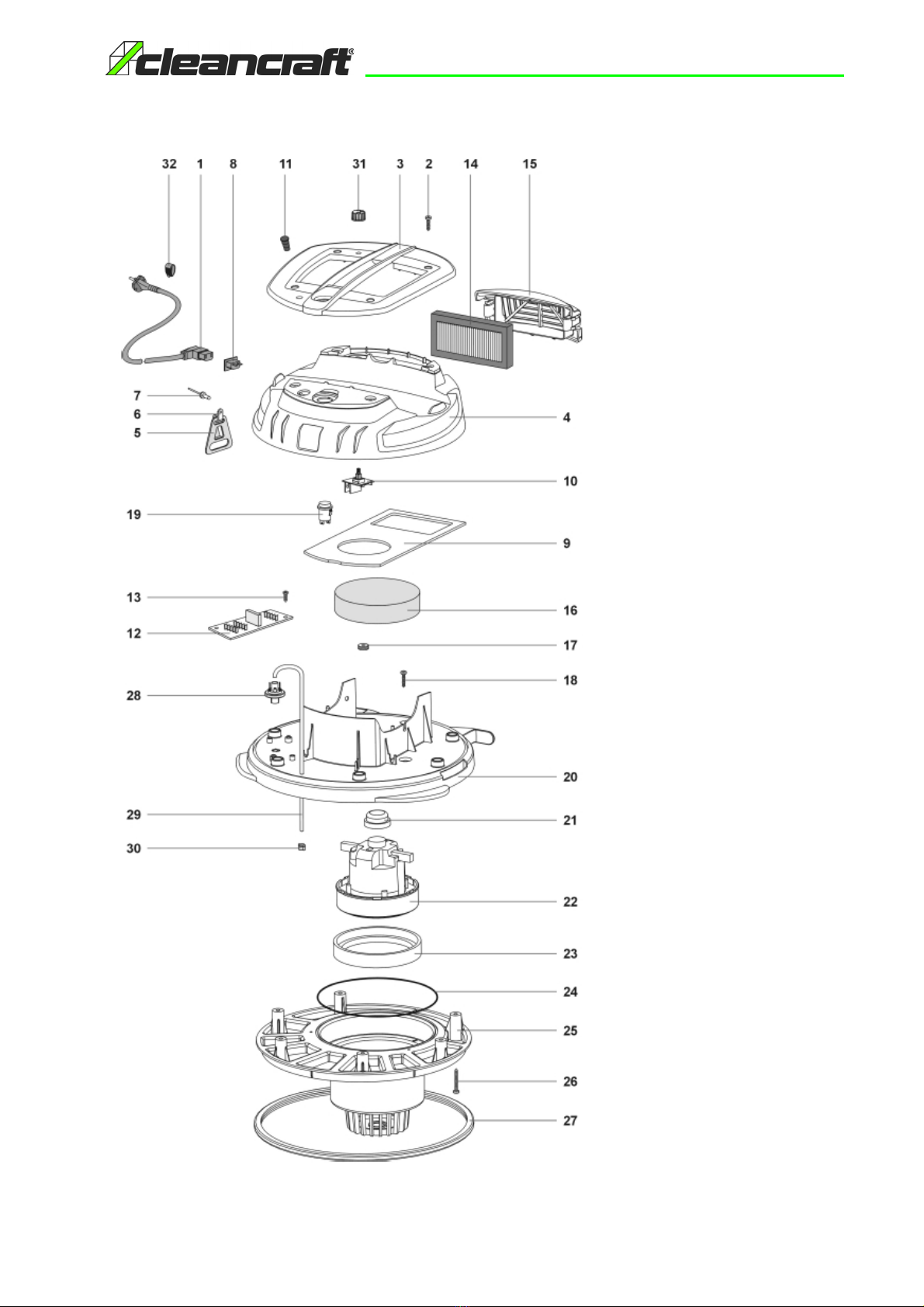

Spare parts drawings flexCAT 116 Q

Fig. 21: Spare parts drawing 1, head, flexCAT 116 Q

20 flexCAT-Series | Version 1.04

Spare parts

Fig. 22: Spare parts drawing 2, main filter, flexCAT 116 Q

Fig. 23: Spare parts drawing 3, base frame, flexCAT 116 Q

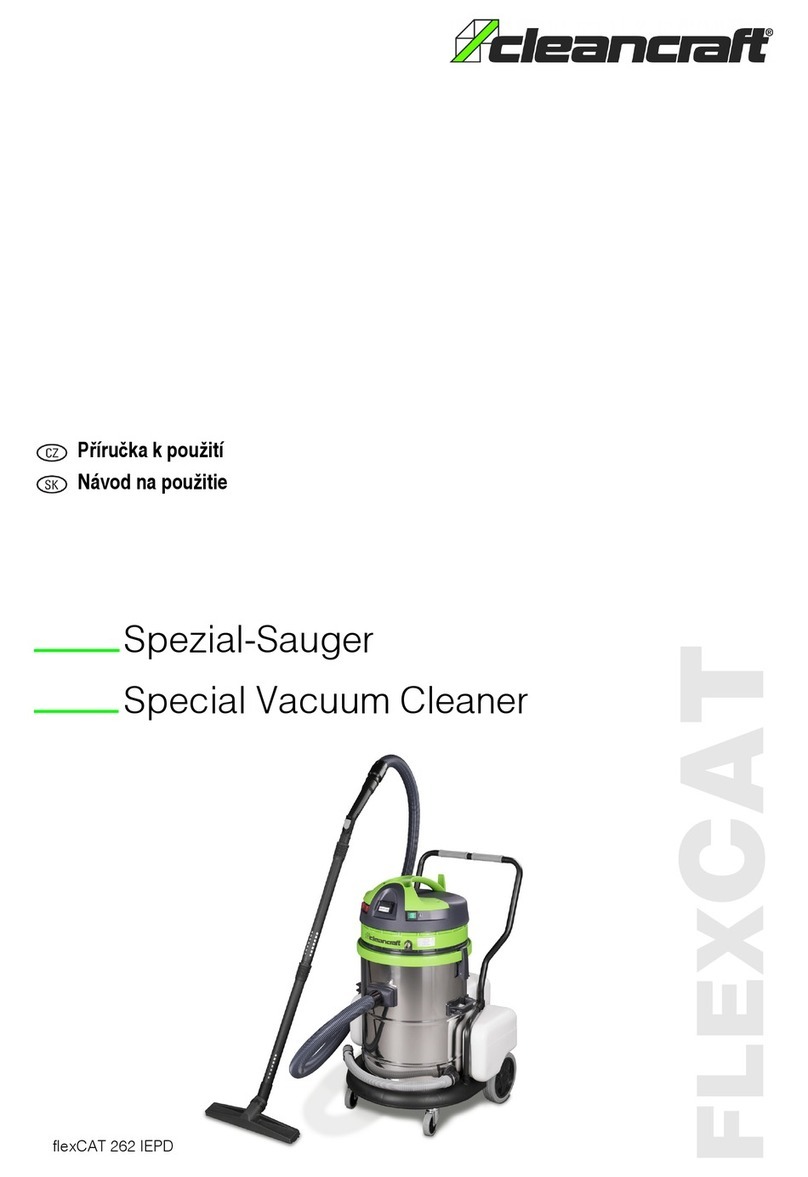

This manual suits for next models

2

Table of contents

Other CleanCraft Vacuum Cleaner manuals

CleanCraft

CleanCraft flexCAT 262 IEPD User manual

CleanCraft

CleanCraft flexCAT 120 VCA User manual

CleanCraft

CleanCraft dryCAT 133 IC-HC Manual

CleanCraft

CleanCraft VCA Series User manual

CleanCraft

CleanCraft flexCAT 16 H User manual

CleanCraft

CleanCraft flexCAT 120 VCA User manual

CleanCraft

CleanCraft dryCAT 16 L - Class User manual

CleanCraft

CleanCraft flexCAT 116 PD User manual

CleanCraft

CleanCraft dryCAT Series User manual

CleanCraft

CleanCraft flexCAT 290 EPT User manual