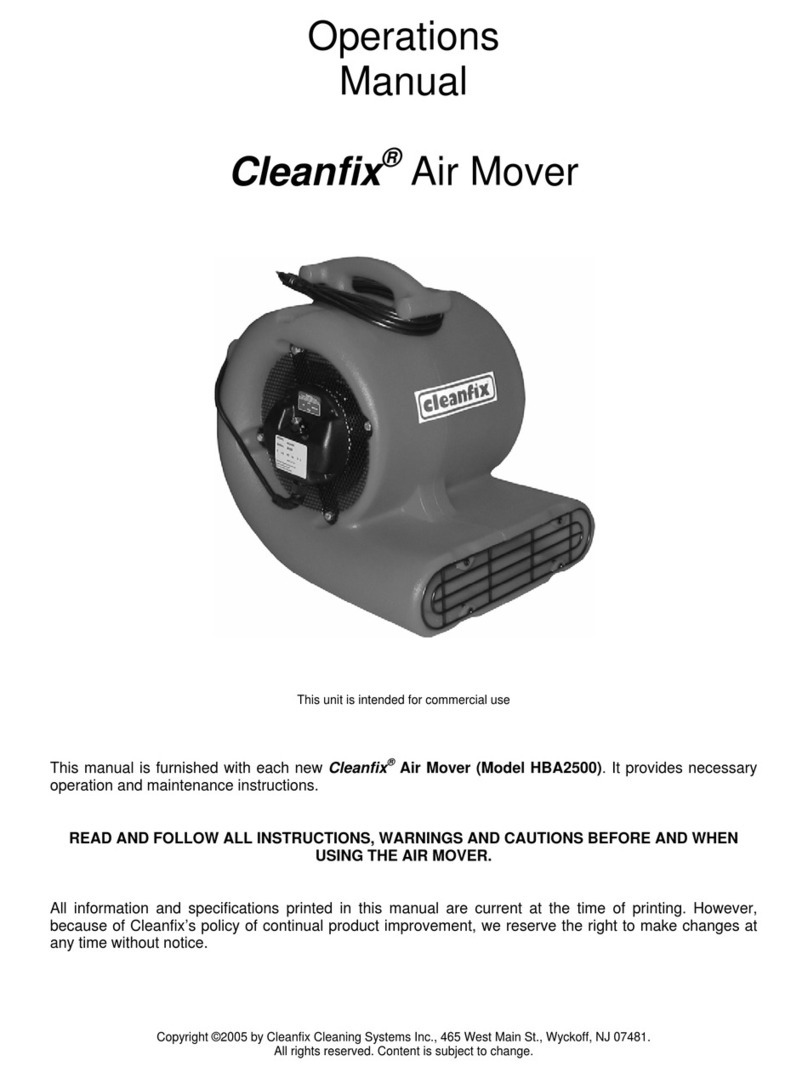

Cleanfix KS 1100 B HD User manual

KS 1100 B HD

KS 1100 B

Swiss Made Quality.

08/2012BA KS1100.000-EN

Swiss Made Quality.

Swiss Made Quality.

Englisch

1

Contents

Introduction Page

To these operation instructions.................................................................2

Symbols used in this manual..................................................................2

Safety indications......................................................................................3

Appropriate use........................................................................................3

Product description.............................................................................................................4

Operating panel........................................................................................4

Safety instructions................................................................................................................5

Applications..............................................................................................5

Safety devices.......................................................................................................................6

Initial start-up, standard, optional.............................................................6

Operation................................................................................................................................7

Safety instructions....................................................................................7

Adjust the driver's seat, driving / Start......................................................7

Driving forward, reverse, acoustic signal (optional)...................................7

Sweeping operation, safety, operating the sweeper..............................8/9

Operation of extraction, filter cleaning, parking.........................................9

Dust bin emptying, removing + installing dust box..................................10

Hydraulic high dump...............................................................................10

Filter replacement, expansion, installation.............................................11

Machine cleaning................................................................................................................12

Maintenance and Service.................................................................................................12

Safety instructions..................................................................................12

Side brushes..........................................................................................13

- Side brushes exchange, installation side brush...................................13

- Side brushes readjustment.................................................................13

Cylindrical brush...................................................................................14

- Cylindrical brush exchange, Installation of the cylindrical brush...........14

- Cylindrical brush readjustment.............................................................15

Batteriy..................................................................................................16

- Safety instructions for the use of batteries............................................16

- Battery charging...................................................................................17

Brakes, Adjust the brakes, the brake control function.............................18

Functionality of the brake, Other adjustment..........................................18

Fuses, safety information........................................................................19

Wheels and steering, broom drive...........................................................19

Maintenance Table..............................................................................................................20

Errors and solutions...........................................................................................................21

Circuit diagram KS 1100 B.................................................................................................22

Circuit diagram KS 1100 B HD...........................................................................................23

Technical Data.....................................................................................................................24

Applied Standards, Product label, Disposal, environmental protection.................25

Declaration of Conformity.................................................................................................26

Service..................................................................................................................................27

Spare Parts...........................................................................................................................27

KS 1100 - Englisch

2

Introduction

To this Operation Instructions and Maintenance Manual

In this paragraph you will find information about how this manual is structured

and explanations for the used signs and symbols.

This manaul contains instructions on how to use the ride-on-sweeper KS1100 B and

KS 1100 B HD.

Our products are being improved continuously, for this reason we cannot include all tech-

nical adaptions within this manual by the date of printing. If you should have any questions,

please feel free to contact our Service for explanations and advise.

This Operation Instructions and Maintenance Manual has to be read and been understood

by all persons who will use or operate or maintain this ride-onsweeper KS1100.

Besides the Operation Manual and the laws and rules abiding in the country of use the

applicant should take all necessary measures to apply and take into consideration all

existing Health and Safety measures to prevent accidents and allow for professional on the

job conditions.

Symbols used in the manual

Following symbols and descriptions are used in this manual for very impor-

tant indications.

Danger!

All dangers for persons which

could lead to serious Injuries or

even death are marked by this

symbol and safety instructons.

Caution!

This symbol stands for possible

dangerous situations or when

light injuries could occur.

Attention!

This symbol is used to indicate

dangers which can damage

machines or auxiliary equipment.

☞This symbol is used for hints

which indicate how to use

the ride-on-sweeper.

•This symbol in the text

indicates that this job has

to be done

-A dash in front of the text

means: This is part of an

itemization

KS 1100 - Englisch

3

Introduction

Appropriate use

The ride-on-sweeper is only designed for

sweeping dry wastes on paved floors e.g.

car parks, industrial halls, storage halls,

pavements.

Never ever use the machine under any

circumstances whatsoever to sweep

flammable or explosive material.

Any other use or unauthorized use which

is not according to the specifications and

determination are prohibited.

The manufacturer cannot be made

responsible and will not be liable for any

damages or consequential damages

resulting out of such a use.

The applicant will bear such risks

and hazards.

The ride-on-sweeper is not intended

for sweeping of strings, ropes, wires

or similiar objects.

For appropriate use according to the

sweepers designation it is important

to abide to this manual and to comply

with all inspection and maintenance

instruction.

Safety indications

The ride-on-sweeper KS1100 ist built

according to the latest standards and

safety regulations. All the same it can

never be foreclosed that life threatening

dangers can occur for the user or for third

parties or restrictions for the ride-on-

sweeper and damage to material assets

may happen.

For this reason the Ride-on-Sweeper

must only be used when in perfect condi-

tion, used in a proper and foreseen way.

At all times the Ride-on-Sweeper should

be used taking all Health and Safety regu-

lations into consideration, the user be

made aware of dangers which can occur

by properly reading and understanding

this Operation Instructions and Mainte-

nance Manual.

All errors which may affect any aspects of

Health and Safety must be solved imme-

diately. Always keep this Manual at the

site where the Ride-on-Sweeper is being

used for quick reference! Observe and

consider all other applicable rules and

laws which abide for accident prevention

an for protection of the environment!

Do not execute any changes, add or

rebuild any components on the Ride-on-

Sweeper without prior consent of the

Manufacturer.

Spare parts must abide to the technical

requirements stated by the manufacturer.

This is always assured by the purchasing

of Original spare parts.

Always follow and indicated maintenance

intervals of the supplier or the indicated

maintenance jobs and intervals mentio-

nend in this Operation Instructiions and

Maintenance Manual.

Please make sure that all waste items are

disposed of in safe and ecological way of

all operational supply items, additives or

replacement parts.! Prevent use by

unauthorized persons, e.g. by pulling out

the keys after use.

KS 1100 - Englisch

4

Product description

The ride-on-sweeper is driven by electro-motors. The KS1100 does the sweeping job by

means of 2 swivel side brushes which brush the wastes to the central cylindrical brush

which is positioned parallel to the driving direction. The cylindrical brush then throws over

the top all wastes into the waste bin behind. The dust which is raisen and dispersed can be

disposed of if required by the vacuum motor which sucks away the dust to the multi-layer

filter unit integrated at the back of the machine. This multi-layer filter can be cleaned by

means of activating the electrical vibrating unit.

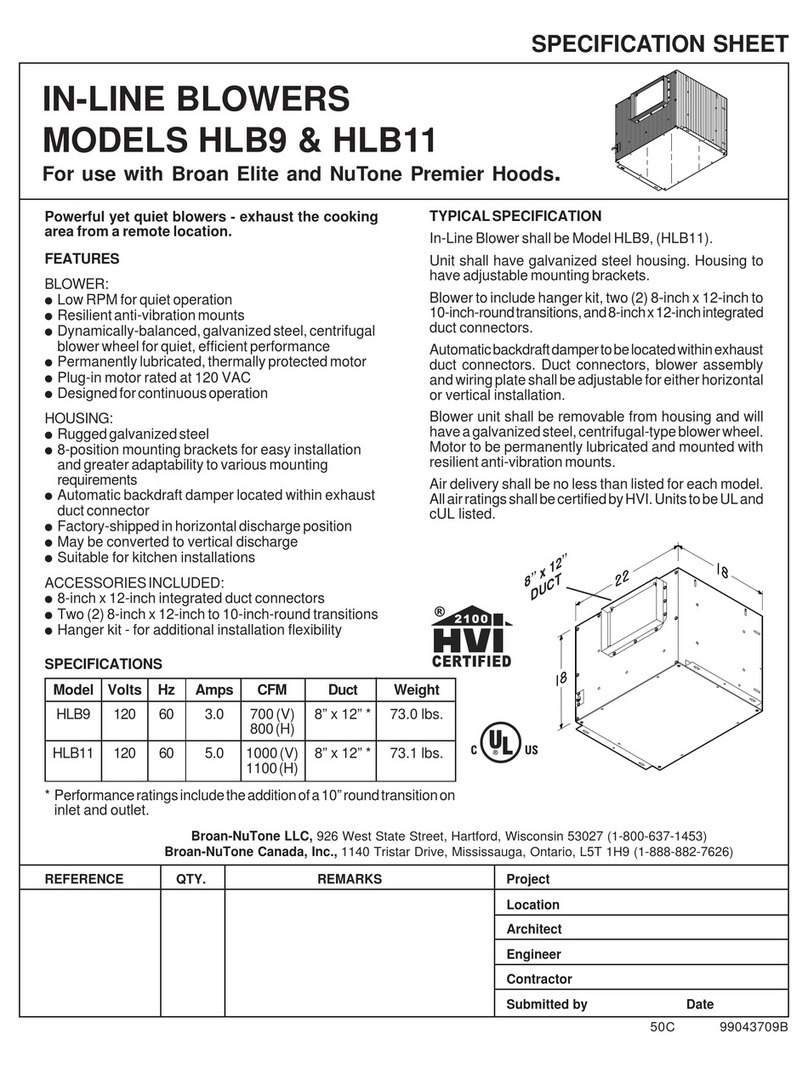

Operator panel (without overhead discharge)

1

0

ON

OFF

ON

OFF

ON

OFF

1

0

ON

OFF

ON

OFF

ON

OFF

Vacuum motor switch

Switch for cylindrical

brush motor

Switch for swivel side

brush motors

Switch for filter

cleaning

Battery charge—Status indication

Battery status indicator (LEDs)

ON /OFF

switch with key

ON / OFF Key (0 or 1)

Emergency-Off / Main Switch

Switch for Vacuum motor

Switch for Cylindrical

brush motor

Switch for swivel side

brush motors

Main Power Key ON/OFF

or Emergency OFF

2 Position key „Lifting“:

lifting/lowering

Switch for filter cleaning device

Operator panel (with overhead discharge)

KS 1100 - Englisch

5

Safety instructions

Swiss Made Quality.

Handle to lift and drop the

cylindrical brush

Brake pedal with with

footoperated parking

brake

Accelerator

Head light

Front wheel

with brake

Excellent climbing ability 20%

360° turning

circle for perfect

manoevrability

Solid stainless steel frame as

bump protection with impact

resistant cover

Applications

1

0

ON

OFF

ON

OFF

ON

OFF

User-friendly Operator panel

Large, non-marking wheels

Side covering (behind is access for

Adjustment of the cylindrical brush

Filter, side brushes and

cylindrical brush are easily

accessible without the use

of tools

Steering column with steering

wheel and operator panel with: -

- Light switch - forwards / backwards

leverl - Drive backwards-alarm

(optional)

Left and right lever on the

steering column to lift

and sink both side brushes

Adjustable seat to allow an ergonomic

Two self-swivelling side-

brushes for large sweepways

●Parking spaces

●Schoolyard

●Petrol station

●Underground park

●Shopping centres

●Warehouses

Simple emptying

KS 1100 - Englisch

Extra large hopper,

ideal use by means of

overthrow system

6

Safety devices

The Ride-On-Sweeper starts only when,

- the battery mains switch (emergency.-

Off) And the start switch with key is in

ON–position;

- Someone sits in the driving seat and

the seat contact is activated and addi-

tionally the accelarator pedal is

pressed down.

If the direction level (forwards/backwards)

at the steering column is in backwards

position, then an acoustic signal is activa-

ted. (optional)

Initial– Start-Up

The Ride-on-Sweeper is delivered as

standard version withou batteries and

without charger.

Optional:

The Ride-On-Sweeper can be delivered

with batteries and charger. The Ride-on-

Sweeper can be delivered with hydrau-

lisch overhead waste-box emptying.

Standard

• Open the transport packing.

• Remove the complete main cover. Lift

the main cover at the back and secure

the open position by using the support

holder.

• Place the batteries inside the machine.

• Connect the batteries to the power

supply according to the Technical Data

and Circuit diagramm/Wiring plan.

• Close the main cover again and put

the support holder back into position.

• Mount the side brushes (page 13)

The Ride-On-Sweeper is now functional

and ready for operation.

• Drive the Ride-On-Sweeper out of the

transport packing down from the

wooden palett by using the ramp.

☞ Make sure to use the closed ramp.

The ramp must be designed

in such a way that not only the

front wheel, but also the rear-

drive-wheels can drive onto, over and

down and off the ramp.

If these instructions are not followed then

the mechanical functions of the Ride On-

Sweeper could be considerably damaged.

The power supply respectively the start

procedure must be interrupted in the

following cases:

Hence, the following is essential:

• The main cover can only be opened if

the Main switch is in OFF position, i.e.

the lever is turned in OFF position which

then allows free opening.

• The side covers and other screwed /

bolted machine parts are only allowed

to be removed if the EMERGENCY-

OFF switch is turned to OFF position

and the key has been removed!

Optional:

• The Ride-On-Sweeper is equipped

with batteries.

• Open the transport packing.

• Open the main cover of the machine.

• Secure the open position of the main

cover with the cover support rod. The

cover has drill holes on the underside.

• Stick the cover support rod into the

drill hole.

• Connect the Plus-pole of the battery.

• Close the main cover.

• Mount the side brushes (see page 13)

• Drive the Ride-On-Sweeper over the

ramp and out of the transport packing.

☞ Make sure to use a closed ramp.

The ramp must be designed

in such a way that not only the

front wheel, but also the rear-

drive-wheels can drive onto, over and

down and off the ramp.

If these instructions are not followed then

the mechanical functions of the Ride On-

Sweeper could be considerably damaged.

The Ride-on-Sweeper is now functionable.

KS 1100 - Englisch

7

Operation

Safety instructions

The Ride-on-Sweeper can only be used

by reliable persons. Only trained and well

instructed persons shall be used. The

responsibilities must be clearly fixed.

Always check the Ride-On-Sweeper

before any drive and test the

functionability.and technical safety.

Do not use the machine if it should have a

defect. Only drive on the tracks and areas

which are strictly assigned for the Ride-

on-Sweeper. The Ride-On-Sweeper is

strictly designed for only one person to

use. The transportation of more than one

person is strictly forbidden.

Adjustment of the driver seat

Undo the seat fixation and move the

driver seat on the it‘s seat console until

you have found the suitable sitting

position.

Drive operation / Starting

the Sweeper

• Seat yourself on the drivers seat.

The Ride-on-Sweeper cannot be put

☞ into operation, if the drivers seat is

not exposed to weight pressure to

switch the contact.

• Check the position of the switch of

the lever on the operator panel.

• The Filter cleaning switch must be

in OFF (AUS) position.

• The red Main Switch must be in ON

(EIN) position.

• The Key switch must be ON

• Check the battery charge status- -

indication on the operator panel.

The luminious LED‘s shine in sequen-

ce and then show the effective char-

ging status of the batteries.

• Press the brake.

• Release the emergency-brake fixation

(next to the brake)

- Driving forwards:

• Move the lever switch to the front for

actuation „drive forwards“. Only when

☞the accelerator has been pressed

down, then the Ride-on- Sweeper will

start driving.

- Driving backwards:

• Move the lever switch to the back for

actuation „drive backwards“. Only

☞when the accelerator has been

pressed down, then the Ride-on-

Sweeper will go backwards.

An acoustic signal is optional

• The speed of the Ride-on-Sweeper

can be chosen variably when

☞pressing down the accelerator.

1

0

ON

OFF

ON

OFF

ON

OFF

Swiss Made Quality.

Brake pedal

Brake fixation

Accelerator

Light switch

Horn

Lever:

forward/backwards

KS 1100 - Englisch

8

Sweeping operation

Safety instructions

Do not switch on the vacuum motor when

sweeping wet areas/wastes This would

lead to a clogged filter and damage to the

vacuum motor. In closed rooms make

sure to have a proper room aeration.

Never sweep wastes dangerous to

health.

Operator panel (without overhead

disposal)

Operation of the cyclindrical brush

• Start the Ride-on-Sweeper

• Release the lever to lower the cylindri-

cal brush to the floor.

• Switch the Tip switch to ON to start

the cylindrical brush

☞ On the switch a control light will shine.

Stopping Cylindrical brush operation:

• Switch the Tipp switch for the cylind-

rical brush to OFF.

• Pull the lever for the cylindrical brush up-

wards and let it sideways fall in the latch.

Operation of the side brushes

• The side brushes are fixed to swivel

connections. When the side brushes

collide with an obstacle they swivel to

the side which prevents damage to

the Ride-on-Sweeper.

• Start the Ride-on-Sweeper.

• Release both levers which hold both

side brushes off the floor. The levers

are on the left and right side of the

steering pillar.

• Move the lever downwards.

• Switch the Tipp switch for side

brushes to ON position.

☞ On the switch a control light will shine.

The side brushes begin to rotate.

Ending the side brush operation:

• Switch off the Tipp switch for the

side brushes

• Pull both lever of the side brushes

upwards and let it fall in each latch.

• Engage the lever.

Switch for side brushes

1

0

ON

OFF

ON

OFF

ON

OFF

Switch for cylindrical brush

Switch for vacuum

motor (suction)

Emergency-Off—

Main Switch

Battery charge

status-indication

Switch for

filter cleaning

(vibration)

ON– and OFF Key switch

Swiss Made Quality.

2 levers to lift

and sink the

side brushes

1 lever to lower the

cylindrical brush

KS 1100 - Englisch

9

Sweeping operation

Operator panel

(without overhead disposal)

Vacuum operation

Vacuum operation helps preventing

Dust accumulation when sweeping.

• Start the Ride-on-Sweeper

• Switch on the Tipp switch for the suc-

tion motor.

☞A control light will shine on the

switch. The suction operation

begins.

Attention !

Do not switch on the vacuum

motor when cleaning wet areas/ wastes.

It will cause damage to the vacuum motor.

— To end the vacuum operation switch the

Tipp switch to Vacuum motor OFF.

Filter cleaning operation

The filter cleaning—vibration device pre-

vents that lamellas of the filter do not

clogg up with dust.

☞Switch off the vacuum operation.

Wait until the ventilator wheel stops

and stands still.

Press the Tipp switch 5-10 seconds long

for the filter cleaning.

The filter cleaning begins to work.

Switching off the Ride-on-Sweeper

• Press the brake pedal

• Secure the brake by pressing

additionally the small brake pedal

(„hand-brake) into the latch.

☞If the brake is released afterwards,

then the brake pedal must be kept

pressed down.

• Switch off all power supply

• Lift up both side brushes by using

both levers on the steering column.

• Latch the lifting / lower level for the

cylindrical brush.

• Turn the key into position 0 = OFF

and take the key out.

Turn the battery main switch

OFF and take it out of the

holder.

Danger !

Inappropriate use of the Ride-on-Sweeper can

lead to severe injuries to persons and heavy

damage to the equipment!

Prevent unauthorized persons to use the

Ride-on-Sweeper.

Never leave the operational Ride-on- Sweeper

unsupervised.

Pull out the battery mains switch key and the

key of the ON/OFF switch when leaving the

machine unattended.

(e.g. at the end of a job or days work the key

should be removed)

Keep the Mains Switch key and ON/OFF key

switch in separate places.

KS 1100 - Englisch

Switch for the side brushes

1

0

ON

OFF

ON

OFF

ON

OFF

Switch for the cylindrical

brush

Switch for cylindrical

brush

Switch for

cylindrical brush

Battery charge-

status indication

Switch for

filter cleaning

ON and OFF key switch

Lever to open a flap and allow large

wastes enter

(Wastes till 65mm) E.g. small PET bottles,...

10

Operation

KS 1100 - Englisch

Waste box emptying

The waste box is used to collect all

sweeped wastes. It can be found at the

back of the machine.

☞The Waste box / hopper must be

emptied regularly but latest after

each use.

Manual Emptying of the Waste Box

• Turn upwards both steel swivelcat-

ches which release the waste box.

They can be found on both sides

foteh waste box.

• Pull out the waste box along the

rails, by pulling upwards and holding

the handle of the waste box.

• The waste box can easily be removed

and put back inside the machine

again.

• Pull out the waste box completely.

• To empty the waste box grab inside

the grip of the handle.

Insertion of the waste box

• Place the waste box in front of the

entrance of the waste box opening

at the back of the Ride-on-Sweeper.

• Lift the waste box to the height where

it can enter the opening to the

guiding rails.

• Slide the waste box inside again

• As soon as the waste box is

completely inside the machine the

steel-swivel catches can easily be

moved downwards to lock position.

Hydraulic Overhead Waste Emptying

• When the waste box is full or ready for

emptying proceed according to the

Stepps 1 to 4 at the switches:

• First switch on the ON/OFF switch for

overhead waste box emptying.

• Then tip the rocker switch to Pos.1

(lift the waste box) and then let go

the rocker switch to middle position,

i.e. „hold“

• Now drive the Ride-on-Sweeper to

the foreseen waste container, close

enough backwards so that the

waste box is above the open waste

container.

• Pull the handhold for buckling (2)

• Push the handhold back to the home

position (3)

• Now you can press the rocker

switch „lower waste box“, pos.4.

Switch lifting / lowering

2-handhold for

buckling

1

0

ON

OFF

ON

OFF

ON

OFF

I

O

II

11

Operation

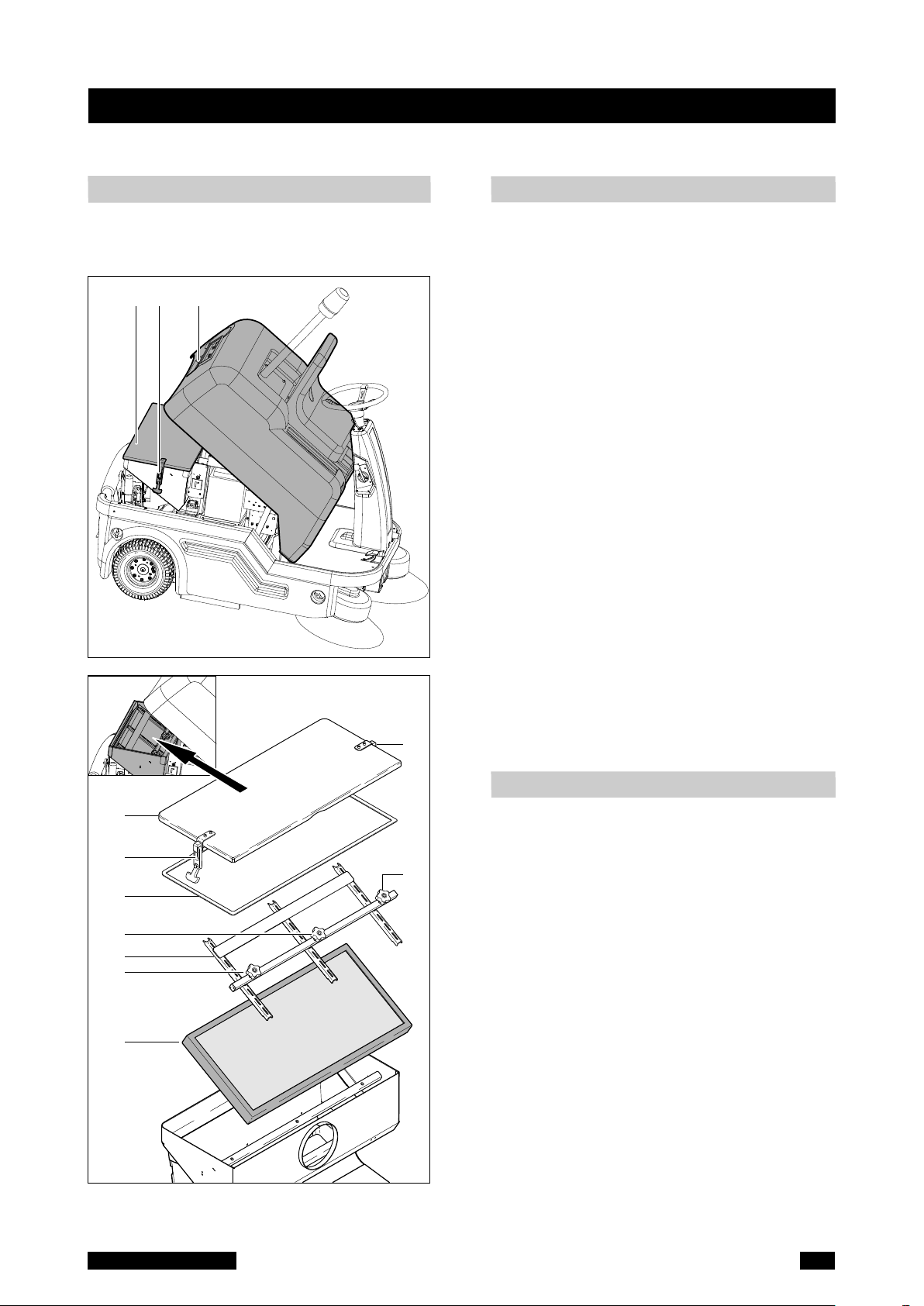

Dismantling

• Open the main cover. (A).

• Secure the main cover with the sup-

port rod in top position.

• The filter box cover (D) is held and

secured by two rubber latches (B).

• The inner lamellar filter plate with the

filter holder and the 3 star handles (C)

and held fixed.

• Loosen both rubber mounts (B) and

remove the air box- Cover (D) with

seal (E) up and away.

• Loosen the 3 star handles (C) to the

frame with plate filter is free.

Pull the plate filter (F) from the filter

box.

☞ Always replace the complete frame

with lamella-filter.

Mounting

• Insert the new lamella filter frame (F).

• Filter holder (G) and use disk filter

clamp with the 3 star knobs.

• The air box lid (D) onto the filter box

with seal (E).

• On each side of the air box lid, the

rubber-mount (B) down into place and

tighten.

• Carefully release the support rod

holding the machine cover and let it

down slowly and close.

Filter exchange

KS 1100 - Englisch

AD B

D

E

G

F

B

C

C

B

C

The integrated lamella filter separates the

fine dust. The lamella filter is cleaned by

electric activation of vibration unit.

12

Machine cleaning

The Ride-on-Sweeper is a machine with electrical components.

Attention !

Humidity damages electronic components.

Humidity can lead to creeping current and short circuits.

Never use high-pressure cleaners.

Attention !

Before doing any work on the Ride-on-Sweeper it is compulsory to first

TURN-OFF and the Main Switch (Emergency-Off Switch) and REMOVE

THE KEY in order to prevent unforeseen switching-on of the machine.

The opened main cover is to be secured by the support rod. Place the

support rod for the main cover in a safe and stable position.

Whenever working on electric and electronic parts of the machine it is

compulsory to first disconnect the negative terminal/pole of the battery!

Only use appropriate and faultless tools and equipment for your

maintenance and service work.

Every twelve (12) months, resp. 200 Operation hours, it will be neceessary to

have professional inspection of the Ride-on-Sweeper by an authorized and

competent person (primarly by the manufacturer or an authorized dealer or

trained specialist).

The results of this inspection must be kept to record in writing and to be

saved at least until the next inspection takes place.

KS 1100 - Englisch

Maintenance and Service

Safety instructions

13

the counter flange coming from the

side brush motor and is fixed tightly.

Side brushes adjustment

Due to wear and tear of the side brushes‘

bristles and the change in floor contact

height, it is necessary to readjust the side

brushes height from time to time.

• Turn-Off / Switch off the Ride-on-

Sweeper.

• Release the levers for both side

brushes and push them downwards.

• The side brushes are each fixed by

means of two supports. The right

support (bowden cable) is to lift or

lower the side brushes, the left sup-

port (butterfly handle screw) is used

to readjust the height of the brushes.

Maintenance and Service

Side brushes

Side brushes exchange

Removal of the side brushes

• Switch off of the Ride-on-Sweeper.

• Pull the levers of the side brushes

upwards.

• Locate both levers in their positions.

• Lift the side brush motor upwards in

order to get better access to the side

brushes.

• Unscrew the three fixation screws in

the centre of each side brush.

• Pull downwards each side brush.

• Replace the side brushes.

Mounting the Side Brushes

• Turn the 3 screw holes of the flange

plate of the side brushes exactly over

the position of the 3 holes of the

counter flange on the side-brush-

motor.

• Screw the three fixation screws in the

centre of the side brush that it con-

nects and lifts the brush upwards to

Counter flange

for side brush

Flange plate for

side brushe

Fixation screws

brush

KS 1100 - Englisch

Spring for constant pressure

Butterfly nut and

hexagon Screw

M10 (height

Adjustment of

the side brushes)

14

• Pull out the cylindrical brush out of

the machine and remove all wastes,

strings, tapes etc. from the cylindrical

mandrel.

Cylindrical brush fitting

• Push and slide the cylindrical brush

(D) under the machine.

☞ Pay attention to the driving/turning

direction of the cylindrical brush

when fitting it into the machine.

• At the cylindrical brush end there is

groove.

• Turn the cylindrical brush until the

pickup mandrel of the roller-rocker fits

in the groove of the cylindrical brush.

• Push and slide the roller rocker over

the threaded rod.

• Make sure, that the cylindrical brush

fits perfectly in the grooves on both

sides of the carrier and that all star

grips are fixed tightly.

Reattach the cover (C), lateral wall (B)

and lateral off- clothing (A).

Cylindrical brush

Cylindrical brush exchange

Dismantling the cylindrical brush

• Switch OFF the Ride-on-Sweeper and

remove the key.

•

Turn-OFF the Main Switch and remove

the red key as well in order to prevent

unforeseen switching ON again.

• Pull up the lever for the cylindrical

brush.

•

Locate and fix the lever in the top position.

• Unscrew the two screws with star grip

holding the machine-side-cover (A)

on the left side (driving view direction)

•

Remove the machine-side-covers (A).

The cylindrical brush is held by total

three star grips/handles. Two star grips

with screw are for the front cover. One

star grip with screw holds the rubber-

flap/waste splash protection).

• Unscrew both front star grips and

remove the front cover (B).

• Loosen the top wing nut and

remove the brush roller cover with

rubber dirt apron the bottom (C).

KS 1100 - Englisch

2 wing nut with side panel (A)

2 Star knobs with side wall inside (B)

1 wing nut cover with brush chamber

and rubber debris apron (C)

C B A

Maintenance and Service

15

machine which is on the right-hand

side when looking in driving direction.

Further adjustment possibilities:

• Remove the side cover of the machine

on the right hand side (driving direc-

tion view).

• Release the clamping screw.

• Put the cylindrical brush-support

sheet metal into the correct position.

• Refasten the clamping screw and

remount the side cover of the machine.

Reference note:

Original diameter of the Cylindrical Brush:

290 mm.

The brush must be replaced when the

diameter is below: 250 mm.

Cylindrical brush

Readjustment of the Cylindrical brush

Sweeping height / Sweeping range

The sweeping height/sweeping range of

the cylindrical brush is important to

achieve perfect surface cleaning results

and for the most effective use of the cylin-

drical brush.

Checking the sweeping height/range:

Drive the Ride-on-Sweeper on a surface

requiring cleaning. Switch-ON the cylind-

rical brush motor but do not drive

onwards. Let the cylindrical brush work

1-2 minutes in standing position. Now lift

the lever of the cylindrical brush. Switch-

OFF the cylindrical brush motor and drive

a few metres forward. The sweep track left

behind on the floor is the Sweeping range.

Test-Cleaning

• Keep the safety cover closed

• Take a piece of chalk and draw a line

on the floor starting inbetween both

side brushes (centre-line) and leading

a few metres ahead of the machine.

• Lift-up the cylindrical brush and drive

slowly towards the chalk line and then

park the machine above this chalk

line.

• As soon as the sweeper stands on top

of the chalk line, lower the cylindrical

brush (release the lever and lead

downwards)

• Switch ON the motor for the cylindri-

cal brush and start cleaning. The cyli-

ndrical brush should clean about 2 cm

Adjustment of the Sweeping

height/ Sweeping range

• Switch-OFF the Ride-on-Sweeper

• Pull the lever upwards which lifts the

cylindrical brush

• Open the main cover of the machine

• Secure the main cover in open-

position by using the support rod

• Now remove the side cover of the

KS 1100 - Englisch

Maintenance and Service

1 Umdrehung

The suitable key for the

height Adjustment of the

cylindrical brush.

Hex nut

Hex bolt

Nut

Counter

nut

16

• Warranty is only applicable if Original Cleanfix batteries and chargers are

used.

• It is compulsory to read and pay attention to the Operation and Safety

Instructions of the Original battery and charger manufacturer! Abide to all

recommendations and advices of the local authorities in the country of

application before using the batteries and charger.

• Batteries should never be left standing and discharged, they should always

be immediately recharged.

• In order to prevent creeping current it is highly important to keep the batte-

ries in clean, dry storage place. Keep them also clean of other wastes such

metall-dust.

• Do not leave tools or other equipment on top of the battery due to the

danger of short-circuits and the danger of explosion.

• Never ever use a flame or spark or smoke near to a battery or in a battery

charging room. Danger of explosion.

• Do not touch any machine parts which become hot, e.g. Drive motor

(Risks of burns)

• Be careful when handling battery acids! Abide to the corresponding Safety

Instructions!

• Used batteries have to be disposed of ecologically in accordance to the

EC-Directive 91/157 EWG.

Safety instructions for the use of batteries!

Maintenance and Service

Batteriy

KS 1100 - Englisch

17

Four Gel batteries type Dryfit each 6 V / 180 Ah provide the Ride-on-Sweeper KS1100 with power. The

charging status of the batteries can be read on the battery indication on the Operator Panel.

Signification of the LED lights on the battery status panel

When switching ON the Ride-on-Sweeper immediatley the LEDs start blinking, nicely one

after another, beginning at the minus/negative terminal and blinks along to the plus/

positive terminal. The result of this self-test is indicated by the 10 LED‘s..

1 LED = Working status / charging status is critical...until….

10 LED‘s = Work status / charge status is not critical, charging completed

Charging the batteries

• Switch-OFF the Ride-on-Sweeper

• In view of driving direction, on the right

hand side, Above the rear wheel is the

socket connection for battery charging

• Open the cover and connect the plug of

the charger to the battery socket on the

Ride-on-Sweeper

• Now connect the power cable of the battery

chargr to a power supply socket.

• The charging cycle requires approx. ??.

hours if the battery was totally discharged

and to be recharged only by an Original Battery Charger (Original Manufacturer)

• The Original-Charger of the Manufacturer should be connected as it allows to maintain

the charging status/trickle charge and therefore always for the maximum capacity of the

batteries even after a long standing time.

• Make sure to only put your Ride-on-Sweeper into operation, if the battery charge status

Is sufficient. The Ride-on-Sweeper will switch off automatically if the batteries are dischar-

ged down to a critical level which could cause damage. (low voltage/deep discharge

disconnect) In such a case all consumer loads muts be completely disconnected and

switched OFF for one to two minutes. Thereafter they can be reconnected and then the

machine must driven immediatly to the charger for battery charging before damage

occurs. Strictly only use the drive motor (do not switch on brush/vacuum motor).

Operator panel (without overhead emptying)

Description

Battery

LED display for

battery charge status

Battery charging indication

1

0

ON

OFF

ON

OFF

KS 1100 - Englisch

Maintenance and Service

Charging

socket sweeper

18

Danger !

The brake is a safety relevant building component! All work for maintenance/

service or exchange have to be done by qualified and trained personell.

The brake (drum brake) affects the front wheel and is activated via the brake pedal and

bowden cable.

Adjustment of the brakes can be done on the right hand side of the front wheel (view driving

direction).

Readjustment of the brakes

• Fix the adjustment nut of the bowden cable with a wrench.

• Release the counter nut of the bowden cable.

• Press the brake upwards until brake feels resistance.

• Hold the brake in this position.

• Turn the counternut of the bowden cable tightly.

Functional Test of the Brakes

Front wheel—free room of movement. The Ride-on-Sweeper should be able to be pushed

forwards easily if the brakes are unlocked. During this motion the front wheel should move

easily and not block. If the brakes are adjusted too tightly then damage could occurto the

drum brakes.

Functionality of the brake

Drive carefully a few metres at low speed. Press the brake pedal, the Ride-on-Sweeper should

stop. If the functional test does succeed as foreseen, then repeat the adjustment procedure.

Further adjustment possibility:

The Bowden cable cannot be adjusted as described above.

• Release the brake cable fixation and lift the brake lever until it has resistance and then hold

the brake lever in this position.

• Pull the brake cable through downwards and push the brake cable fixation upwards.

• Fasten the brake cable fixation in this position.

• Proceed with the functional tests as described above

Brake

Bowden cable

Brake cable

Adjustment nut of the

Bowden cable

Counter nut of the

Bowden cable

Brake cable fixation

Brake lever

KS 1100 - Englisch

Maintenance and Service

19

Safety information

There is an integrated contact in the drivers seat.

The Ride-on-Sweeper cannot be driven or other switch functions used unless someone is

seated and the seat contact is activated.

The fuse box is on the right side of the Ride-on-Sweeper under the main machine cover,

underneath the cylindrical-brush lever.

Never repair fuses.

Never replace fuses by

stronger ones (for higher

Amps).

This would lead to damage to the

electrical equipment.

It can lead to a short circuit and under the circumstances even lead to a fire.

Wheels and Steering

The steering of the front wheel is actuated by a chain and chain pinion. The Ride-on-

Sweeper has total three wheels. The wheels of the Ride-on-Sweeper are Gel-wheels and

help ease the adjustment of the cylindrical brush and side brushes. (air filled wheels loose

air and cause the machine to have different operation heights)

The wheels and steering have to be greased regularly with a grease gun/grease press.

For this maintenance job please abide to the Maintenance chart on the following page.

Cylindrical brush drive

The cylindrical brush drive is on the right side of the Ride-on-Sweeper (drive direction

view) The cylindrical brush is driven via a chain by an electric motor. The chain is diverted

over a chain wheel and driven by chain wheels of the cylindrical brush. A spring-loaded

chain tensioner holds the chain under tension.

Grease the chain wheels in regular intevals.

See the Maintenance Chart on the next page.

In order to grease the chain wheels, open the machine‘s main cover and remove the side

covers. Please refer to the Maintenance Chart on the next page.

Fuses

Relays

F = Filter cleaning

S = Side brushes

B = Blower/Vacuum pump

C = Cylindrical brush

L = Light

Safety fuses

F

12A 25A

SBCL

KS 1100 - Englisch

Maintenance and Service

This manual suits for next models

1

Table of contents

Other Cleanfix Blower manuals