Cleanfix Falcon Guide

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0

Safety, Operations & Maint. Manual

Cleanfix®Falcon

(RA 530 B)

This unit is intended for commercial use

This manual is furnished with each new RA 530 B.

It provides necessary operation and maintenance instructions.

READ AND FOLLOW ALL INSTRUCTIONS, WARNINGS AND CAUTIONS BEFORE AND WHEN

USING THIS AUTO-SCRUBBER. THE MACHINE MAY ONLY BE USED BY PERSONS WHO HAVE

BEEN INSTRUCTED IN ITS HANDLING AND EXPRESSLY ENTRUSTED WITH THE OPERATION

THEREOF.

All information and specifications printed in this manual are current at the time of printing. However,

because of Cleanfix’ policy of continual product improvement, we reserve the right to make changes at

any time without notice.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 2

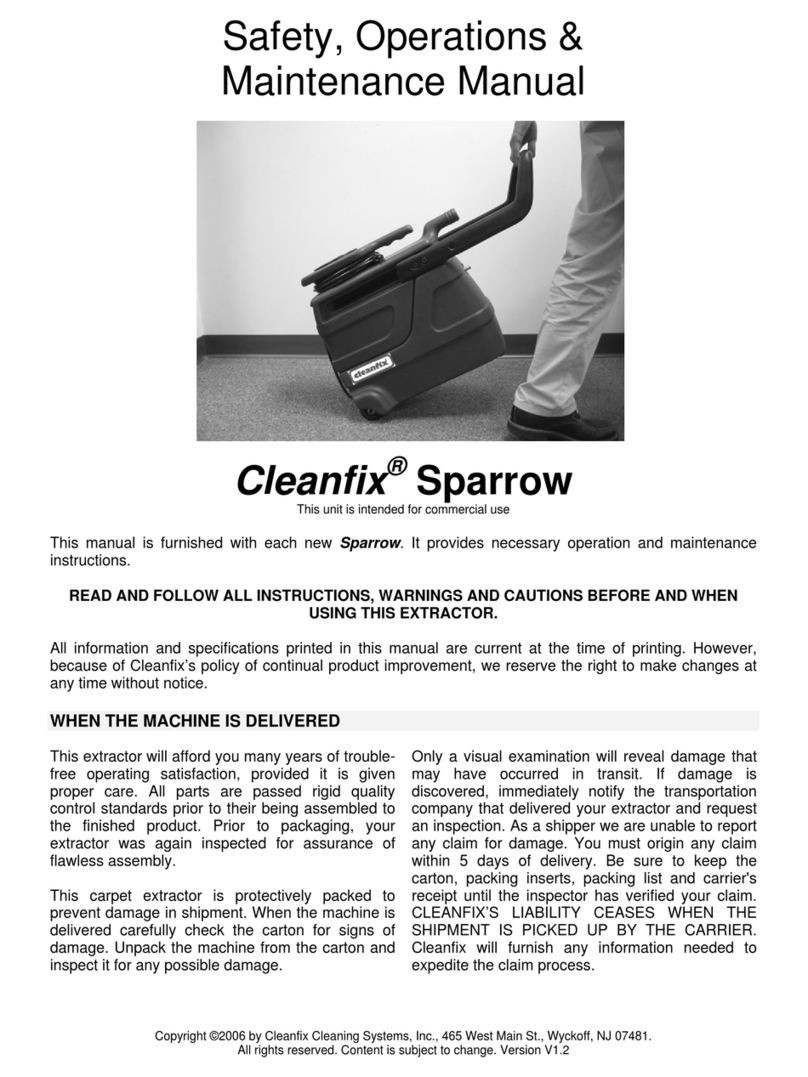

WHEN THE MACHINE IS DELIVERED

This auto-scrubber will afford you many years of

trouble-free operating satisfaction, provided it is

given proper care. All parts are passed rigid

quality control standards prior to their being

assembled to the finished product. Prior to

packaging, your auto-scrubber was again

inspected for assurance of flawless assembly.

This auto-scrubber is protectively packed to

prevent damage in shipment. When the machine

is delivered carefully check the carton for signs

of damage. Unpack the machine from the carton

and inspect it for any possible damage.

Only a visual examination will reveal damage

that may have occurred in transit. If damage is

discovered, immediately notify the transportation

company that delivered your auto-scrubber and

request an inspection. As a shipper we are

unable to report any claim for damage. You

must origin any claim within 5 days of delivery.

Be sure to keep the carton, packing inserts,

packing list and carrier's receipt until the

inspector has verified your claim. CLEANFIX’

LIABILITY CEASES WHEN THE SHIPMENT IS

PICKED UP BY THE CARRIER. Cleanfix will

furnish any information needed to expedite the

claim process.

GENERAL PRECAUTIONS

FAILURE TO FOLLOW PRECAUTIONS AND WARNINGS MAY CAUSE SERIOUS INJURY TO

THE OPERATOR AND CAUSE DAMAGE TO MACHINE, WHICH CAN VOID WARRANTY.

TO REDUCE RISK OF FIRE, ELECTRIC SHOCK OR INJURY: READ ALL INSTRUCTIONS

BEFORE AND WHEN USING THIS AUTO-SCRUBBER.

•The auto scrubber may only be operated by

persons who have been fully trained and

authorized to use it.

•This is NOT a toy. Close attention is

necessary when used around or near

children.

•Use only as described in this

safety/operations manual. Use only

manufacturer’s recommended attachments

and accessories.

•Do not use this auto-scrubber with

damaged cables or plugs. If the auto-

scrubber is not working as it should,

because it has been dropped, damaged, left

outdoors or dropped into water, contact

authorized service center or factory.

•Do not handle the plugs of the auto-

scrubber with wet hands.

•Store auto-scrubber indoors in a dry area.

Do not expose to freezing temperatures.

•Do not put any objects into openings. Do not

use with any opening blocked; keep free of

dust, lint, hair and anything that may reduce

air flow.

•Keep hair, loose clothing, fingers and all

parts of body away from openings and

moving parts.

•Any manner of working that represents a

safety hazard must be refrained from.

•The usage of the auto-scrubber is subjected

to national regulations.

•Do not use the auto-scrubber to pick up

flammable or combustible liquids such as

gasoline or use in areas where they may be

present. Do not pick up anything that is

burning or smoking, such as cigarettes,

matches or hot ashes.

•Do not use where anesthetics or oxygen is

used.

•Replace damaged or worn parts

immediately with genuine original equipment

parts to maintain safety and to protect your

limited warranty.

•Do not pressure-wash the auto-scrubber, as

it may cause a short circuit, damage to

components and/or operator injury.

•Never drive over steps!

To Avoid Electric Shock, Do Not Expose to Rain. Store Indoors.

WARNING

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 3

GENERAL PRECAUTIONS (cont.)

•Never drive over power cords! Danger of

electric shock!

•In elevators always turn-off unit with key and

lower brushes to prevent unit from moving.

•Whilst operating, caution is to be exercised

with respect to third parties, especially

children.

•Wear sturdy footwear.

•When cleaning and servicing the machine,

changing parts or converting to a different

function, turn off the drive and withdraw the

key from the key switch.

•Besides the operating instructions and the

national rules for safety in the work place,

we also recommend that the unwritten rules

of safe working should be respected. Using

the auto scrubber on public roads, paths

and any other outdoor surface is prohibited.

TRANSPORT

•The applicable user and safety

instructions/regulations, in particular for

those pertaining to load-bearing capacity,

must be observed when transporting the

machine in elevators.

•Raise the brushes by means of the foot

lever before transporting the auto-scrubber.

•Notice: The brushes should also be lifted

during working breaks and during charging

operations. The life expectancy of the

brushes and pads will be increased.

•To prevent the batteries from spilling the

machine should not be tilted more than 45

degrees to the back.

•Take care when moving the machine over

thresholds and landings – this may damage

wheels and the squeegee assembly. Please

ensure that the brush unit and the squeegee

assembly are raised. To lift/carry the

machine grab it by the handle and

underneath the front outside cover of the

machine.

•Make sure that the temperatures during

transportation are never below 32°F / 0°C.

•When transporting in elevators, their safety

regulations and precautions are to be

respected as well as the maximum load

capacity of the elevator.

GRADIENTS, STEPS AND THRESHOLDS

•NEVER drive auto-scrubber over steps.

•Do not use the auto-scrubber on inclines

exceeding 4% unless higher inclines are

approved in the operating instructions.

Always use extreme caution when moving

the auto-scrubber on ramps or inclines.

•Do not change directions on inclines.

•Do not park the auto-scrubber on inclines.

•Care should be taken when driving the

machine over thresholds or sills as damage

may occur to the brushes, wheels and

squeegee assembly. It is advisable to lift the

brushes and the squeegee assembly.

CLEANING CHEMICALS AND HAZARDOUS DUST/LIQUID

•Attention must be paid to the manufacturer’s

safety instructions when using cleaning and

care chemicals. Wear safety glasses and

clothing if necessary.

•The danger of using easily flammable, toxic,

health-damaging, caustic or irritating

substances is expressly pointed out.

•Do not use the auto-scrubber for surfaces

that can release dust and liquids that are

hazardous to health.

•Only use low foaming and non-inflammable

cleaning agents, which do not include

hazardous components.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0

GENERAL PRECAUTIONS (cont.)

SAFETY INSTRUCTIONS FOR BATTERY-OPERATED MACHINES

•Observe the safety and accident prevention

regulations pertaining to the handling and

installation of batteries.

•Observe the operating and handling

instructions of the battery manufacturer.

•Before charging, check the battery cables

and the charger cable and replace them if

necessary.

•Smoking is strictly PROHIBITED when

charging batteries.

•Avoid open flames, flying sparks and

glowing objects.

•Keep the room in which machine/batteries

are charged well ventilated. Highly explosive

toxic gas is generated when the batteries

are being charged.

•Open all cavities, covers and lids etc. in

which the explosive gas can gather.

•Open recovery tank.

•Fire fighting/prevention equipment must be

within reach.

•Eating and drinking is PROHIBITED in

rooms where batteries are being charged.

•After handling batteries, immediately wash

hands thoroughly.

•Do not touch or pour away battery acid.

•Never spill or touch battery acid. Never lay

metallic parts or tools onto the batteries.

Danger of short circuit, fire and explosion!

SOURCES OF DANGER

•Do not run the brushes when the machine is

stationary as it may cause damage to the

surface being cleaned.

•Care should be taken when driving the

machine over thresholds or sills as damage

may occur to the brushes, wheels and

squeegee assembly. It is advisable to lift the

brushes and the squeegee assembly.

•When transporting in elevators, their safety

regulations and precautions are to be

respected as well as the maximum load

capacity of the elevator.

PLACE OF WORK

The working place of the operator is behind the handle of the machine.

CARE OF AUTO-SCRUBBER

This auto-scrubber is designed to be safe when

used to perform cleaning functions as specified.

Should damage occur to electrical parts, the unit

should NOT be used until the damage is

repaired by the manufacturer or an authorized

service center. This will avoid further damage to

the auto-scrubber or injury to the user.

These instructions are for your protection and

information.

PLEASE READ CAREFULLY! Failure to follow

instructions or precautions could result in injury

or damage to the user and/or the auto-scrubber.

SAVE THESE INSTRUCTIONS!

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 5

INTENDED USE

•Only use for wet cleaning of water-

resistant floor coverings in building

interiors.

•Do not use the auto-scrubber on public

roadways.

•The autoscrubber is not to be used at

temperatures under 32°F (0°C).

•The water temperature may not exceed

122°F (50°C).

•Any other use is considered to be

improper. The manufacturer is not

liable for any resulting damage; all risks

are the responsibility of the user.

•The appropriate accident prevention

rules, as well as other known

regulations for health and safety in

operation, must be respected.

•Use for intended purpose also includes

adherence to the manufacturer’s

operating, service and maintenance

regulations.

•Modifications made to the auto-scrubber

by the user releases Cleanfix from all

liability for resulting damage.

•Floor coverings must be checked for

suitability for this cleaning method

before using the auto-scrubber!

•Pay attention to surface pressure in

case of point-elastic floors such as

gymnasium floors. Check that the

wheels will not damage the surface.

•Cleanfix does not accept liability for

damage caused to the machine and

floor covering being cleaned if wrong

brush and chemicals have been used

BEFORE USING THE AUTO-SCRUBBER

QUICKGUIDE

1. Check that the machine is in proper

condition.

2. Remove obstacles, such as furniture

etc. from the area to be cleaned. Large

pieces can be removed to opposite end

of the room from where you start

cleaning.

3. All covers, hoods and lids must be

correctly attached and closed. Make

sure all switches are in the OFF

position.

4. Fill the machine with clean water using a

clean bucket or a hose attached to a

water source.

5. Add the chemical required. Check the

label for the correct dilution portions.

6. Before plugging the batteries in all

switches must be in the OFF position.

All cables and connectors must have

proper protection from spray water.

7. Check all cables for damage and signs

of aging at regular intervals. The auto-

scrubber may only be used if the battery

cables are in perfect condition.

CHECK IF COMPLETE

•Machine

•Squeegee assembly

•Scrub brushes or pad driver and cylindrical brush

•Operations manual

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 6

BEFORE USING THE AUTO-SCRUBBER

INSTALLING THE BATTERIES

•Open recovery tank by tilting sideways.

•Put in batteries with metal poles facing

each other.

•Battery clamps are marked with either + or

- . Connect – clamp attached to black

cable (coming from the machine) to the

nearest – pole on the batteries and

tighten.

•Connect + clamp attached to the red cable

(coming from the machine) to the nearest

+ pole on the batteries and tighten.

•Take the short, red jumper cable and

connect the respective clamps ( + and - )

to the remaining poles and tighten.

•Plug in red plug into machine plug.

CHARGING THE BATTERIES

•Turn machine off with the main switch and

with the key.

•Empty recovery tank completely and tilt

sideward.

•Remove charging plug from machine.

•Connect cable of charger with battery cable.

•Turn-on battery charger.

When using gel batteries (maintenance free) the waste water tank can be left closed

during the charging process. Using wet batteries (lead-acid batteries), the waste water

tank must be kept tilted OPEN during the entire charging process.

ATTENTION! The manufacturer takes no responsibility when batteries spill occurs!

Metal parts in batteries and battery cells are always live. Exercise extreme

caution when handling and installing batteries.

Make sure that at no time a short circuit is created when installing the batteries.

WARNING

- +

+ -

Machine

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 7

BEFORE USING THE AUTO-SCRUBBER (cont.)

PREPARATIONS FOR WORK

Depending on the type of operation the machine must be equipped respectively with the correct brushes

or pad-holders and pads.

•Place squeegee (E1) into the holder.

•Fix squeegee with the two star handle

screws (E2).

•Connect hose from the squeegee to the

waste water tank cover.

•Lower the squeegee with lever (A10).

•Fill the clean solution tank with water and

the cleaning agent required for the specific

task (Dilution rates will be on the label of the

cleaning solution). The maximum capacity of

the clean solution tank is 12 gal. (45 liters).

•Set the solution flow rate with the knob (C1)

(recommended position 1-2)

FUNCTIONAL PARTS AND ACCESSORIES

A. General view

1. Controls

2. Handle

3. Dome

4. Guide wheel

5. Solution flow regulating valve

6. Brush assembly side roller

7. Squeegee assembly

8. Disc brushes

9. Cylindrical brush

10.Lever to raise/lower squeegee assembly

11.Recovery tank

12.Solution tank bladder

13.Drain hose for recovery tank

14.Brush operation lever

B. Controls

1. Key switch

2. Operating LED

3. Low battery signal

4. Vacuum push button

5. Brush push button

6. Solution push button

C. Adjustments and connectors

1. Solution flow valve

2. Quick disconnect for external

solution hose

3. Cylindrical brush access plate

D. Brushes

1. Disc brushes

2. Cylindrical brush

E. Rear view

1. Squeegee assembly

2. Knob for fixation of squeegee

3. Angle adjustment for squeegee

assembly

4. Foot lever for raising brushes

5. Battery container

7. Solution bladder drain hose

F. Front view

1. Brush pressure adjustment

2. Supporting bar / Kick stand

G. Access to battery/component

compartment

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 8

FUNCTIONAL PARTS AND ACCESSORIES

A

E

D

G

F

CB

1

10

13

12

7

9 8

6

4

11

3

2

5

1

3

2

5 64

1

3

2

1

2

6

4

1

7

5

3

2

2

1

14

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 9

OPERATING THE AUTO-SCRUBBER

OPERATION

The controls have clear symbols for the function they control.

•Turn the key for main switch (B1).

•Turn on the different applications in the

following order by pressing switches:

1. Push button for solution pump (B6), if

necessary adjust water flow (C1)

2. Push button for brush motor (B5)

3. Push button for vacuum motor (B4)

•By pulling the brush operation lever (A14) the

machine will start moving forward.

•Drive the first 10 to 15 feet to test the water

flow as well as the chosen brushes or pads

and make sure that these meet the

requirement to properly clean the floor.

•At the same time check the vacuuming

performance. If necessary adjust the

squeegee angle (E3).

•If the auto scrubber should run forward too

fast or too slow it can be regulated with the

screw for adjusting the brush pressure (F2).

The screw is at the front on the right side

(seen from the operator’s position). The

adjustment can be set between a pressure of

35 and 70 lbs.

Turning the screw upwards ¬Decreases

pressure

Turning the screw downwards ¬Increases

pressure

IMPORTANT INFORMATION

•When the machine is not being operated,

immediately turn of the brush in order to

avoid damage to floor surface.

•If either liquid or foam leaks from machine

unintentionally, immediately switch off the

machine.

•Brush wear is automatically adjusted for by

the weight of the entire brush support.

•In case of foam in the recovery tank add

defoamer to prevent foam entering the tube

of the vacuum motor.

•Check filling level regularly and empty

recovered water in time. Make sure enough

water is dispensed whilst running the

brushes or pads as these should never be

run dry.

•Use brushes, pads and accessories as

described in this operations manual. Failure

to comply with this can be hazardous.

REPLACING DISC BRUSHES OR PAD DRIVER

Tilt the machine backwards and place it on the

kickstand for replacing brushes (F1) underneath

the front of the machine. The kickstand is on the

front left side (seen from operators view).

All disc brushes and pad holders are removed

by turning the left one clockwise and right one

counter-clockwise and by pulling them

downwards.

To insert the brushes or pad holders, place the

pins on the brushes into the holes of the drive

disc underneath the machine. Fix the brushes or

pad holders by quickly turning the left one

counter-clockwise and the right one clockwise.

Important

•The direction of rotation of the left brush is

clockwise and the right brush counter-

clockwise.

•The brush pressure can be adjusted with the

screw for adjusting the brush pressure (F2).

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 10

OPERATING THE AUTO-SCRUBBER (cont.)

REPLACING THE CYLINDRICAL BRUSH

To remove the cylindrical brush, remove two

screws on the metal plate on the right side of the

machine (C3). Pull the metal plate outwards.

The brush can be removed from the metal plate

by pulling it off. Mount the new brush onto the

metal plate and place back into the housing.

Make sure that the connections for correct fitting

of the brush, which are at the other end of the

housing fit onto the brush.

When the metal plate is correctly fitted, tighten

the two screws securely back into position.

WORKING WITH EXTERNAL TOOLS/ACCESSORIES

•Disconnect the hose between the recovery

tank cover and the squeegee assembly.

•Attach the vacuum hose used with the

external tool to the connector of the recovery

tank.

•Connect the solution hose used with the

external tool to the quick disconnect (C2).

•Set the solution flow rate (C1) to position „0“.

•Connect the external tool to the hoses.

•Push button for the pump (B6) and for the

vacuum motor (B4).

•Hard-to-reach areas, stairs and corners can

now easily be cleaned with the external tool.

FINISHING THE JOB

•Turn off the solution flow (B6).

•Turn off brushes (B5).

•Turn off vacuum motor (B4).

•Raise squeegee with lever (A10).

•Tilt the machine backwards and place it on

the kickstand (F1) underneath the front of the

machine. Remove brushes or pads and pad

driver and rinse thoroughly with clean water.

•Remove machine from kick-stand back to

normal upward position.

•Rinse and clean recovery tank cover with

clean water.

•Clean below the machine with a damp cloth.

•Fill solution tank with approximately 1 gallon

of clean water.

•Attach water drain hose to connector (C2).

•Set the solution flow rate (C1) to „0“.

•Turn on pump (B6).

•Pump out coming water into a bucket or a

drain.

•Clean entire machine with a damp cloth.

•Remove squeegee assembly from the holder

and clean it.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 11

APPLICATIONS AND WORKING METHODS

1. Working methods Effective cleaning is achieved by

following a few guidelines,

combined with your own

experience in particular areas.

Correct use of special

accessories will increase the

cleaning effect. Some basic

instructions can be found below.

2. Applications The machine is suitable for:

•Deep cleaning of non-sensitive hard floors surfaces.

•Daily cleaning of non scratch-proof hard floor surfaces.

•Daily maintenance cleaning, normal soiled floors.

3. Chemicals •Basic cleaner, deep cleaner

•Floor cleaner, maintenance cleaner, oil and grease remover

•Floor cleaner, scented cleaner

4. Accessories •Squeegee assy.

•2 x disc scrub brushes

•1 x cylindrical brush

•Brush (soft)

•Pad driver

•Pad white

•Pad red

•Pad blue

•Pad black

•Battery (lead-acid and gel)

•Battery charger

FREEZING TEMPERATURE PRE-CAUTIONS

If it becomes necessary to store or transport the

unit where temperatures could drop below

freezing (32° F), the solution lines and valves

must be protected from freezing with a solution

of automotive radiator antifreeze.

1. Mix ½ gallon of water and ½ gallon of

anti-freeze and pour into the solution

tank.

2. Switch on machine with key switch (B1),

set the solution flow rate to “1” (C1) and

turn on solution pump (B6).

3. Let pump run until anti-freeze mixture is

coming out of machine.

4. To prevent damage to unit, allow the

auto-scrubber to reach room

temperature before using. The anti-

freeze MUST be flushed out of the

solution system with clean water before

auto-scrubber is used on a cleaning job;

otherwise, the floor may be damaged.

STORAGE OF AUTO-SCRUBBER

Always store the auto-scrubber in a dry,

protected area at temperatures above freezing.

This auto-scrubber should be stored in an

upright position. Objects should not be stored or

stacked on top of unit.

This unit should not be stored in vehicles or

areas where extreme heat or cold occurs.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 12

MAINTENANCE AND REPAIR

•Only do maintenance work described in

this manual.

•Always use original spare parts.

•WARNING! Do not make any technical

alterations to auto-scrubber. This can

put your safety at risk and will cease the

warranty.

•Always contact authorized service

center or factory for other maintenance

and repair work.

After every use Weekly When required

Thoroughly flush solution lines

with clean water ●

Rinse solution and recovery tank

with clean water ●

Clean solution filter ●

Clean recovery tank filter ●

Clean squeegee assembly ●

Inspect squeegees for wear;

replace if necessary ●

Replace brushes / pad drivers ●

Check battery ●

Charge battery ●

If you maintain the machine carefully it will stay in good working condition for a long period of time.

Regularly check the machine for any wear and tear.

•Before repairing machine disconnect any chargers attached and unplug batteries from machine.

•Repairs and any type of service may only be done by an authorized service center or factory

personnel.

Always disconnect cord before

cleaning and maintaining the

auto-scrubber.

WARNING

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 13

INSTRUCTIONS FOR GEL AND LEAD-ACID BATTERIES

•Only carry out work on batteries

according to battery manufacturer’s

instructions.

•Wear safety glasses and clothing when

working on batteries.

•Observe the accident prevention rules

and regulations.

•Smoking is strictly prohibited.

•Keep battery away from open flames,

glowing objects and sparks, otherwise

there is a danger of explosion and fire.

•Immediately rinse any acid splashed

into eyes or onto skin out or off with

plenty of clean water. Then immediately

consult a physician.

•Wash out clothing contaminated with

acid with water.

•Avoid short circuits! Explosion and fire

hazard!

•WARNING! Metal parts in the battery

cells are always live. Therefore, do not

put/store objects or tools on the battery.

•Electrolyte is extremely caustic. Contact

with the electrolyte is not possible during

normal operation.

•In the event of destruction of the casing

of maintenance-free gel batteries, the

bound electrolyte released is just as

caustic as the liquid electrolyte.

•Acid and/or batteries filled with acid

must not be handled by children.

•Use only approved lifting and transport

equipment.

•Lifting hooks must not cause damage to

cells, connectors or connection

cords/cables.

1. Preparing for operation

•The batteries are to be checked to

ensure proper mechanical condition.

•Battery connectors and charging plugs

are to be connected to the proper

terminals, as otherwise the batteries and

the charging set may be destroyed.

•The connection with the battery

connectors of the machine and/or the

charger may take place only with the

key switch and/or the charger switch off.

Maintenance-free, sealed gel batteries:

The batteries are to be recharged

before being put into operation.

Lead-acid batteries:

For reasons of durability unfilled, pre-

charged lead-acid batteries should be

charged immediately before insertion.

Observe the battery manufacturer’s

instructions when doing so.

2. Discharging

•The vent openings in the machine must

not be closed or covered.

•Opening or closing of electrical

connections (e.g. plugs, connectors,

etc.) may take place only in the

currentless state with the main switches

off.

•In order to reach an optimum service

life, discharges are permissible only up

to the point at which a certain residual

capacity is reached.

•In order to avoid total discharge, the

controls of the machine contain an

automatic switch-off device which

switches off the main feed line in time

when cut-off voltage is reached and

signals this by means of a red warning

lamp. Discharged batteries are to be

charged immediately and must not be

left in the discharged state. This also

applies after partial discharging.

3. Charging

WARNING!

Only use chargers approved by Cleanfix for charging.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 14

INSTRUCTIONS FOR GEL AND LEAD-ACID BATTERIES (cont.)

4. Maintenance

Maintenance-free,

sealed gel batteries Lead-acid batteries

Daily −Charge battery/batteries after every discharge or partial discharge

Weekly −Visual inspection for dirt and mechanical damage.

−Grease terminals with terminal grease (Vaseline) and check to ensure firm fit.

−No topping with water

is required for the entire

service life.

−The water consumption is influenced

by the operating conditions and the

charger used.

The water level should not fall below

the minimum mark. If necessary, top-

up with distilled water after charging.

5. Care

•Batteries are to be kept clean and dry at

all times in order to avoid leak currents

and sparking.

•For cleaning, remove batteries, wear

safety glasses and protective clothing.

Select the place of installation so that

dirty water produced during cleaning is

channeled to a suitable waste water

treatment plant.

•The cell plugs must not be unscrewed.

•The plastic parts of the batteries may

only be cleaned with water or cleaning

cloths soaked in water without additives.

After cleaning, the surface of the

batteries is to be dried (compressed air,

cleaning cloth).

6. Storage

•If batteries are taken out of service for

any length of time, they are to be stored

fully charged in a frost-free room.

•Due to the batteries’ spontaneous

discharging, recharging needs to be

done at regular intervals.

Maintenance-free, sealed gel batteries:

Gel batteries are to be recharged at

quarterly intervals.

Lead-acid batteries:

Lead-acid batteries are to be recharged

at least once a month.

7. Faults

If faults are found, the customer service staff must be informed promptly.

8. Disposal

Old batteries showing recycling symbols are re-usable commercial goods and must be channeled to

the recycling process.

All other batteries are to be disposed of as hazardous waste in accordance with existing regulations.

9. Warranty

Failure to comply with the operating and handling instructions, carrying out repairs using non-original

spare parts and attempts to carry out the repairs by the user lead to a loss of the right to make claims

under the warranty.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 15

TROUBLESHOOTING

Symptom: Machine does not run! No power to the machine!

Problem: Batteries not correctly installed in machine.

Solution: Install batteries correctly in machine. Follow instructions give above (see page 8 + 11).

Problem: Internal fuse or FI protection switch tripped.

Solution: Check internal fuse and FI protection switch.

Problem: Power supply interrupted.

Solution: Have power supply checked by authorized technician.

Problem: Frayed cables, damaged plug or loose internal wiring.

Solution: Have an authorized service technician check cord and replace if necessary. Have an

authorized service technician open switch panel and check for loose wire connection.

Problem: Brush motor protection switch tripped.

Solution: Allow motor to cool, press motor protection switch pushbutton, put less clean water into

the tank.

Problem: Discharge signal transmitter has activated.

Solution: Charge batteries.

Symptom: Insufficient vacuuming power! Loss of vacuum!

Problem: Tank cover/dome not properly seated or gasket on dome damaged/worn out.

Solution: Reseat tank cover correctly or replace gasket.

Problem: Vacuum hose and squeegee assembly is clogged up with dirt, or hose is not correctly

inserted into squeegee assembly.

Solution: Remove dirt and re-attach vacuum hose.

Problem: Filter in recovery tank is clogged up.

Solution: Clean filter with clean water.

Problem: Recovery tank drain hose not properly closed.

Solution: Close properly.

Problem: Wrong angle of squeegee assembly.

Solution: Adjust angle of squeegee assembly.

Problem: Defective vacuum motor.

Solution: Have an authorized service technician replace vacuum motor.

Symptom: Poor cleaning performance!

Problem: Worn brush or pads.

Solution: Replace brush or pads.

Problem: Improper chemical for cleaning job or improper dilution.

Solution: Change chemical or adjust dilution.

Service and re

p

airs should onl

y

be

p

erformed b

y

an authorized service center.

WARNING

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 16

TROUBLESHOOTING (cont.)

Symptom: Motors (vacuum, brush & pump) will not run!

Problem: Faulty ON/OFF switch.

Solution: Have an authorized service technician replace switch or switches.

Problem: Loose wiring.

Solution: Have an authorized service technician trace and repair.

Problem: Faulty motor.

Solution: Have an authorized service technician replace motor.

Symptom: Little or no solution flow.

Problem: Solution lines blocked.

Solution: Flush out solution tank and lines with clean water.

Problem: Solution tank filter clogged.

Solution: Remove cover of solution line filter and clean filter screen.

Problem: Solution flow rate metering closed (set to pos. “0”).

Solution: Set to position 1 to 5.

Problem: Solution tank supply hoses kinked.

Solution: Inspect hoses.

Problem: Solution tank empty.

Solution: Refill solution tank.

Symptom: Squeegee assembly making stripes.

Problem: Worn squeegee blades.

Solution: Replace squeegee blades.

Problem: Dirt clogged under squeegee blades.

Solution: Clean squeegee blades.

Problem: Wrong angle of squeegee assembly.

Solution: Adjust angle of squeegee blades.

Symptom: Machine runs too fast or too slow

Problem: Screw for adjusting brush pressure (F2) incorrectly set.

Solution: Turn screw upwards = lift brushes (less pressure) machine runs slower.

Turn screw downwards = lower brushes (more pressure) machine runs faster.

Problem: Brushes are not touching the floor.

Solution: Lower the brushes with pedal.

Safety, Operation and Maintenance Manual for Falcon (RA 530 B); Version 1.0 17

TECHNICAL SPECIFICATIONS

Technical specifications

Technische Daten

Caracteristiques techniques

Voltage

Spannung

Tension

24 Volt DC

Runtime of batteries

Einsatzdauer pro Batterieladung

Autonomie par charge de batterie

ca./approx./env. 2-½ to 4 hrs.

Theoretical cleaning capacity

Theoretische Flächenleistung

Surface possible à nettoyer

1800 m2/h

Capacity solution tank

Inhalt Frischwassertank

Contenance réservoir eau fraîche

12 gal. / 45 lt.

Capacity recovery tank

Inhalt Schmutzwassertank

Contenance réservoir eau sale

16 gal. / 60 lt.

Cleaning path (2 brushes)

Arbeitsbreite

Largeur de travail

21 inches / 53 cm

Squeegee width

Saugbreite

Largeur d’aspiration

31.5 inches / 80 cm

Overall length

Gesamtlänge

Longueur hors-tout

41 inches / 104 cm

Overall height

Gesamthöhe

Hauteur hors-tout

39 inches / 99 cm

Overall width (machine)

Gesamtbreite (Gerät)

Largeur hors-tout (machine)

23 inches / 58 cm

Weight without batterie (with batteries)

Gewicht ohne Batterie (mit Batterie)

Poids sans batteries (avec batteries)

174 lbs. (300 lbs.) / 79 kg (136 kg)

Disc brushes

Tellerbürsten

Brosses plat

Ø 2 x 10 ½ inches / 2 x 270 mm

Walzenbürste

Cylinder brush

Brosses cylindrique

17 inches / 440 mm

Brush pressure regulation

Bürstendruckverstellung

Règlage de pression des brosses

35 – 70 lbs. / 16 - 32 kg

Traction

Antriebsart

Traction

with brushes

über Bürsten

par les brosses

Wassermenge

Waterflow

Quantité eau

0 – 0.8 gal./min. / 0 - 3 lt/min

Waterlift of vacuum motor

Unterdruck Saugmotor

Depression du moteur d’aspiration

63 inches / 180 mbar

New Machine Warranty

Copyright ©2007 Cleanfix Cleaning Systems Inc.

All rights reserved. Content is subject to change without notice. Version 5.1.

1. Limited Warranty. These terms and conditions of the New

Machine Warranty are a material part of the agreement

between Buyer and Cleanfix Cleaning Systems Inc., a New

Jersey-based corporation (hereinafter “Cleanfix”), and

supersede warranty terms and conditions in documentation

submitted by Buyer to Cleanfix. Cleanfix warrants new

machines of its manufacture against defects in material and

workmanship under normal use and service to the original end-

user purchaser. No person, agent, representative or distributor

is authorized to give any warranties on behalf of Cleanfix, or to

assume any other liability for Cleanfix in connection with any

Cleanfix machine. Cleanfix reserves the right to make changes

to its equipment without notice. The warranty coverage is

subject to the conditions below.

2. Registration of Warranty. The warranty commences on the

date of purchase by the original end-user from an authorized

Cleanfix distributor or agent, subject to proof of purchase. The

warranty commences latest, however, after six (6) months of

the purchase date by the authorized distributor or agent of

Cleanfix. Any new Cleanfix machine must be registered

immediately with Cleanfix by the original end-user customer by

fully completing and returning the warranty registration form to

Cleanfix. If proof of purchase cannot be identified through a

completed and returned warranty registration form, the warranty

commences from the date of sale to the authorized Cleanfix

distributor.

3. Warranty Coverage. Subject to conditions outlined below,

Cleanfix warrants rotationally molded PE housings and tanks on

all of its machines to be free from defects in material and

workmanship, under normal use and service for ten (10) years

to the original end-user.

Subject to conditions outlined below, Cleanfix warrants

fiberglass housings and tanks on all of its machines to be free

from defects in material and workmanship, under normal use

and service for three (3) years to the original end-user.

Under this warranty Cleanfix warrants the performance of non-

polyethylene and non-fiberglass components to be free from

defects and workmanship for up to one (1) year to the original

end-user. Parts replaced or repaired under this warranty are

warranted for the remainder of the original warranty period.

(See table below)

Rotationally molded PE housings and tanks 10 years

Fiberglass housings and tanks 3 years

Vacuum motors, brush motors, pump motors,

boards and electronics 1 year

Battery and battery charger* 1 year

* The 1 year period warranty commences with the purchase date by the

authorized distributor or agent of Cleanfix.

Service labor charges are covered for up to one (1) year from

the date of purchase through an authorized Cleanfix service

provider. A total maximum of one (1) hour travel time - equal to

one (1) hour labor rate - is covered for large machines, namely

Falcon, Raven, Eagle and larger for 90 days. No coverage is

extended for diagnosis time.

4. Product Exceptions and Exclusions. ALL vacuum cleaners

and air movers are warranted for one (1) year. No warranty is

extended for wear items, accessories and attachments

including, but not limited to, belts, brushes, pad holders,

capacitors, carbon brushes, wheels, casters, glides, clutches,

cords, filters, filter bags, gaskets, hoses, rectifiers, switches,

float switches, valves, squeegees, bearings, pulleys, relays,

actuating cables, wheels, tires, vacuum cleaner attachments.

The purchaser is assured that meticulous care has been

exercised in the selection, assembling and testing of these parts

and components before shipping. No warranty is extended for

machine finish, labels and other cosmetic parts or features.

5. Stated Warranties. Stated warranties are in lieu of all other

warranties, expressed or implied. Any statutory implied

warranties, including any warranty of merchantability or fitness

for a particular purpose, are expressly limited to the duration of

the written warranty. Cleanfix will not be liable for any other

damages, including but not limited to incidental, indirect or

special consequential damages arising out of or in connection

with the furnishing, performance, use or inability to use the

machine, including damages to persons or property. This

remedy shall be the exclusive remedy of the buyer. The

warranty is limited to the warranty.

6. Warranty is null and void for the following.

•Damage, defects, malfunction or other failures caused by

not using the electric current indicated on the spec plate,

including the use of improper extension cords.

•Damage or defect caused by accident, misuse, neglect,

abuse, fire etc., including use of incompatible or corrosive

chemicals or overloading of capacity.

•Failure caused by lack of proper maintenance and care,

including proper machine clean-up after use, proper

charging procedures for batteries.

•Failure caused by loss, damage or removal of protective

components, including, but not limited to, filters and filter

screens, tank covers and lids, skirts and bumpers, float

shut-off assemblies.

•Freezing of any water or chemical related components

(this will void all warranties on water or chemical related

components, internal or external, of the product).

•Deposits and buildup in any water or chemical related

systems due to hardness in water (this will void all

warranties on affected systems).

•Any design alterations, adjustments and/or repairs

performed on the equipment by an organization not

authorized or specified by Cleanfix.

•Use of any parts not approved by Cleanfix, including, but

not limited to, batteries, battery charger, filter bags, belts,

electric components, motors.

•Use of machine for a purpose other than which it was

designed and intended, and use of machine in excess of

design duration.

•Damage in transit.

7. Warranty Claim Procedure. If a difficulty develops during

the specified warranty period, contact the authorized Cleanfix

distributor/partner from whom the machine was originally

purchased. Do not return any products to Cleanfix unless

explicitly authorized by Cleanfix. Cleanfix may elect to require

the return of the machine or component(s) to validate the claim.

Any defective machine or component to be returned must be

shipped freight pre-paid to an authorized Cleanfix

distributor/service center.

Cleanfix will provide and charge for replacement parts, including

shipping and handling, to the original purchaser through an

authorized service center. If the part is returned within 30 days

and is found defective, the purchaser will be credited for the

cost of the replacement part including shipping and handling.

8. Term. This warranty is valid for all products sold after

January 1, 2006. A product sold before that date will be covered

by the limited warranty in effect at the date of sale to the original

purchaser.

This manual suits for next models

1

Table of contents

Other Cleanfix Scrubber manuals

Cleanfix

Cleanfix FloorMac Guide

Cleanfix

Cleanfix RA 410 E User manual

Cleanfix

Cleanfix RA 410 E User manual

Cleanfix

Cleanfix Robo 40 User manual

Cleanfix

Cleanfix RA805 User manual

Cleanfix

Cleanfix Sparrow Guide

Cleanfix

Cleanfix MasterCraft RA-300 Guide

Cleanfix

Cleanfix RA 330 IBC Instruction Manual

Cleanfix

Cleanfix RA705 IBC User manual

Cleanfix

Cleanfix RA565 IBCIBD User manual